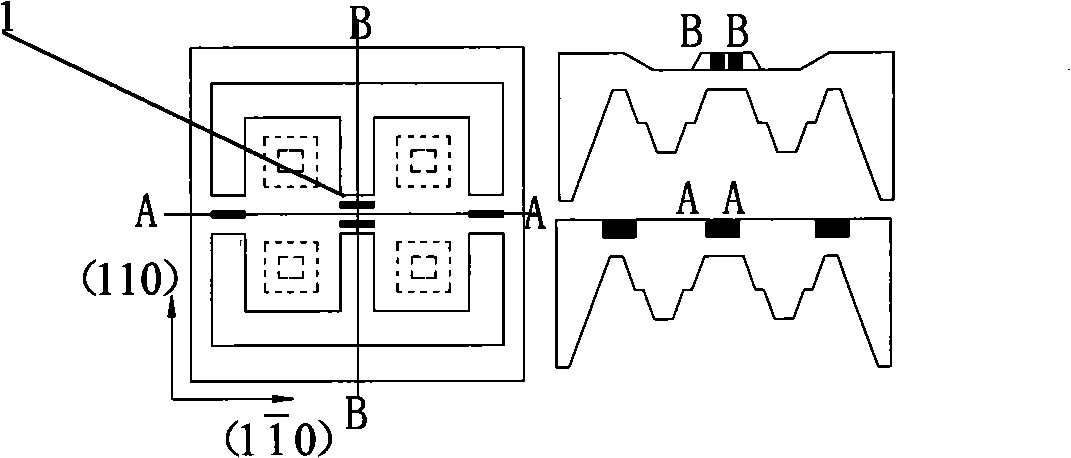

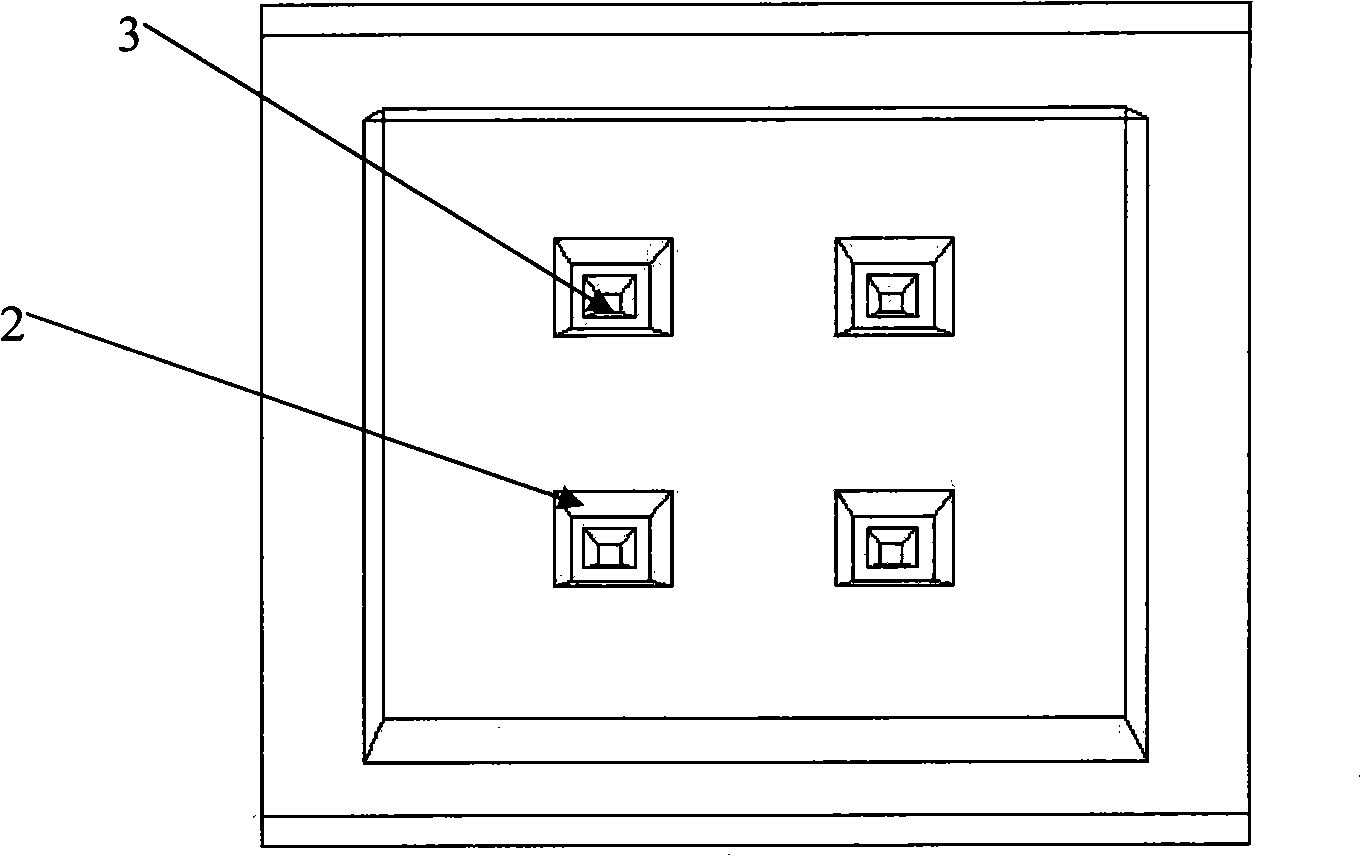

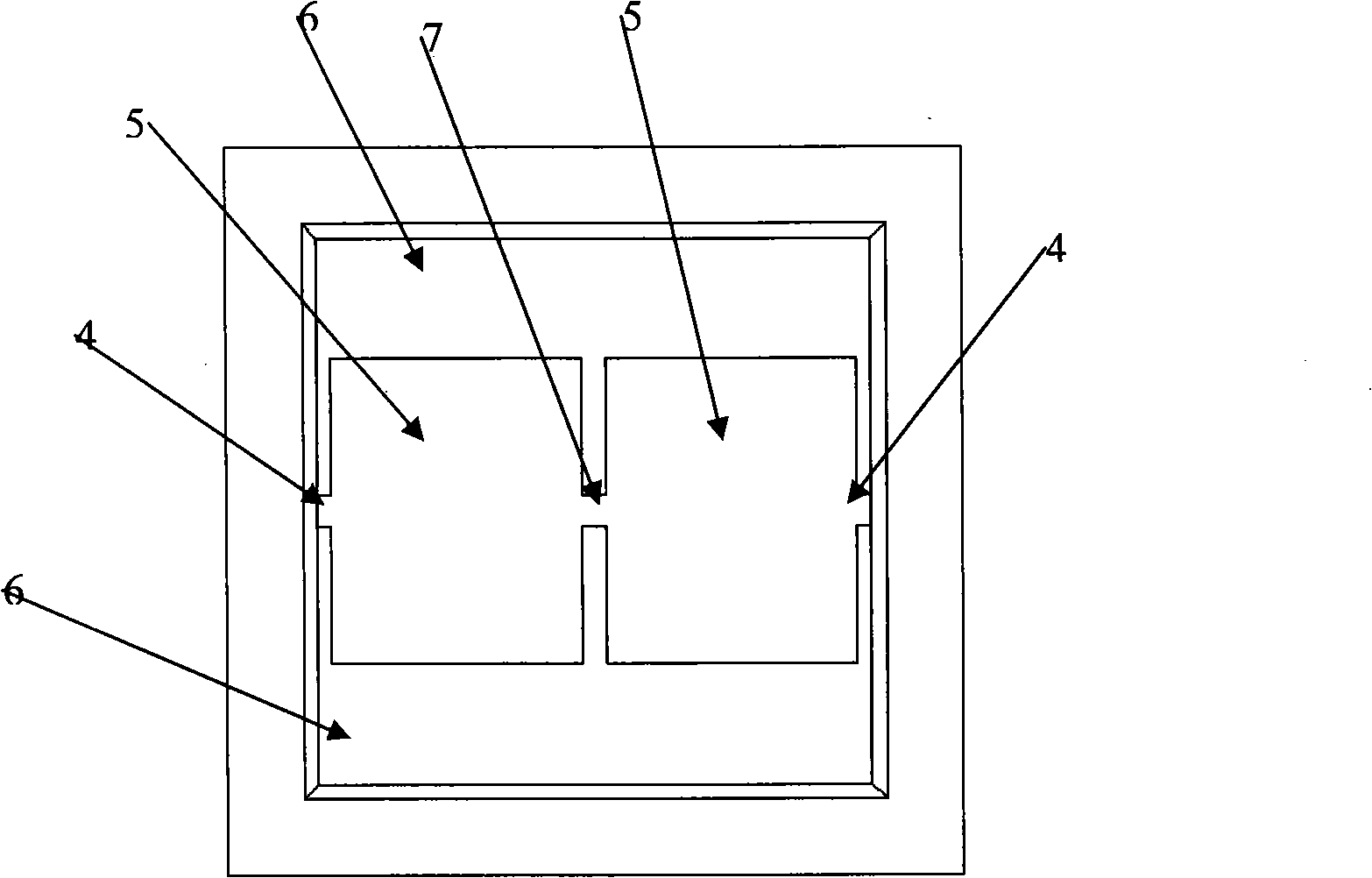

Nano-silicon thin-membrane four-island-beam-membrane sensor chip and preparation method thereof

A technology of nano-silicon thin film and membrane sensor, which can be used in instruments, manufacturing microstructure devices, piezoelectric devices/electrostrictive devices, etc., can solve problems such as difficult pressure measurement, and achieve the effect of improving sensitivity and linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0061] Example: Preparation of sensor chip

[0062] Use double-sided polished n-type (100) crystal orientation single crystal silicon wafer with a thickness of 200±10μm and a resistivity of 5-8Ω·cm. The chip manufacturing process is as follows:

[0063] 1. Thermal oxidation

[0064] A dry-wet-dry oxidation process is used to grow an oxide layer with a thickness of 100nm on the upper and lower surfaces of the silicon wafer. Oxidation temperature is 1150℃, dry oxygen for 10 minutes, steam wet oxygen for 30 minutes, and dry oxygen for 10 minutes.

[0065] 2. Double-sided lithography alignment mark

[0066] Double-sided photoetching of the oxidized silicon wafer to form double-sided alignment marks. Glue is applied on the back side, and the pre-baking temperature is 80°C for 8 minutes, and then the glue is applied on the front side, and the pre-baking temperature is 80°C, and the time is 15 minutes. Expose, develop and etch the alignment marks. (Simultaneously lithographically align the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com