Transient unloading test simulation system for deep fractured rock mass under high confining pressure

A technology of fractured rock mass and transient unloading, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

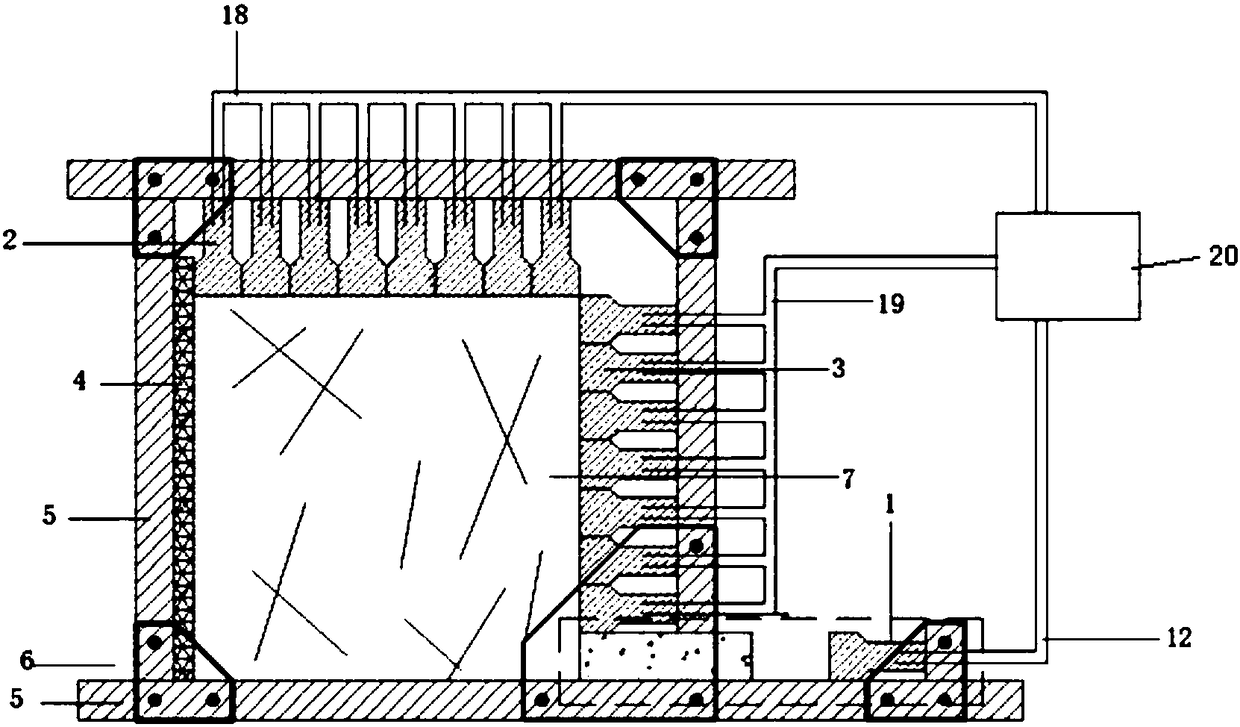

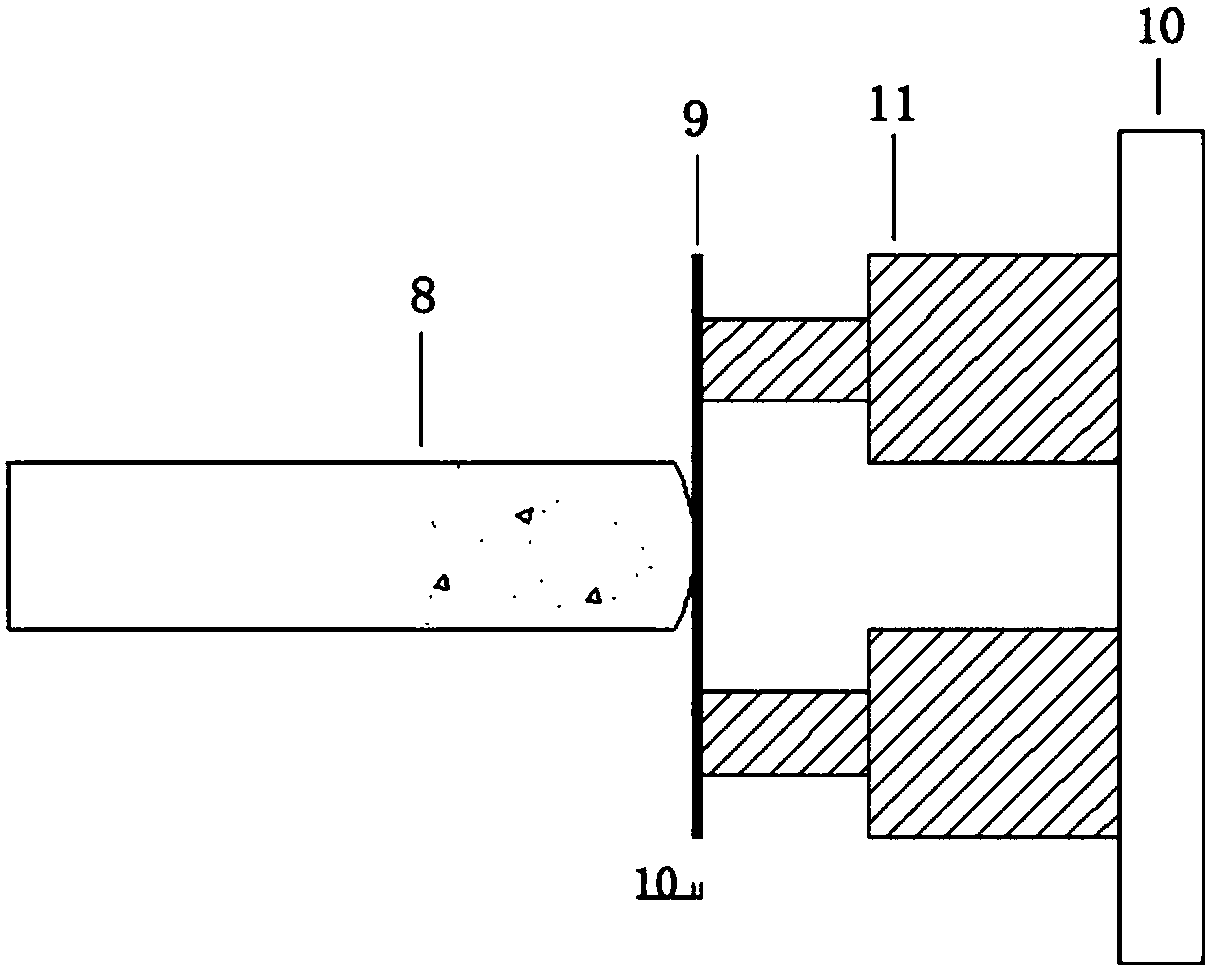

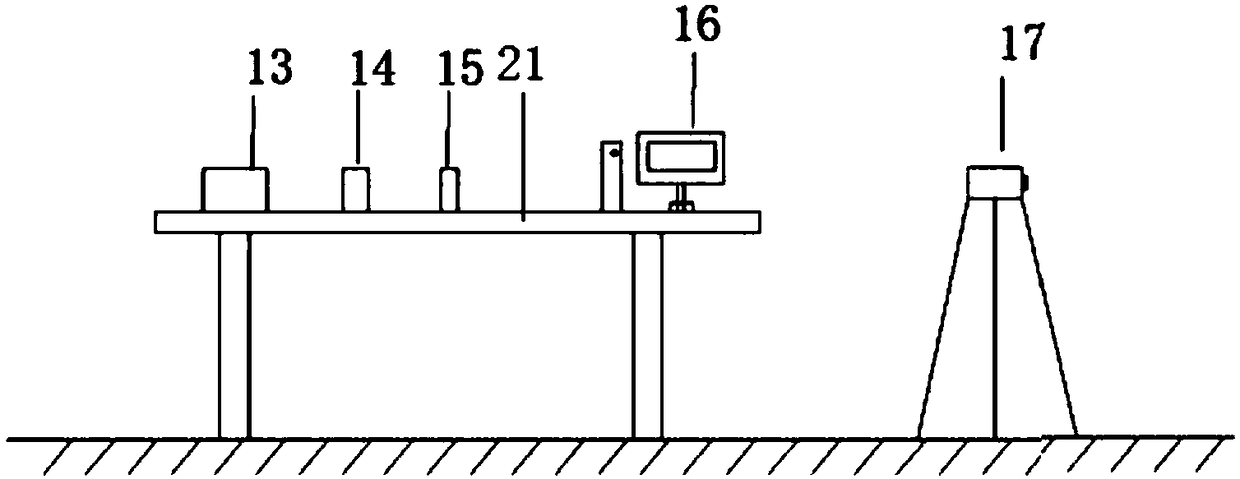

[0023] Such as figure 1 A high confining pressure local transient unloading test simulation system for deep fractured rock mass shown mainly includes a rock mass model 7, a support frame 5, a test bench, a horizontal loading device, a vertical loading device, a loading and unloading device 1 and Monitoring device, described rock mass model 7 is built in support frame body 5, and support frame body 5 is arranged on the test bench; The right side of the model 7 is connected to the output end of the horizontal loading device, and the top of the rock mass model 7 is connected to the vertical loading device; connected; the input end of the monitoring device is connected with the rock mass model 7. In this embodiment, a wave-absorbing plate 4 is installed between the left side of the rock mass mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com