Transient unloading loosening simulation test system for structural surface excavation of underground caverns

A technology of transient unloading loosening and simulation test system, which is applied in the direction of machine/structural component testing, measuring devices, instruments, etc., can solve the problems of inability to intuitively understand the displacement and vibration of rock mass with structural planes, and achieve the applicable Wide range of effects suitable for research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

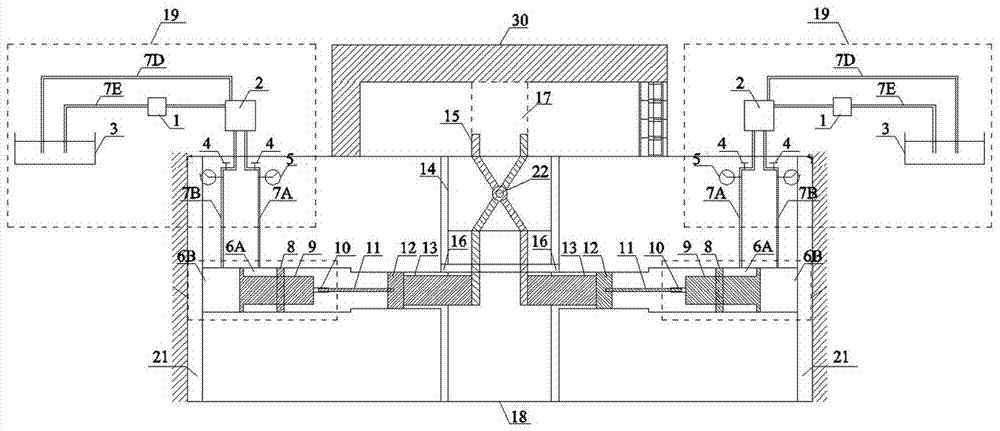

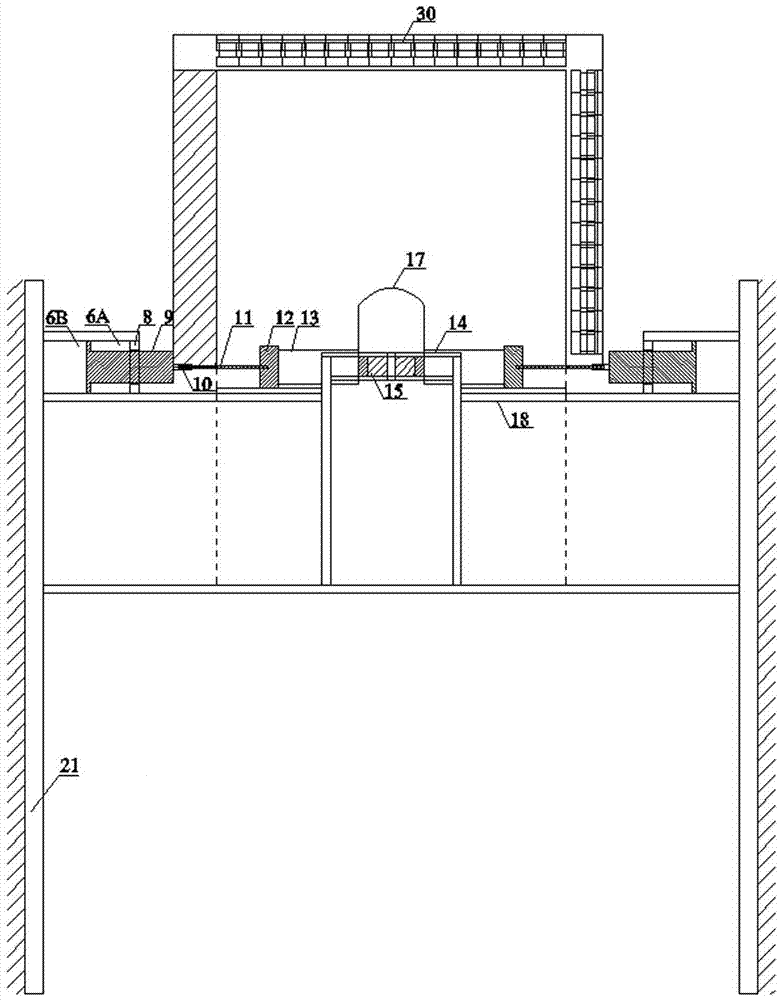

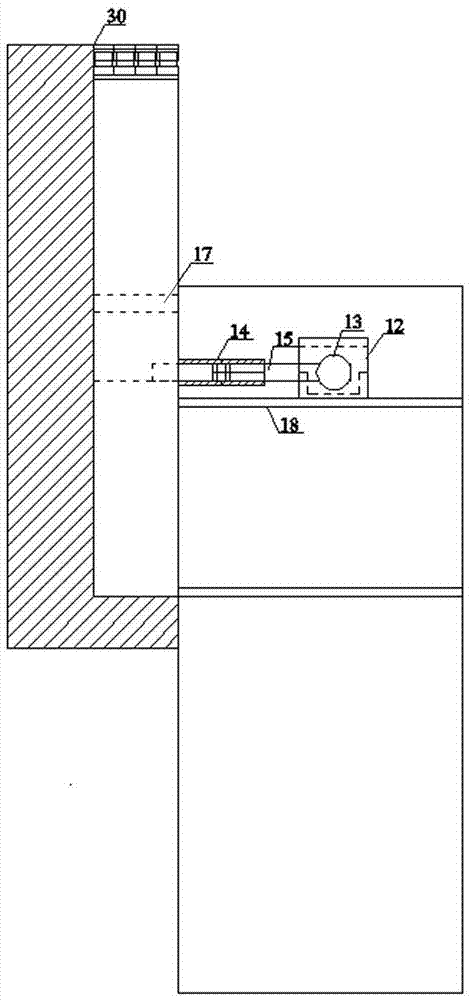

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

[0039] see Figure 1-Figure 11 , an underground cavern structural surface excavation transient unloading loosening simulation test system, it includes the excavated underground cavern surrounding rock model 17 containing the structural surface, a confining pressure loading system 30, a test bench 18, a loading device, Excavation cavern loading and unloading device 15, monitoring system, the excavated underground cavern surrounding rock model 17 containing structural surface is placed in the confining pressure loading system 30;

[0040] The excavated cavern loading and unloading device 15 includes a lever-type loading and unloading member, the front end of which extends into the excavated underground cavern surrounding rock model 17 with structural surfaces, and is close to the excavated underground cavern surrounding rock model 17. The groove wall of the underground ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com