Broad-spectrum deformable while-drilling leak-proof sealing agent

A plugging agent and drilling-while-drilling technology, which is applied in the direction of reagents, drilling compositions, chemical instruments and methods, etc., can solve the problems of poor acid solubility, low acid solubility rate, narrow plugging range, etc., and achieve stable performance , The construction process is simple and the sealing effect is wide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

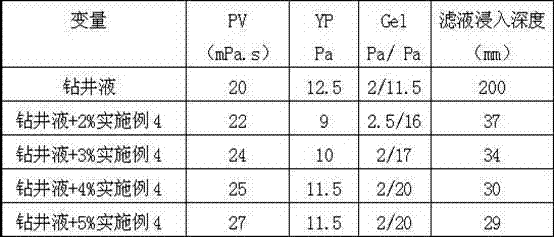

Examples

Embodiment 1

[0011] Put 40 kg of natural ore tailings powder, 25 kg of superfine konjac powder, 5 kg of elastic tire rubber particles, and 30 kg of superfine calcium carbonate into the mixer and mix evenly.

Embodiment 2

[0013] Put 50 kg of natural ore tailings powder, 20 kg of superfine konjac powder, 5 kg of elastic tire rubber particles, and 25 kg of superfine calcium carbonate into the mixer and mix evenly.

Embodiment 3

[0015] Put 40 kg of natural ore tailings powder, 20 kg of superfine bamboo powder, 5 kg of elastic tire rubber particles, and 35 kg of superfine calcium carbonate into the mixer and mix evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com