Method for repairing asphalt pavement cracks

A technology for asphalt pavement and crack size, applied in the field of traffic road maintenance, can solve the problems of poor repairing effect, too simple repairing process, inability to emulsified asphalt and other problems, and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

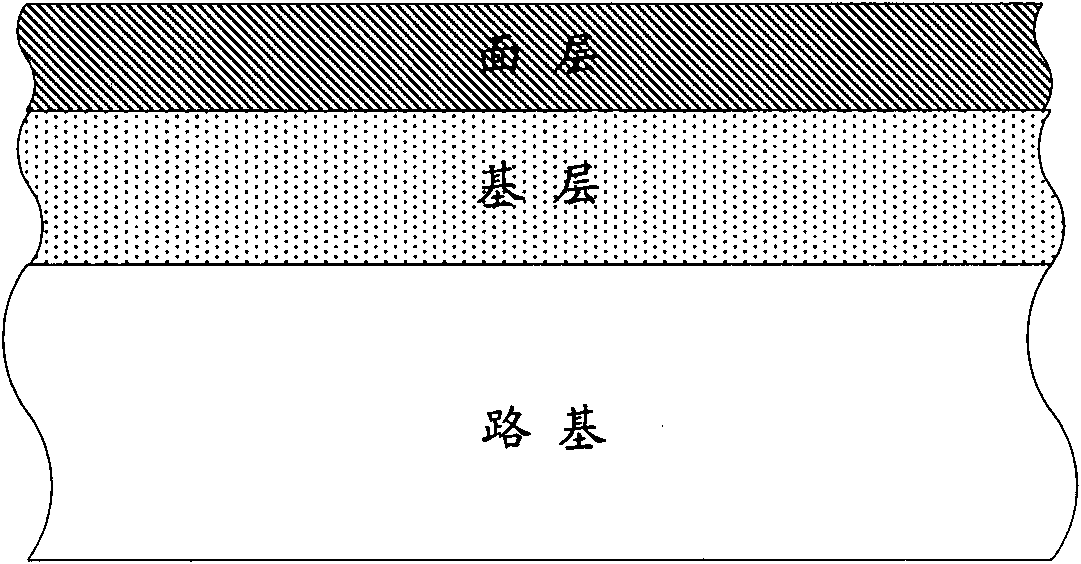

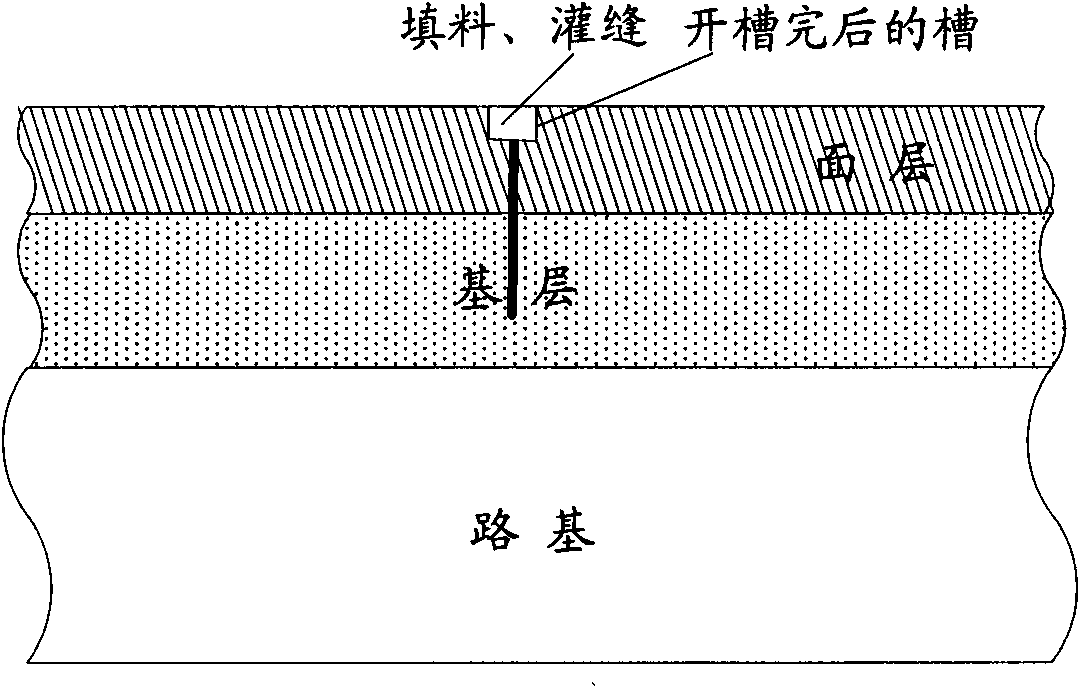

[0026] In order to effectively improve the repair effect of asphalt pavement cracks and improve the service life of asphalt pavement, the method of the present invention firstly performs slotting operations on the cracks when processing asphalt pavement cracks. After slotting, cleaning, vibrating joint filling, vibrating filling and curing operations were carried out respectively. Through this method, the crack and its surrounding gaps can be completely closed, and the repaired crack has the same strength as the original asphalt pavement, which is completely the same as the original The asphalt pavement is integrated, which effectively increases the service life of the asphalt pavement and saves its maintenance investment throughout its life.

[0027] figure 2 It is a schematic cross-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com