A kind of surface covering and preparation method thereof

A surface covering and mixture technology, applied to chemical instruments and methods, fertilizer mixtures, soil conditioning materials, etc., can solve the problems of competing for water and nutrients, affecting tree growth, affecting tree species growth, etc., and achieves a simple and easy preparation process, Low cost, resistance to damage caused by long-term water immersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

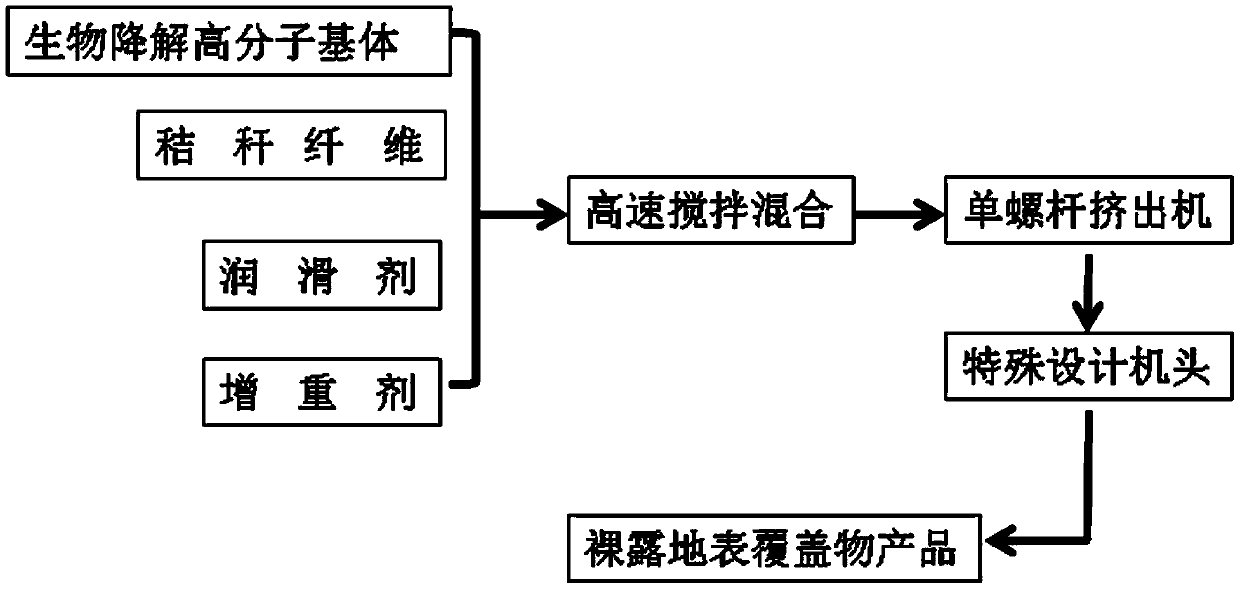

[0037] The present invention also provides a preparation method for the ground cover described in the above technical solution, comprising the following steps:

[0038] a) mixing straw fiber, polymer matrix, lubricant and weighting agent to obtain a mixture;

[0039] b) extruding the mixture through a screw extruder to obtain a ground covering.

[0040] According to the present invention, the straw fiber, the polymer matrix, the lubricant and the weighting agent are firstly mixed to obtain the mixture. Wherein, the types, dosages and sources of the straw fiber, polymer matrix, lubricant and weighting agent are consistent with the above-mentioned technical solutions, and will not be repeated here.

[0041] In the present invention, the raw materials are preferably mixed in the following manner: a1) applying a lubricant to the mixture of straw fiber and polymer matrix to obtain a pre-mixture; a2) stirring and mixing the pre-mixture with a weighting agent to obtain a mixture. I...

Embodiment 1

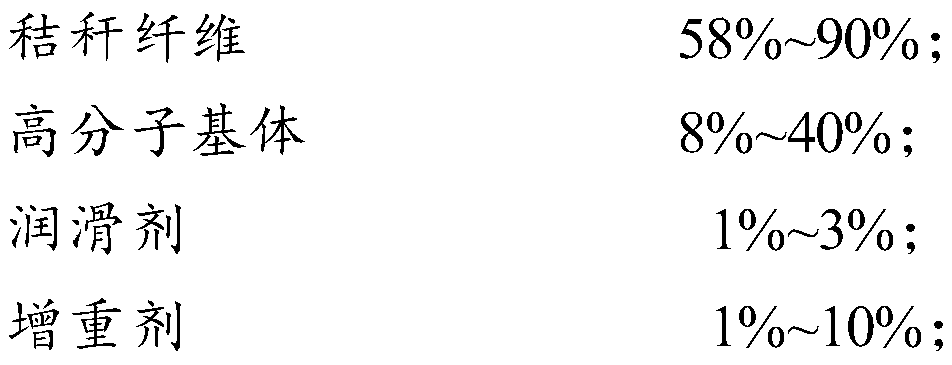

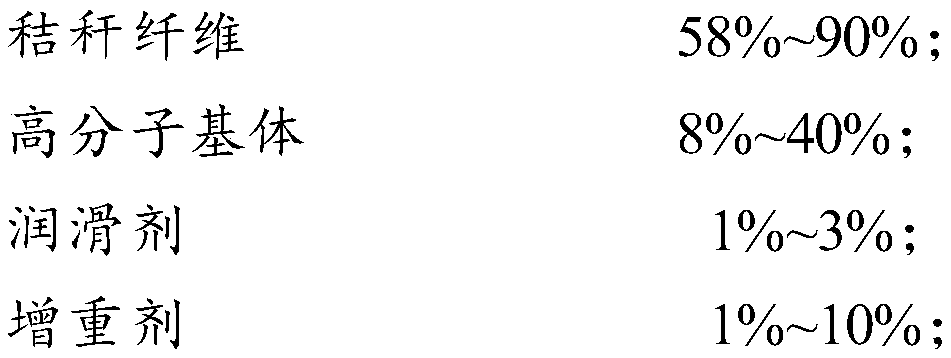

[0046] 60g of rice straw fibers after gas explosion treatment were mixed with 31g of different polymer substrates (starch, carbon dioxide copolymer-based thermoplastic polyurethane, polypropylene carbonate, terephthalic acid-adipic acid-butylene glycol, respectively). Copolyester) mixed to obtain 4 parts of pre-mixture; then 3g of glycerin was sprinkled on the above-mentioned 4 parts of pre-mixture respectively to obtain 4 parts of pre-mixture; after that, 4 parts of pre-mixture and 6g of barium sulfate were added to high stirring In the extruder, stir and mix at room temperature for 3 minutes at a speed of 2000rpm to obtain 4 parts of the mixture; put the resulting 4 parts of the mixture into a single-screw extruder, and the temperature of the extruder from the feeding port to the die head is 145 ° C, 160 ° C, At 165°C and 165°C, the die head is in the shape of a three-petal plum blossom, and after being extruded by an extruder, 4 parts of ground covering products (respectivel...

Embodiment 2

[0052] Prepared according to the preparation process of sample 1b, the difference is that the amount of straw fiber is adjusted to 160g (that is, the straw fiber content is 80%), and the obtained ground cover is recorded as sample 2m;

[0053] It was prepared according to the preparation process of sample 1c, except that the amount of straw fiber was adjusted to 360g (that is, the content of straw fiber was 90%), and the obtained ground cover was recorded as sample 2n.

[0054] According to the test method of Example 1, the performance test of the obtained ground cover is carried out, and the test results are shown in Table 2. Table 2 shows the performance test results of the ground cover of this embodiment.

[0055] The performance test result of the surface covering of table 2 embodiment 2

[0056]

[0057]

[0058] It can be seen from this example that the surface covering product provided by the present invention has good water absorption, wind resistance, water imme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com