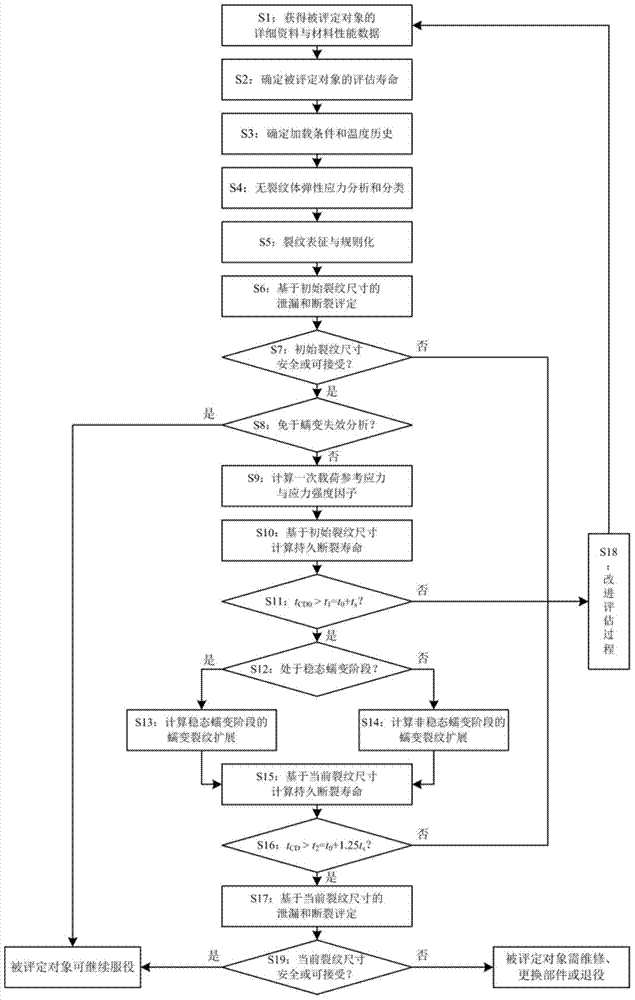

Safety assessment method for high-temperature pressure pipeline with crack type defects

A technology for pressure pipelines and cracks, which is applied in the field of safety assessment of high-temperature pressure pipelines with crack defects, and can solve problems such as assessment technology methods and the establishment of safety for crack defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0172] This embodiment only illustrates a specific implementation of the present invention, and does not limit other implementations of the present invention.

[0173] Taking a certain high-temperature pressure pipeline as an example, according to the safety assessment method of a high-temperature pressure pipeline with crack-like defects of the present invention, the safety assessment under creep load is completed, and the specific steps are as follows:

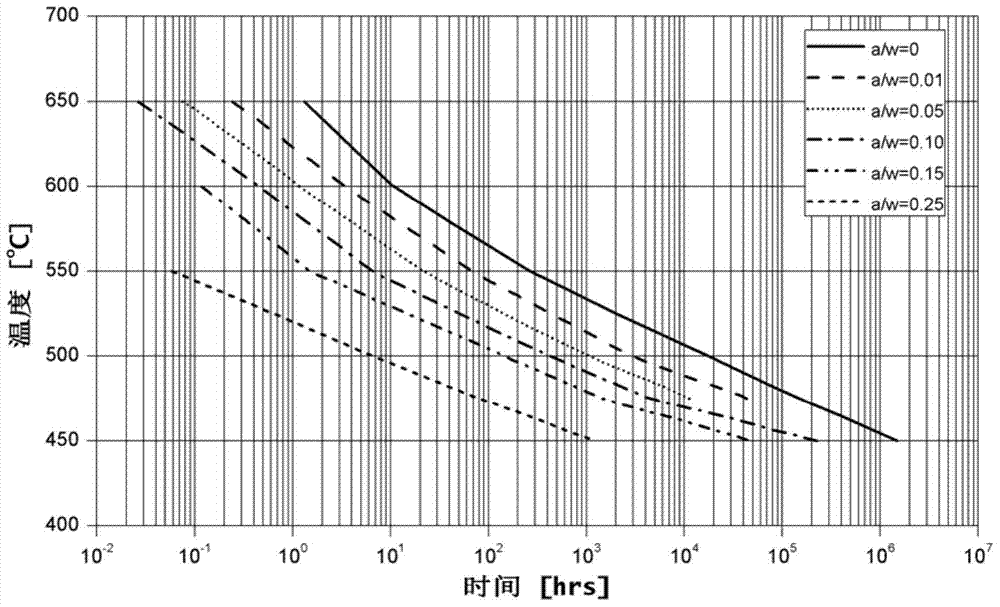

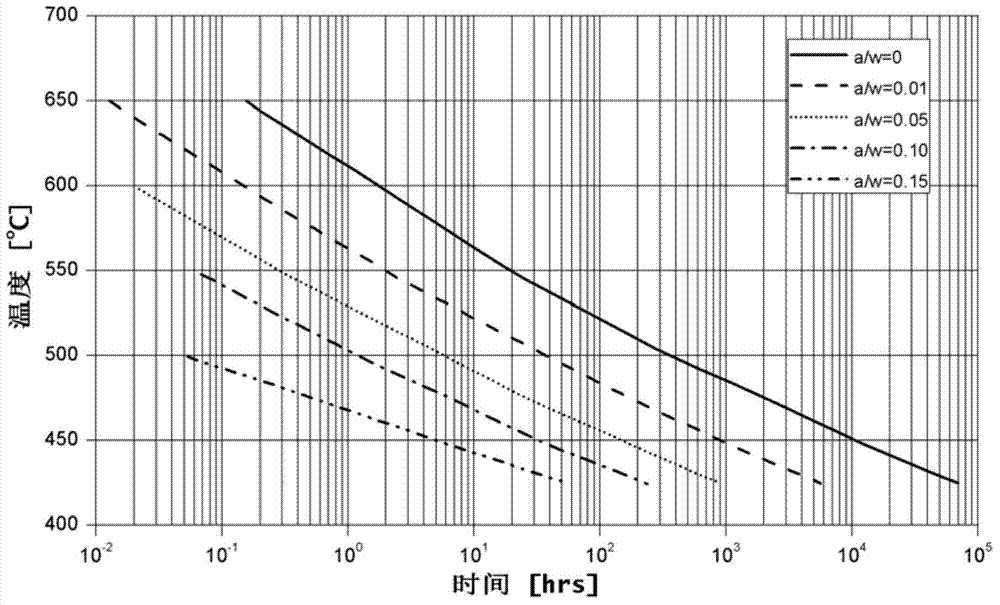

[0174] S1: Obtain detailed information and material performance data of the assessed object

[0175] The specification of the high-temperature pressure pipeline is Φ273×12mm, the material is 316 type austenitic stainless steel, the operating pressure is 2.7MPa, the operating temperature is 550°C, the corrosion allowance is 0mm, and the welding joint coefficient is 1.0. It was put into use in 2004. An axial crack with a length of 20mm and a depth of 2mm was found on the base metal of the inner surface of the pipe.

[0176] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com