Aero-engine turbine blade reliability evaluation method based on fracture mechanics

A technology for aero-engines and turbine blades, which is applied in the field of probabilistic life prediction, can solve the problem that the value of stress intensity factor cannot be found, and achieve the effect of accurate life prediction and reliability evaluation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

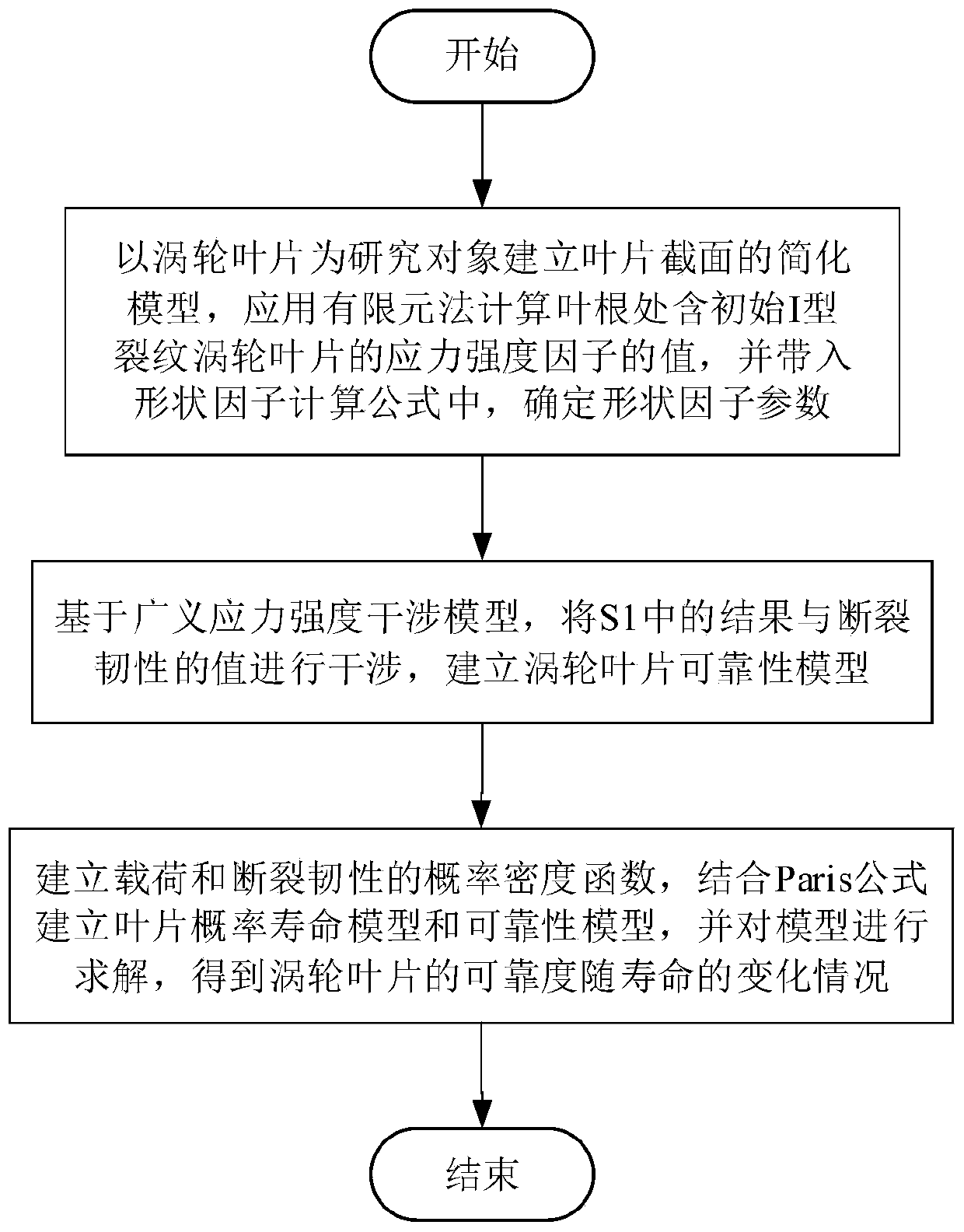

[0067] Such as figure 1 Shown, the object of the present invention is achieved by the following technical solutions: the method for evaluating the reliability of aero-engine turbine blades based on fracture mechanics is characterized in that, comprising the following steps:

[0068] S1. Taking the turbine blade as the research object to establish a simplified model of the blade section, apply the finite element method to obtain the stress intensity factor of the turbine blade with the initial I-type crack at the blade root, and bring the stress intensity factor into the shape factor calculation formula to determine the shape the value of the factor parameter;

[0069] Specifically include the following sub-steps:

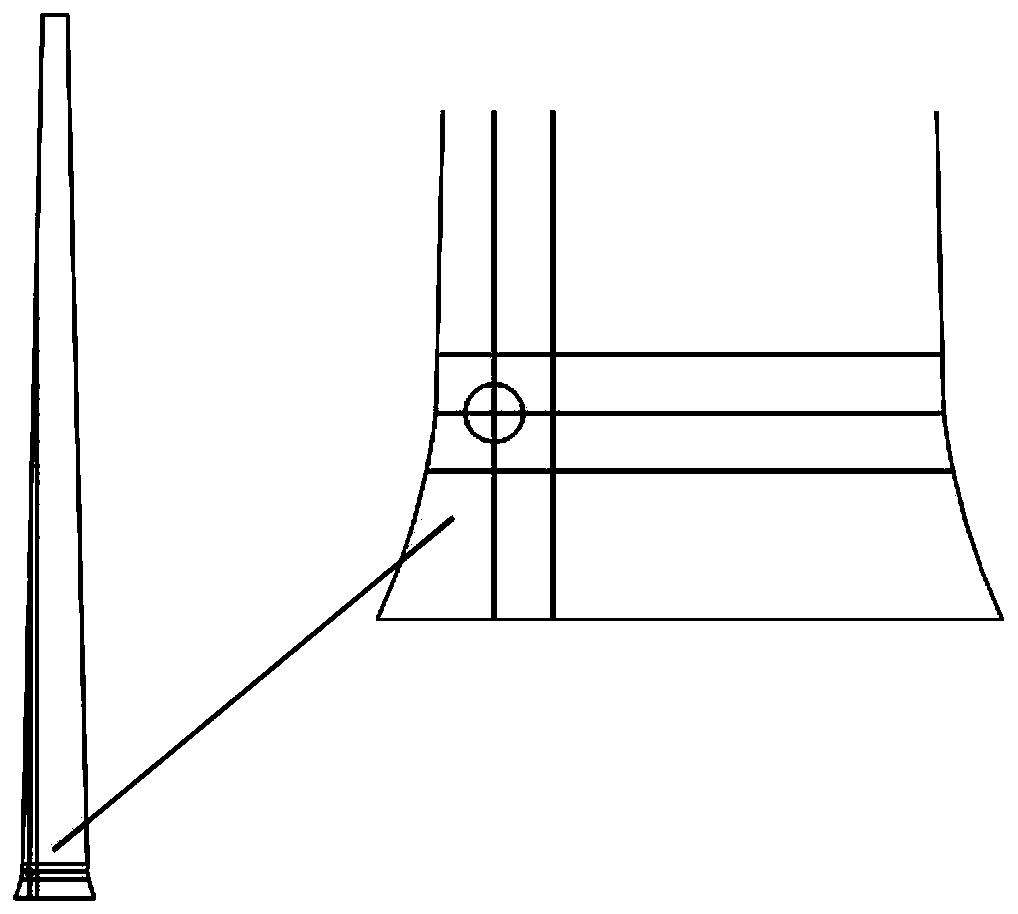

[0070] S11. Assuming that the crack is a type I penetrating crack, the three-dimensional model of the blade is divided along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com