Power supply capable of automatically monitoring service life and method for monitoring service life of power supply

An automatic monitoring and power supply technology, applied in the direction of power supply testing, measuring electricity, measuring electrical variables, etc., can solve problems such as errors, difficult power supply life estimation, and ripple current value monitoring difficulties, and achieve the effect of avoiding losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

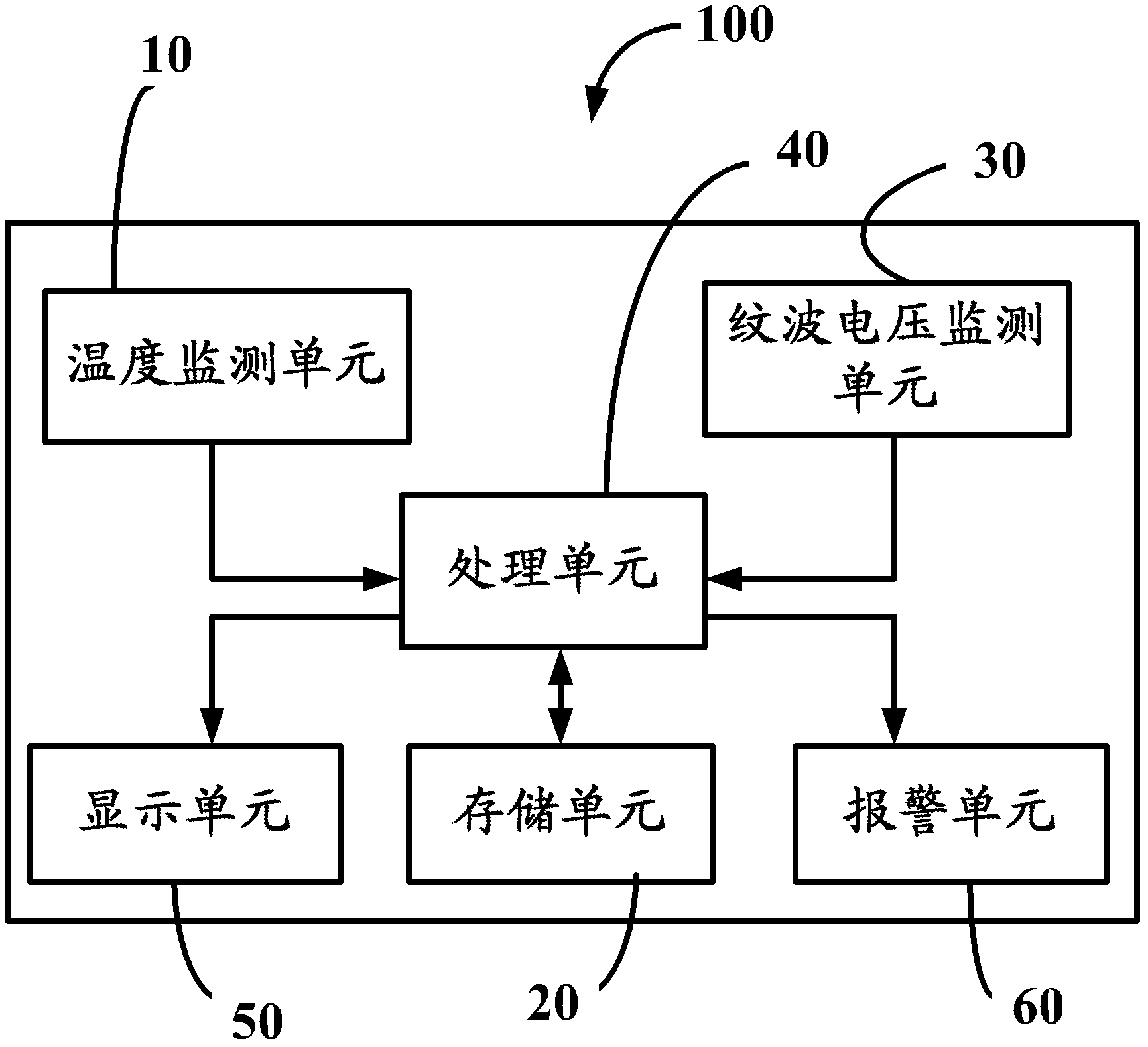

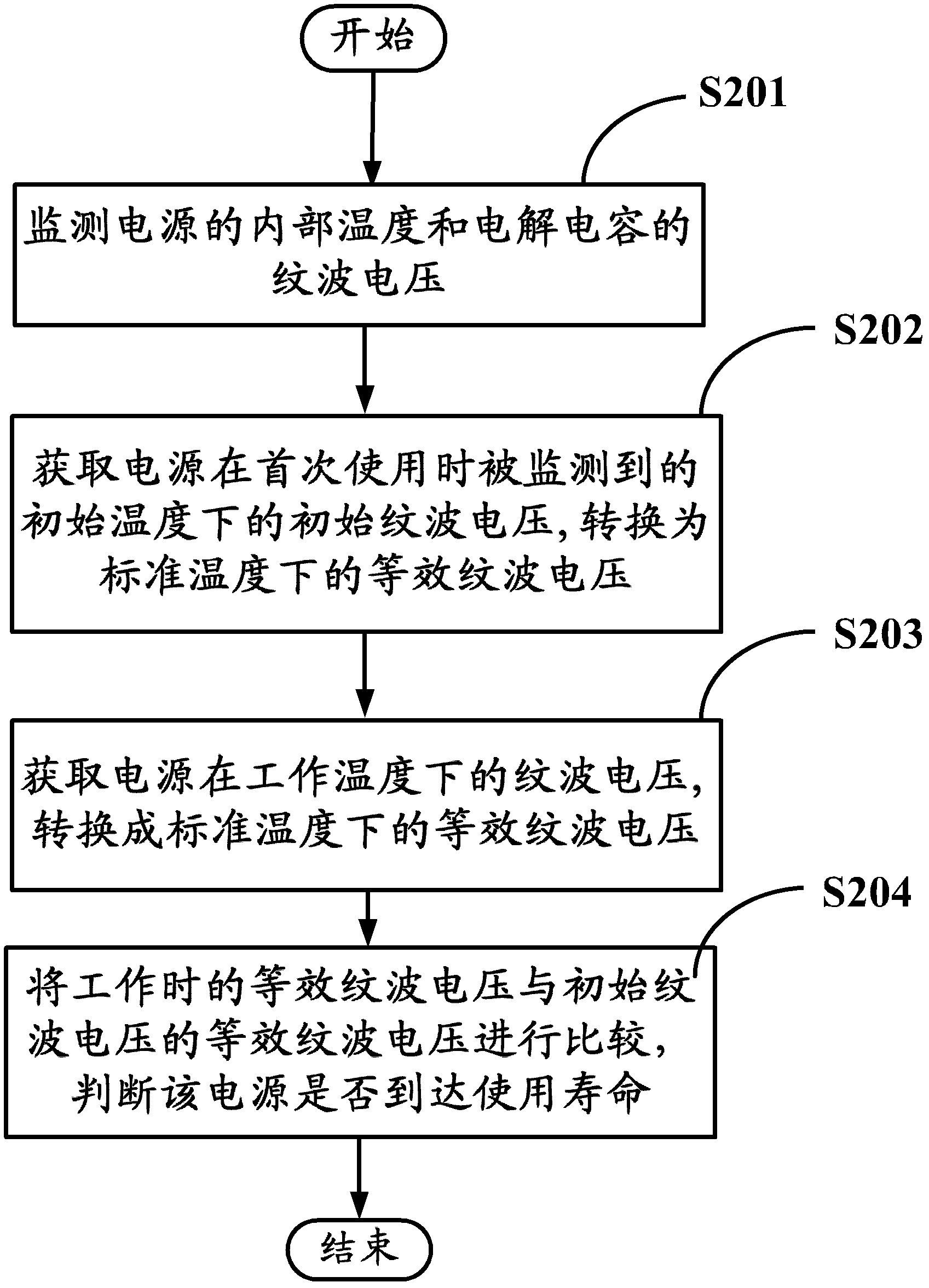

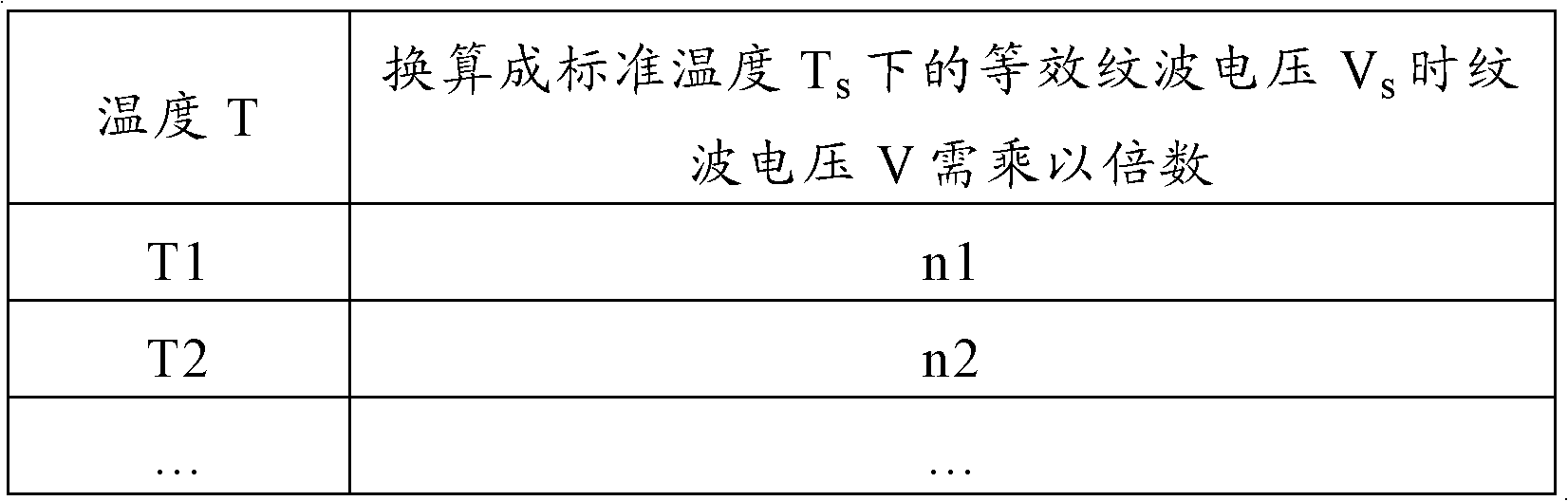

[0017] see figure 1 , is a schematic diagram of a power supply 100 capable of automatically monitoring service life in an embodiment of the present invention. Generally speaking, the ESR (Equivalent Series Resistance, Equivalent Series Resistance) value R of the power supply 100 is an important parameter indicating the life of the power supply 100. With the use of the power supply 100, the ESR value R of the power supply 100 will continue to increase. For the power supply 100 connected to the loop, the ripple current value I flowing through the electrolytic capacitor inside the power supply 100 does not change much, and generally can be considered approximately constant. Assuming that the ripple voltage value of the electrolytic capacitor inside the power supply 100 is U, according to the formula U=I*R, it can be known that the ripple voltage value U of the electrolytic capacitor inside the power supply 100 will increase continuously with the use of the power supply 100 . In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com