Method for evaluating service life of polyolefin cable insulation material for nuclear power station

A cable insulation and life evaluation technology, applied in the direction of analyzing materials, using stable tension/pressure to test material strength, measuring resistance/reactance/impedance, etc., can solve problems such as inaccuracy and short cable life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] A method for evaluating the life of a polyolefin cable insulation material for a nuclear power plant, comprising the following steps:

[0041] Step 1. The polyolefin cable insulation material is subjected to radiation crosslinking and then plate vulcanization simulation to obtain cable insulation samples for nuclear power plants.

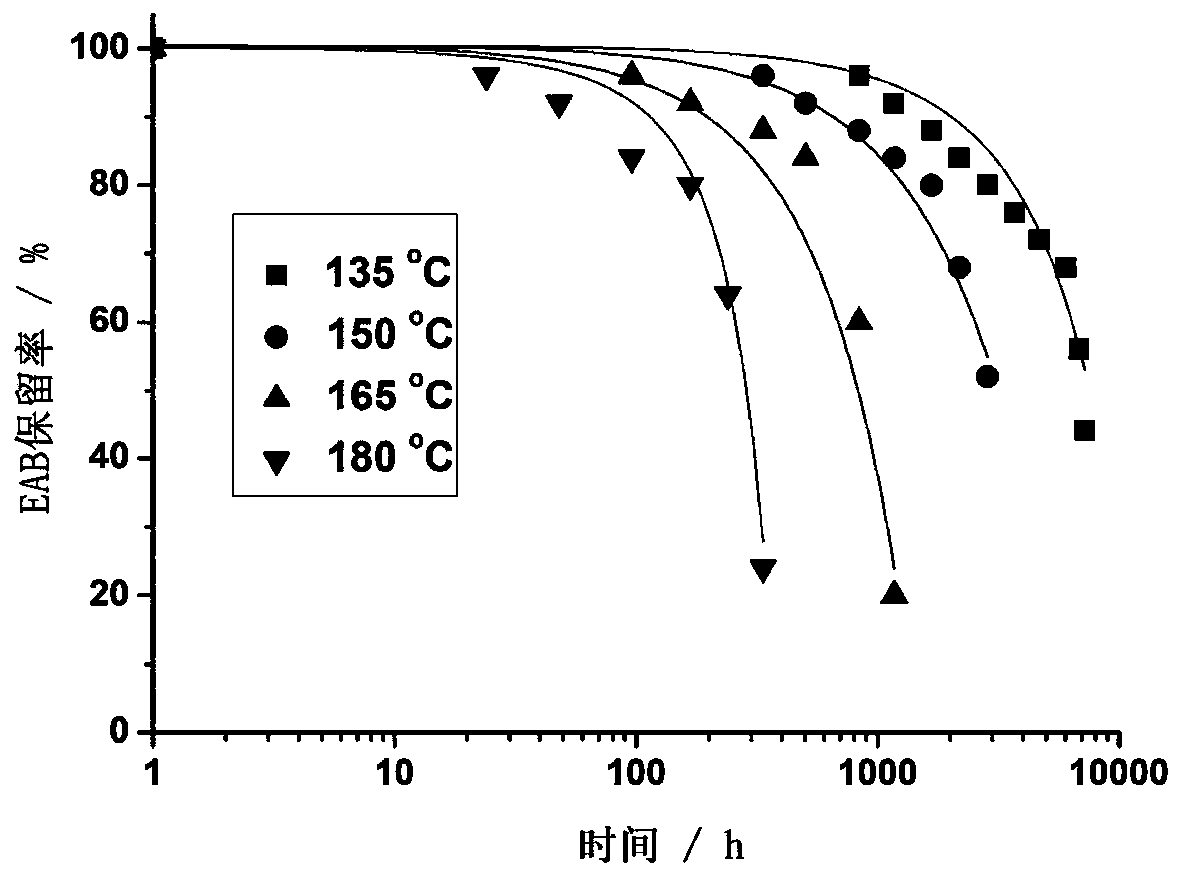

[0042] Step 2. The cable insulation sample obtained in step 1 is subjected to thermal oxygen aging treatment for 48h, 96h, 168h, 336h, 504h, 672h, and 840h at four temperature points of 135°C, 150°C, 165°C, and 180°C, respectively. Simulate the cable aging process. And take the elongation at break as the ordinate, and the aging time as the abscissa, draw the relationship diagram of mechanical properties and aging time (see attached figure 1 ).

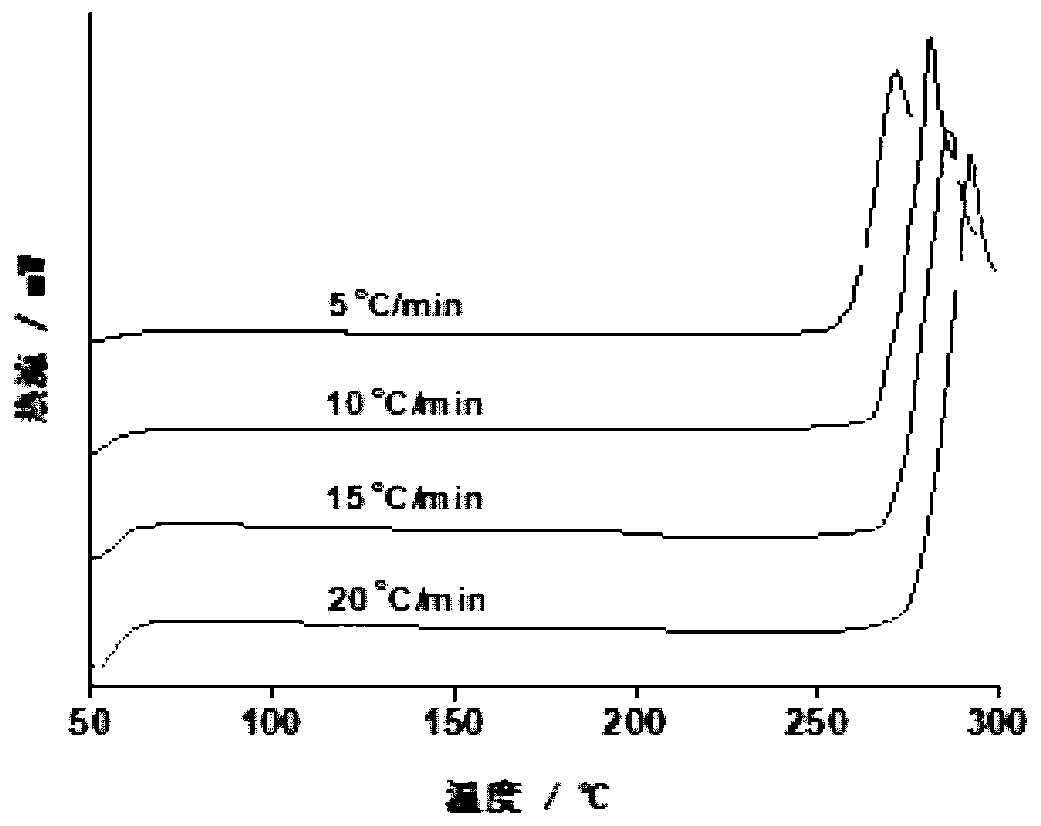

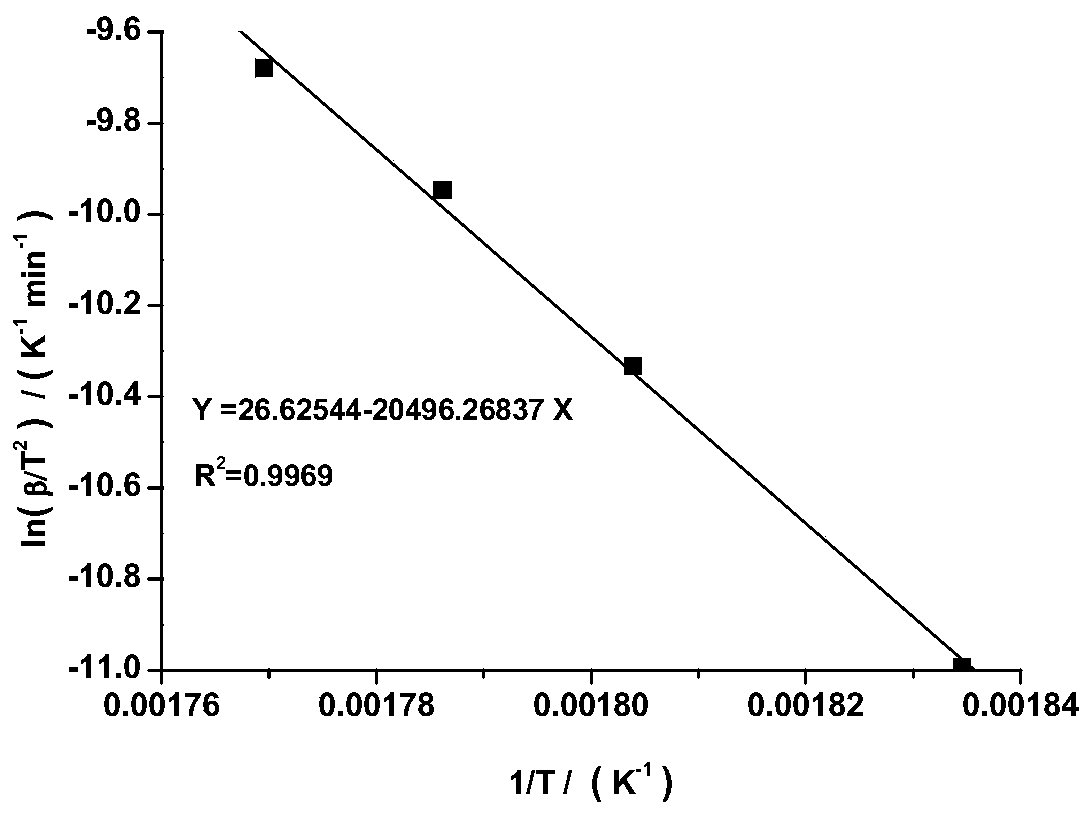

[0043] At the same time, the mechanical properties, insulation properties, and infrared microscopic parameters of the cable insulation samples at different temperatures and aging times are obtained, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com