Experimental method for evaluating adaptability of plugging agent in low permeability crack rock core

A plugging control agent and low-permeability technology, which can be used in earth-moving drilling, wellbore/well components, construction, etc., and can solve the problems of accelerated production decline, high permeability, and unbalanced water flooding degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] (1) Preparation of fractured low-permeability core

[0042] ① Fractured columnar core model

[0043] The gas permeability is 30×10 -3 μm 2 The artificial homogeneous columnar core (diameter: 2.5cm, length: 7cm) is used as the matrix, and artificial fractures are made, that is, the core is radially squeezed to create fractures, and the core is pressed into two halves from the middle; The sand grains act as a support to obtain fractures with different fracture widths, and then the two halves of the cores are joined together; considering that the end effect of a single short core is serious, two columnar cores that have been treated above are finally spliced together to obtain Fractured columnar core model with a length of 15-30cm.

[0044] The equivalent permeability of the core after fracturing can be measured by water flooding and calculated according to Darcy's formula. In the state of no confining pressure, since the fractures created are relatively regular, and...

Embodiment 1

[0095] The plugging effect of the modified starch system with different injection volumes on the core was studied, and the appropriate injection volume of the plugging agent was determined at the same time. The specific experimental results are shown in Table 3.

[0096] Table 3 Experimental data of modified starch plugged fracture core

[0097]

[0098]

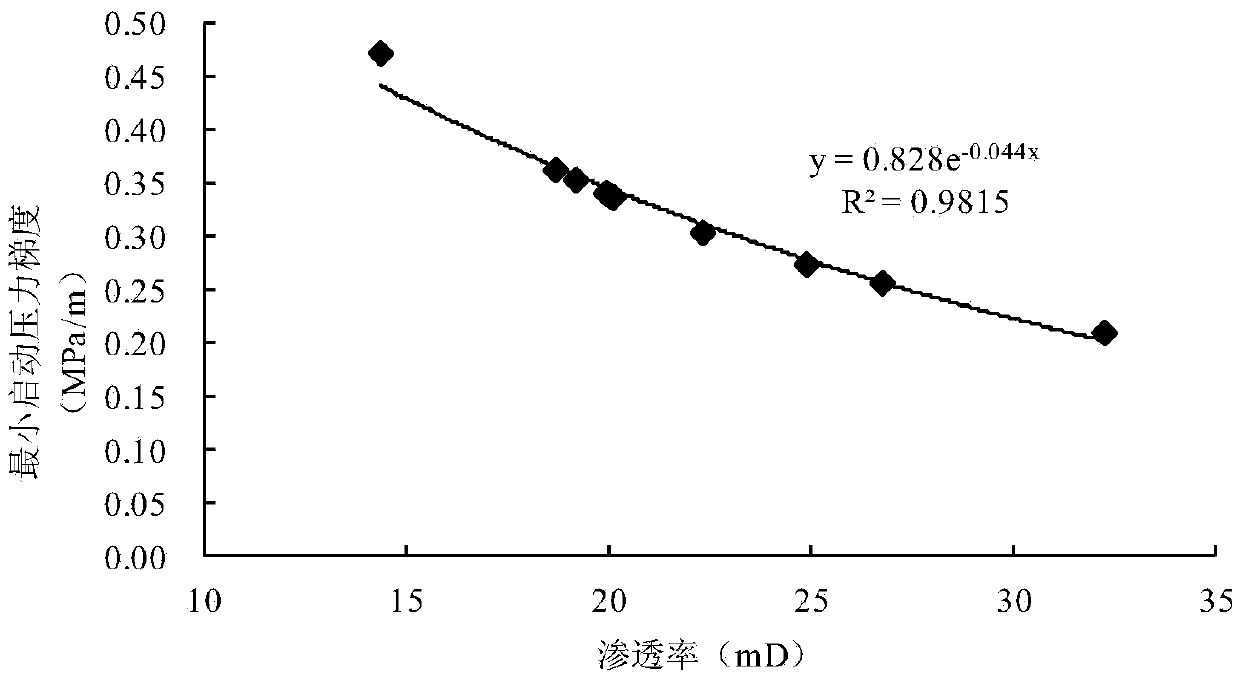

[0099] The minimum starting pressure gradient in the table is given by figure 2 Calculated using the fitting formula in .

[0100] PV refers to the pore volume of the whole core after fracture creation; V f is the fracture volume.

[0101] When the injection amount of modified starch is 0.05PV, the breakthrough pressure is less than 0.4MPa / m, the plugging rate is lower than 80%, and the sealing effect of the plugging agent on fractures is poor; moreover, the breakthrough pressure gradient of the plugging agent is smaller than the minimum of the matrix Initiate a pressure gradient so that the hypotonic matrix cannot...

Embodiment 2

[0107] Referring to the research results on the injection rate of the modified starch system, the plugging performance of the organic chromium gel on the fractured columnar core was directly studied when the injection rate was 1 times the fracture volume. The experimental results are shown in Table 4.

[0108] Table 4 Experimental data of organic chromium gel plugging fracture cores

[0109]

[0110]

[0111] The minimum starting pressure gradient in the table is given by figure 2 Calculated using the fitting formula in .

[0112] When the gel injection volume is 1 times the fracture volume, the greater the equivalent permeability of the fractured columnar core, the smaller the resistance coefficient, indicating that the gel is easier to inject. Although the core plugging rate of the system after gelling is above 97%, and the breakthrough pressure gradient of the plugging agent is greater than the minimum starting pressure gradient of the low-permeability matrix, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com