Method and system for testing nuclear power station pipeline leakage rate

A technology of pipeline leakage and test method, which is applied in the field of test method and system of pipeline leakage rate in nuclear power plants, and can solve problems such as difficulty in quantitative measurement and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

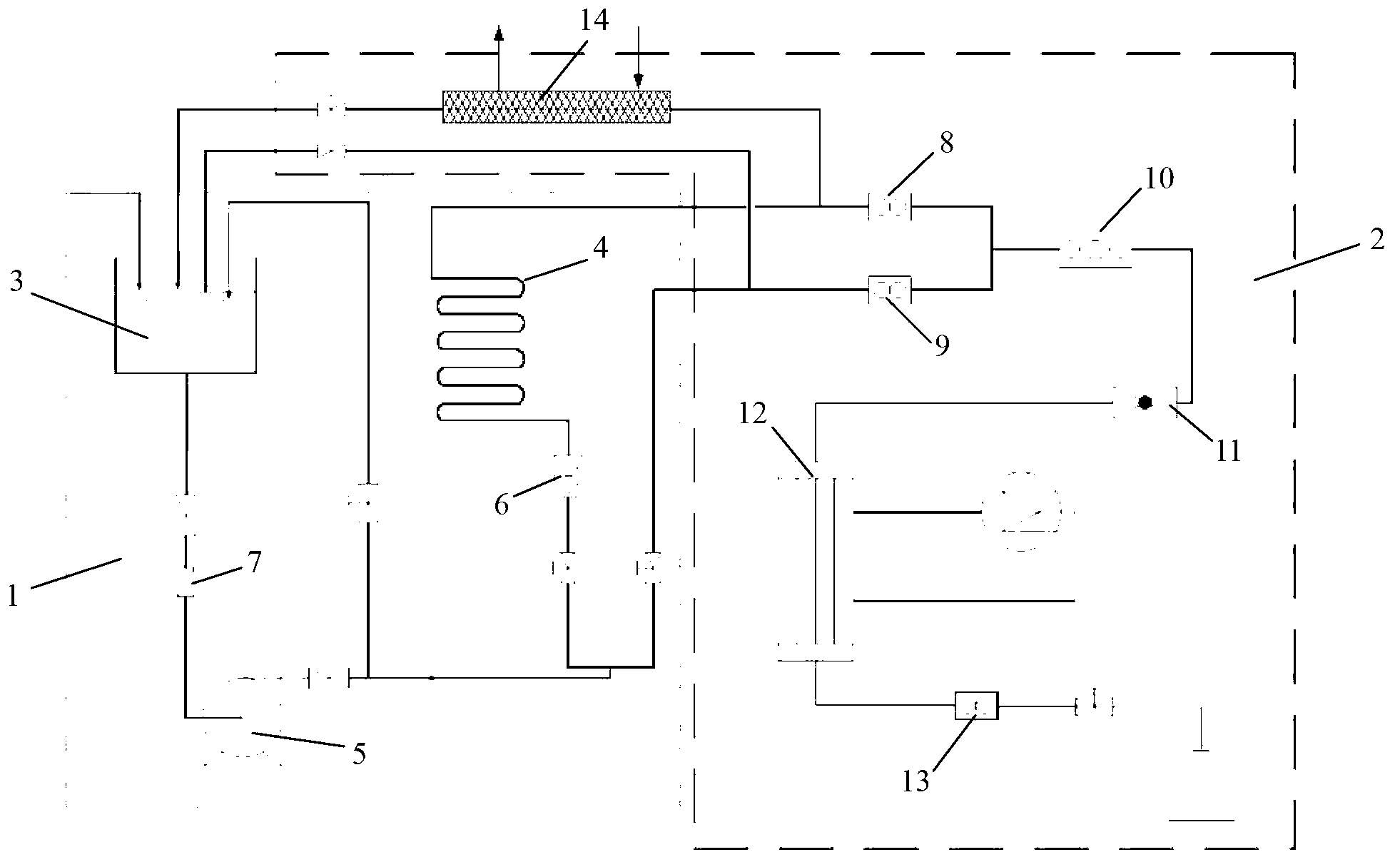

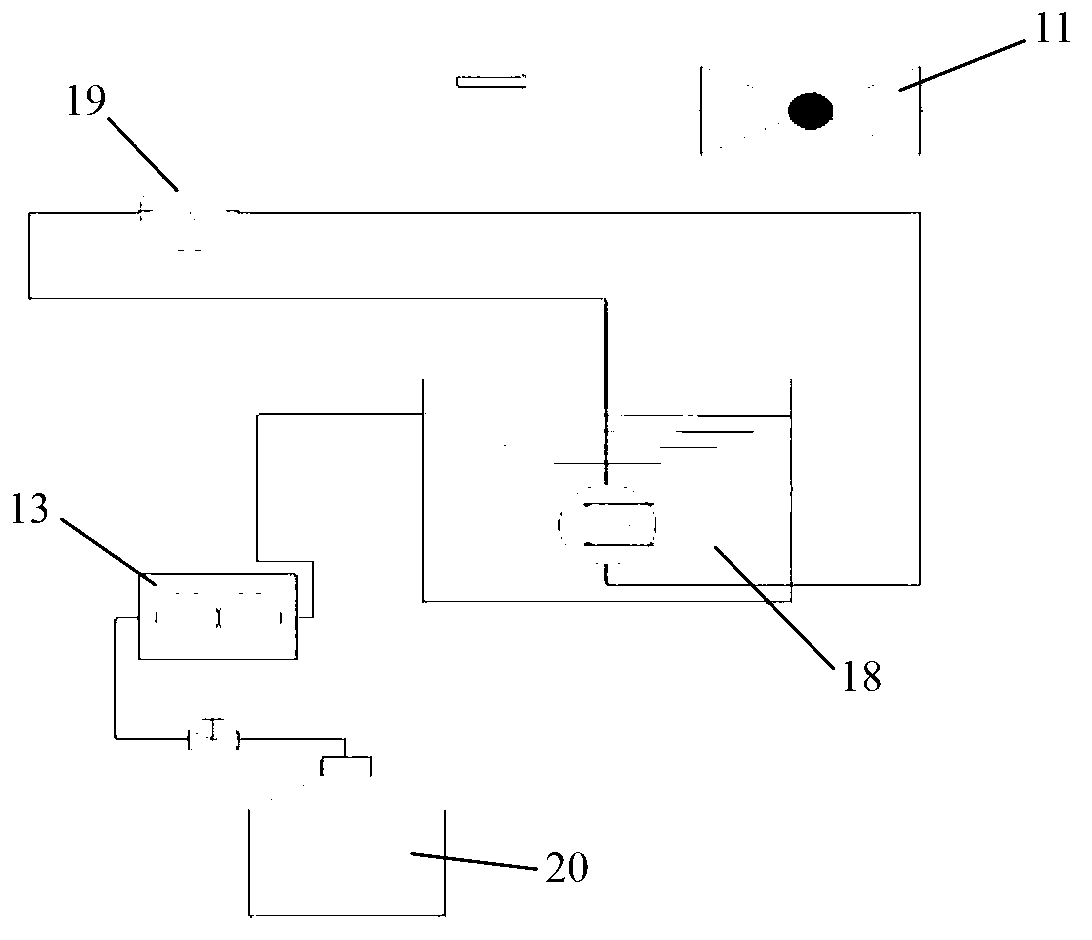

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0023] The method and system of the present invention mainly relate to the quantitative test of leakage rate in high-pressure fluid penetration crack leakage and critical leakage. The test is aimed at the pipeline crack leakage rate with multiple working medium parameters and multiple inlet forms, and can simulate the geometric shape of the inlet cross-section as ellipse, rhombus, rectangle or circle; the inlet parameters are underheated liquid, saturated liquid, gas-liquid two-phase mixture , saturated steam, superheated steam and supercritical fluid outlet leakage rate, the method and system of the present invention can correct the calculation model of the leakage rate of pipeline penetrating cracks, and correct the existing critical leakage model to compile calculation programs.

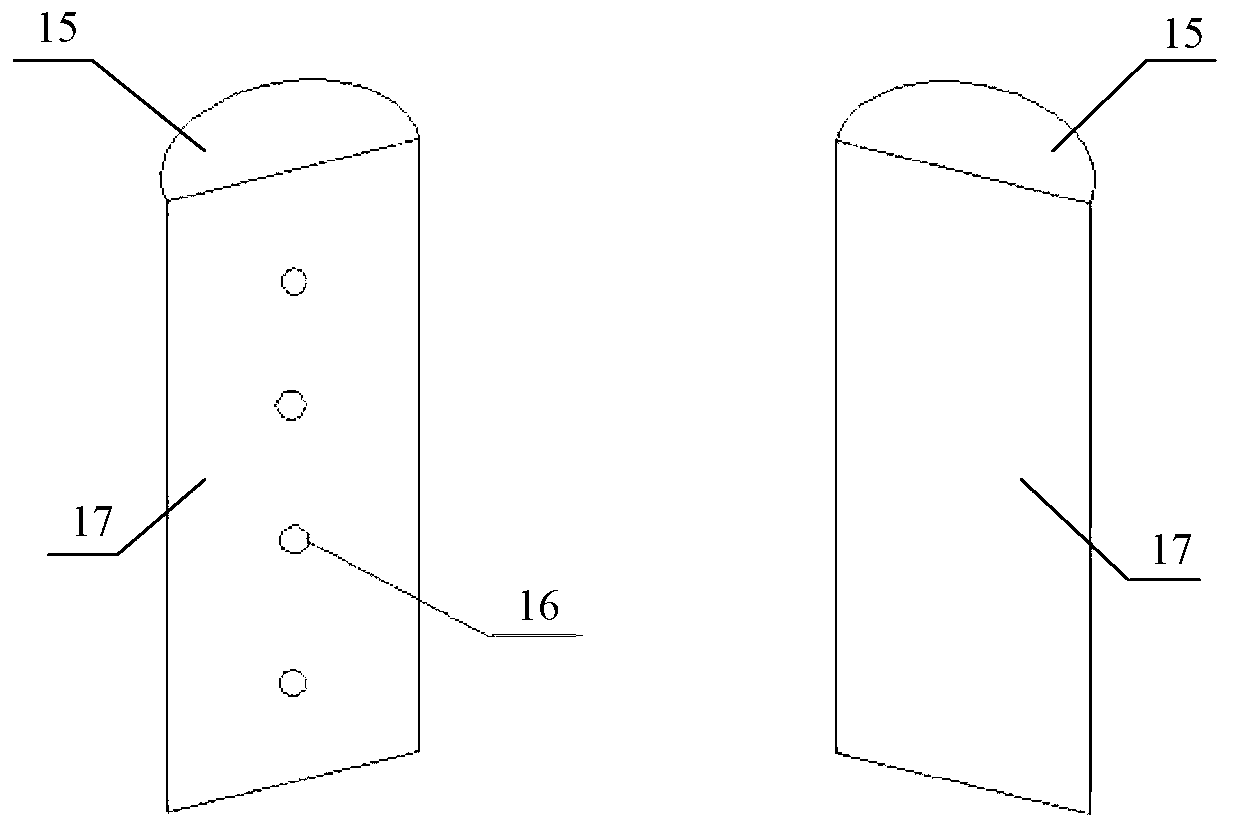

[0024] The structure of the nuclear power plant pipeline leakage rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com