Device for monitoring service lives of valve casing of steam turbine and crack propagations of cylinder and method

A technology of crack extension life and crack extension, applied in the field of steam turbines, can solve problems such as brittle fracture of valve casings and cylinders, damage accidents of steam turbines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

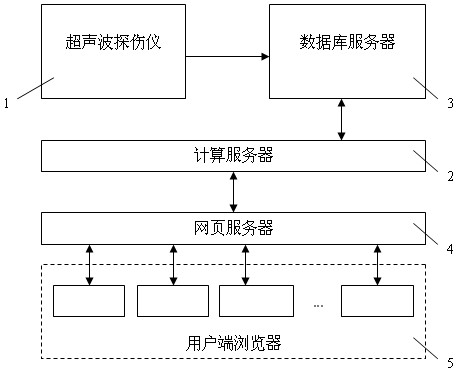

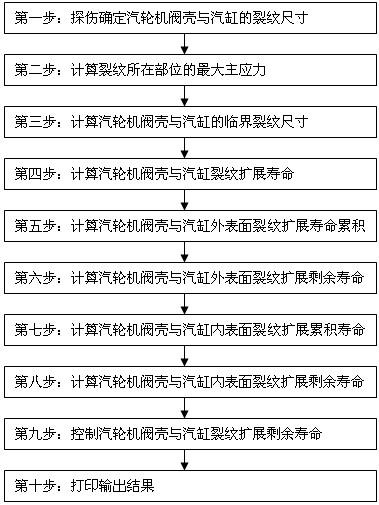

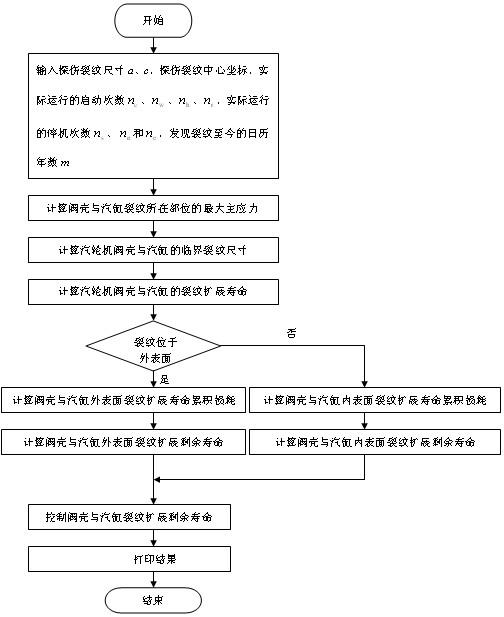

[0078] The structure of the valve casing of the high-pressure main steam regulating valve of a certain type of 300MW steam turbine is as follows: Figure 4 As shown, during the service period of the 300MW steam turbine, the figure 1 the device shown, figure 2 The flow chart shown and image 3 The computer software shown can calculate the calculation result of the crack growth life of the high-pressure main steam regulating valve valve casing.

[0079] Step 1: During the overhaul of the steam turbine cylinder, use an ultrasonic flaw detector to determine the location and size of the crack. It is measured that there is an oval crack on the inner surface part B of the high-pressure main steam valve regulating valve casing of the 300MW steam turbine. Radius is a =2mm, c=10mm;

[0080] Step 2: Establish the mechanical model of the three-dimensional finite element calculation of the valve housing and cylinder of the steam turbine; use the existing finite element analysis techno...

Embodiment 2

[0107] The structure of the high-pressure inner cylinder of a certain type of 300MW steam turbine is as follows: Figure 5 As shown, during the service period of the 300MW steam turbine, the figure 1 the device shown, figure 2 The flow chart shown and image 3 The computer software shown is used to calculate the calculation result of the crack growth life of the high-pressure inner cylinder.

[0108] Step 1: During the inspection and maintenance of the steam turbine cylinder, use an ultrasonic flaw detector to determine the location and size of the crack. Use an ultrasonic flaw detector to measure an oval crack on the outer surface of the high-pressure inner cylinder of the 300MW steam turbine. Shaft radius is a =2mm, c=10mm;

[0109] The second step: establish the mechanical model of the three-dimensional finite element calculation of the valve casing and cylinder of the steam turbine; use the existing finite element analysis technology to calculate the cold start, warm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com