Metal plate micro-defect detection method based on nonlinear Lamb waves

A detection method and non-linear technology, applied in measuring devices, processing detection response signals, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problem of low accuracy, variable and complex Lamb wave propagation, and lack of unity and other issues to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A metal plate micro-defect detection method based on nonlinear Lamb waves, comprising the following steps:

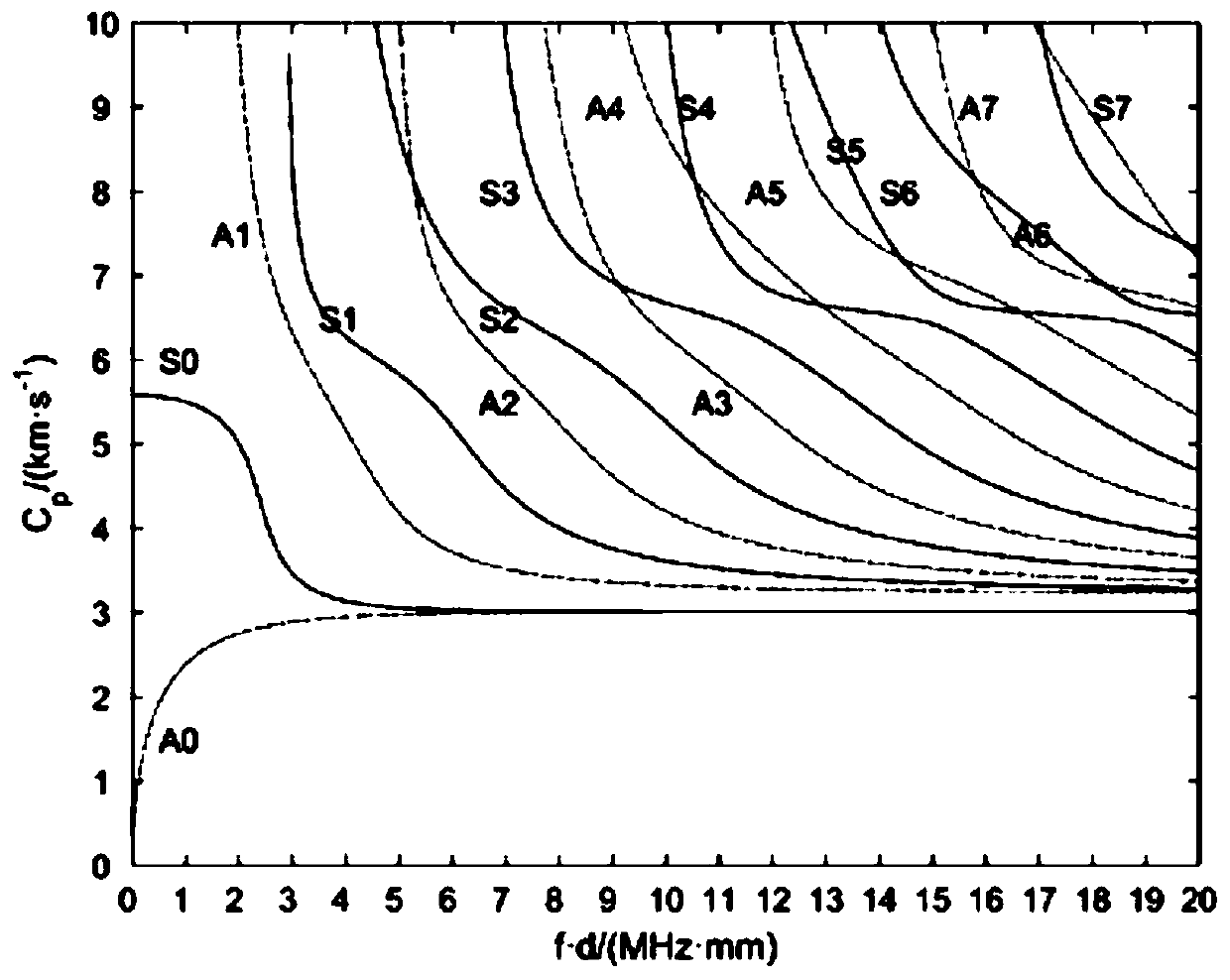

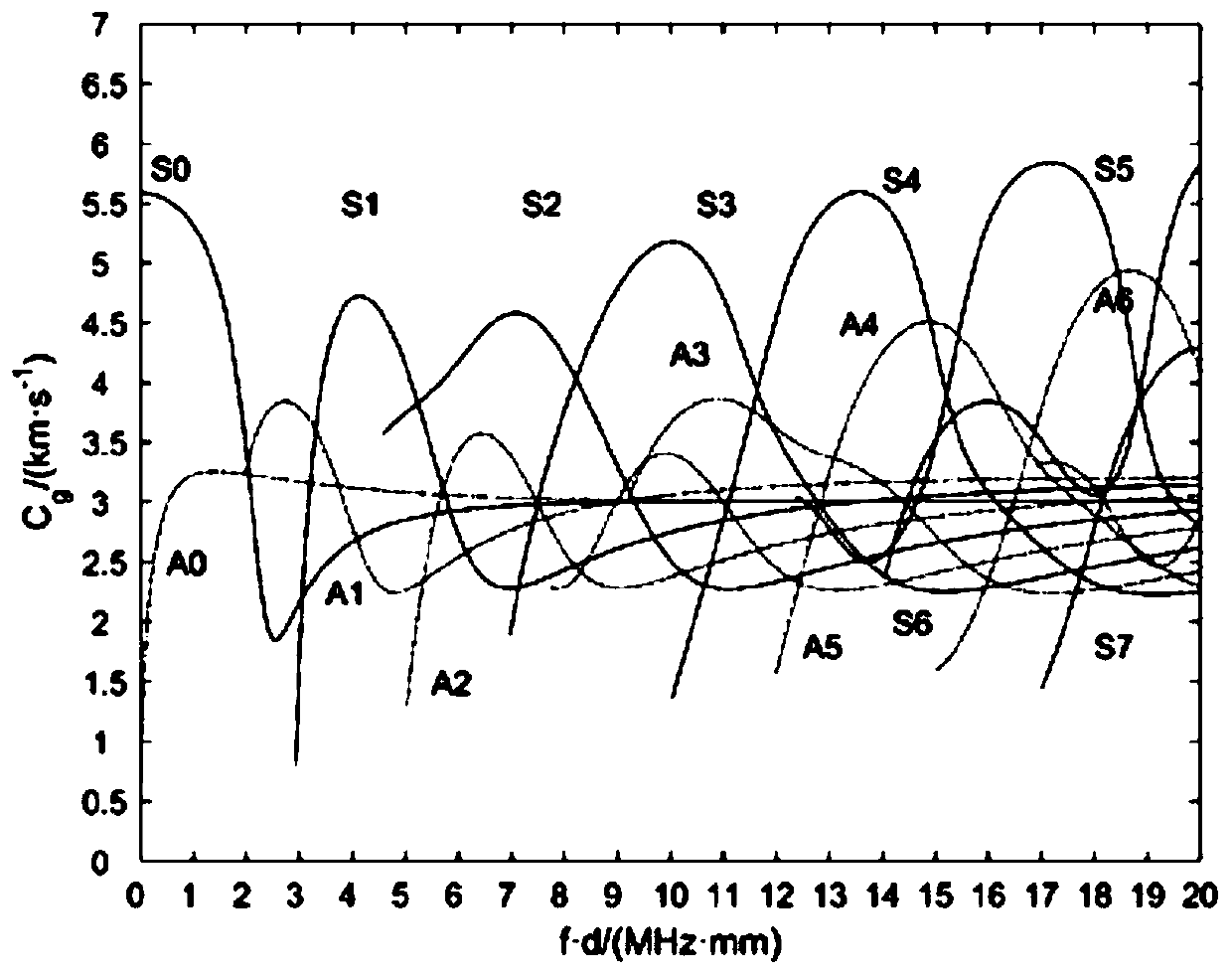

[0058] S1: Obtain the phase velocity dispersion curve and group velocity dispersion curve of the metal plate;

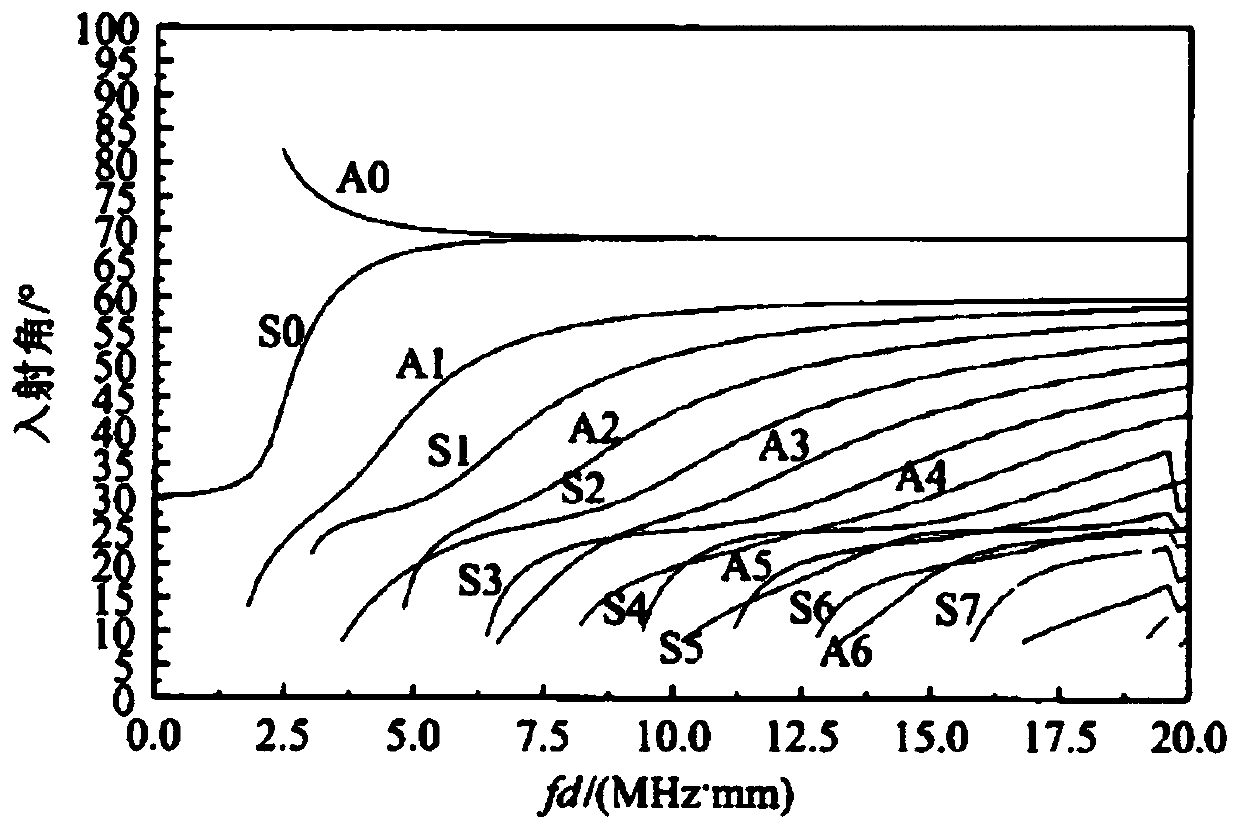

[0059] S2: According to the phase velocity dispersion curve and the group velocity dispersion curve, the excitation frequency, the Lamb wave of a specific mode and the incident angle of the Lamb wave of a specific mode are obtained as model parameters;

[0060] S3: Deduce the relative nonlinear coefficient β' according to the Lamb wave of a specific mode in S2, and the relative nonlinear coefficient β' is used to characterize the depth of the defect;

[0061] S4: Establish a nonlinear ultrasonic testing system according to the model parameters;

[0062] S5: Test the metal plate according to the nonlinear detection system established in S4 and judge whether the relative nonlinear coefficient β' is reliable, and if reliable, use the relative nonlinear co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com