Wavelet-based microcrack location method by utilizing nonlinear ultrasonic opposite-side exciting mixing frequency

A non-linear ultrasonic and positioning method technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. It can solve specific locations where micro-cracks cannot exist and give solutions and other issues to achieve good reference, improve utilization, and avoid safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

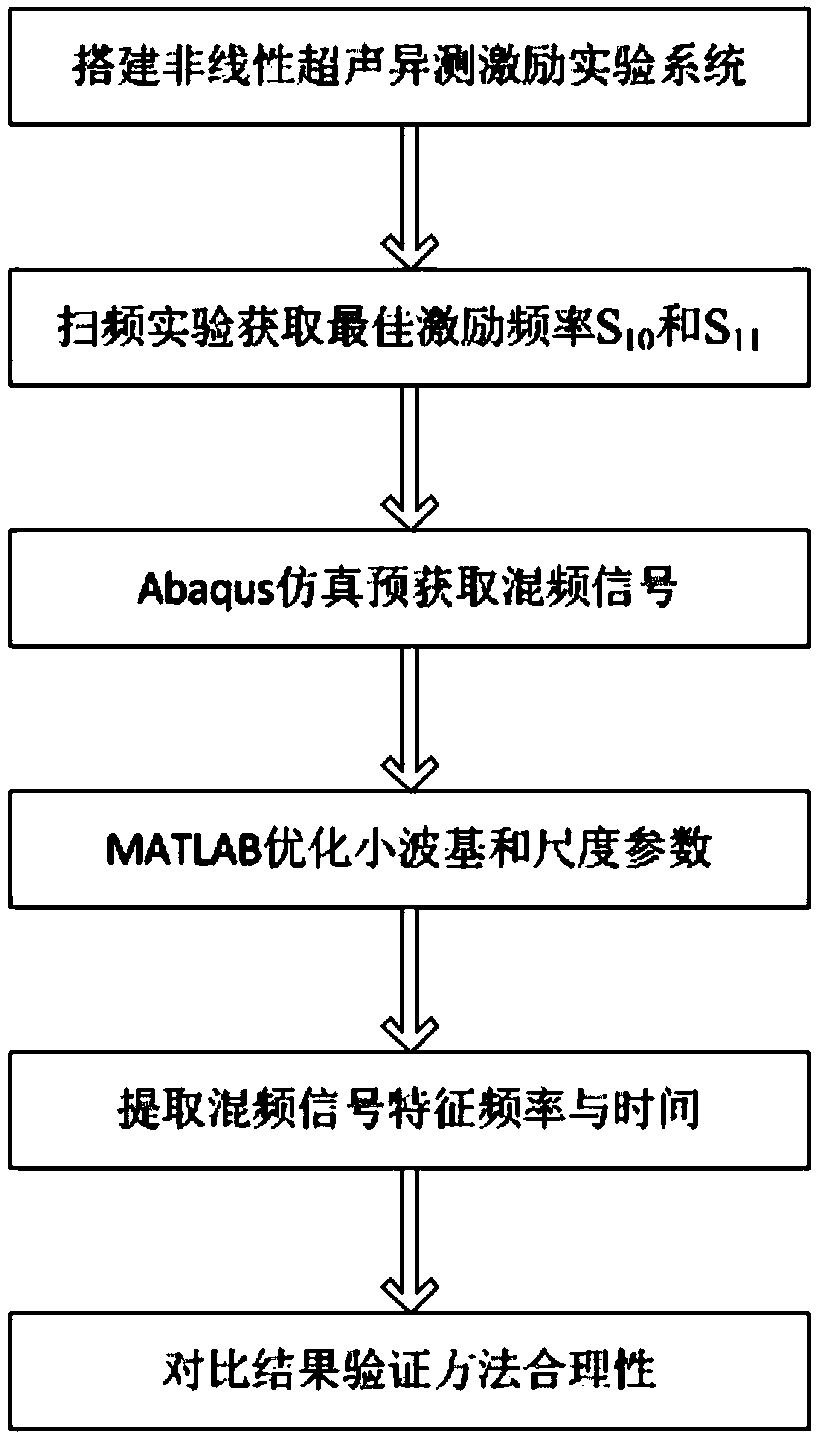

[0045] A microcrack localization method based on non-linear lamb wave different-side excitation mixing, see figure 1 , the method includes the following steps:

[0046] 101: The first sensor and the second sensor are respectively arranged on both sides of the tested object to form non-linear lamb wave different-side excitation;

[0047] 102: Collect the mixed frequency signal generated by the fatigue crack existing in the tested piece under the action of different side excitation;

[0048] 103: Perform time-frequency analysis on the mixed frequency signal through wavelet transform, extract the characteristic frequency and the time when the characteristic frequency appears, and realize the identification and location of the fatigue damage structure.

[0049] Wherein, the collection in step 102 is specifically:

[0050] First fix the frequency S transmitted by the first RF output port 10, under the premise of matching the frequency responses of the first sensor and the second...

Embodiment 2

[0058] The scheme in this embodiment 1 will be described in further detail below in conjunction with specific drawings and examples, see below for details:

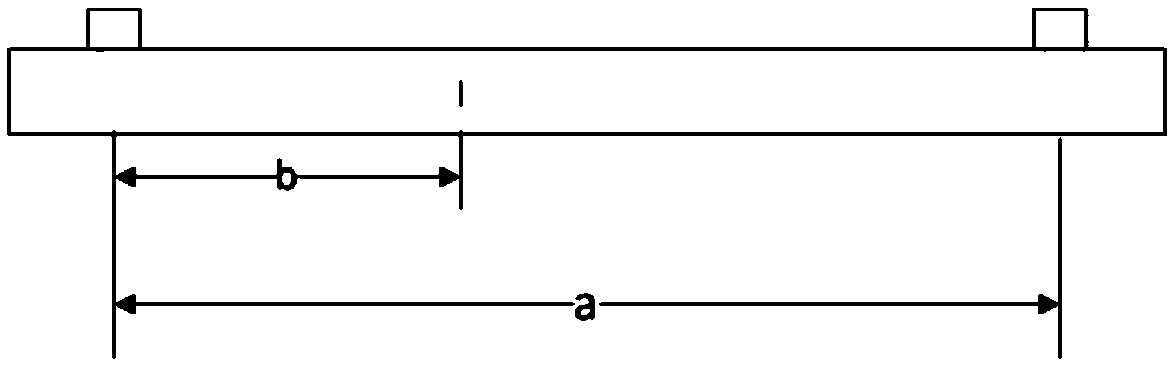

[0059] 201: Build a non-linear lamb wave different-side excitation mixing detection experimental system, collect the mixed-frequency signal generated by the fatigue crack 5 existing in the test piece 14 under the action of different-side excitation, and use it for subsequent processing and analysis;

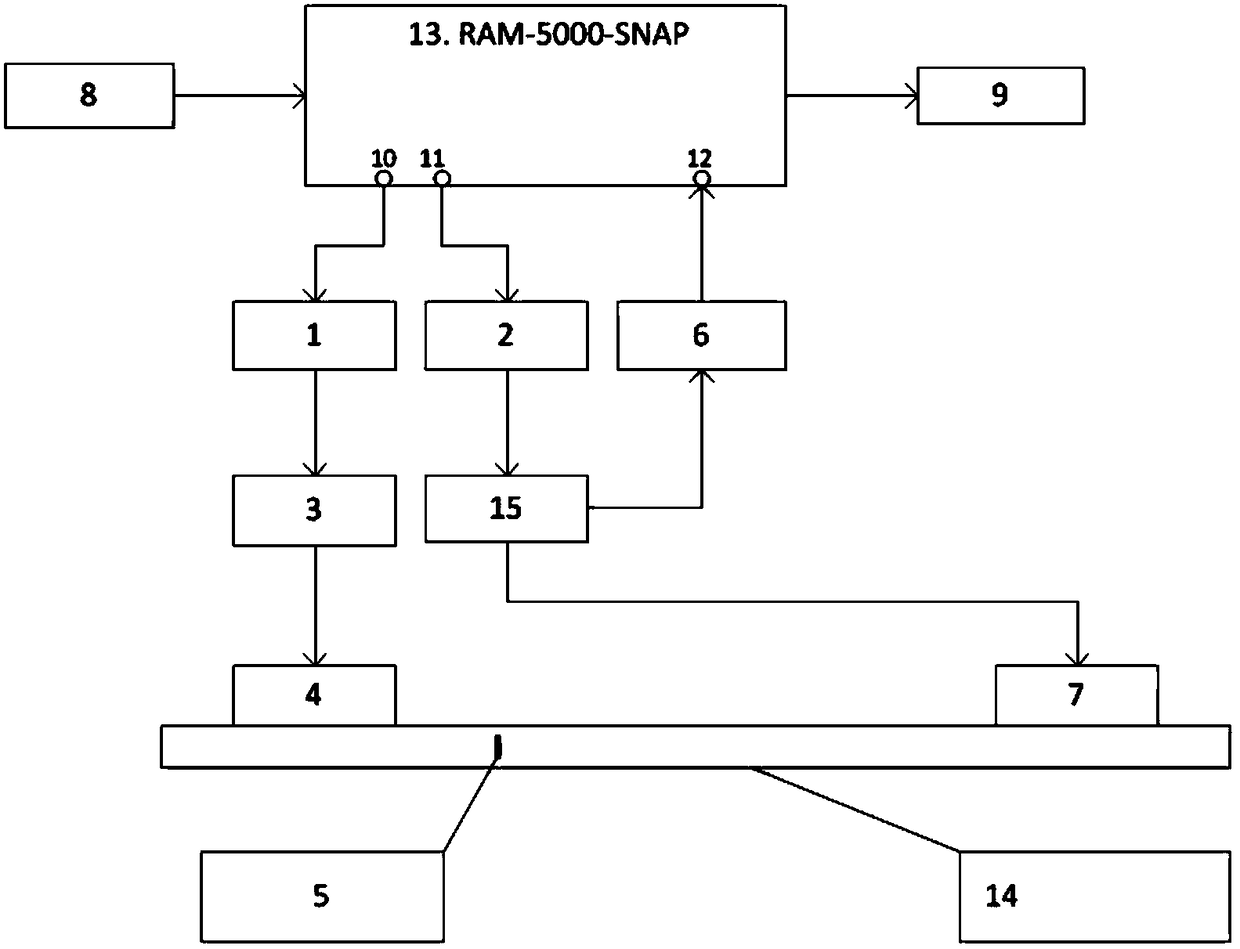

[0060] Among them, the experimental system such as figure 2 As shown, the detailed operation of the step 201 is:

[0061] 1) Build a nonlinear lamb wave different-side excitation mixing detection experimental system;

[0062] The system includes: a first attenuator 1 and a second attenuator 2 corresponding to the two radio frequency outputs, a low-pass filter structure 3 for processing the two output signals 10 and 11 of the nonlinear ultrasonic instrument 13, and a low-pass filter structure 3 for processing the second Th...

specific Embodiment approach

[0065] The specific implementation is as follows: first fix the frequency S transmitted by the first radio frequency output port 10 10 , under the premise of matching the frequency response of the first sensor 4 and the second sensor 7, set a frequency scanning range (f1, f2) and scanning step size f0, and set the frequency S transmitted by the second RF output port 11 11 According to the range and step size set above, apply the excitation with frequencies f1, f1+f0, f1+2f0, f1+3f0...f2 in sequence, observe and record the best effect of the mixing effect, that is, the amplitude of the mixing signal reaches The corresponding frequency S at the maximum 11 , as the excitation source of the second radio frequency output port 11. According to the nonlinear ultrasonic mixing theory, the frequency of the target feature mixing signal to be extracted is S 10 +S 11 .

[0066] The embodiment of the present invention is described based on the RAM-5000-SNAP nonlinear ultrasonic instrum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com