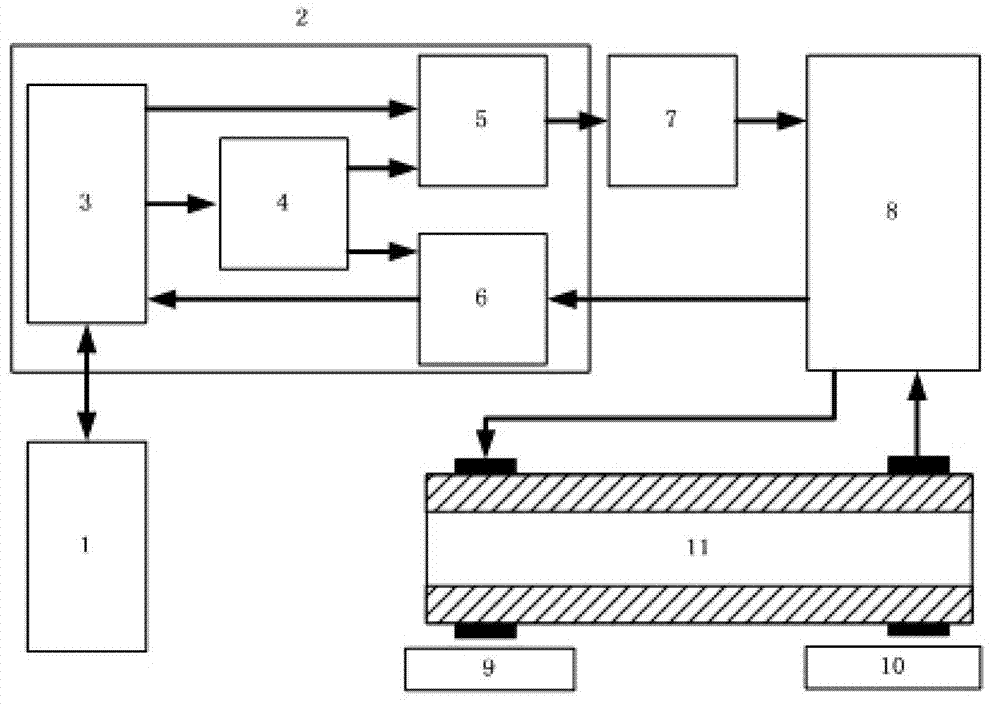

Nonlinear ultrasound system used for detecting super austenitic stainless steel inter-granular corrosion

An austenitic stainless steel, nonlinear ultrasonic technology, which is applied in the processing of the detected response signal and the use of sonic/ultrasonic/infrasonic waves to analyze solids and other directions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] The use of the method and system of the present invention is illustrated by taking the detection of intergranular corrosion of Super304H austenitic stainless steel as an example. The materials used in the examples are Super304H austenitic stainless steel produced by Sumitomo, Japan, and their chemical composition is shown in Table 1.

[0058] Table 1 Chemical composition of raw material Super304H stainless steel

[0059]

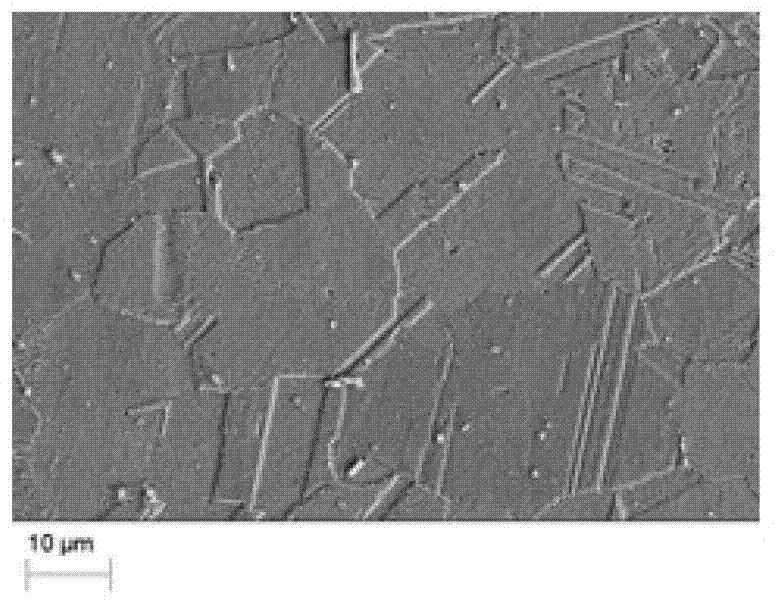

[0060] Stainless steel sulfuric acid + copper sulfate + copper chip corrosion method was used to prepare Super304H austenitic stainless steel corrosion samples with different corrosion degrees. and Alloy Corrosion Stainless Steel Intergranular Corrosion Test Method" and Microstructure Analysis Method. Among them: sample S1 has no cracks in the original state, hot corrosion state, and sensitized + hot corrosion state; sample S2 has no cracks in the original state and hot corrosion state, but cracks appear in the specimen after hot corrosion and sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com