Nonlinear ultrasonic imaging detection method based on automatic scanning

A non-linear ultrasonic and automatic scanning technology, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., can solve the problems of missed detection, increased detection cost, poor resolution, etc., and achieve high-sensitivity and high-resolution ultrasonic imaging Detection, improvement of detection sensitivity and resolution, and realization of the effects of detection sensitivity and resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The method of the invention consists of four parts: a nonlinear ultrasonic unit, a nonlinear ultrasonic detection signal acquisition method, a nonlinear ultrasonic imaging, and an automatic scanning nonlinear ultrasonic imaging detection step.

[0045] 1) Non-linear ultrasonic unit

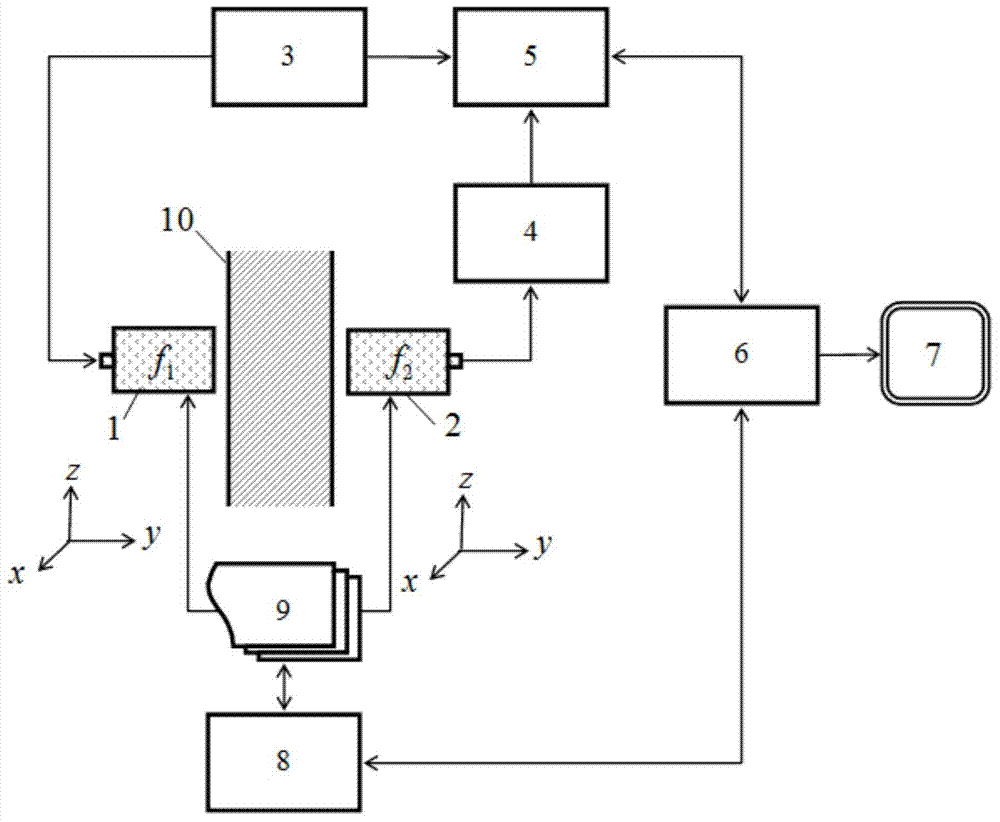

[0046] The nonlinear ultrasonic unit of the nonlinear ultrasonic imaging detection method for automatic scanning includes ultrasonic automatic scanning detection equipment, a transmitting transducer 1, a receiving transducer 2, an ultrasonic unit 3, and a preprocessor 4, such as figure 1 shown;

[0047] The transmitting transducer 1 and the receiving transducer 2 are designed to adopt water spray pulse transducers, which are respectively installed on the two transducer mounts in the scanning mechanism 9 of the ultrasonic automatic scanning detection equipment, and the transmitting transducer 1 And the receiving transducer 2 is controlled by the scanning mechanism 9 in the ultrasonic automati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com