Nonlinear ultrasonic detection method for axial stress of bolt

A nonlinear ultrasonic and axial stress technology, applied in the direction of measuring force components, force/torque/work measuring instruments, measuring devices, etc., can solve the problem of inaccurate stress, simplify the measurement process, avoid measurement, and improve accuracy sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

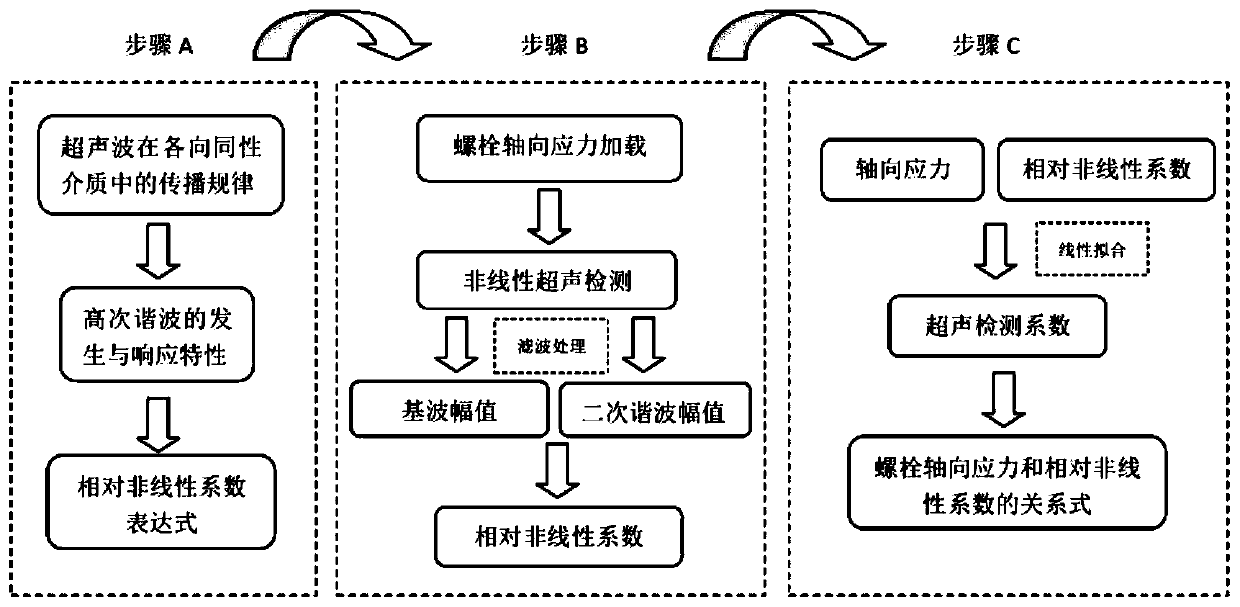

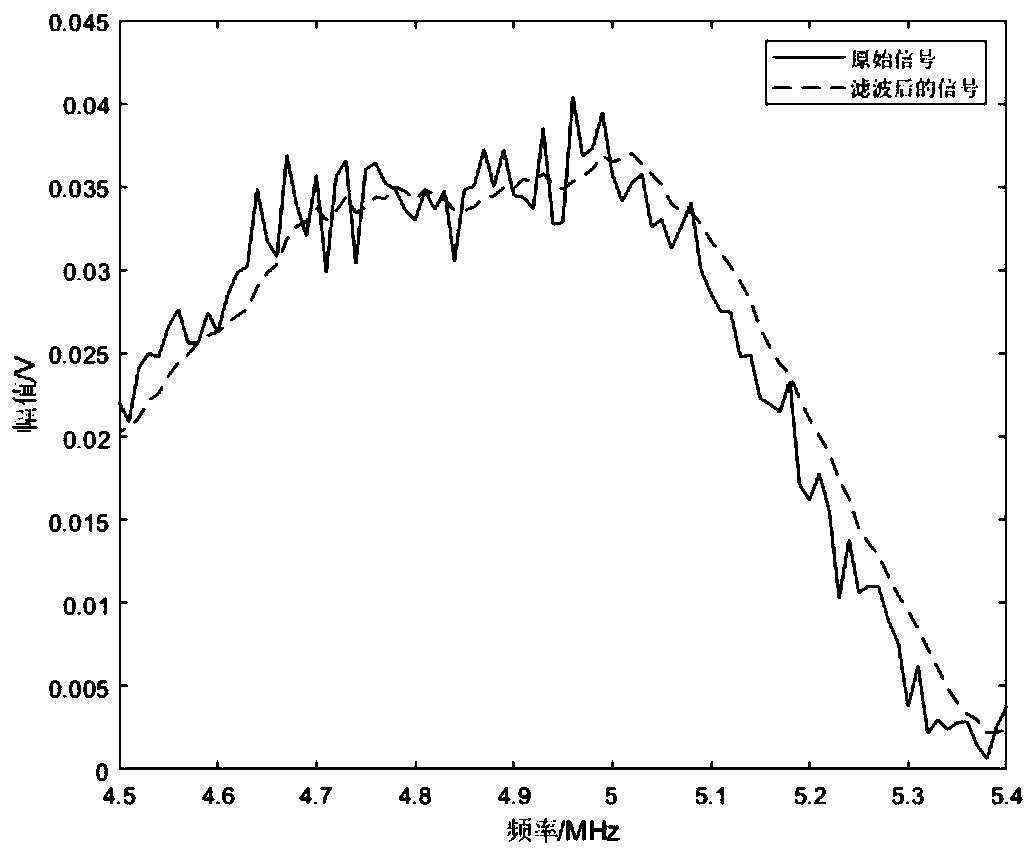

[0072] The invention proposes a nonlinear ultrasonic detection method for the axial stress of bolts, with the purpose of accurately and quickly measuring the axial stress of bolts. The existing ultrasonic measurement method is mainly based on the principle of acoustic elasticity, relying on the change of sound velocity to judge the magnitude of the stress. However, when the stress changes by 100MPa, the sound velocity only changes by 0.01%. Therefore, it is not accurate enough to reflect the stress on the material through the change of wave velocity. . Based on the shortcomings of the existing methods, the present invention detects the axial stress of the bolt from the perspective of nonlinear response. The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

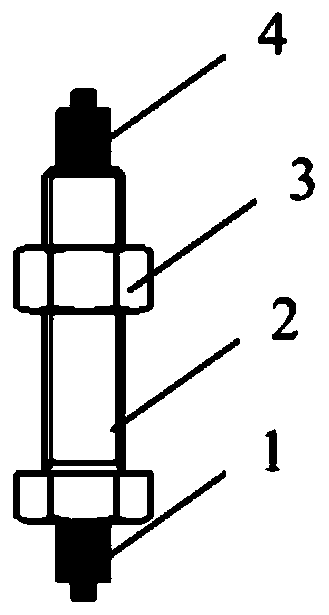

[0073] In the embodiment of the present invention, the method of the present invention is described by taking a bolt whose material is 45 steel, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com