Nonlinear ultrasonic evaluation method of metal material plating damage

A nonlinear ultrasonic, metal material technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

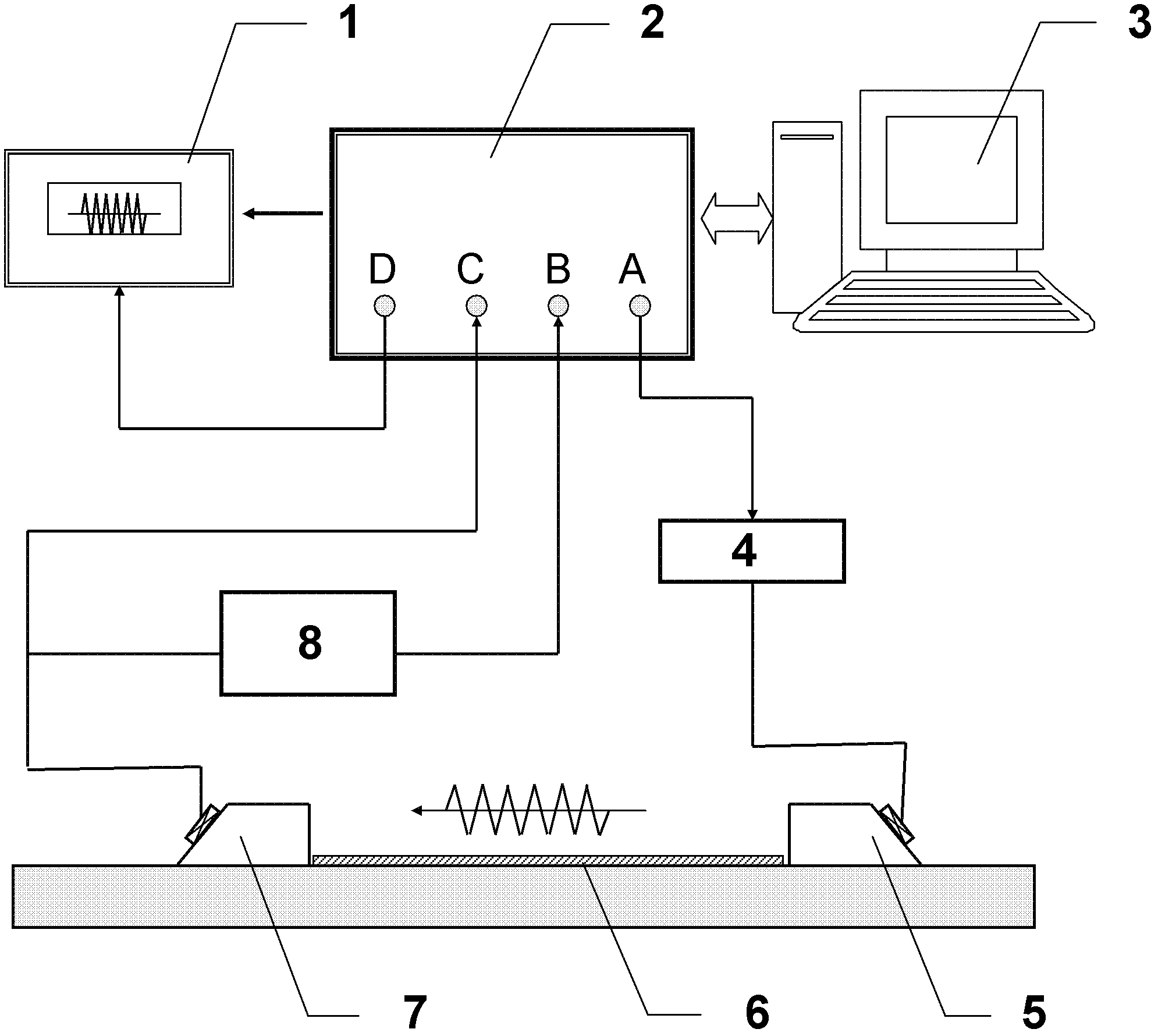

[0054] Non-linear ultrasonic testing systems such as figure 1 As shown, it includes: an oscilloscope 1, a host computer 2, a computer 3, a pre-attenuation and low-pass filter module 4, a Rayleigh wave excitation device 5, a Rayleigh wave receiving device 7, and a high-pass filter module 8. The model of oscilloscope 1 is TDS3034B, the model of host 2 is Ritec SNAP-0.25-7-G2, the model of pre-attenuation and low-pass filter module 4 is RLP-2, and the model of high-pass filter module 8 is RHP-4. Utilize the coaxial cable to connect the signal output terminal A of the host computer 2 with the input terminal of the pre-attenuation and low-pass filter module 4, and the output terminal of the pre-attenuation and low-pass filter module 4 is connected with the Rayleigh wave excitation device 5, Rayleigh One signal of the wave receiving device 7 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com