Construction Method of Prediction Model for Remaining Service Life of Wind Turbine Bearings

A life prediction model, wind turbine technology, applied in wind power generation, mechanical component testing, biological neural network model, etc., can solve problems such as increased cost, large difference between bearings and bearings, poor generalization ability of wind turbines, etc. The effect of improving accuracy, reducing the number of downtimes, and reducing labor maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

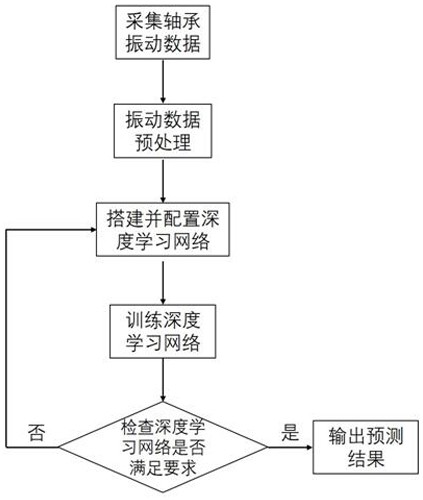

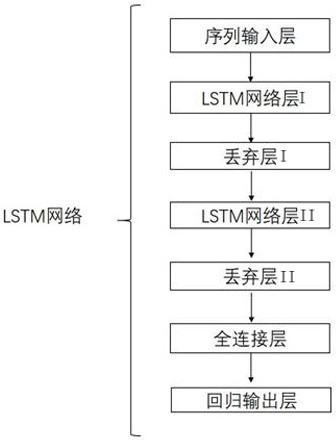

[0037] The construction method of the remaining service life prediction model of the wind turbine bearing is realized by the following steps:

[0038] Step 1. Collect bearing vibration data

[0039] Bearings with 16 failure classes are preset, and each failure class bearing is given a remaining service life value. The remaining service life value of the bearing used for the first time is 150, the remaining service life value of the bearing that needs to be replaced in serious failure is 0, and the remaining service life value of the bearing that needs to be replaced is 0. The remaining service life value of the bearing of the failure level is normalized to the interval of 0-150, and the difference of the remaining service life value between the bearings of each failure level is measured by the test;

[0040] Referring to the real operation scene, place the wind turbine on the bench test bench with a 5 degree angle, the rotor is short-circuited, and run at no-load; use the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com