Method for non-linear ultrasonic online detection of early fatigue damage to metal material

A nonlinear ultrasonic and metal material technology, applied in the field of non-destructive testing, can solve the problems that the acoustic emission technology cannot detect the early fatigue damage of metal materials, is prone to misjudgment, and increases the dispersion, and achieves the effect of continuous online testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

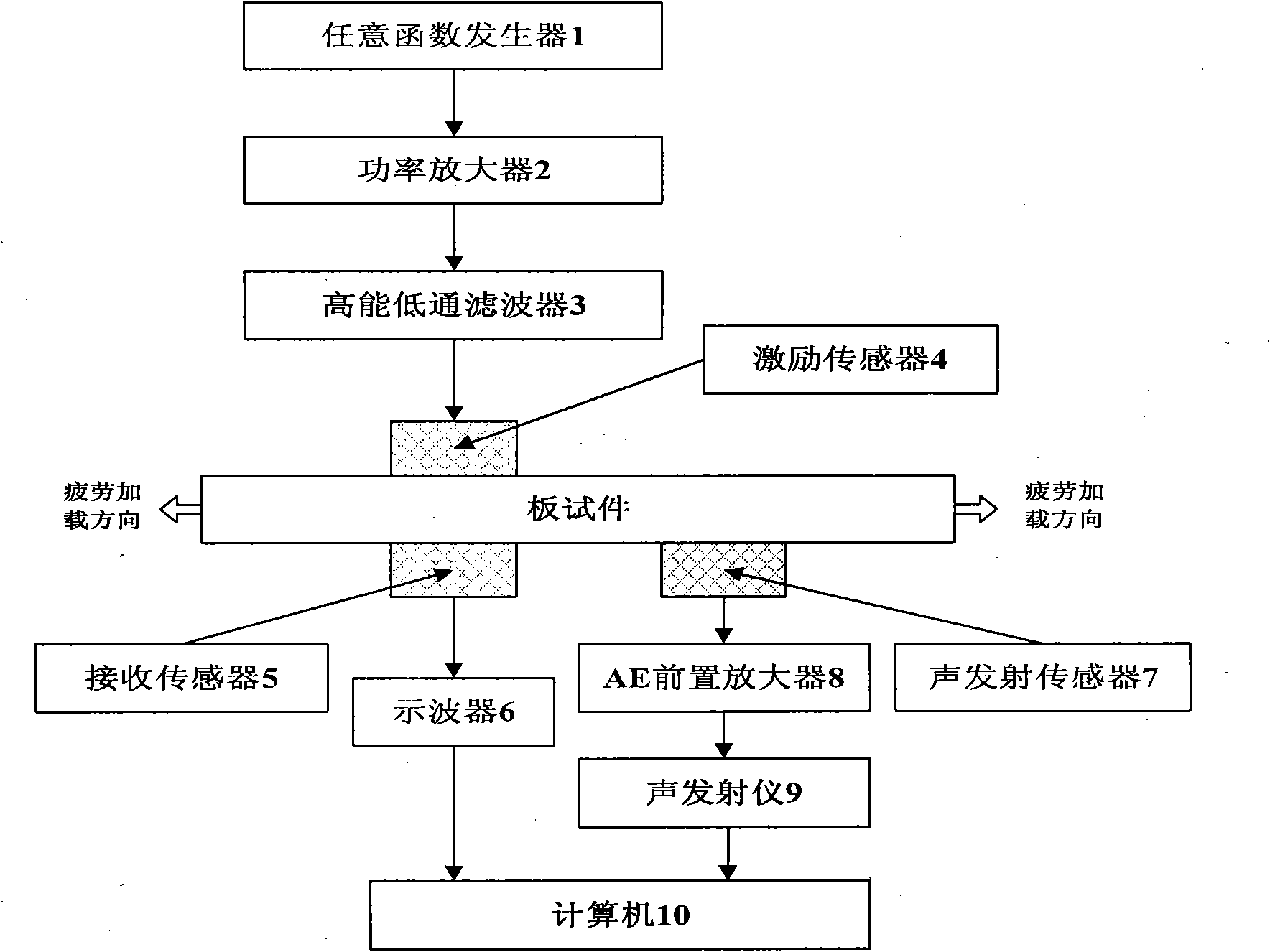

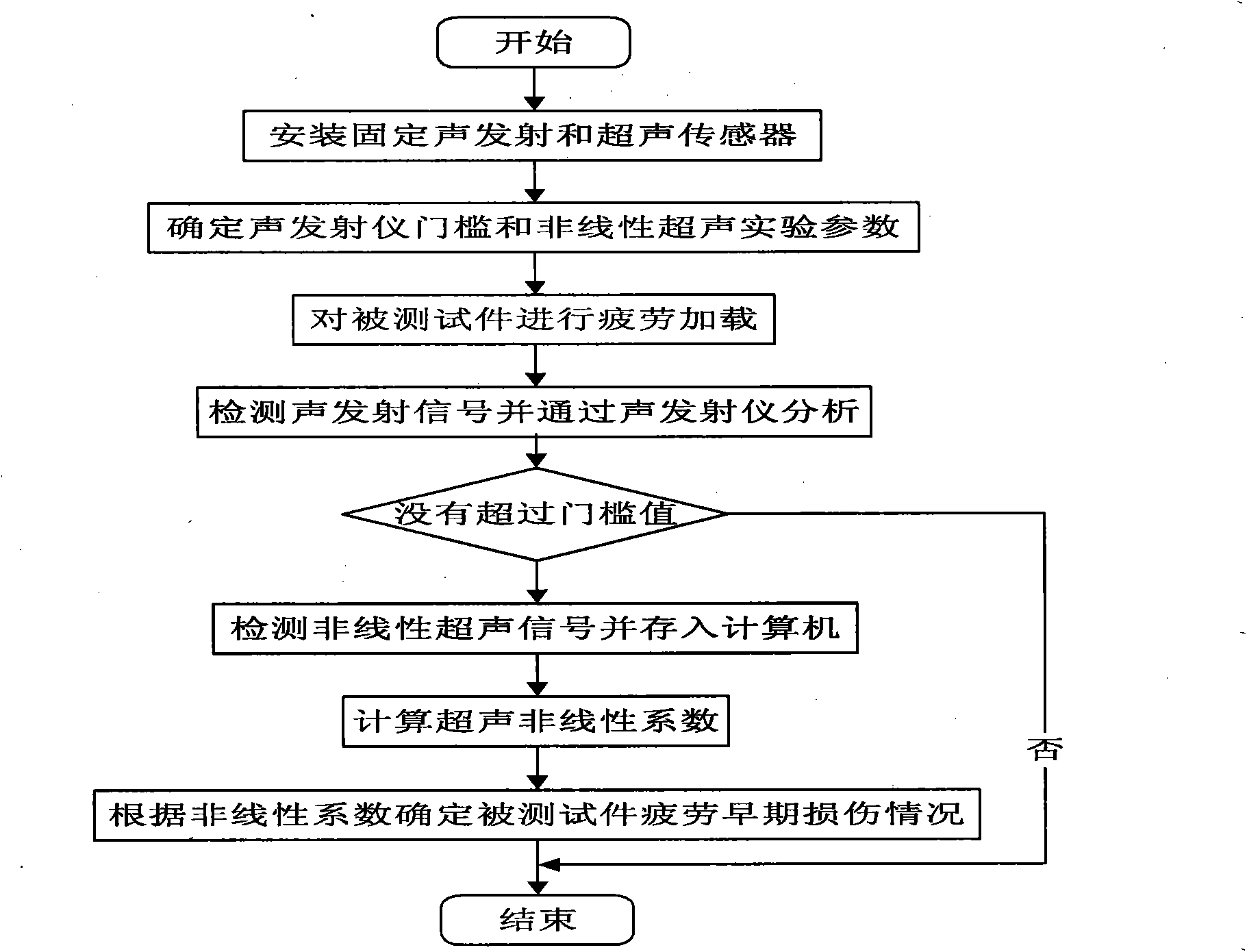

[0035] Combine below Figure 1 to Figure 5 This embodiment will be described in detail.

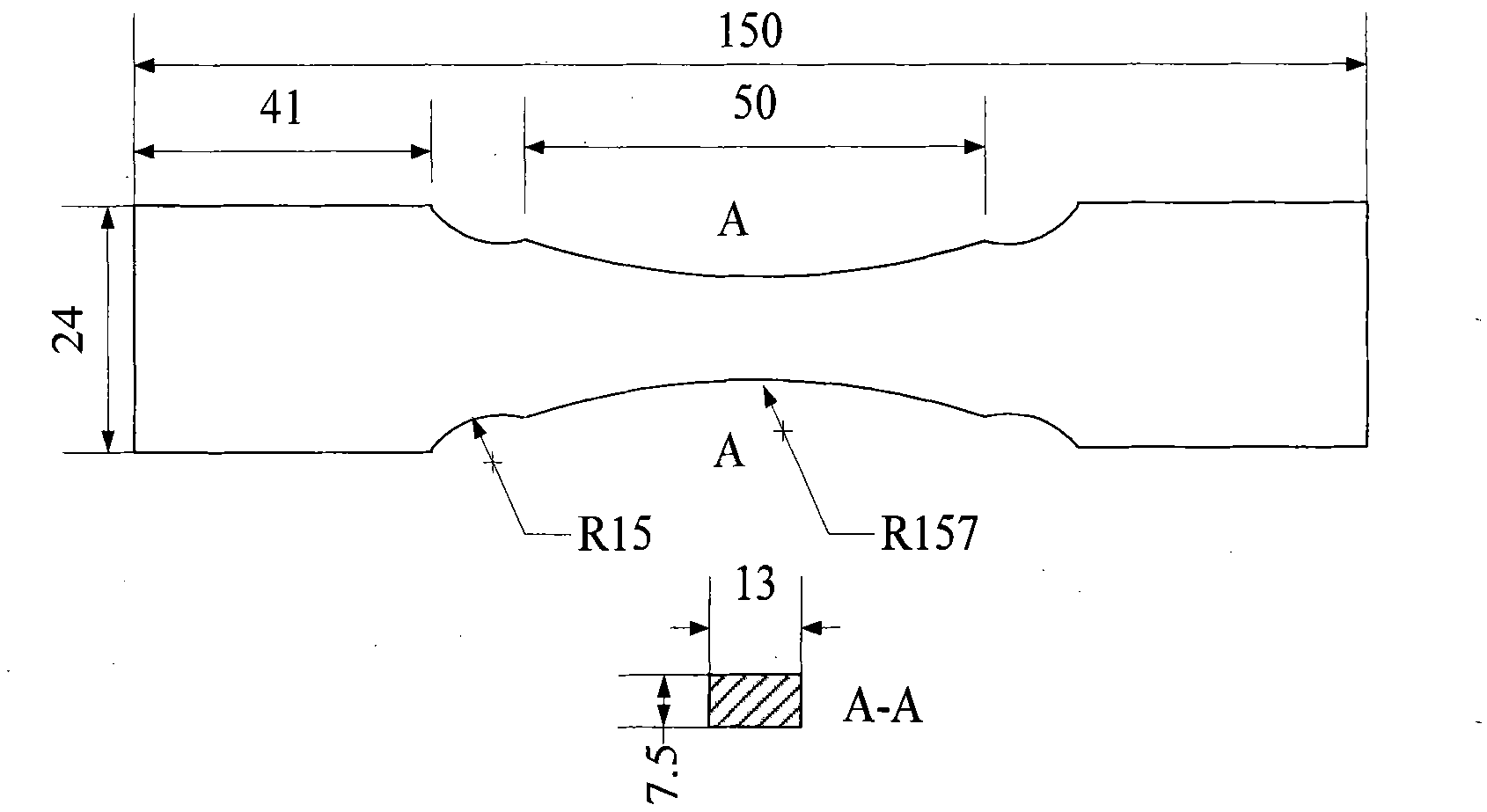

[0036] like image 3 As shown, the tested piece in this experimental example is an AZ31 magnesium alloy dog bone plate with a thickness of 7.5mm and a length of 150mm. The density is 1770kg / m 3, the longitudinal wave velocity is 5763m / s. The yield limit is 199MPa, and the strength limit is 259MPa.

[0037] 1) According to the center frequency of the excitation sensor, the excitation signal frequency is determined to be 5MHz. In order to reduce the harmonic interference generated by the instrument and random factors, the maximum number of cycles that the specimen can accommodate in the thickness direction without overlapping with the received signal is taken as the sinusoidal pulse train signal number of cycles, such as Figure 4 (a) shown. A pair of Panametrics narrowband PZT ultrasonic probes with center frequencies of 5MHz and 10MHz are used as excitation and reception transduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com