Method of applying Rayleigh waves in non-linear ultrasonic evaluation of surface damage of metal material

A non-linear ultrasonic and surface damage technology, which is applied to the analysis of solids using sonic/ultrasonic/infrasonic waves, which can solve the problems of insensitivity to the degradation of mechanical properties, achieve favorable propagation distance, simple and easy method, and simple and easy measurement process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

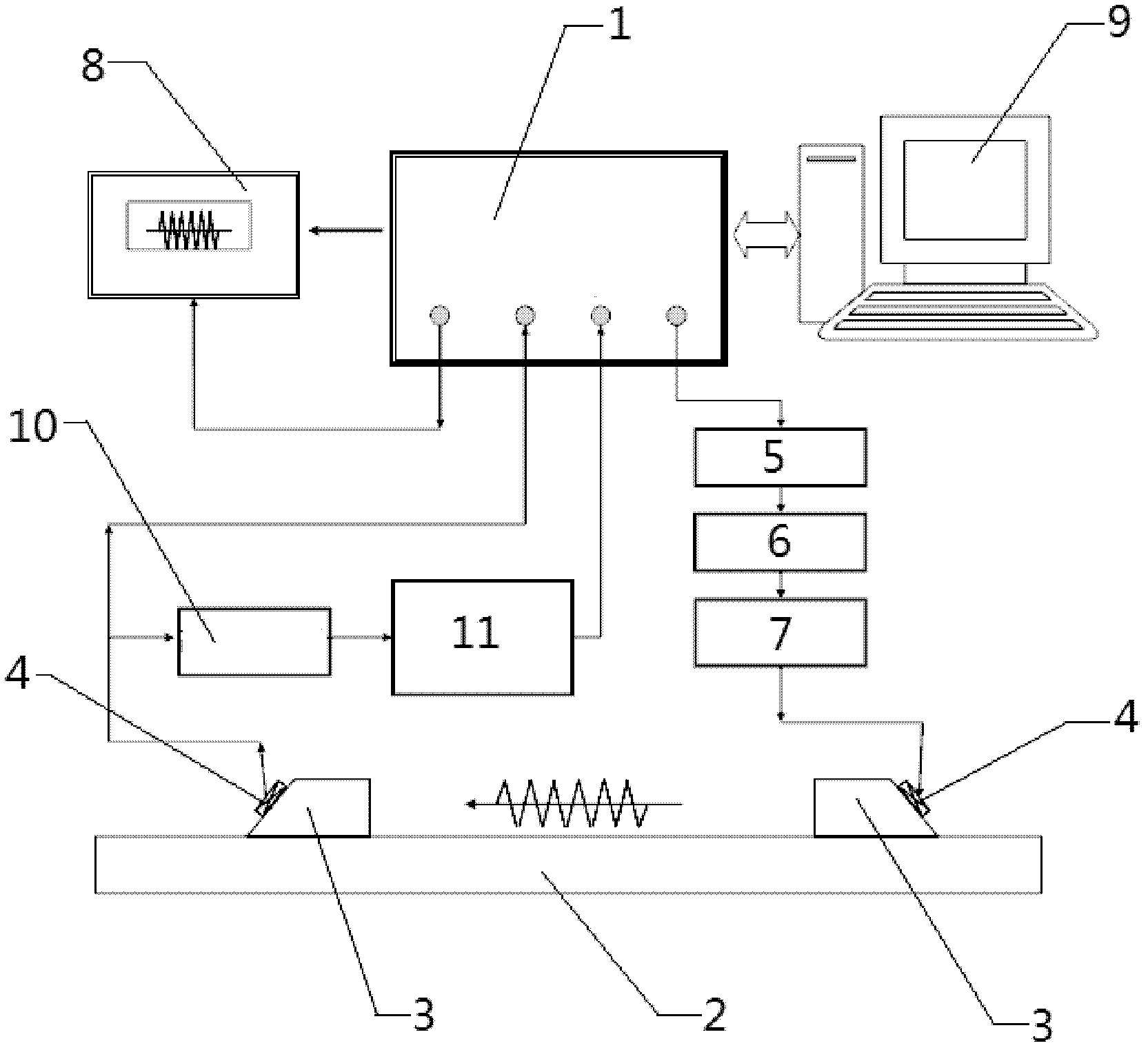

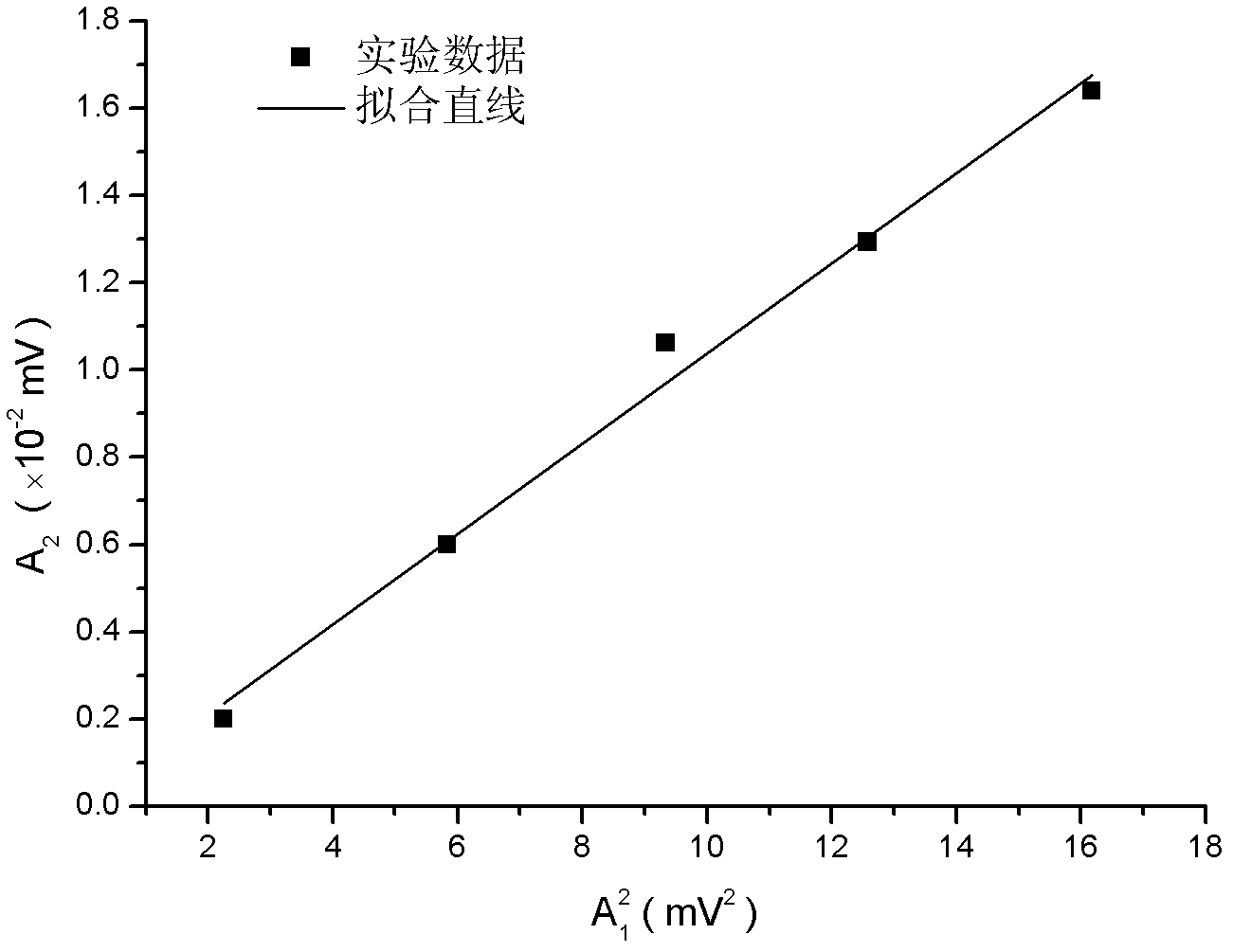

[0025] Such as Figure 1-6 As shown, a nonlinear ultrasonic evaluation method for surface damage of metal materials using Rayleigh waves, including the following steps:

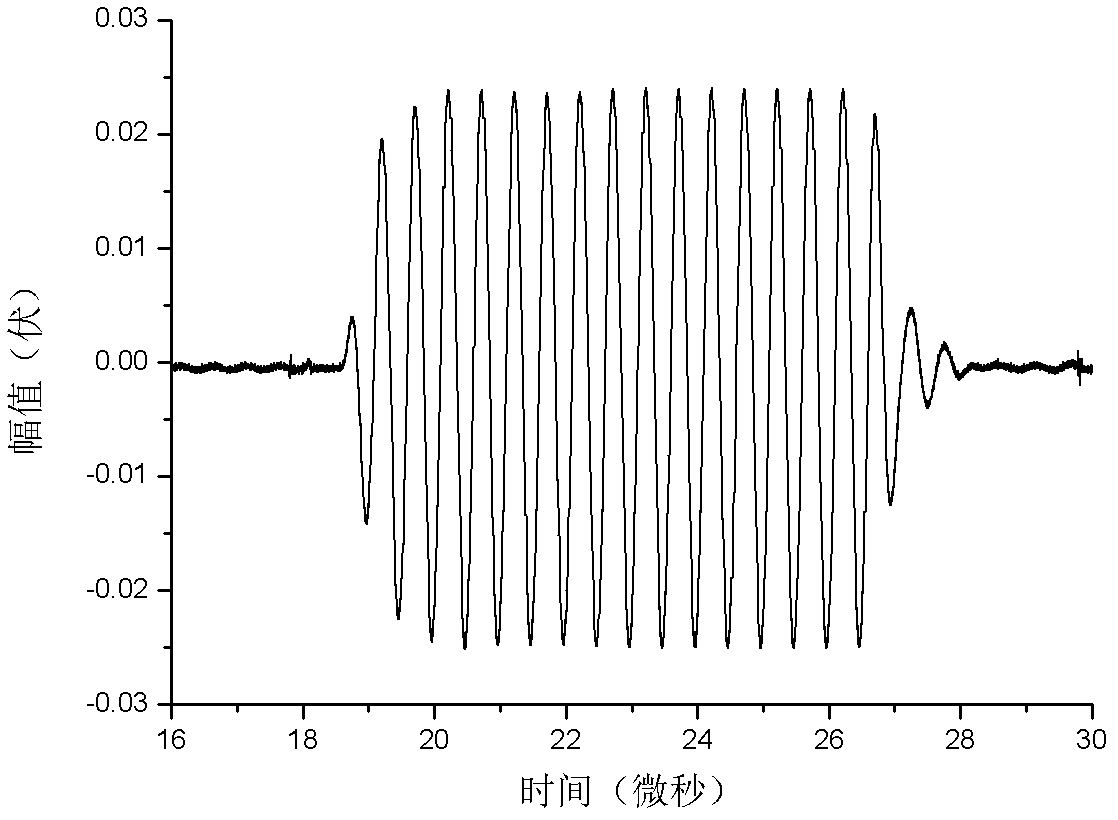

[0026]1) Excitation and reception of Rayleigh waves: the lithium niobate wafer transducer 4 is bonded on the plexiglass wedge, and then the plexiglass wedge 3 is pasted on the surface of the magnesium alloy specimen 2 using a coupling agent; the Ritec SNAP -0.25-7-G2 The host 1 of the nonlinear ultrasonic testing system generates ultrasonic signals, which excite Rayleigh waves on the surface of the aluminum-magnesium alloy specimen 2; The same plexiglass wedge receives Rayleigh waves, and the center fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com