Internal flaw position detecting method in depth direction for glass base plate

A glass substrate, depth direction technology, applied in measuring devices, optical devices, instruments, etc., can solve the problem that the detection cannot clearly detect the glass substrate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, preferred embodiments of the present invention will be described in detail based on the drawings.

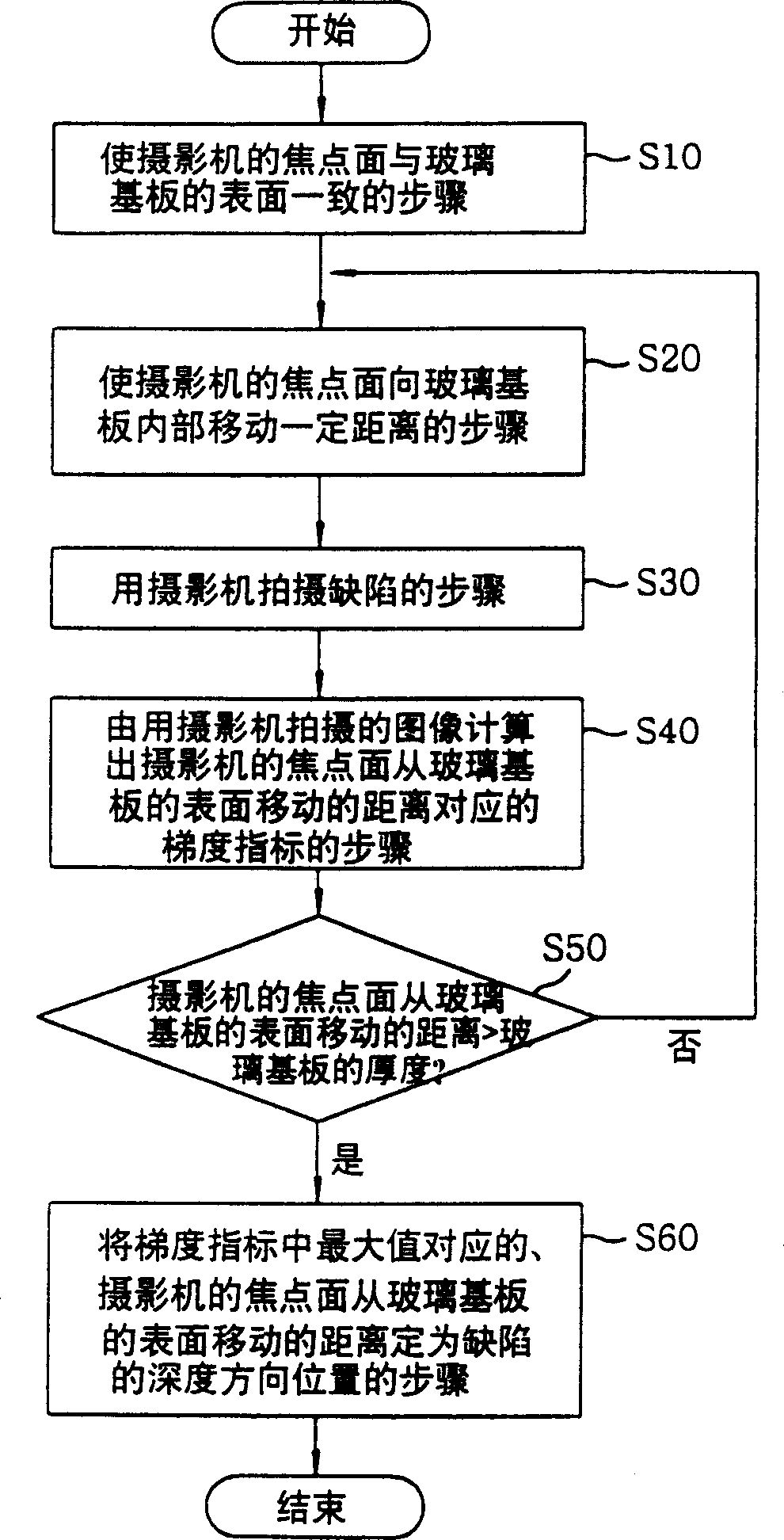

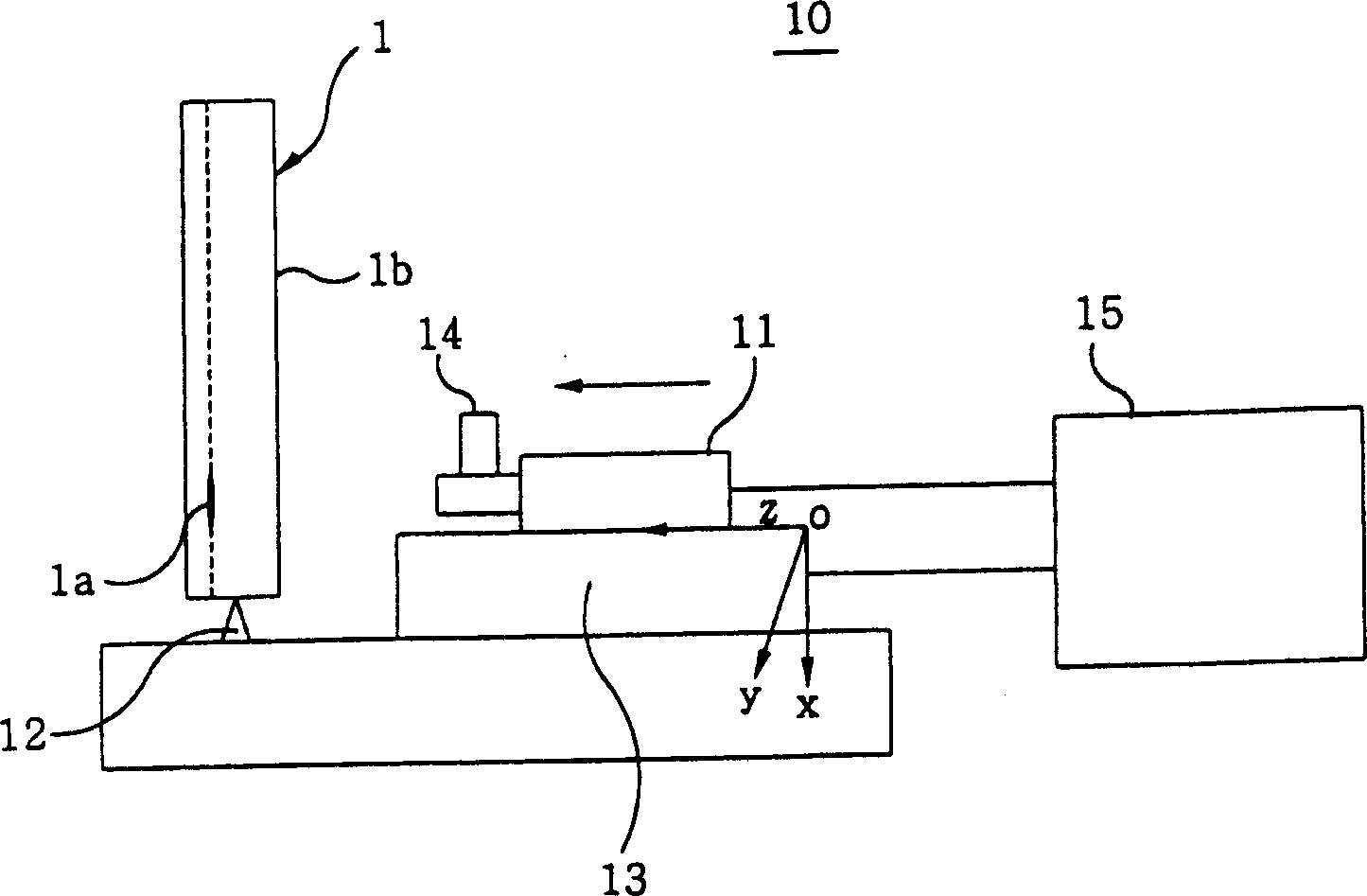

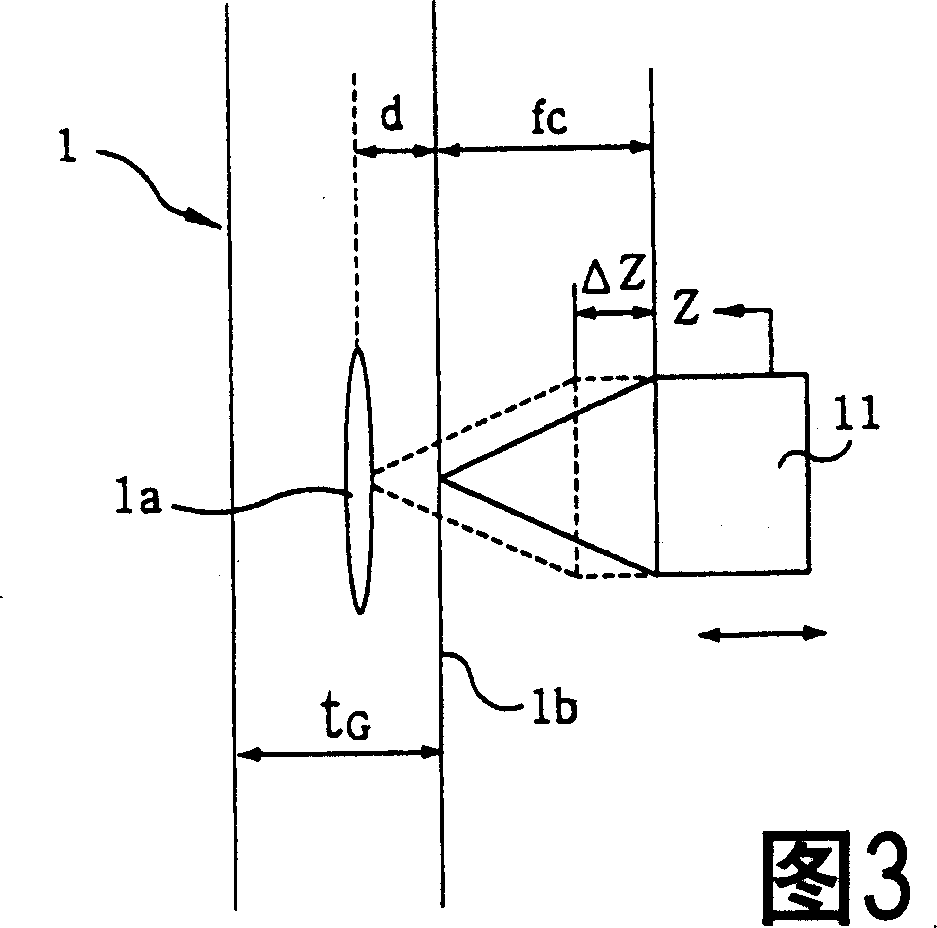

[0028] figure 1 It is a flowchart showing a method for detecting a position in a depth direction of a defect in a glass substrate according to the present invention, figure 2 3 is a schematic diagram showing an apparatus used in the method according to the present invention, and FIG. 3 is a schematic diagram showing an operation when the focal plane of the camera is aligned with the surface where the defect is located in the method according to the present invention.

[0029] The method for detecting the position in the depth direction of a defect in a glass substrate according to the present invention comprises the following steps: a step (S10) of making the focal plane of the camera 11 (such as a CCD camera) coincide with the surface 1b of the glass substrate 1 (that is, the surface 1b of the substrate 1 The distance between 1b and the camera 11 becomes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com