Surface treatment method and texturing method for diamond wire cutting silicon wafers

A diamond wire, surface treatment technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., to achieve the effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

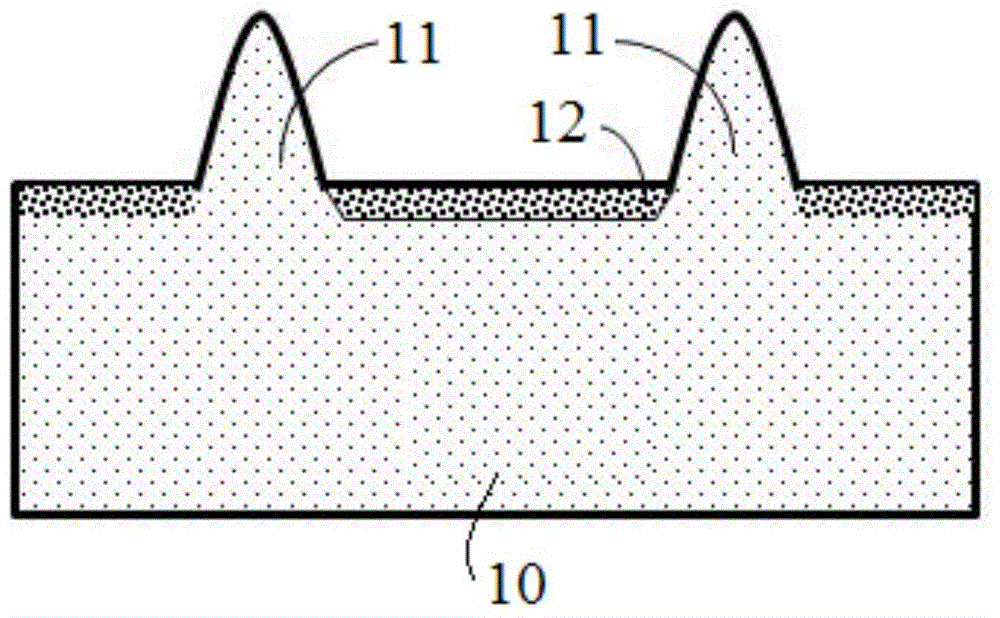

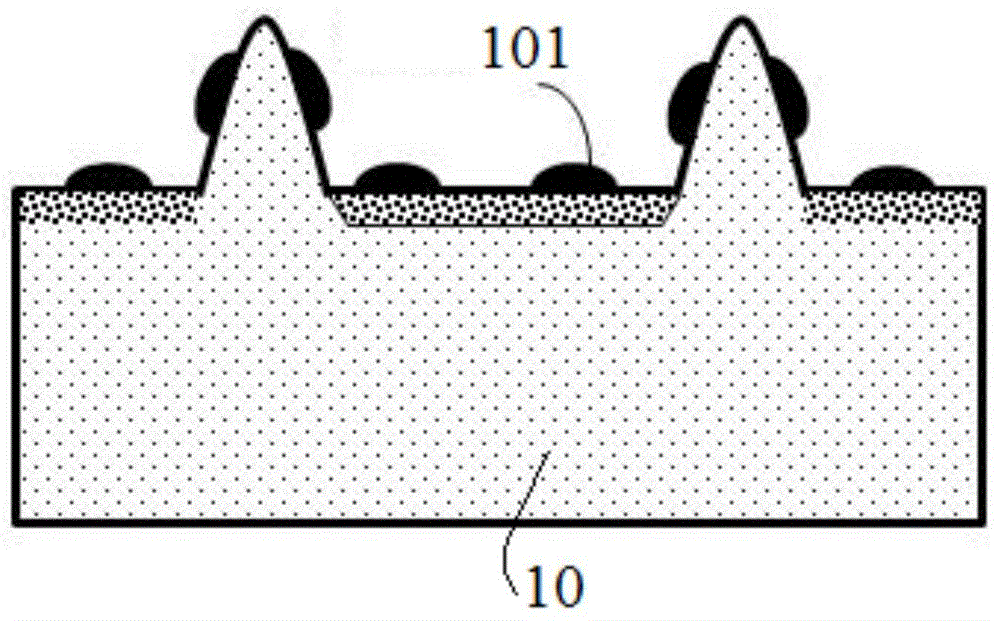

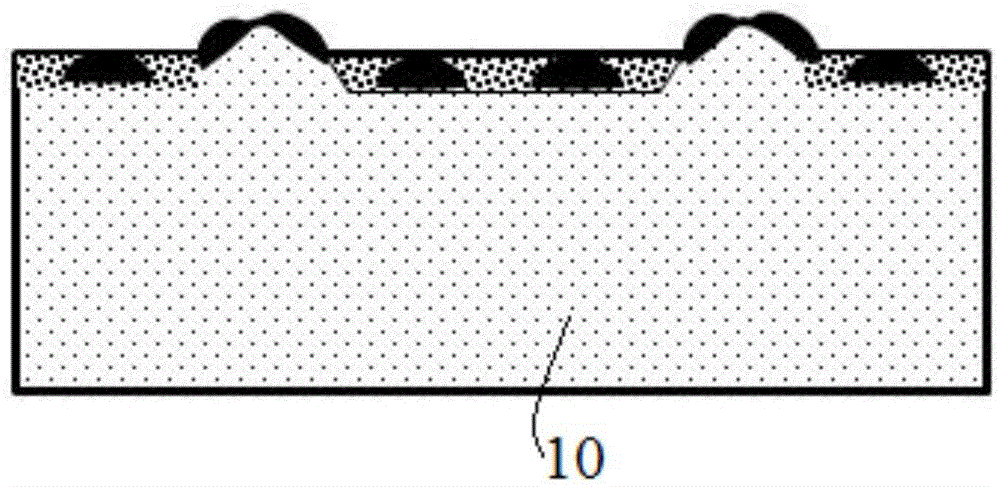

[0069] A surface treatment method for diamond wire-cut silicon wafers, such as Figure 1a-1d shown, including the following steps:

[0070] (1) Put a diamond wire-cut silicon wafer with a thickness of 180±10 μm and a size of 156mm×156mm into 4% HF solution for 240s to remove SiO on the surface 2 oxide layer; then put into deionized water and ultrasonically clean for 120s; wherein, the diamond wire-cut silicon wafer in this embodiment can be a diamond wire-cut monocrystalline silicon wafer or a diamond wire-cut polycrystalline silicon wafer;

[0071] (2) Put the silicon wafer after the previous step into the silicon wafer containing Ag ions, HF, H 2 o 2 In the mixed aqueous solution, the concentrations are 0.005mol / L, 3mol / L, and 0.1mol / L respectively, and react at 25°C for 60s;

[0072] (3) Putting the silicon chip after the previous step into a 69% nitric acid solution by mass and cleaning it for 300 s, the cleaning temperature is 25° C.;

[0073] (4) Put the silicon wafer...

Embodiment 2

[0082] A surface treatment method for diamond wire-cut silicon wafers, such as Figure 1a-1d shown, including the following steps:

[0083] (1) Put a diamond wire-cut silicon wafer with a thickness of 180±10 μm and a size of 156mm×156mm into 4% HF solution for 240s to remove SiO on the surface 2 oxide layer; then put into deionized water and ultrasonically clean for 120s; wherein, the diamond wire-cut silicon wafer in this embodiment can be a diamond wire-cut monocrystalline silicon wafer or a diamond wire-cut polycrystalline silicon wafer;

[0084] (2) Put the silicon wafer after the previous step into the silicon wafer containing Cu ions, HF, H 2 o 2 In the mixed aqueous solution, the concentrations are 0.01mol / L, 3mol / L, and 0.1mol / L respectively, and react at 30°C for 60s;

[0085] (3) Putting the silicon chip after the previous step into a 69% nitric acid solution by mass and cleaning it for 300 s, the cleaning temperature is 25° C.;

[0086] (4) Put the silicon wafer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com