Visual detection method for micro-defects on surface of magnetic tile

A visual inspection and micro-defect technology, applied in image data processing, instruments, calculations, etc., can solve the problems of difficult detection, complex light source, long processing time, etc., to achieve the effect of easy maintenance and clear and accurate defect images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

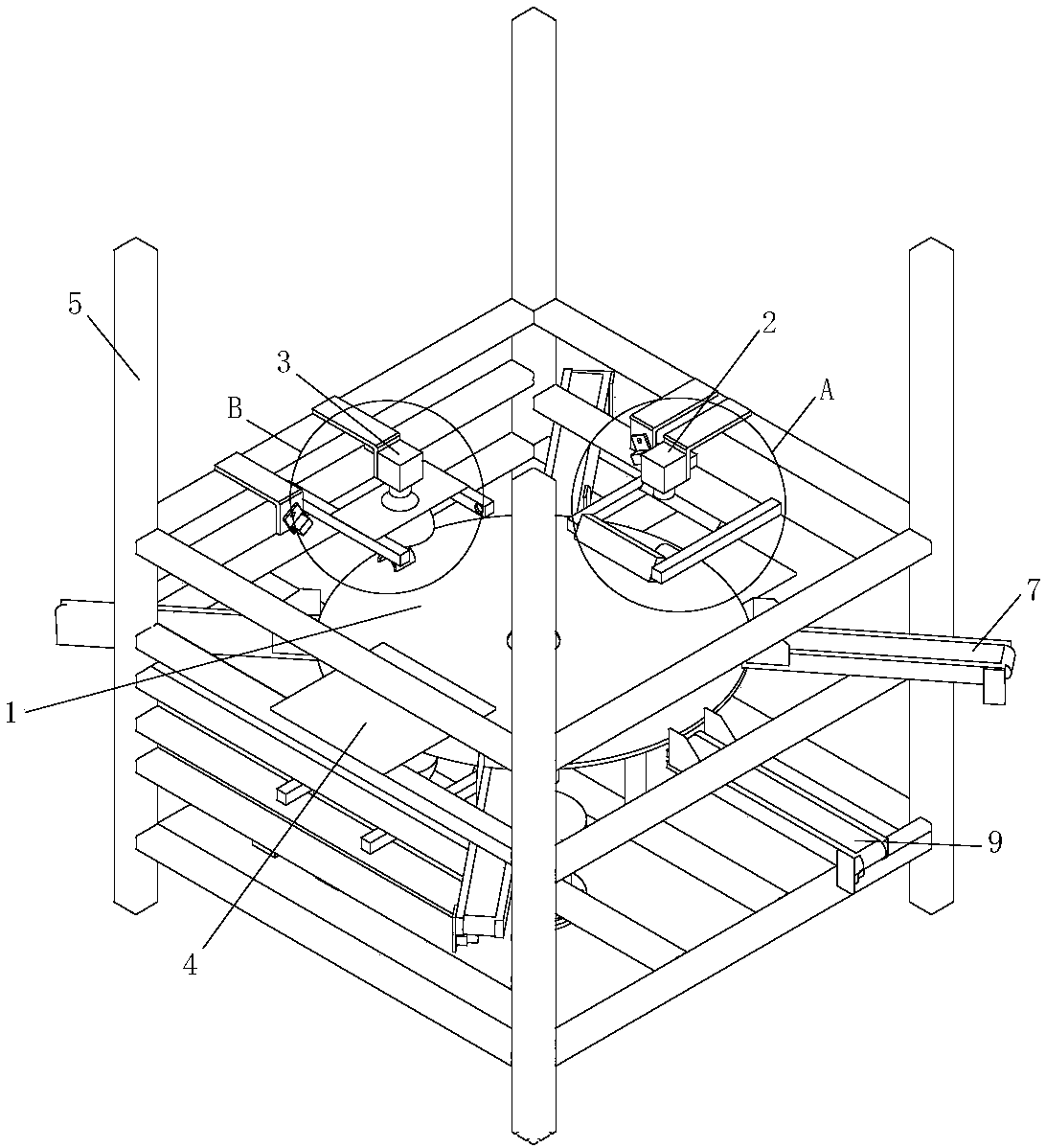

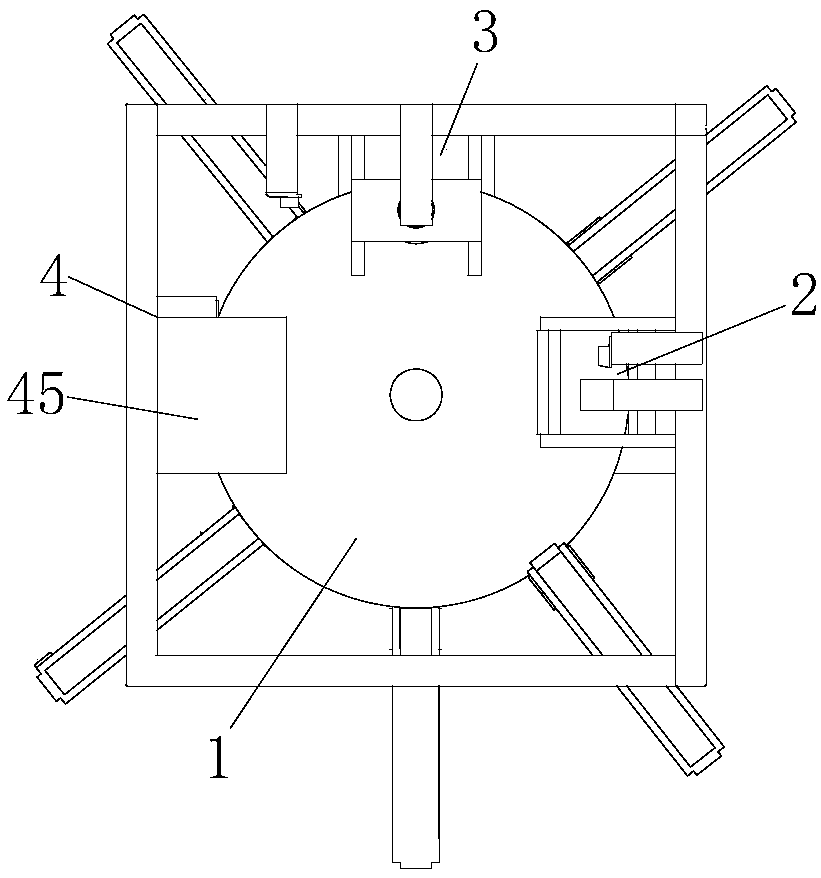

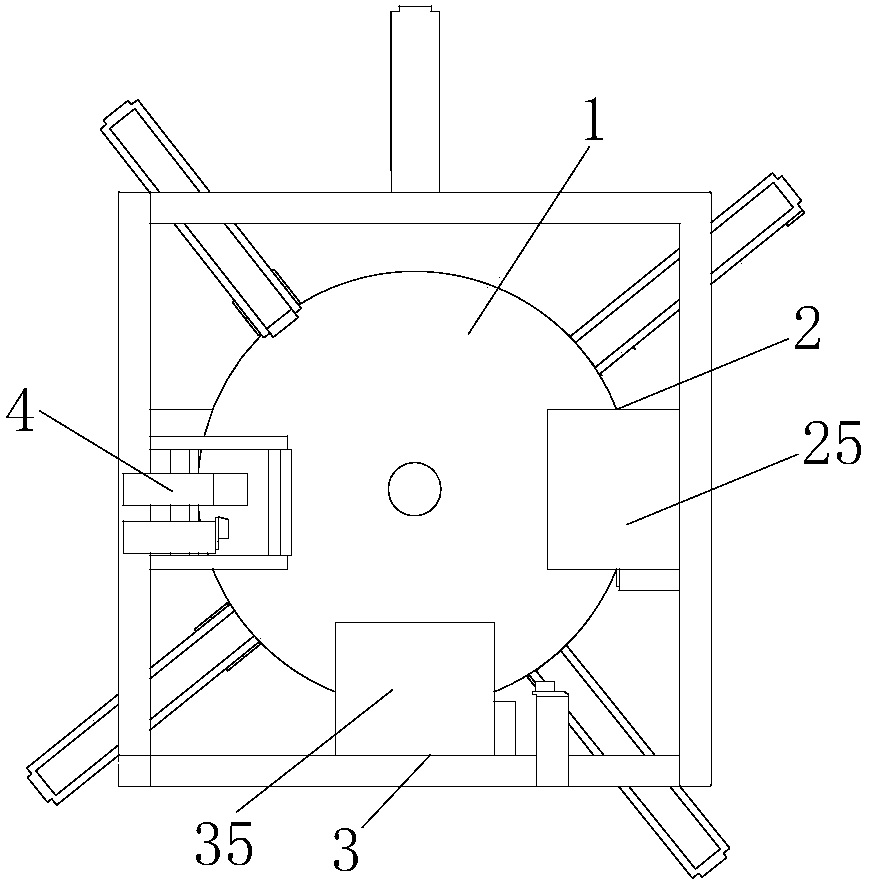

[0092] Embodiment 1. A visual detection device for micro-defects on the surface of magnetic tiles, such as Figure 1-21 As shown, it is used to detect magnetic tiles, including a detection device, a turntable 1 and a fixed frame 5 . The detection device includes a front detection device one 2, a front detection device two 3 and a reverse detection device 4 for detecting the quality of the upper and lower surfaces of the magnetic tile;

[0093] Front detection device 1 2 is the first detection device after magnetic tile feeding and loading; front detection device 2 3 detection sequence is second, reverse detection device 4 is located at the end of the detection station, and the three detection devices are connected by turntable 1 .

[0094] Turntable 1 is used to place magnetic tiles, turntable 1 is transparent (glass turntable can be used), fixed frame 5 is a square frame, turntable 1 is placed horizontally at the center of fixed frame 5, and three detection devices are place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com