Mirror-like object surface optical imaging device and imaging method thereof

An object surface, optical imaging technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of large difference in gray value, small surface defects, and inability to image, and achieve the effect of uniform background, obvious contrast, and low noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

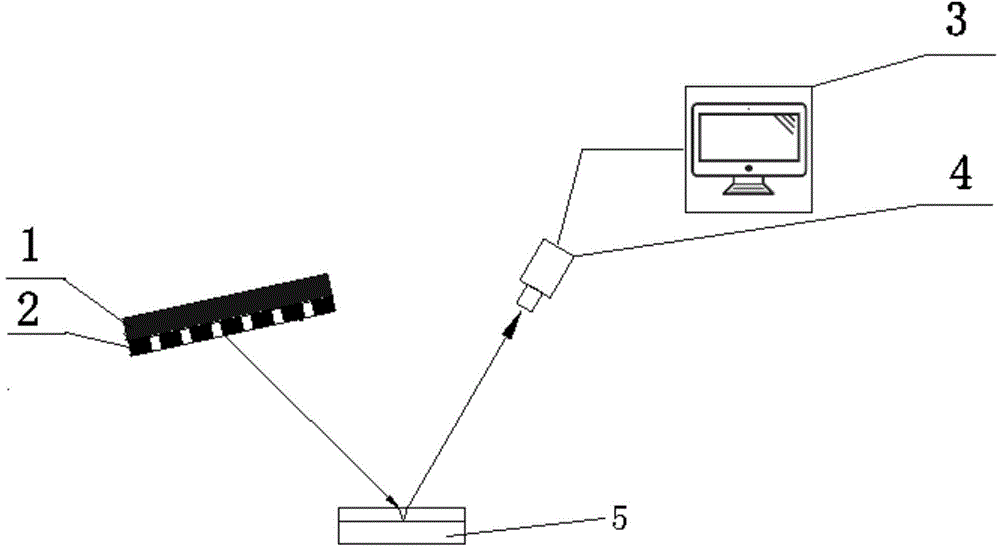

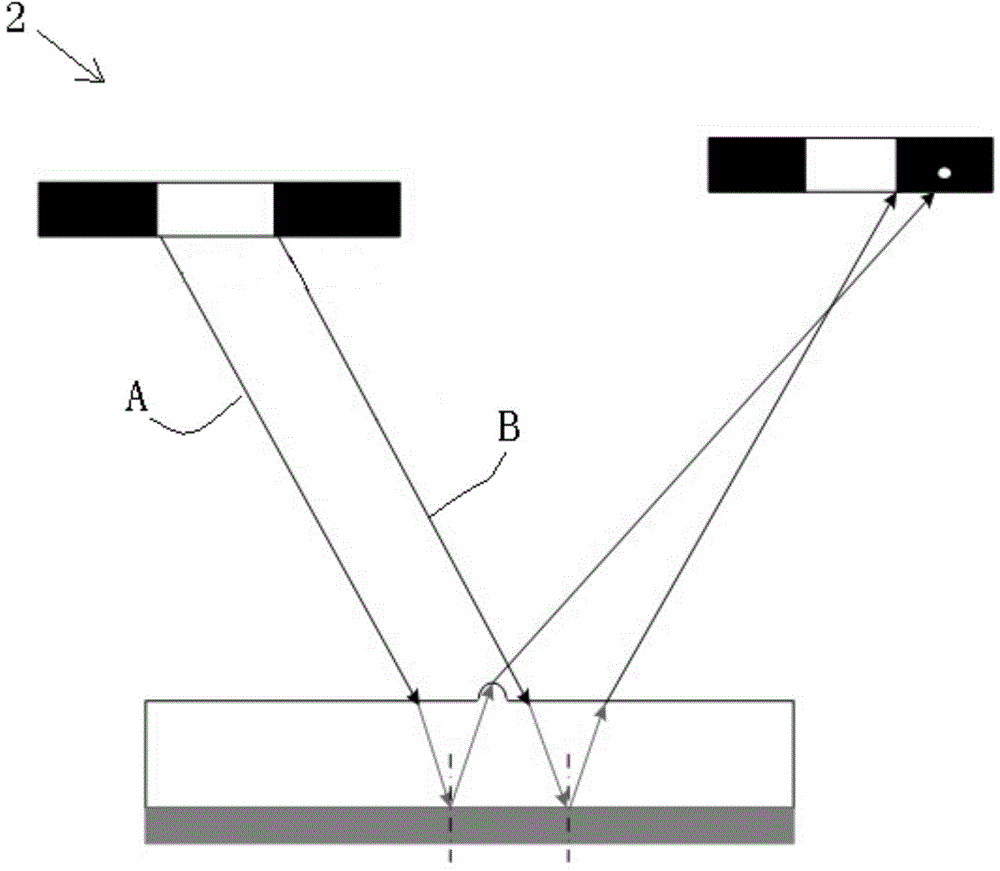

[0024] Such as figure 1 --4 shown. The invention discloses an optical imaging device for the surface of a specular object, which includes a parallel light source 1, a grating 2, a camera 4, a computer 3 and a light source controller (not shown) for controlling the parallel light source; the camera 4 is connected with computer 3.

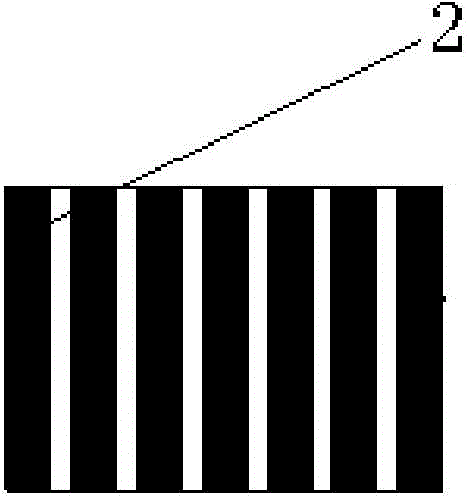

[0025] The planar light source 1 cooperates with the grating 2 to produce a non-uniform light source with bright and dark stripes.

[0026] The imaging method of the above-mentioned mirror-like object surface optical imaging device is as follows:

[0027] According to the principle of refraction and reflection of light, the plane light source 1 and the grating 2 are used to cooperate to produce a non-uniform light source of light and dark stripes, and then the light and dark stripes are scanned by moving the non-uniform light source to scan the entire surface of the object 5 to be scanned, and the camera 4 is used in a moving cycle Continuously co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com