PDMS microlens array and method for preparing PDMS microlens array by liquid phase molding of concave mold

A technology of microlens array and concave mold, which is applied in the fields of lenses, instruments, optics, etc., can solve the problems of complex process, high cost, and difficult operation, and achieve the effect of simple process, easy operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The method for preparing the PDMS microlens array 160 by liquid phase forming of a concave mold comprises the following steps:

[0073] (1) Adopt SU-8 thick glue photolithography process to manufacture SU-8 photoresist cylinder structure array punch 110, the size of each cylinder is

[0074] (2) Mix 8 g of PDMS prepolymer and 0.8 g of curing agent, vibrate in an ultrasonic oscillator for 5 min to make the mixing more uniform, and vacuumize for 30 min to obtain a PDMS mixture.

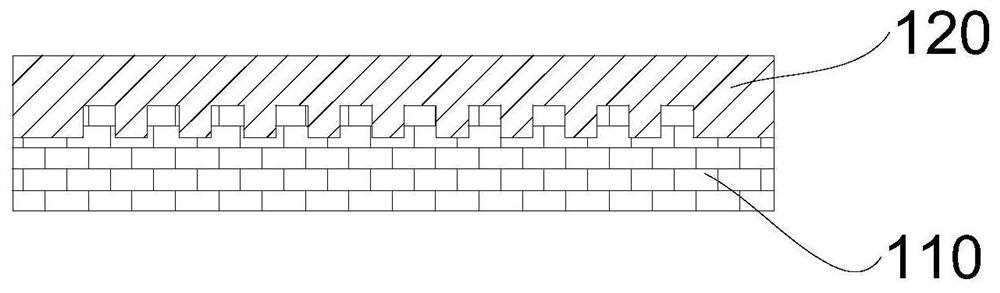

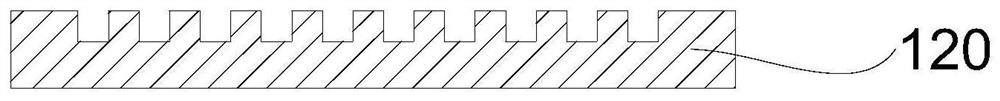

[0075] The PDMS mixture is evenly poured into the center of the cylindrical structure array punch 110, and the mold is placed on a horizontal plate to allow the PDMS mixture to flow and spread until it evenly covers the entire mold. After standing at 25° C. for 36 hours, the PDMS mixture is cured, and then the cured PDMS is peeled off from the mold to obtain a PDMS sheet 120 with a circular hole array.

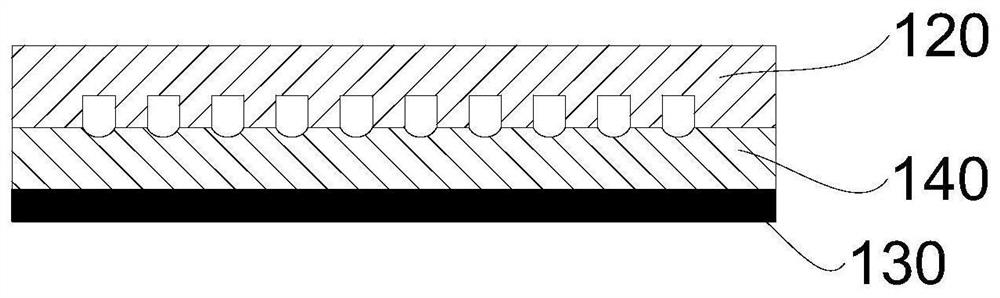

[0076] (3) Dip the silicon substrate 130 (18mm×18mm) into an acetone solution, clean it in...

experiment example 1

[0084] Figure 8 It is an optical micrograph of the SU-8 photoresist cylinder structure array convex mold manufactured in Example 1. It is observed from the pictures that the circular outlines of each cylindrical structure are of the same height, and the vertical and horizontal arrangement of the cylindrical structures is regular.

[0085] Figure 9 It is the optical micrograph of the SU-8 microlens array concave mold manufactured in embodiment 1. The bright area in the picture is the planar structure of the die surface, and the circular dark areas are the concave surface structure. The circular contours of each circular dark area have the same height, and the vertical and horizontal arrangement of the circular dark areas is neat and regular.

[0086] Utilize probe type surface profilometer (Veeco, Dektak150) to scan the surface of the SU-8 microlens array die prepared in embodiment 1, obtain the surface profile of a single die in the array die as follows Figure 10 shown....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com