Machine-vision-based method and device for intelligently detecting surface micro-defects of product

A technology of intelligent detection and machine vision, which is applied in the direction of optical testing flaws/defects, can solve problems such as poor and difficult detection of subtle defects, and achieve good and excellent detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

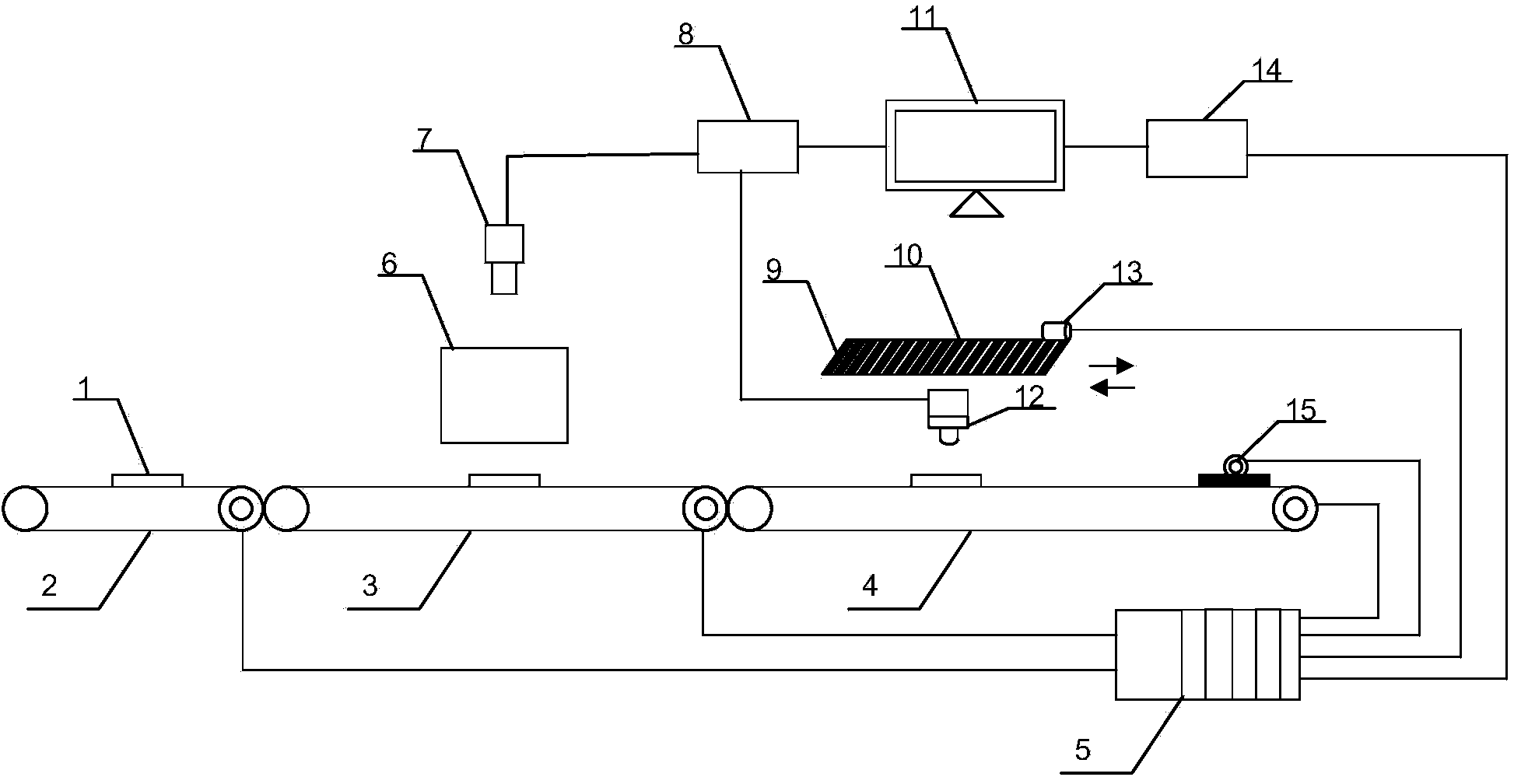

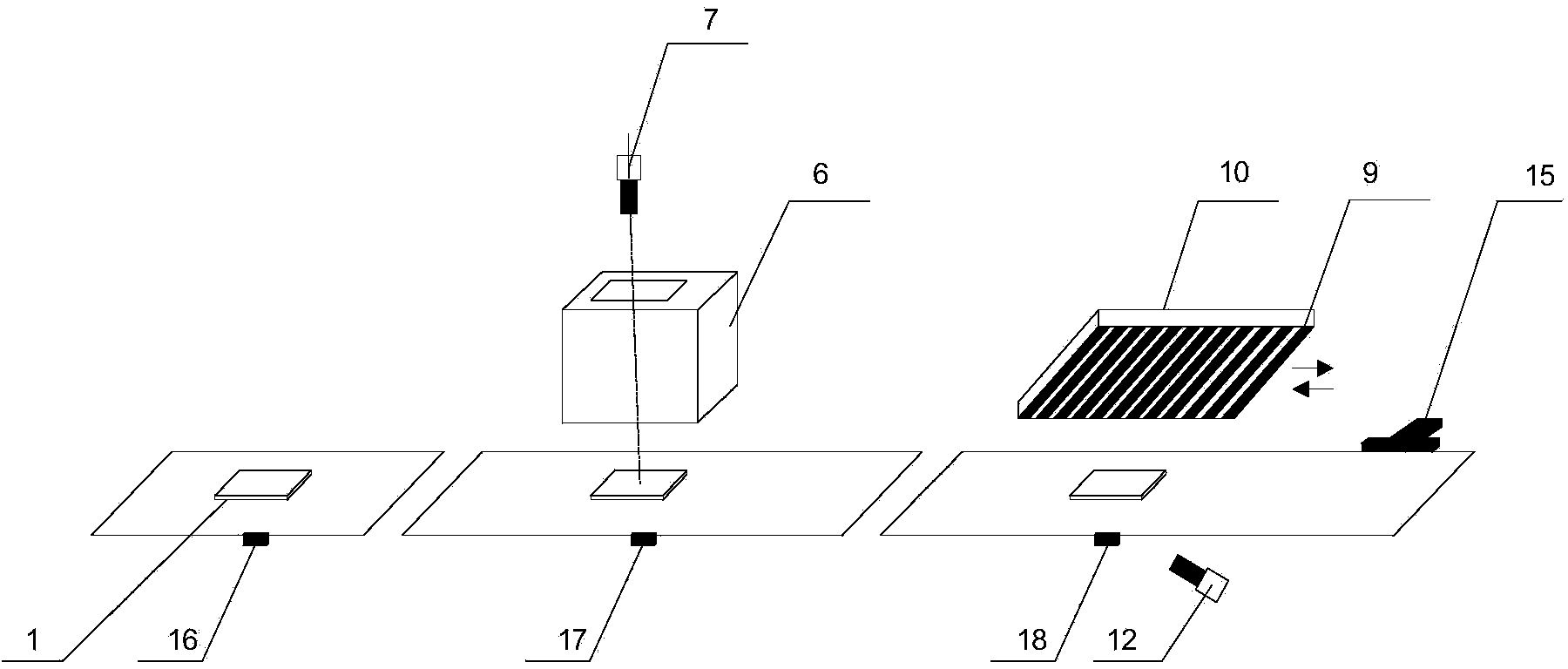

[0020] Such as figure 1 , 2 shown. The intelligent detection device for micro-defects on the surface of machine vision products of the present invention includes a first conveyor belt 2, a second conveyor belt 3, a third conveyor belt 4 and a conveyor belt driving device, and the conveyor belt driving device is controlled by a PLC control system 5; it is characterized in that: the first conveyor belt 2 , The two sides of the second conveyor belt 3 and the third conveyor belt 4 are respectively provided with photoelectric sensors 16, 17, 18;

[0021] The upper of described second conveyor belt 3 is provided with coaxial light source 6, A camera 7 successively; A camera 7 is connected with image acquisition card 8, industrial control computer 11, DAQ data acquisition card 14, PLC control system 5 successively;

[0022] The top of the third conveyor belt 4 is provided with a non-uniform light source composed of a grating 9 and a parallel light source 10, and a B camera 12 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com