Multi-axis linkage mechanical device used for finely repairing micro-defects on surface of optical element

A technology of optical components and multi-axis linkage, which is applied in the direction of working accessories, stone processing tools, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

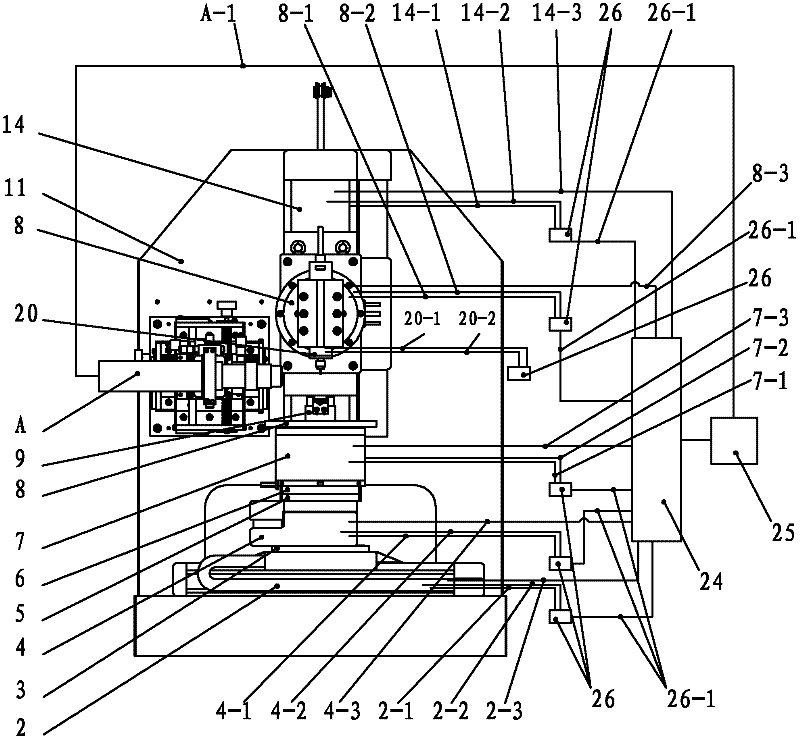

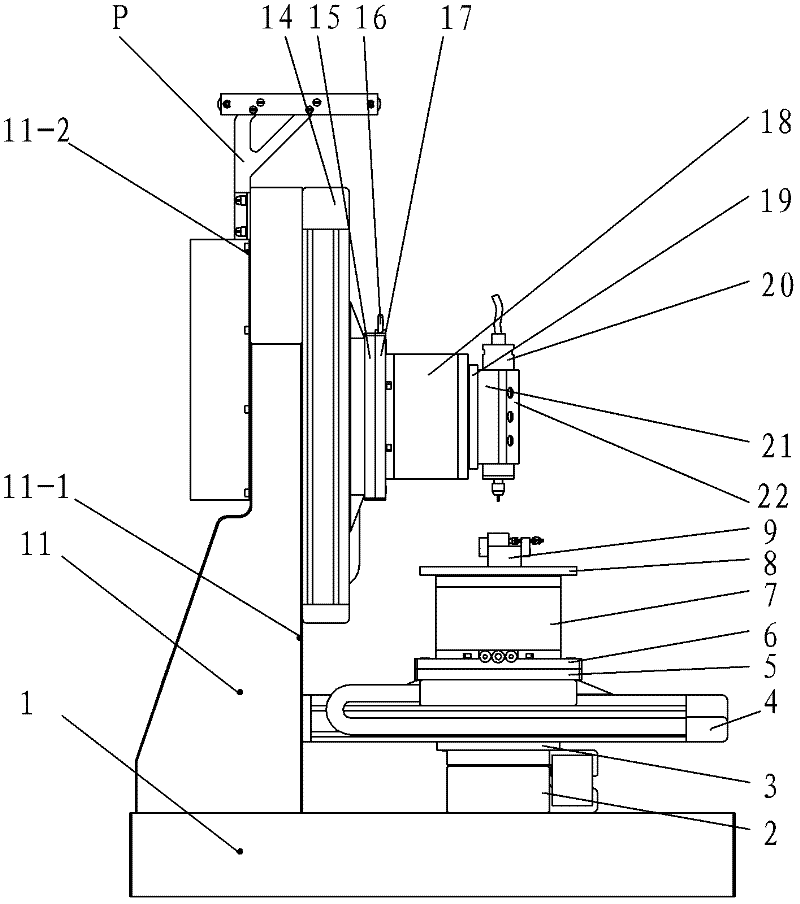

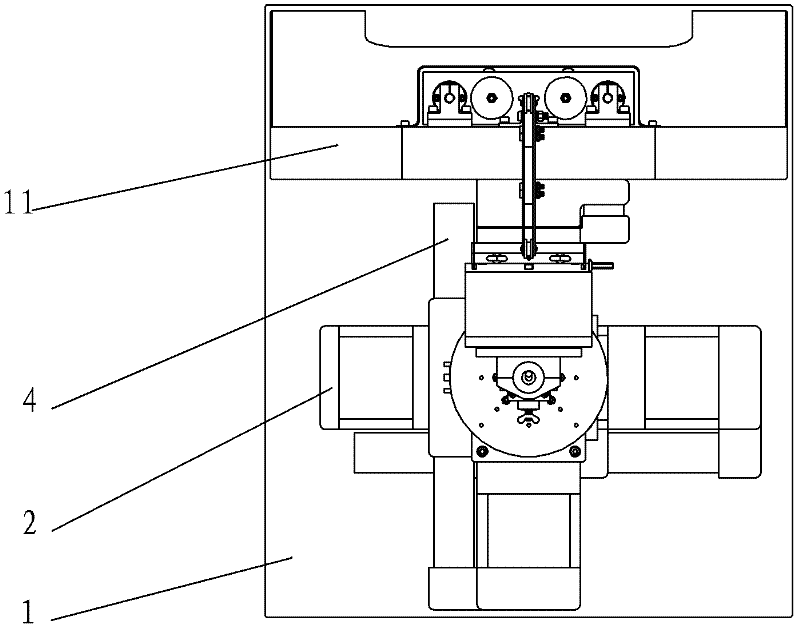

[0044] Specific implementation mode one: combine Figure 1 to Figure 11 Describe this embodiment. The multi-axis linkage mechanical device for micro-repair of micro-defects on the surface of optical elements in this embodiment includes a flat plate base 1, an X-axis linear unit 2, an XY-axis linear unit connector 3, a Y-axis linear unit 4, and a YC-axis first Connector 5, YC-axis second connector 6, C-axis rotation unit 7, workbench 8, chuck body 9, CCD tool setting and monitoring device A, vertical member 11, Z-axis linear unit 14, ZB-axis first connection Part 15, ZB axis second connecting part 17, B-axis rotating unit 18, main shaft part connecting part 19, electric main shaft 20, main shaft first pressing part 21 and main shaft second pressing part 22, ball end milling cutter 23, multiple Axis controller 24, host computer 25 and six drivers 26, vertical member 11 is vertically installed on the flat base 1, and X-axis linear unit 2 is also installed on the flat base 1, and ...

specific Embodiment approach 2

[0064] Specific implementation mode two: combination Figure 1 to Figure 3 To illustrate this embodiment, the flat base 1 and the vertical member 11 of this embodiment are both made of granite. With such arrangement, the dynamic performance of the whole device can be improved because the granite has a good shock-absorbing performance. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0065] Specific implementation mode three: combination Figure 1 to Figure 3 The present embodiment will be described. The shaft hole interference fit is used between the table 8 and the C-axis rotation unit 7 in the present embodiment. Such setting ensures that the axis of the worktable 8 coincides with the rotation axis of the C-axis rotation unit 7 . Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com