Patents

Literature

33 results about "Tool setters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

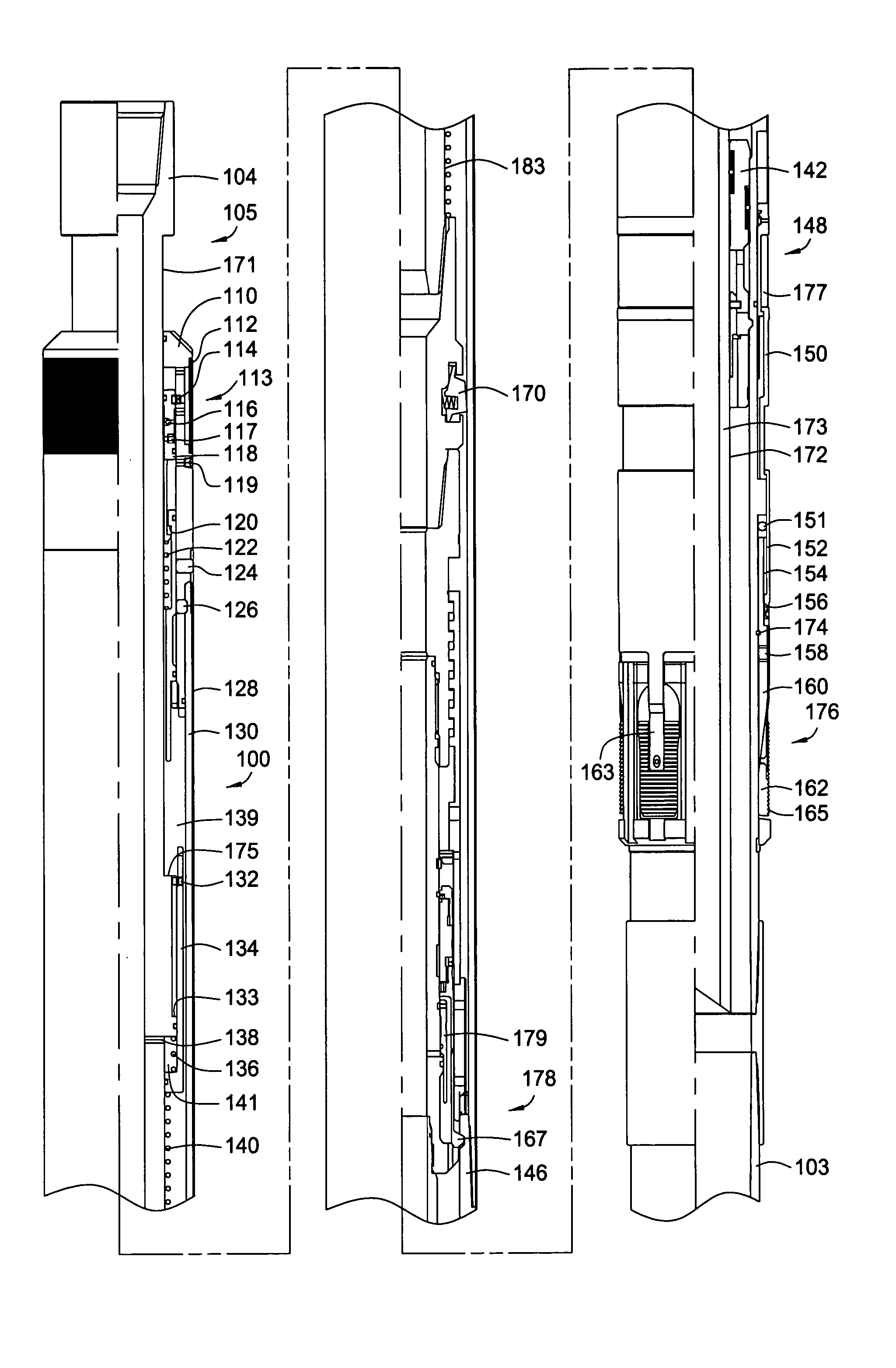

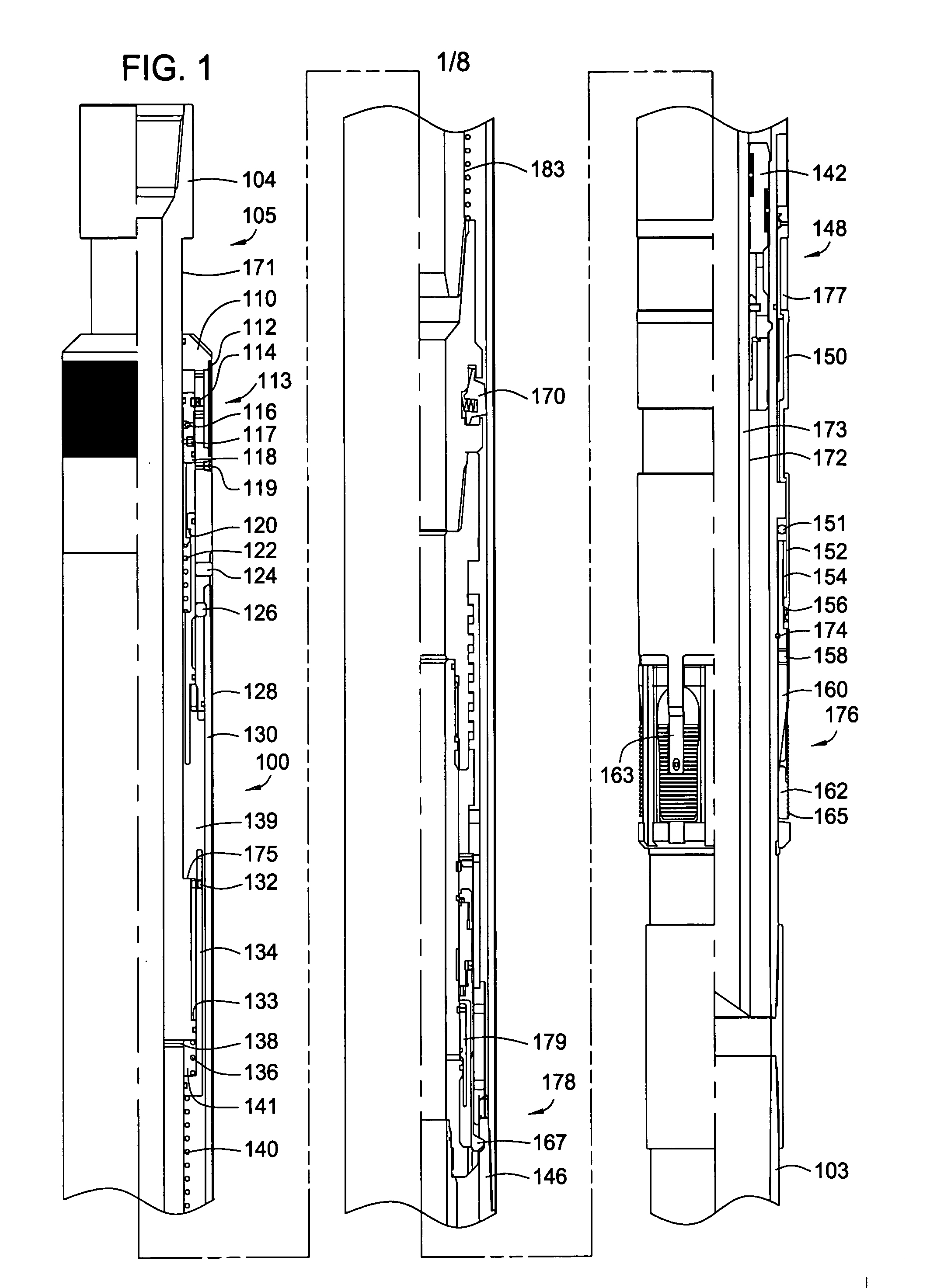

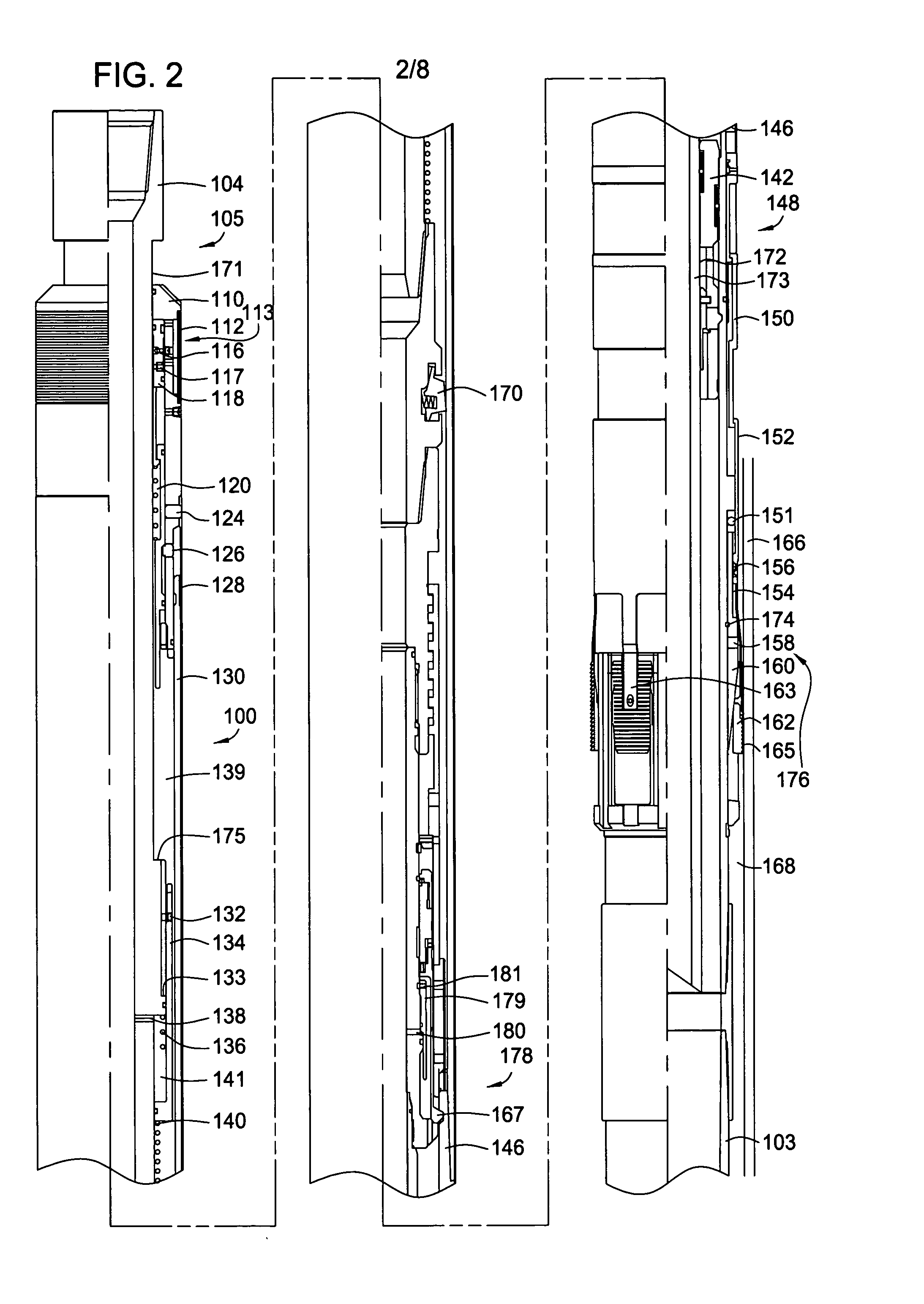

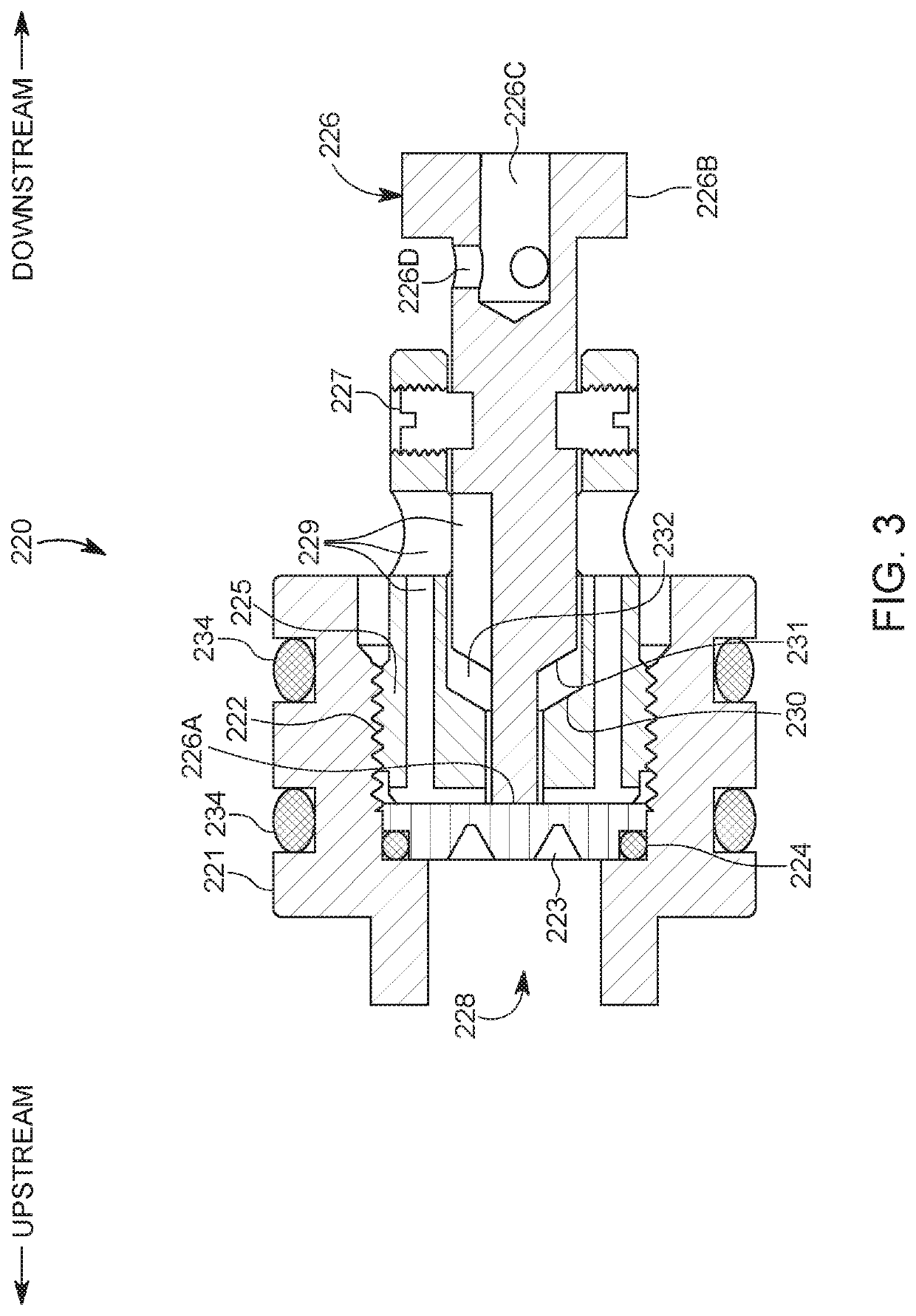

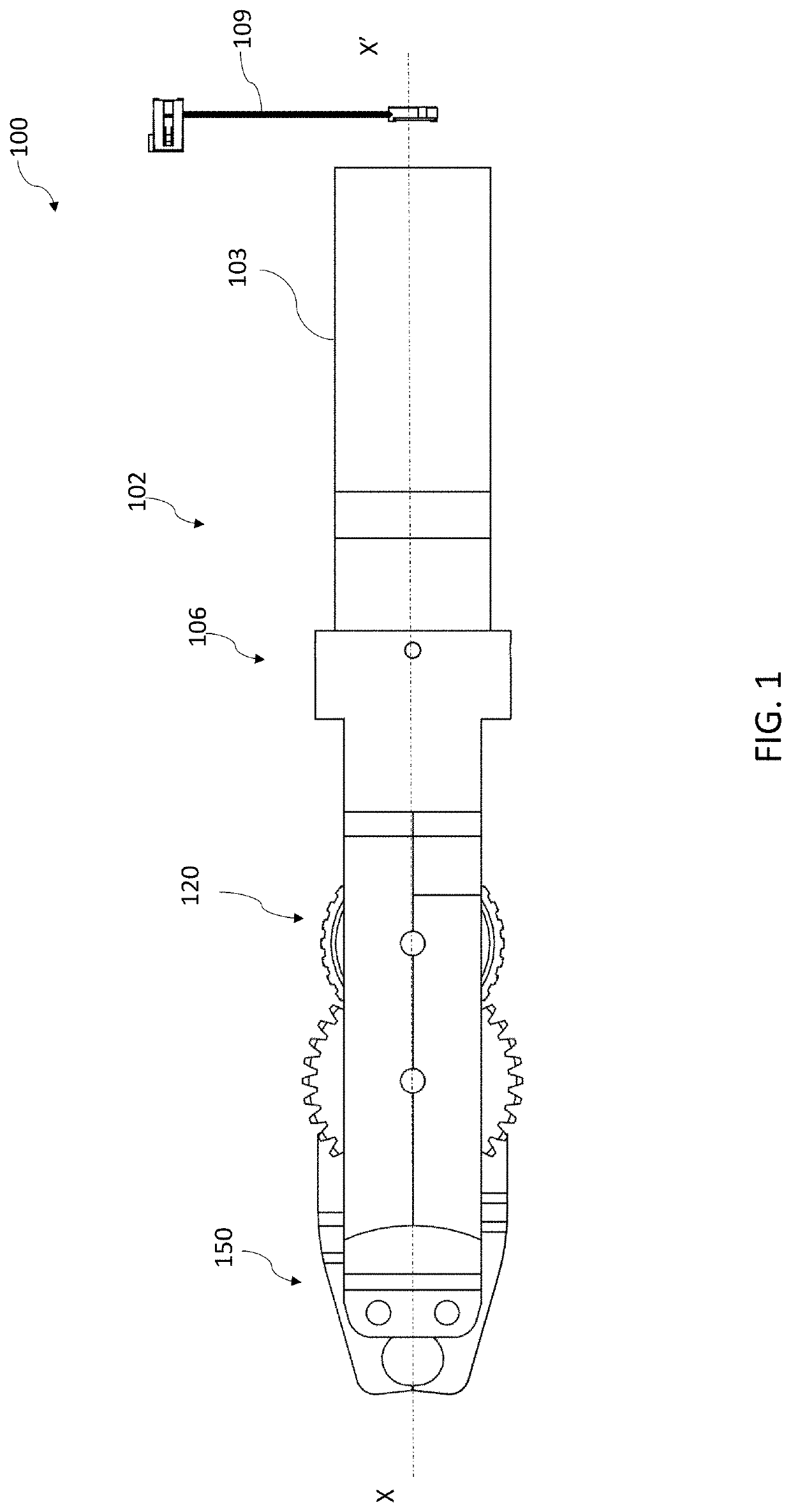

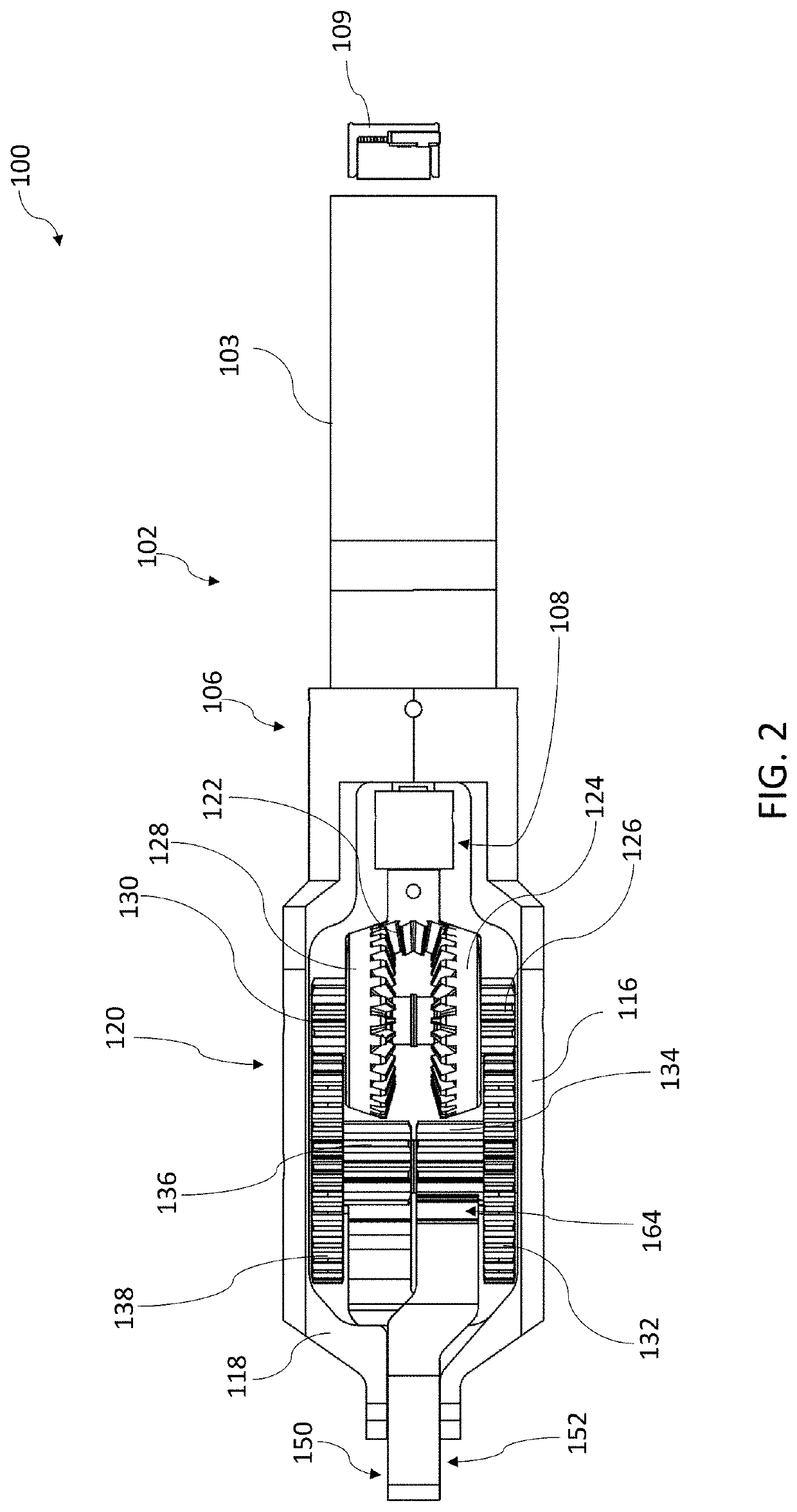

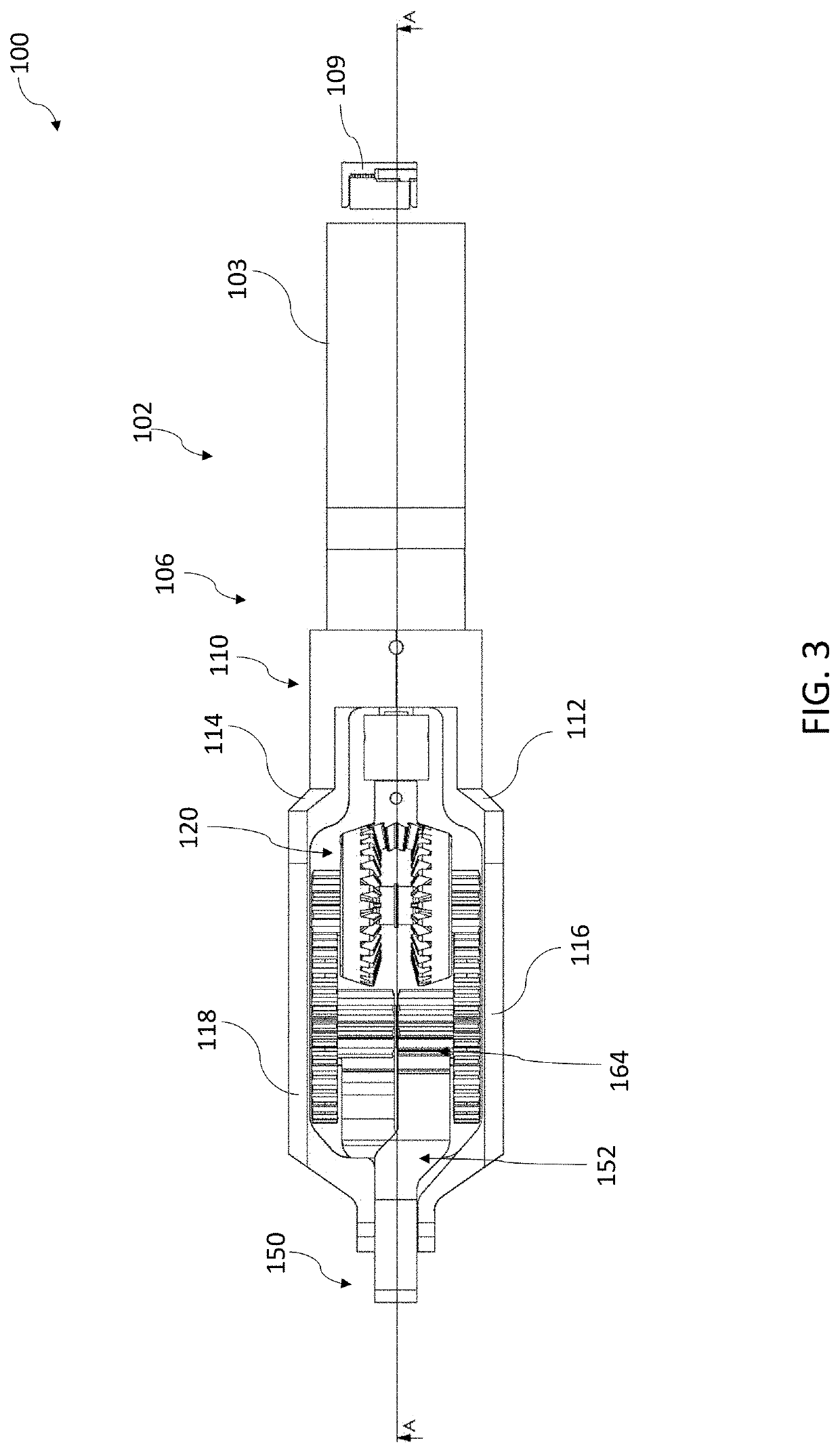

Hydraulic setting tool for liner hanger

Embodiments of the present invention relates to hydraulically actuated tools, which may be used to actuate a liner hanger assembly. In one embodiment, the present invention provides a hydraulic setting tool for use in wellbore operations. The setting tool includes a first tubular member and a second tubular member disposed around the outer diameter of the first tubular member. A piston is mechanically attached to an upper portion of the second tubular member and adapted to move axially in relation to the first tubular member. The piston acts to transmit a force to the second tubular member. A slip assembly is operatively connected to the second tubular member and the second tubular member transmits the force to the slip assembly thereby actuating the slip assembly.

Owner:WEATHERFORD TECH HLDG LLC

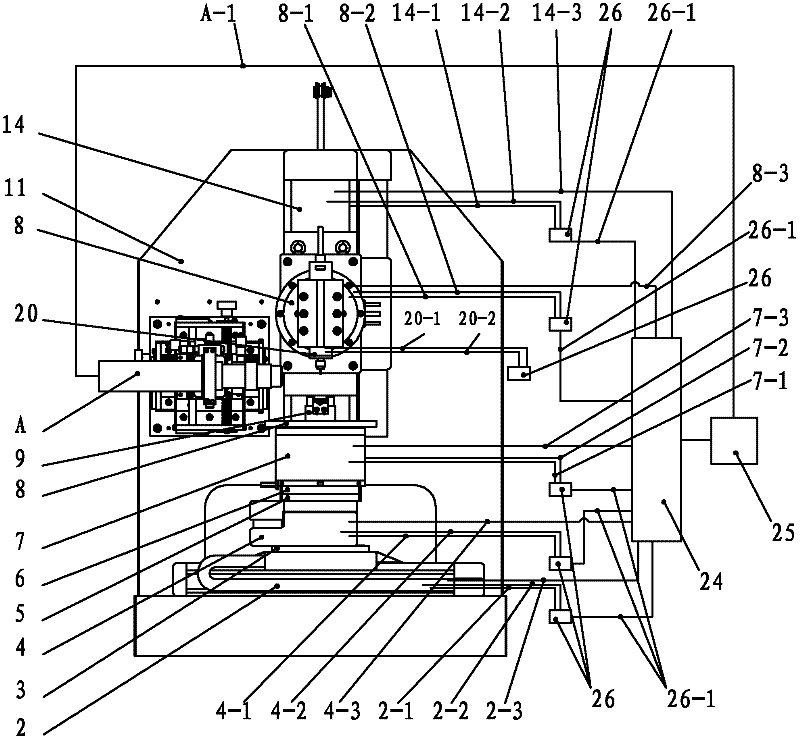

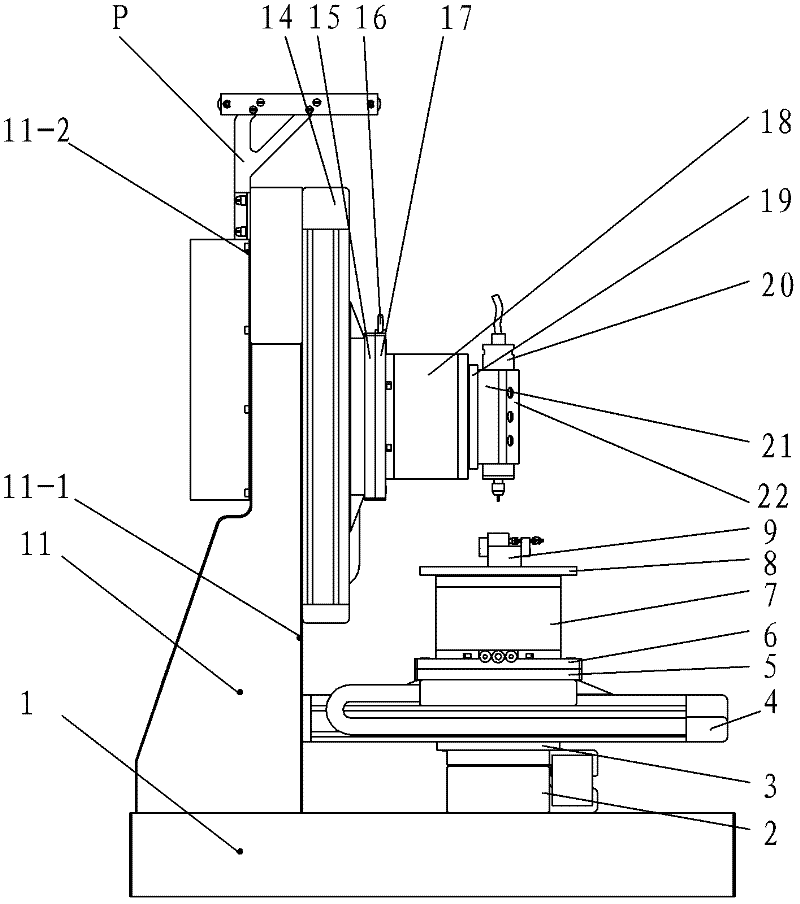

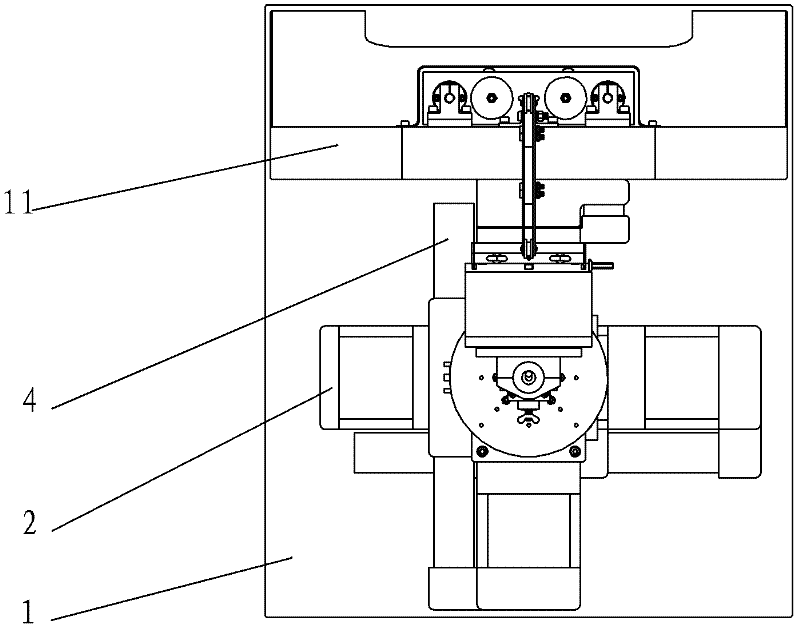

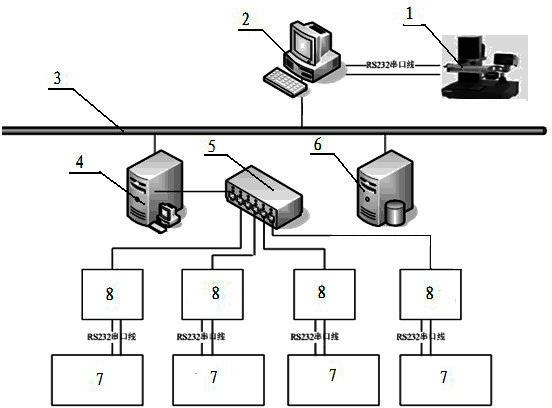

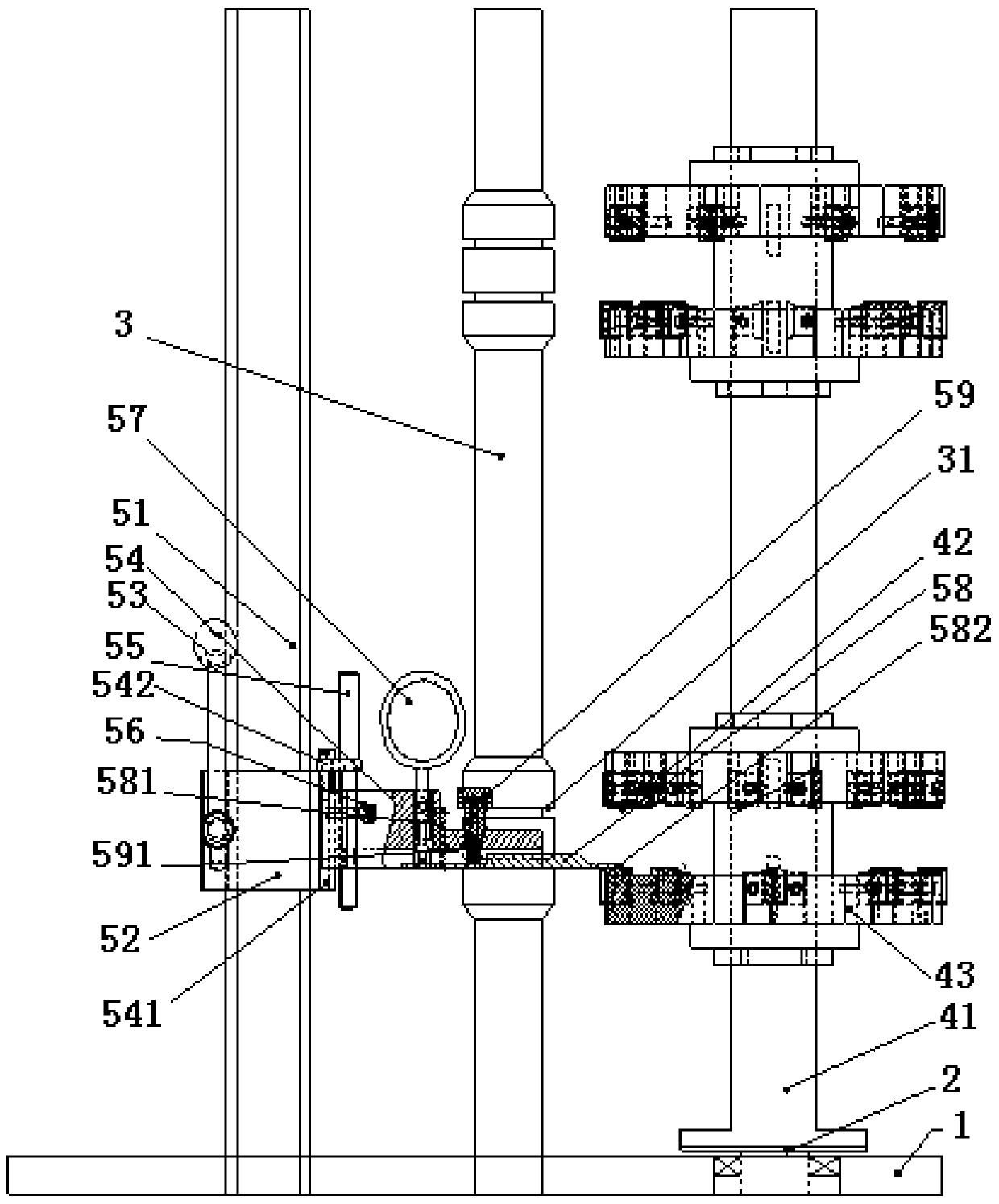

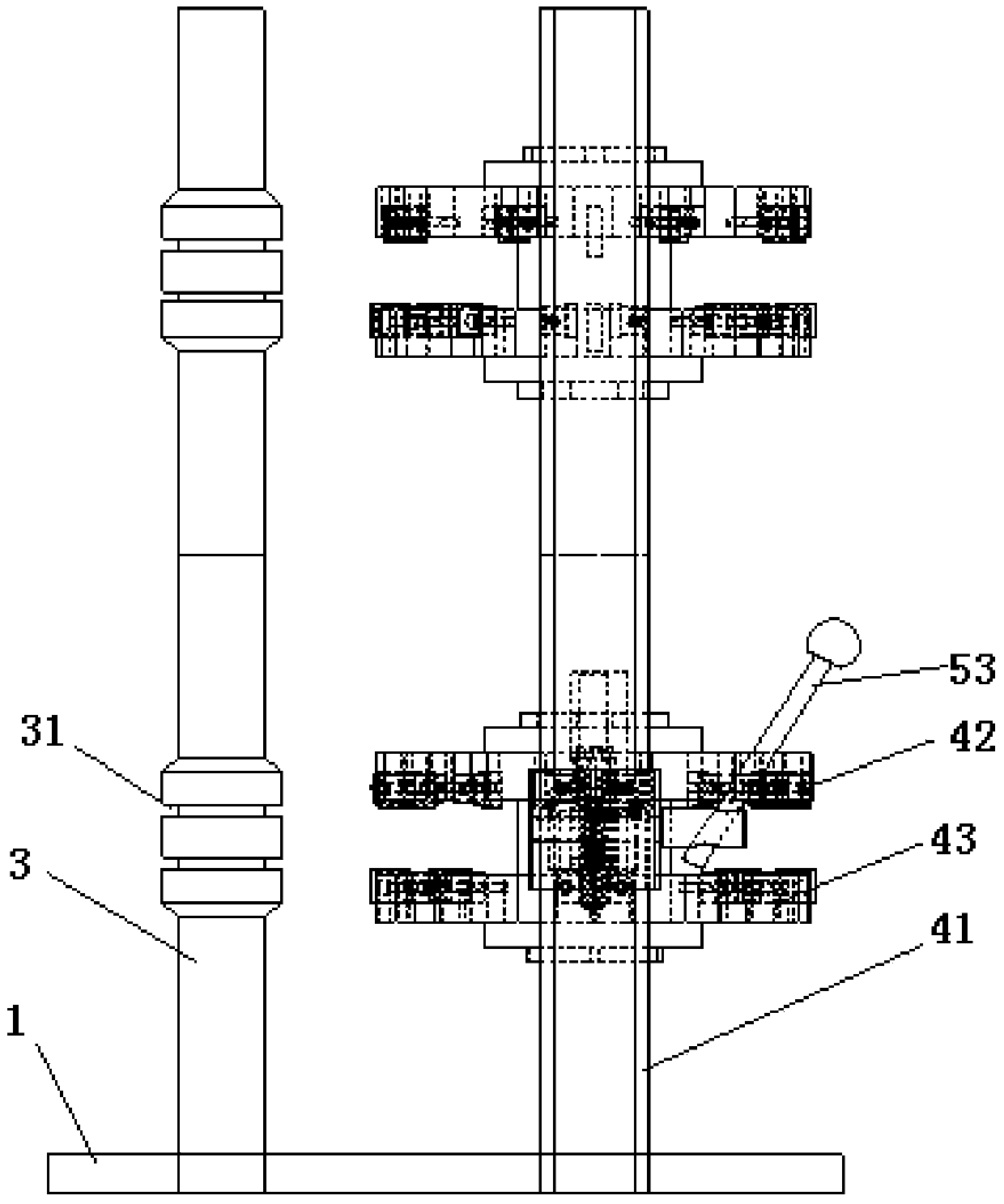

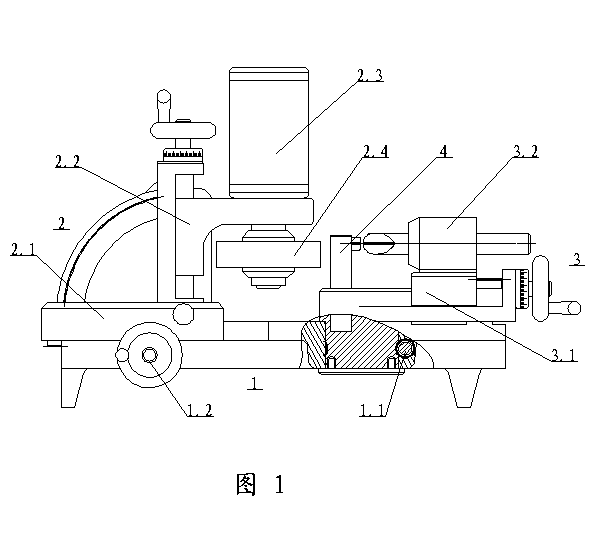

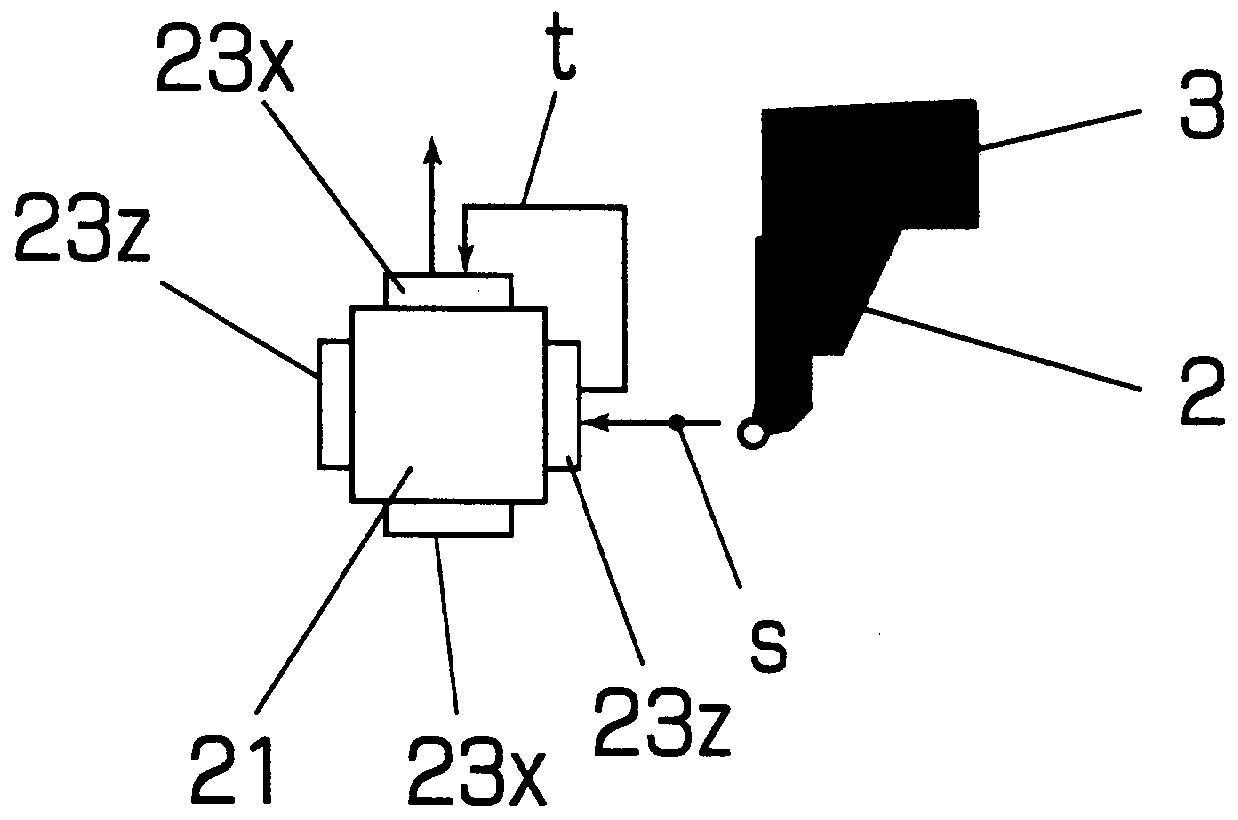

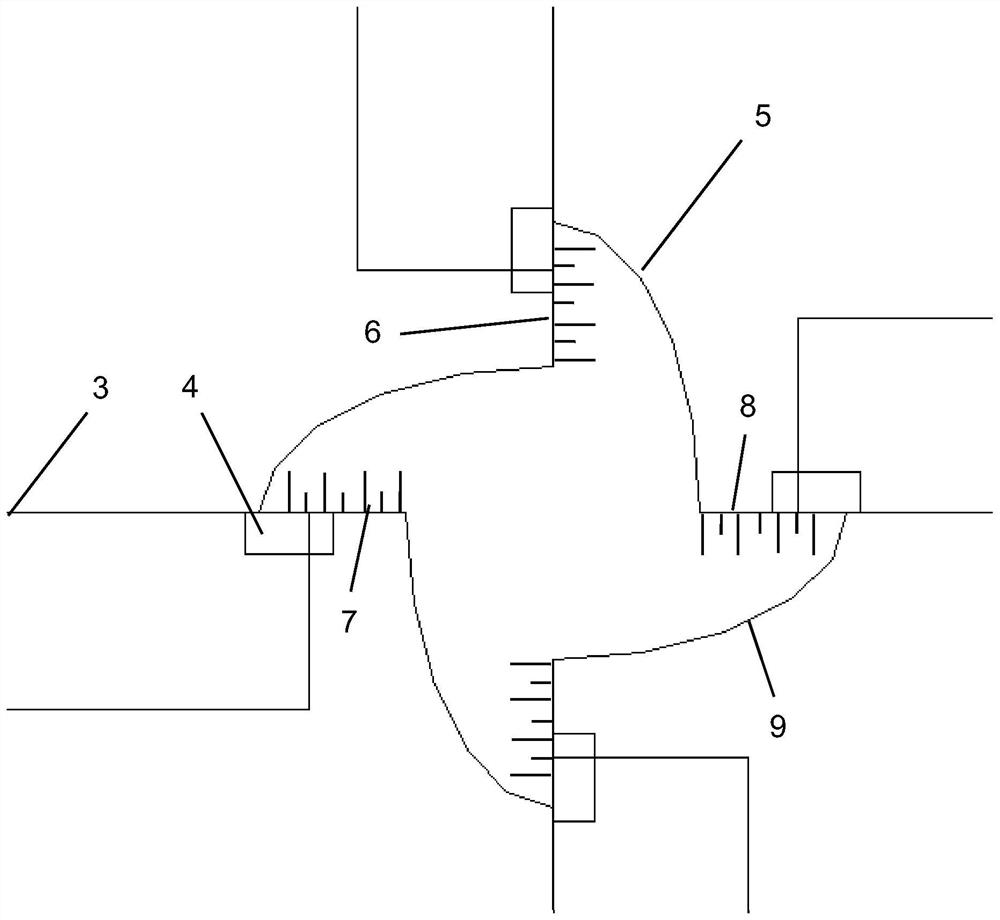

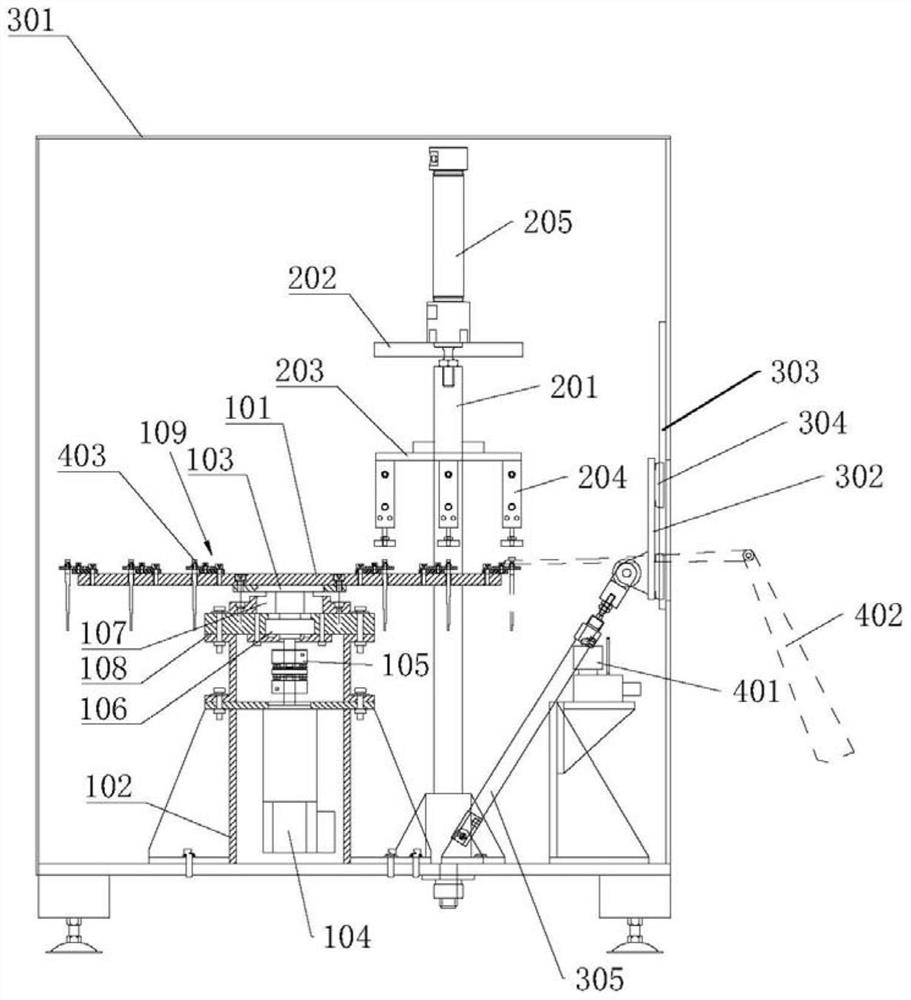

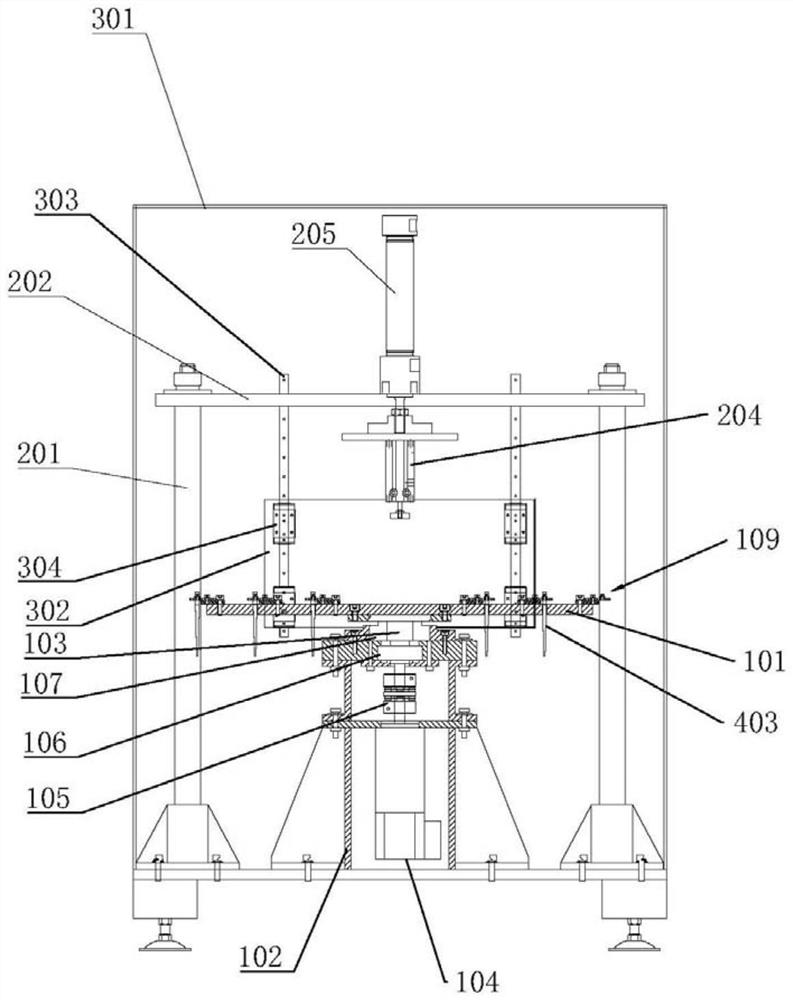

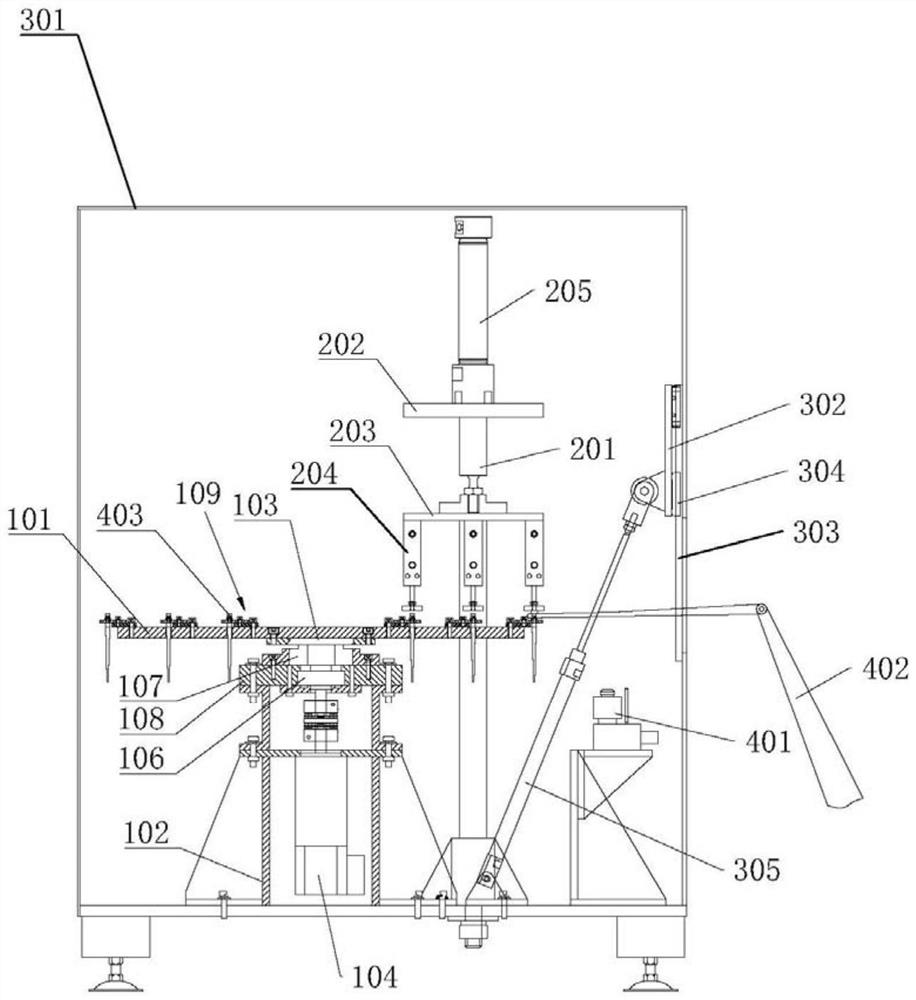

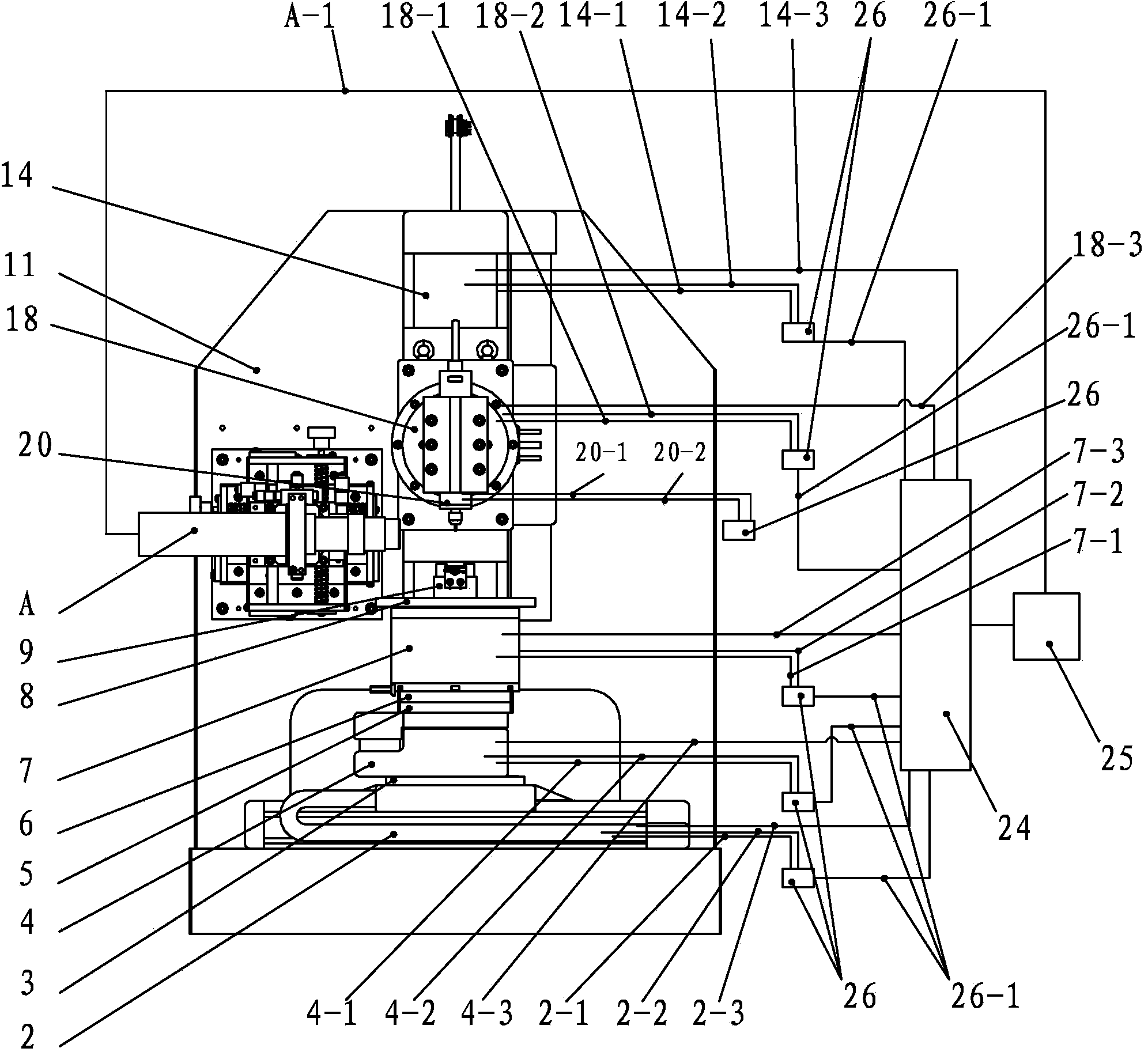

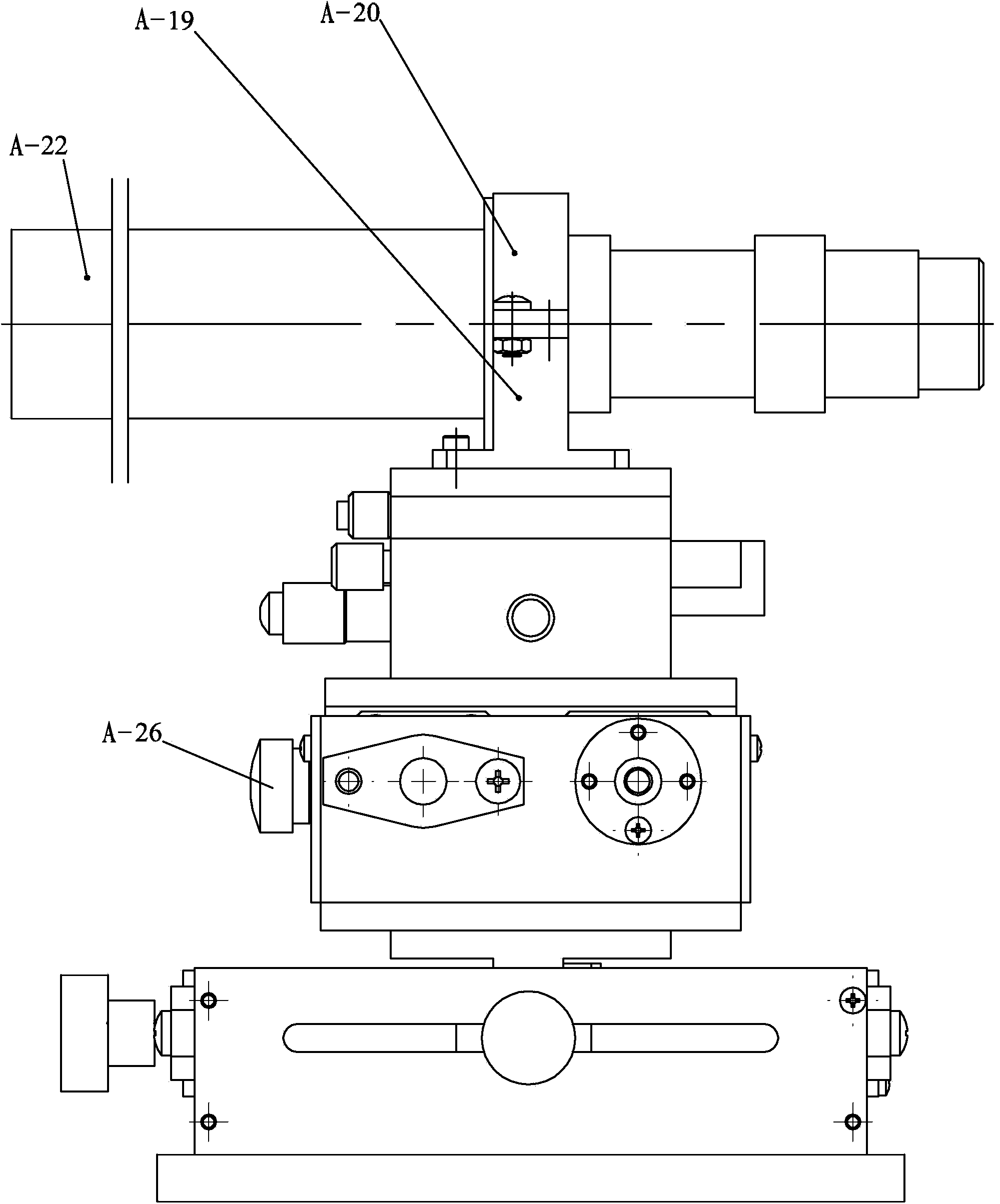

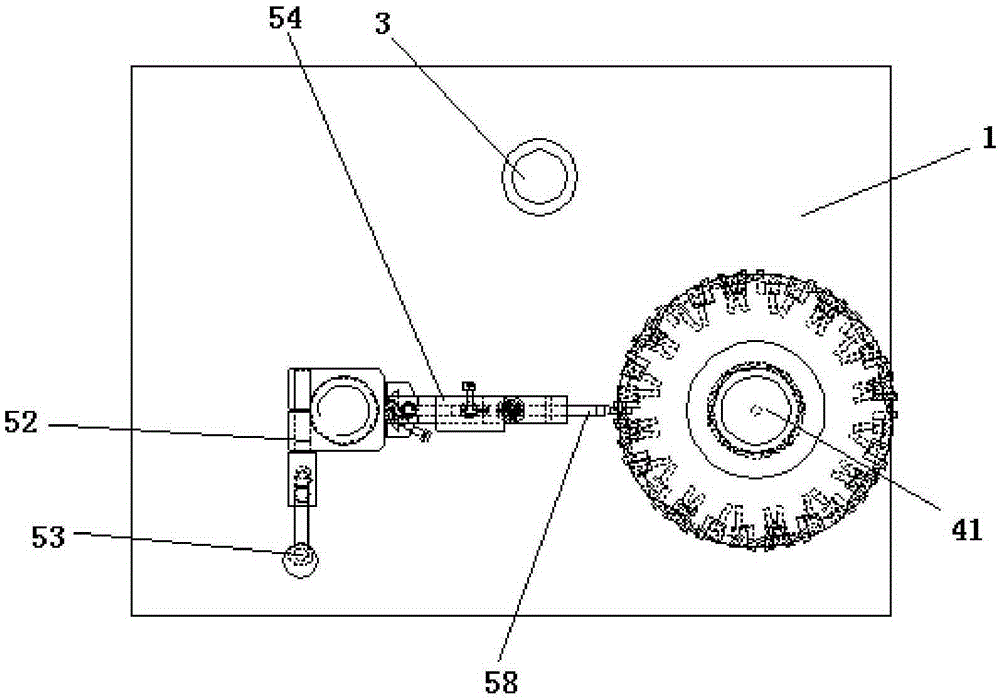

Multi-axis linkage mechanical device used for finely repairing micro-defects on surface of optical element

ActiveCN102380913AAccurate observationWorking accessoriesStone-like material working toolsElectricityLaser target

The invention provides a multi-axis linkage mechanical device used for finely repairing micro-defects on a surface of an optical element and relates to a mechanical device for repairing the optical element. The mechanical device is used for solving the problem of the growth of micro-defects generated during a high-energy beam intense laser targeting process of the optical element. A vertical element is vertically mounted on a plate base; an X-axis linear unit is mounted on the plate base; the X-axis linear unit is connected with a Y-axis linear unit through an XY linear unit connector; the Y-axis linear unit is connected to a C-axis rotating unit through two connectors; an operating platform is mounted on the C-axis rotating unit; a fixture body is mounted on the operating platform; a Z-axis linear unit is mounted on the vertical element; the Z-axis linear unit is connected to a B-axis rotating unit through two connectors; a spindle connector is mounted on the B-axis rotating unit; an electric spindle clamping fixture is mounted between a first spindle clamping element and a second spindle clamping element; and a CCD (Charge Coupled Device) tool setter and a monitoring device are mounted on a main mounting surface of the vertical element. The multi-axis linkage mechanical device is used for repairing the surface of the optical element.

Owner:HARBIN INST OF TECH

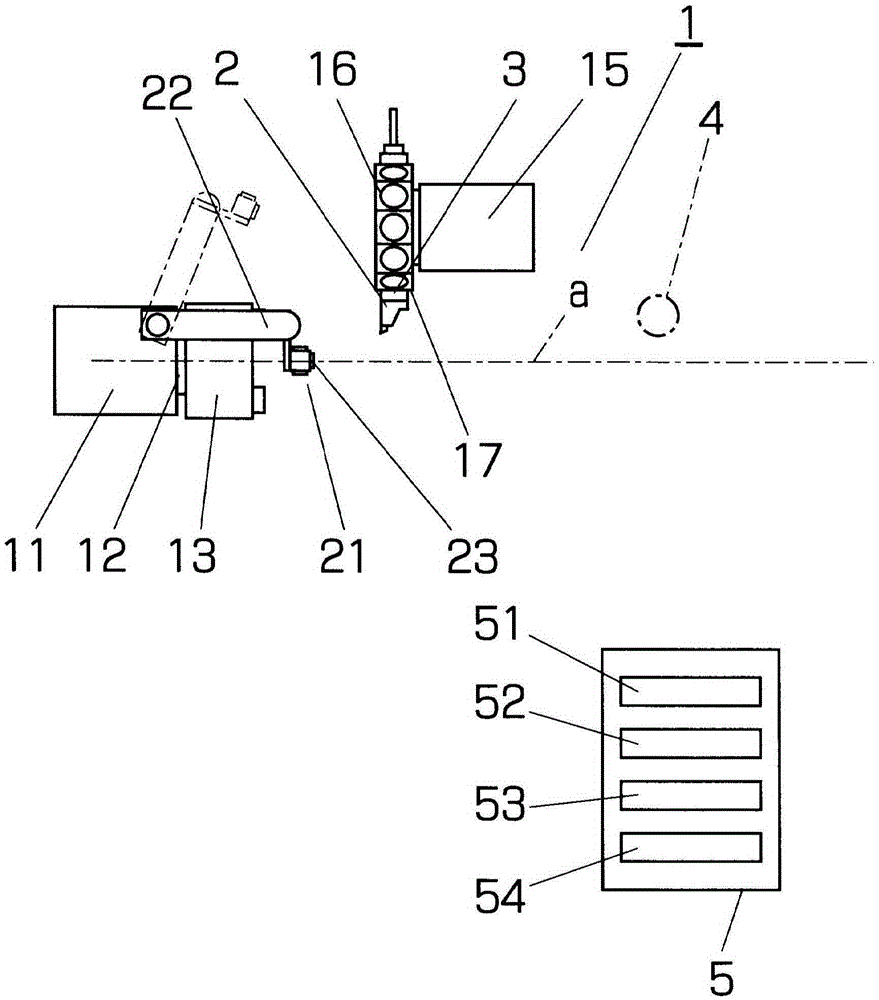

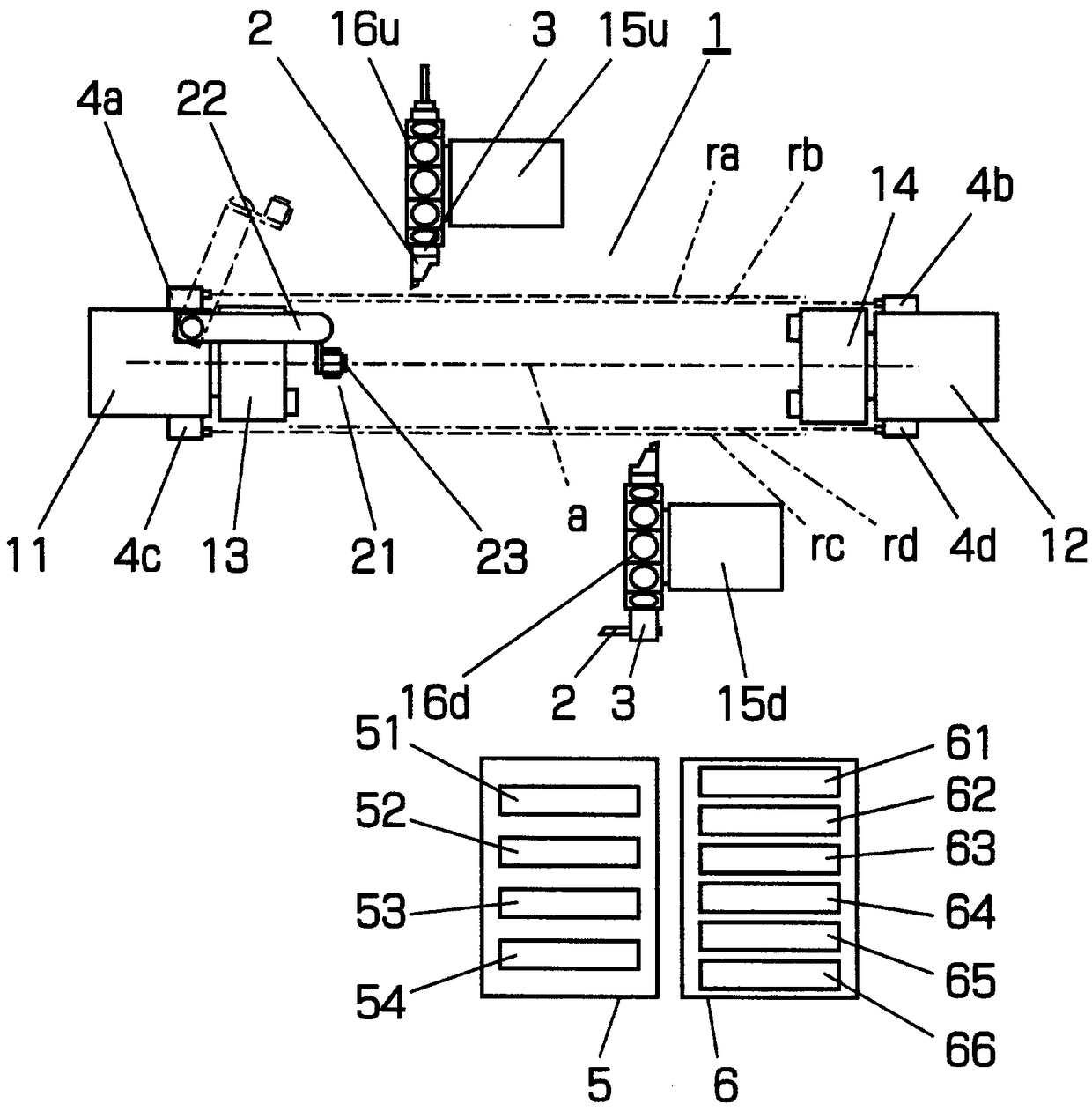

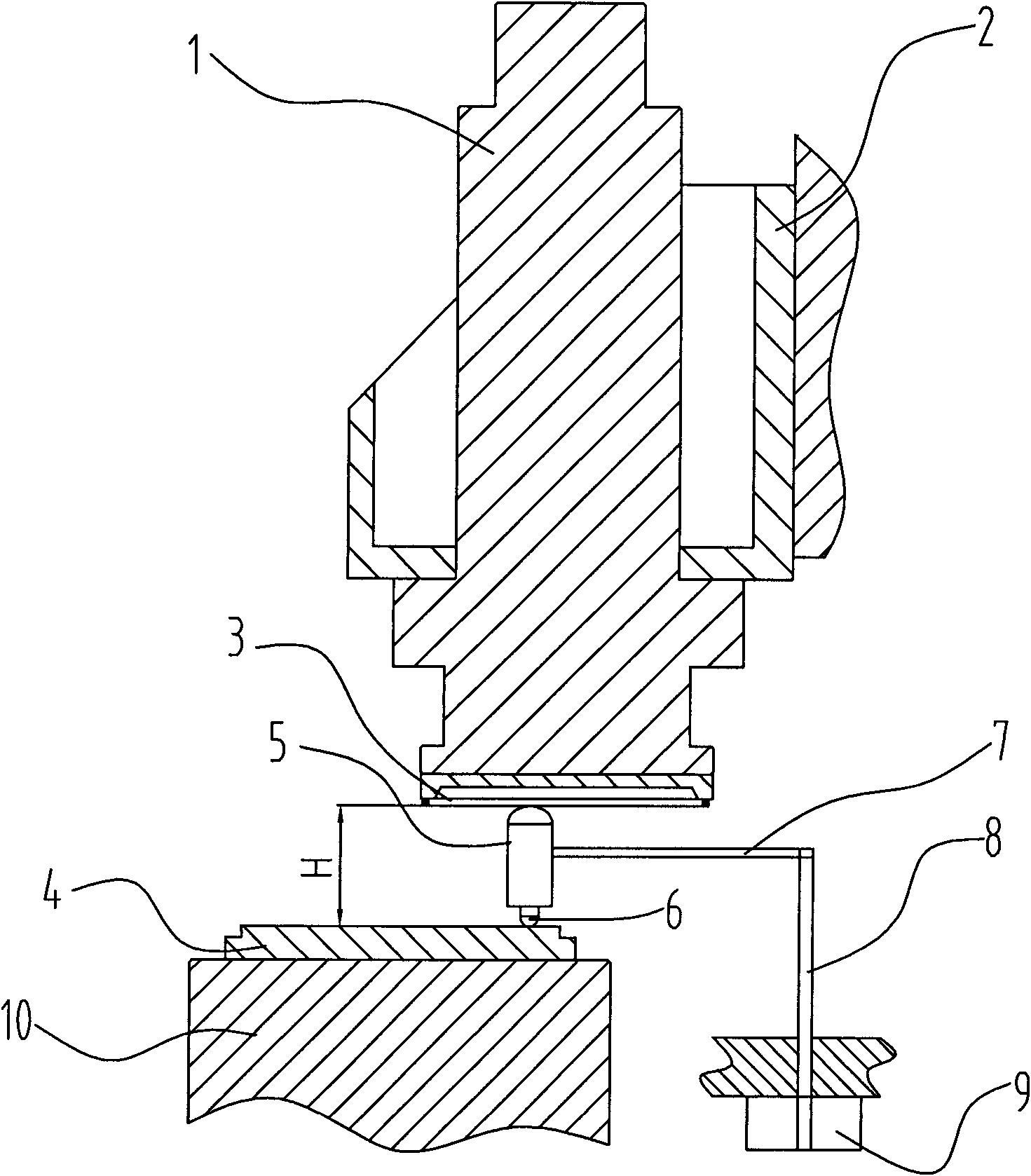

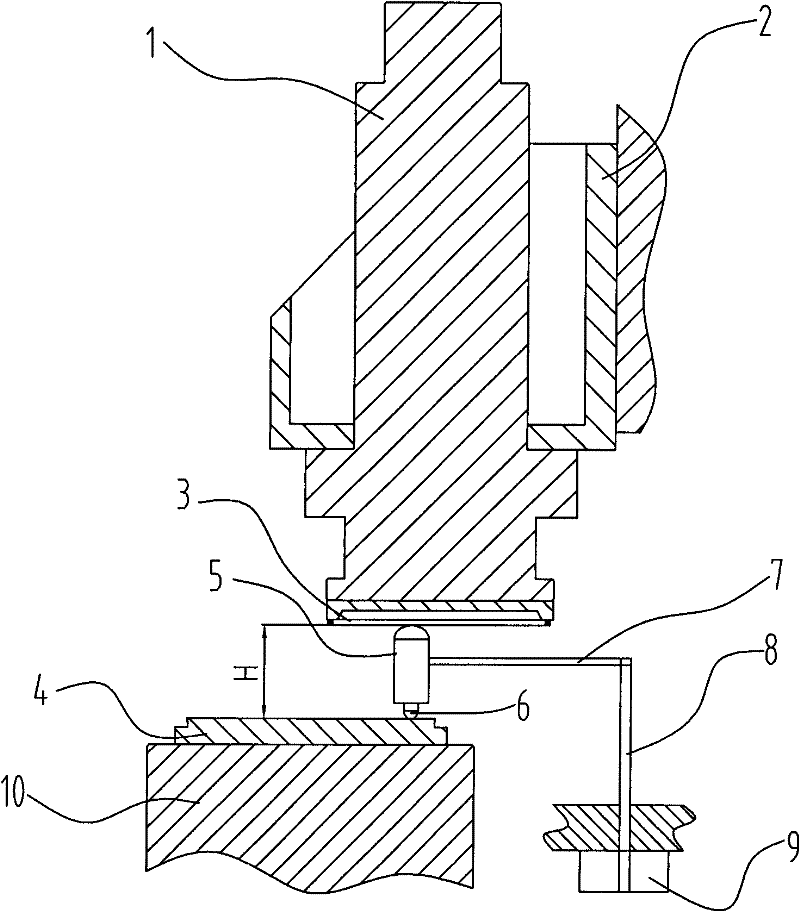

Method and device for automatically setting tool correction value of machine tool

InactiveCN105598743AReduce workloadPrevent operabilityProgramme controlAutomatic control devicesValue setEngineering

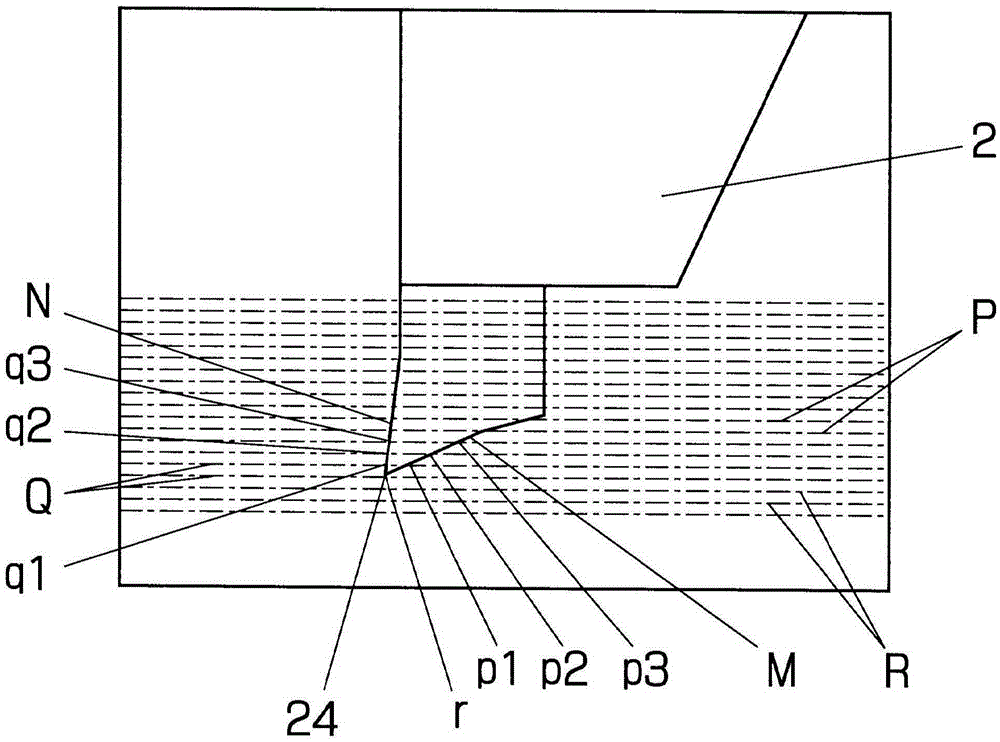

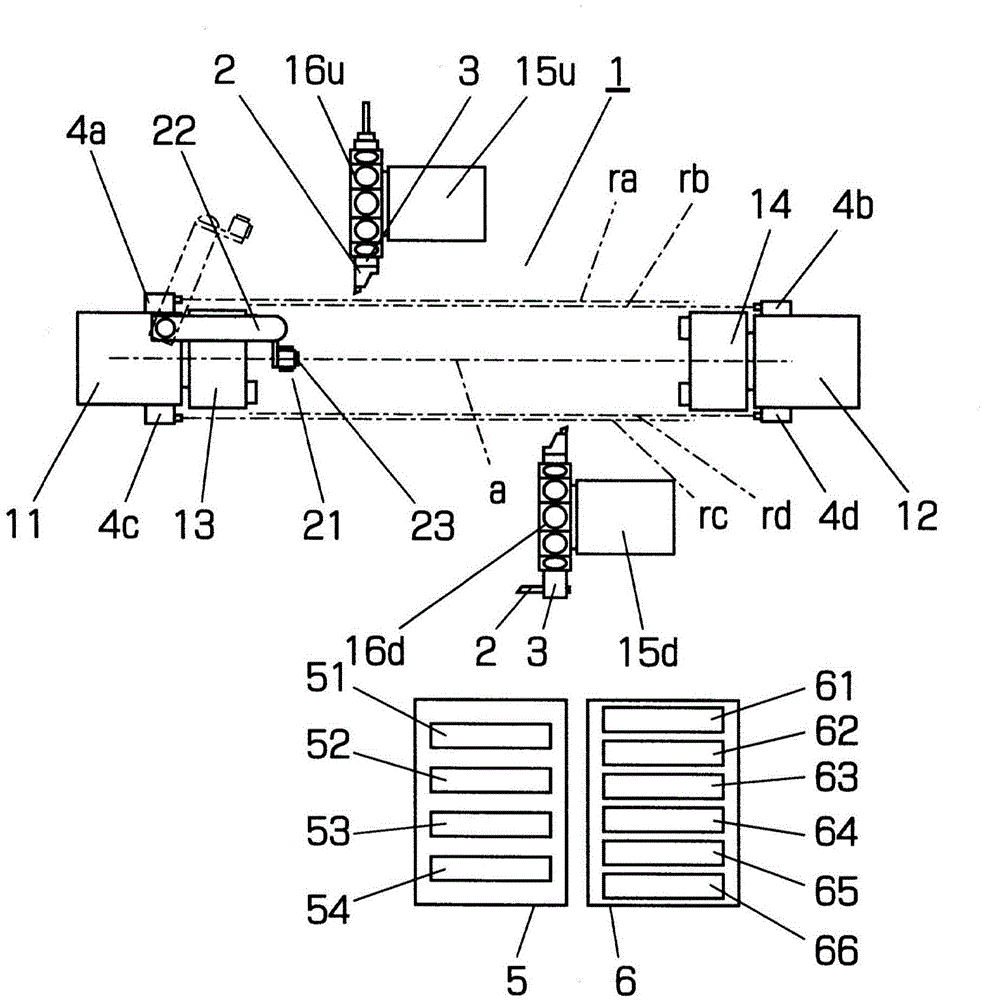

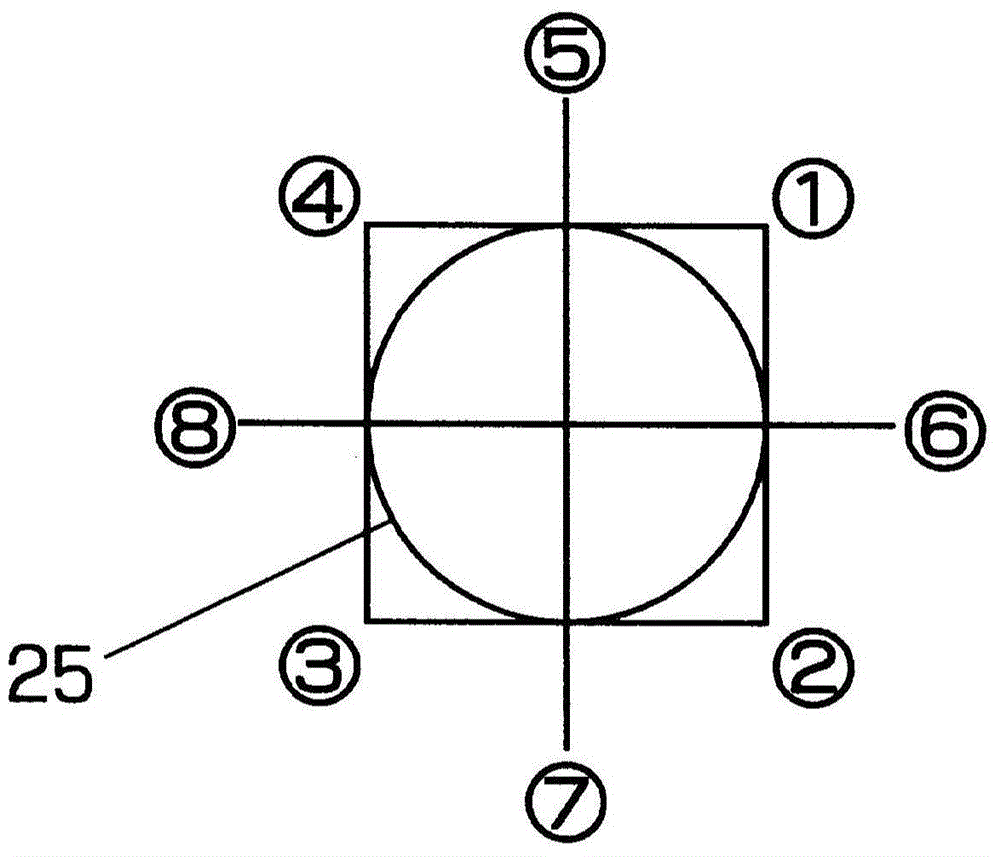

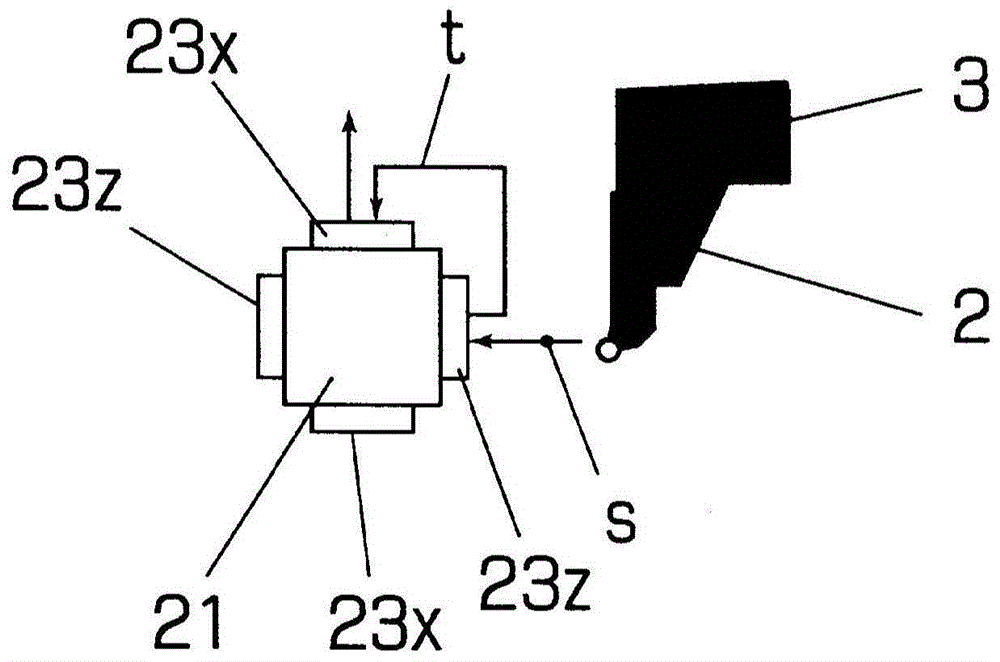

The invention provides a method and device for automatically setting tool correction value of machine tool, which can automatically set a tool correction value for a plurality of tools attached to a tool post of a NC machine tool (a relative positional relation between a tool post and a cutting edge of the tool). An image (A) of a tool (2) attached to a tool post (15) is acquired by a camera (4) installed inside a machine tool, the position and the direction of a cutting edge (24) of the tool (2) on the image are obtained, and a tool correction value is automatically set in a controller while being obtained from a positional relation between the installation position of the camera (4) and the position of the tool post (15) when the image is acquired. The tool correction value set by the controller (5) can be measured by a tool setter (21). In this case, a false tool correction value is obtained from the image, the cutting edge (24) of the tool is detected by a detection sensor (23) of the tool setter (21), and a correction value setting program (53) registered in the controller (5) is automatically executed.

Owner:NAKAMURATOME SEIMITSU IND

Device and method for automatically setting tool offset value of machine tool

ActiveCN104423322ATool offsets are accurateEliminate homework burdenProgramme controlComputer controlNumerical controlMachine tool

Provided are a method and device for automatically setting a relative position relation between a tool post of a numerical control (NC) machine tool and an edge of a tool mounted on the tool post and fully automating work of setting a tool offset value of a machine tool in which multiple tools are used. Tools mounted on tool posts are measured by cameras or laser length measuring devices. A temporary tool offset value is set using shape data of the tool and data indicating a direction of an edge of the tool designated to a machining program and / or tool data registered with a controller. The edge of the tool is automatically brought into contact with a tool setter using the temporary tool offset value. Thereby, the accurate tool offset value is acquired and set for an NC device. It is possible to simulate a machining operation using the temporary tool offset value or to check interference using the shape data of the tool which is acquired by the camera or the laser length measuring devices.

Owner:NAKAMURATOME SEIMITSU IND

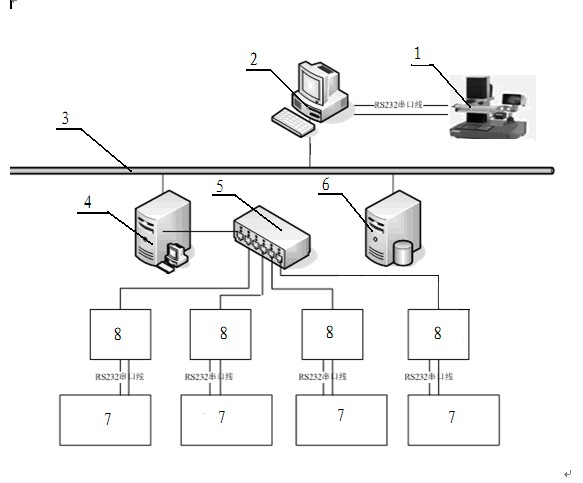

System and method for automatically recording geometric parameters of numerical-control tools

InactiveCN102662352ALess data entryImprove work efficiencyProgramme controlComputer controlControl engineeringProcess engineering

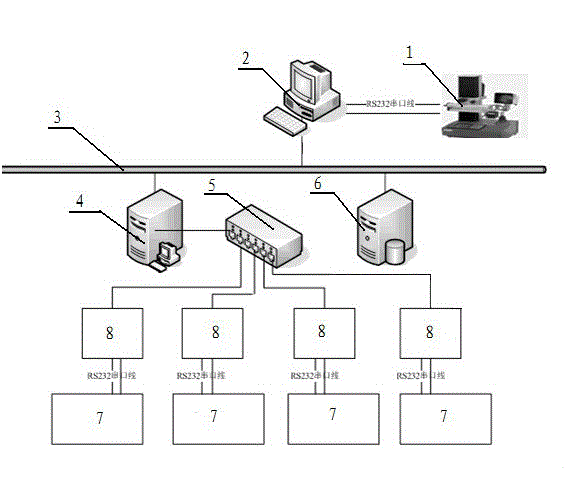

The invention relates to the technical field of numerical-control machining and discloses a system and a method for automatically recording geometric parameters of numerical-control tools. The method includes that an industrial computer transmits tool geometric parameters acquired by a numerical tool setter to a numerical-control tool management system; the numerical-control tool management system analyzes tool geometric parameters, tool codes and numerical-control machining center codes corresponding to the tools from received data, converts tool geometric parameters and tool codes into a text corresponding to the numerical-control machining center codes and identifiable by the numerical-control system according to the numerical-control machining center codes, and transmit the text to a DNC (direct numerical control) server; a numerical-control machining center downloads the text identifiable by numerical-control system types of the numerical-control machining center from the DNC server, analyzes the text and updates data corresponding to the tools according to acquired data analyzed. During the whole recording process of the tool geometric parameters, the tool codes and the numerical-control machining center codes are recorded only during tool aligning, so that recorded data are few, work efficiency is improved, error is small and safety is high.

Owner:CHONGQING UNIV

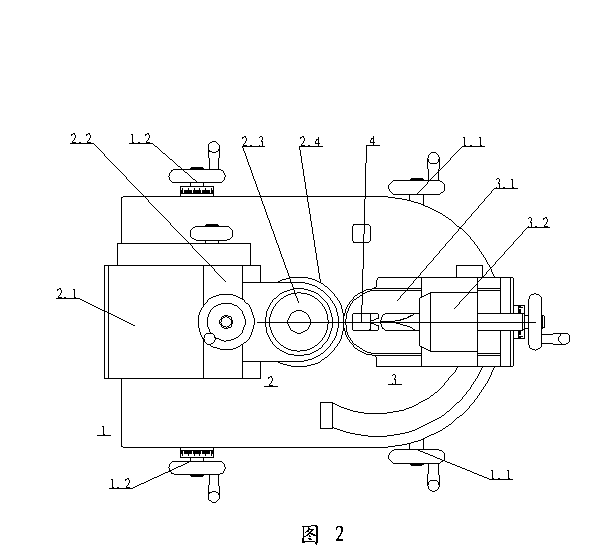

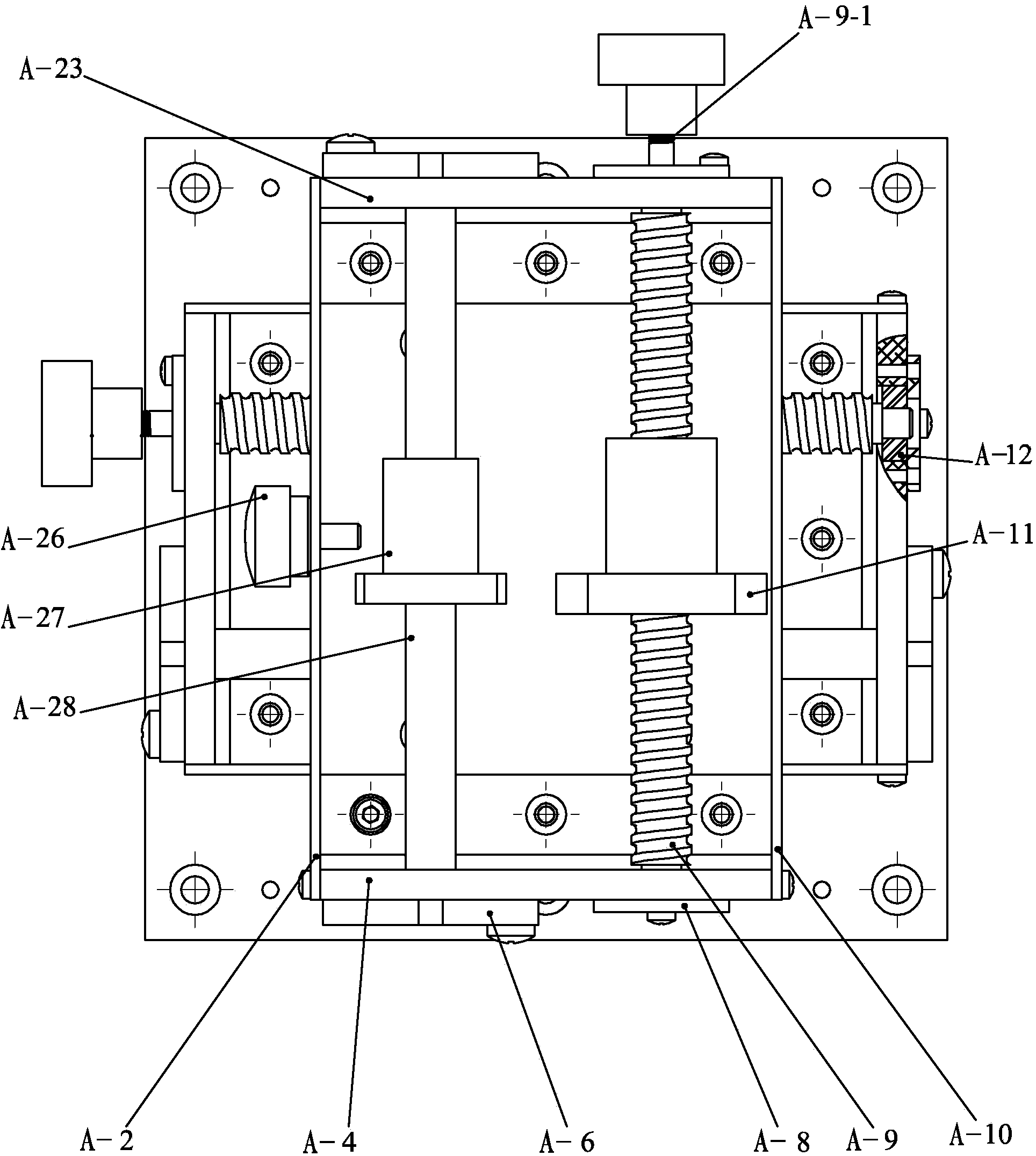

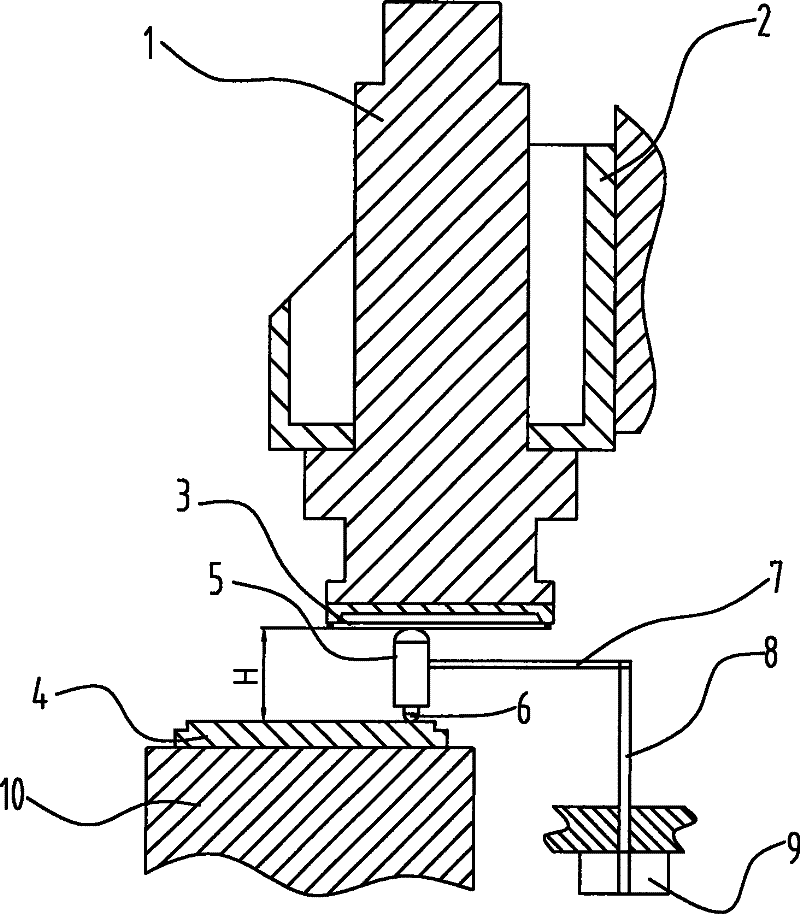

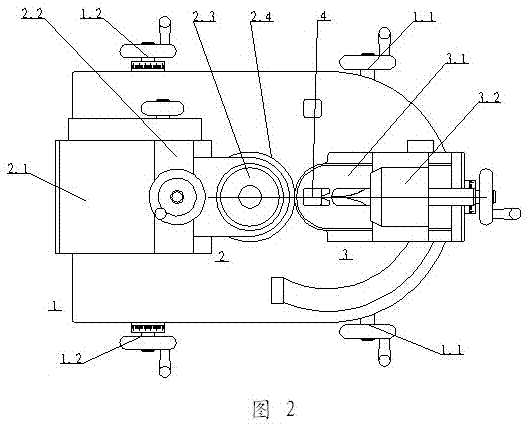

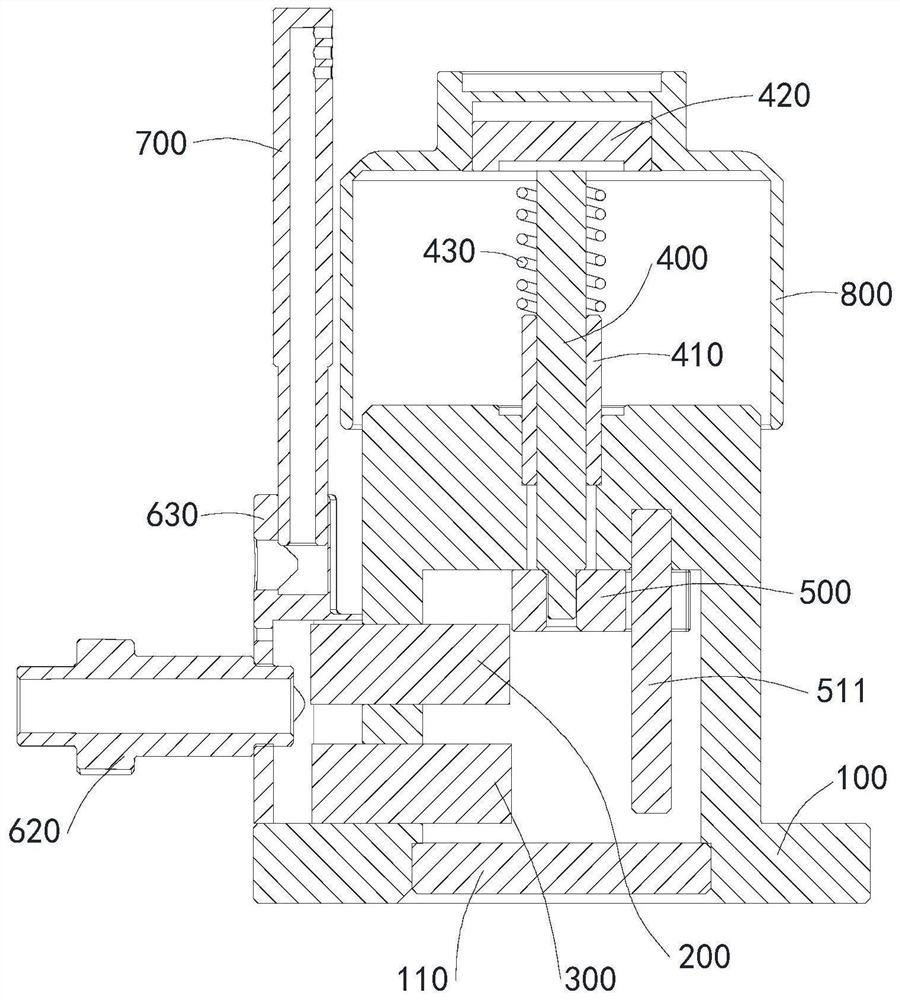

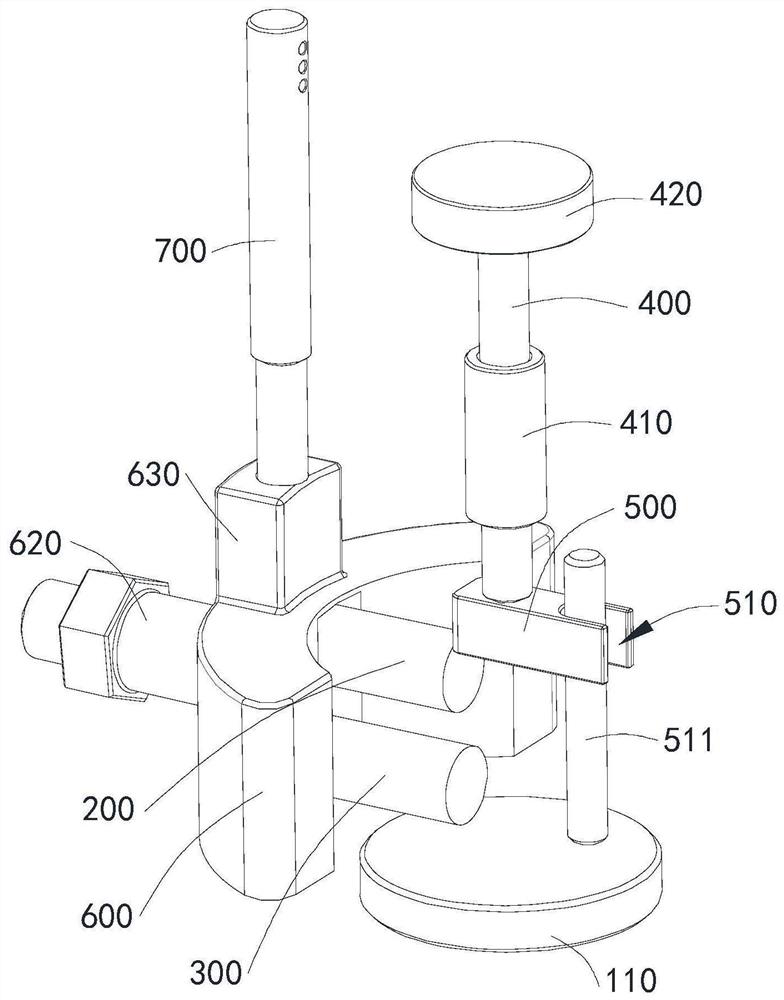

Composite tool setting and adjudging device

ActiveCN103785867ASimple structureFast and efficient elastic functionPrecision positioning equipmentMeasurement/indication equipmentsEngineeringMechanical engineering

The invention discloses a composite tool setting and adjudging device which comprises a tool setter base, a rotary tool apron plate, a cylindrical tool-setting basic shaft and an adjusting and measuring component. The rotary tool apron plate is rotationally arranged on the upper surface of the tool setter base. The tool-setting basic shaft is fixed through the lower end and is vertically arranged on the upper surface of the tool setter base. A plurality of tool-setting reference surfaces are arranged on the peripheral surface of the tool-setting basic shaft. The adjusting and measuring component comprises a rough adjusting component and a fine adjusting component arranged on the rough adjusting component. The rough adjusting component comprises a rough adjusting screw, a ringent nut and a fixing handle. The fine adjusting component comprises a fine adjusting block, a fine adjusting screw, a fastening bolt, a dial indicator, a measuring press rod and a change-over switch. The composite tool setting and adjudging device is simple and reasonable in structure; the contact surface of the measuring press rod is parallel to the processing and rotating surface of a blade, and tool setting reference is provided, so that the device is accurate in tool adjusting, free from inter-component interference, simple and convenient to operate and high in adjusting efficiency.

Owner:GUANGXI YUCHAI MASCH CO LTD

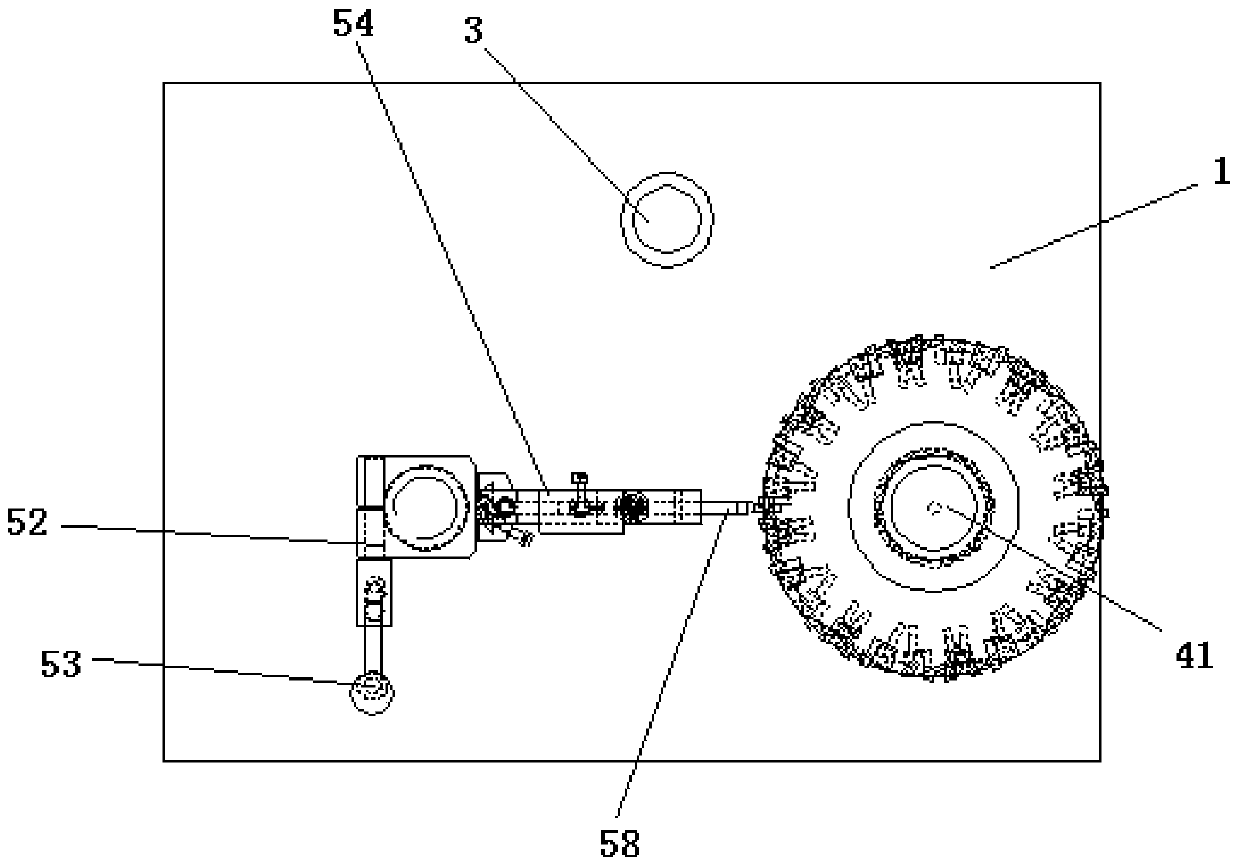

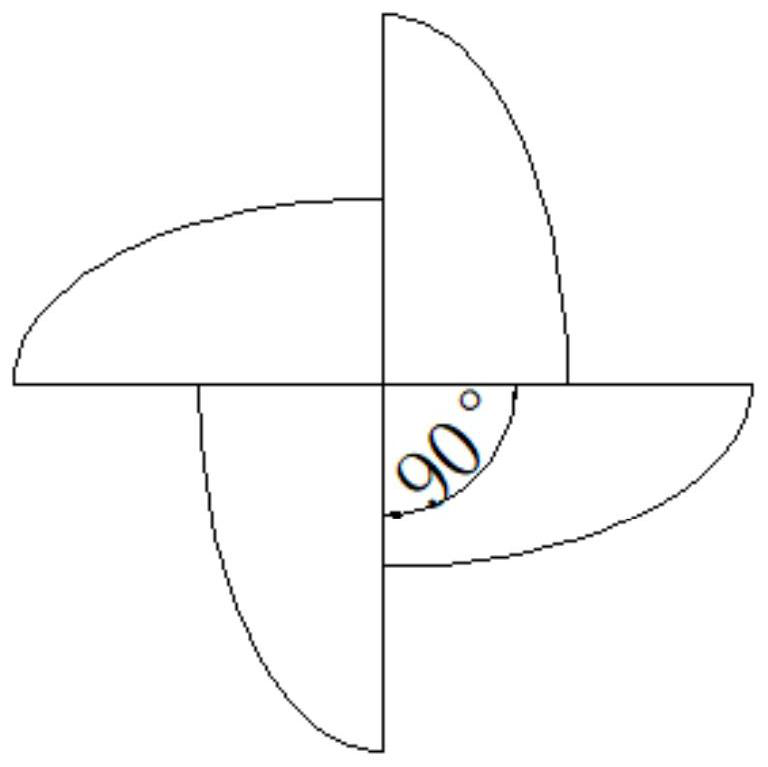

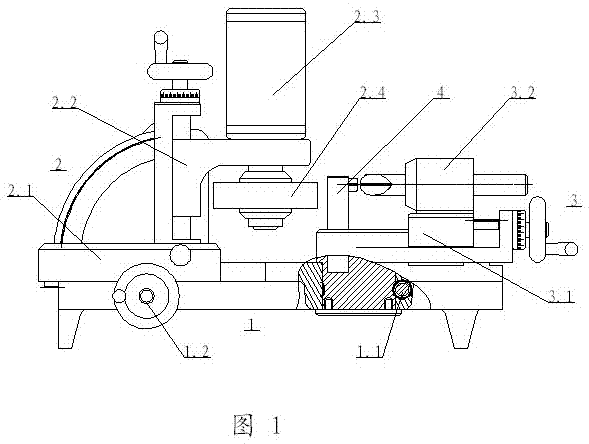

Shaft cutting tool edge grinder

InactiveCN103567817ALow costSmall body designGrinding drivesOther manufacturing equipments/toolsDrive shaftEngineering

The invention relates to a shaft cutting tool edge grinder which comprises a base plate, a grinding assembly and a tool feeding assembly. The grinding assembly is connected onto the base plate and comprises a translation towing platform, a vertical inclinable carriage, a motor and a grinding wheel, the tool feeding assembly comprises an eccentric journal rotating carriage combination, a tool clamping head and a tool setter, the motor on the vertical inclinable carriage on the translation towing platform drives the grinding wheel to run, front and back parallel movement and up and down height adjustment of the grinding wheel are realized along with the inclinable carriage tilting by maximum 90-degree angles, and a journal deflection carriage matched with the tool feeding assembly is moved in a circulating manner by a worm drive journal deflection carriage to grind the edge of a shaft cutting tool by taking a shaft through hole in a vertical rotating shaft connecting seat plate on the journal deflection carriage and by taking opposite 90-degree arc track projecting layers on the seat plate as rotating strokes. The shaft cutting tool edge grinder is small in size, simple to operate, accurate and rapid, and can easily grind the shaft rotary-cutting tool without profession.

Owner:JINGJIANG CHANGYUAN HYDRAULIC MACHINERY

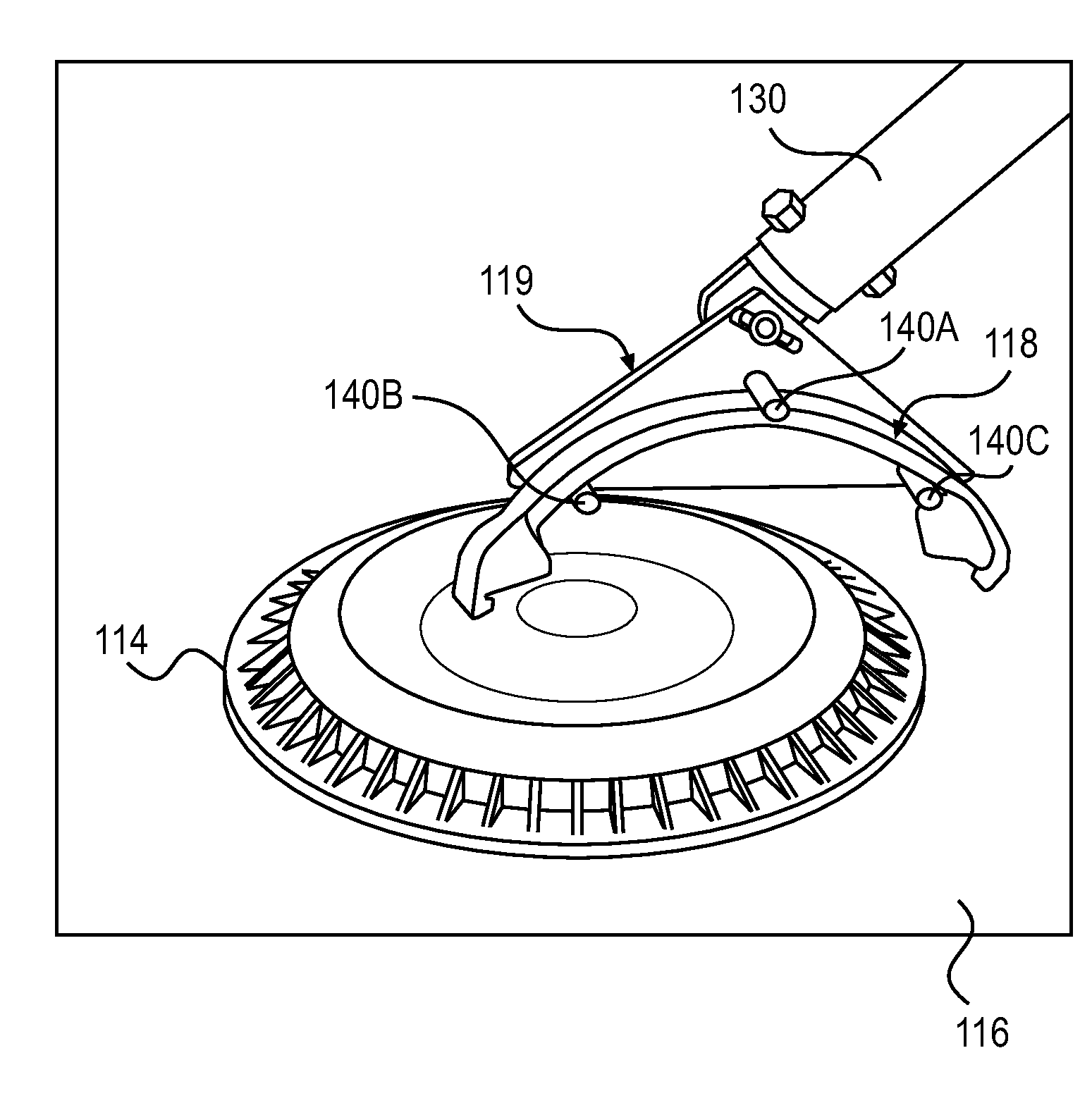

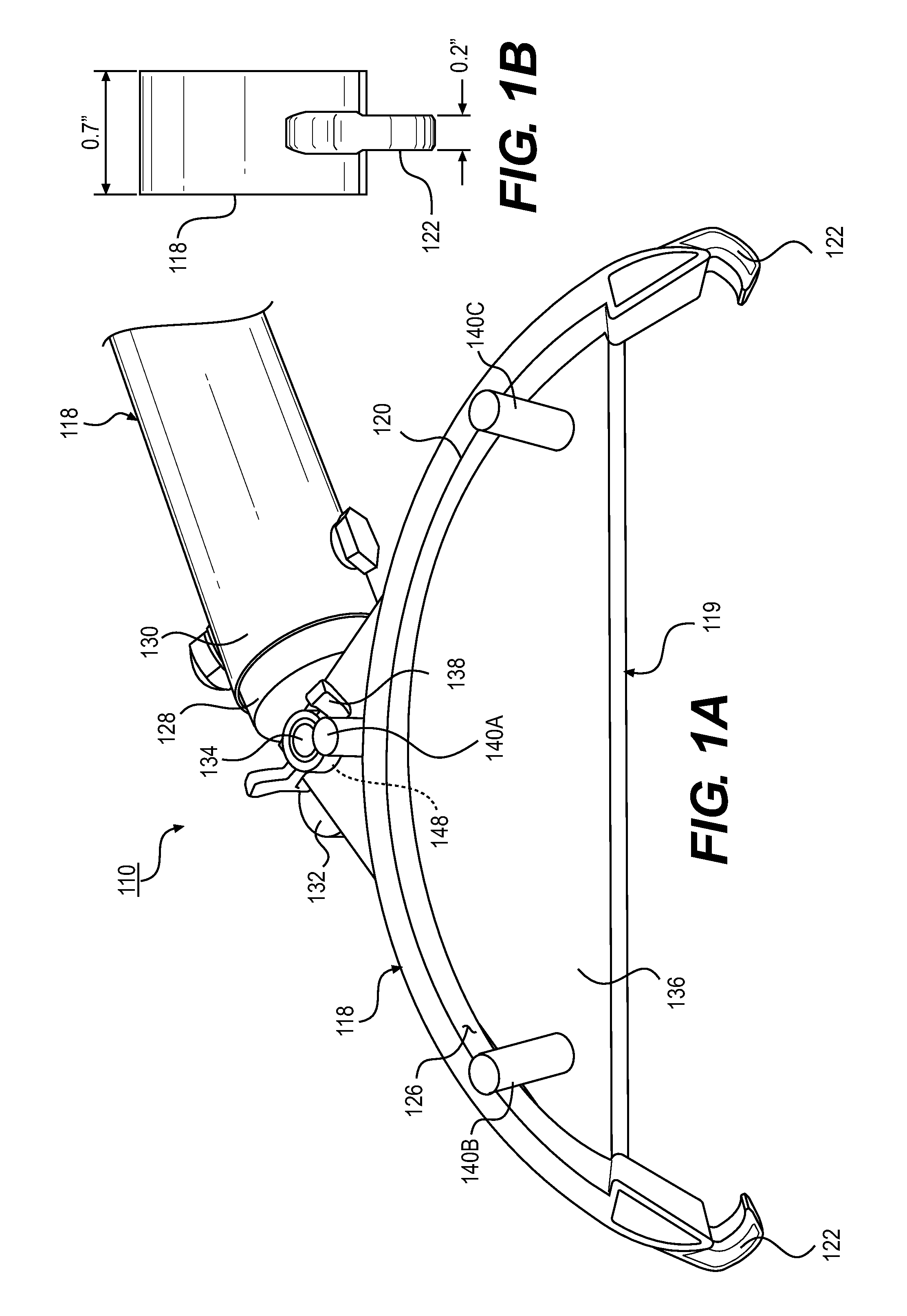

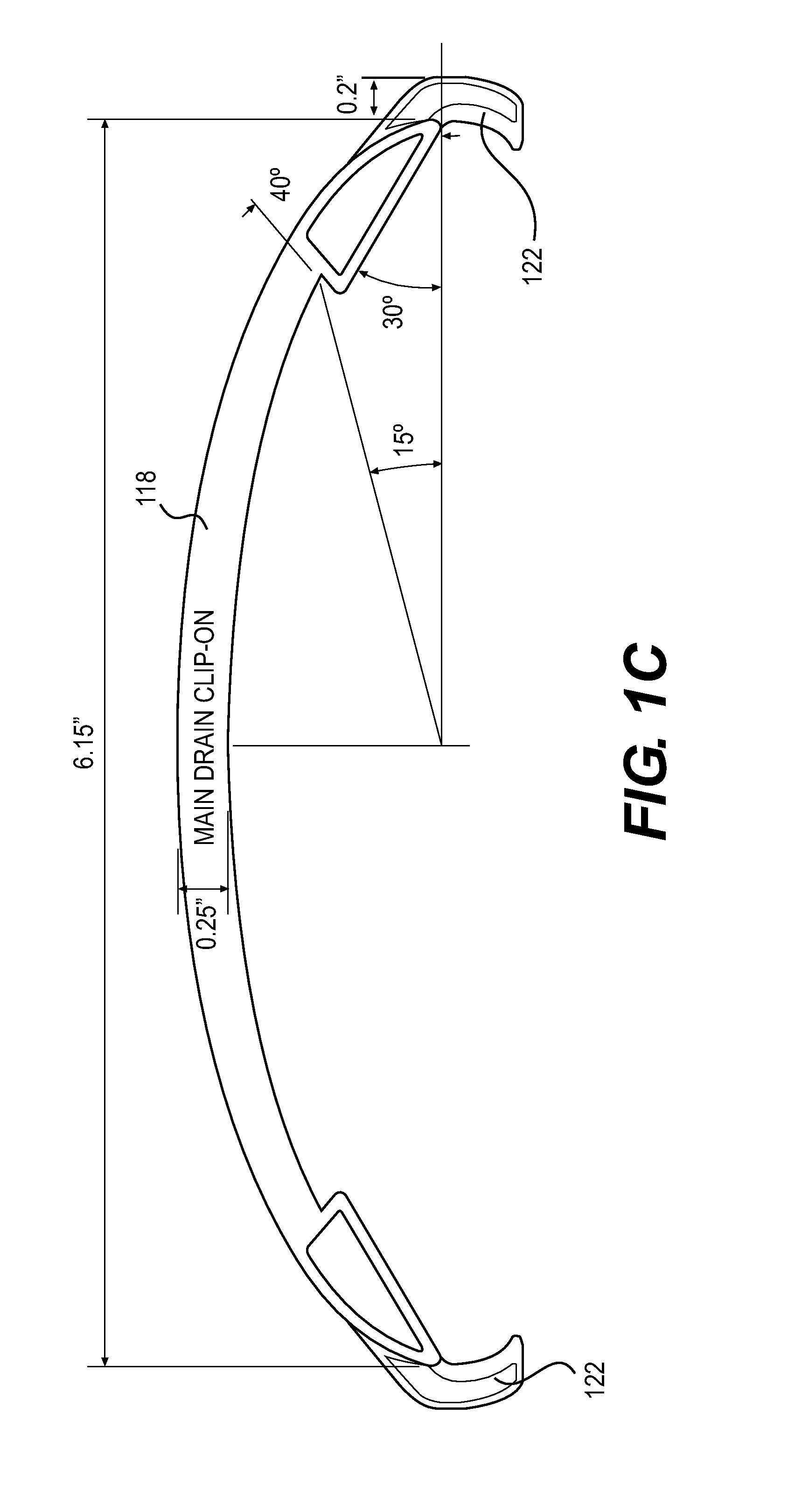

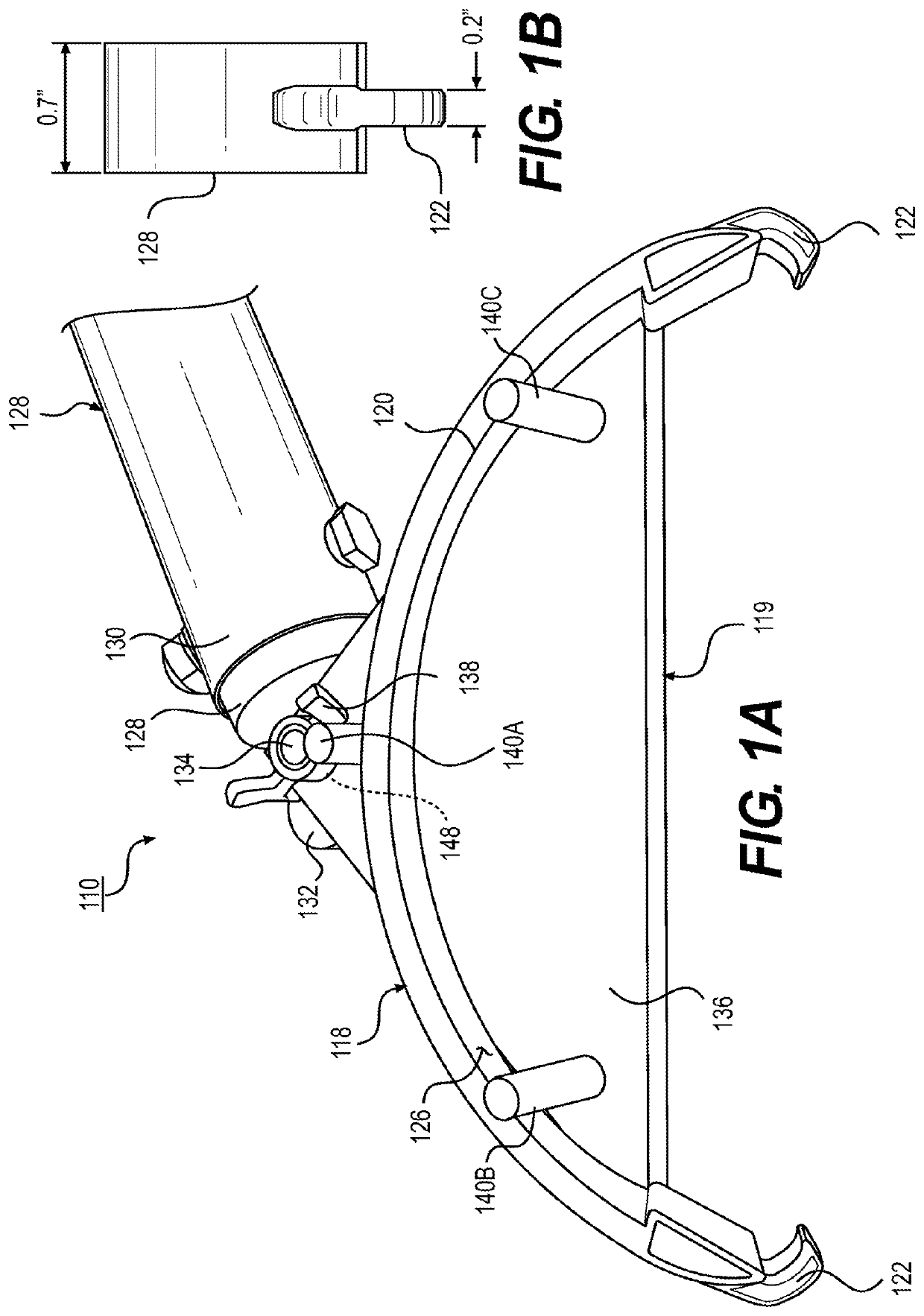

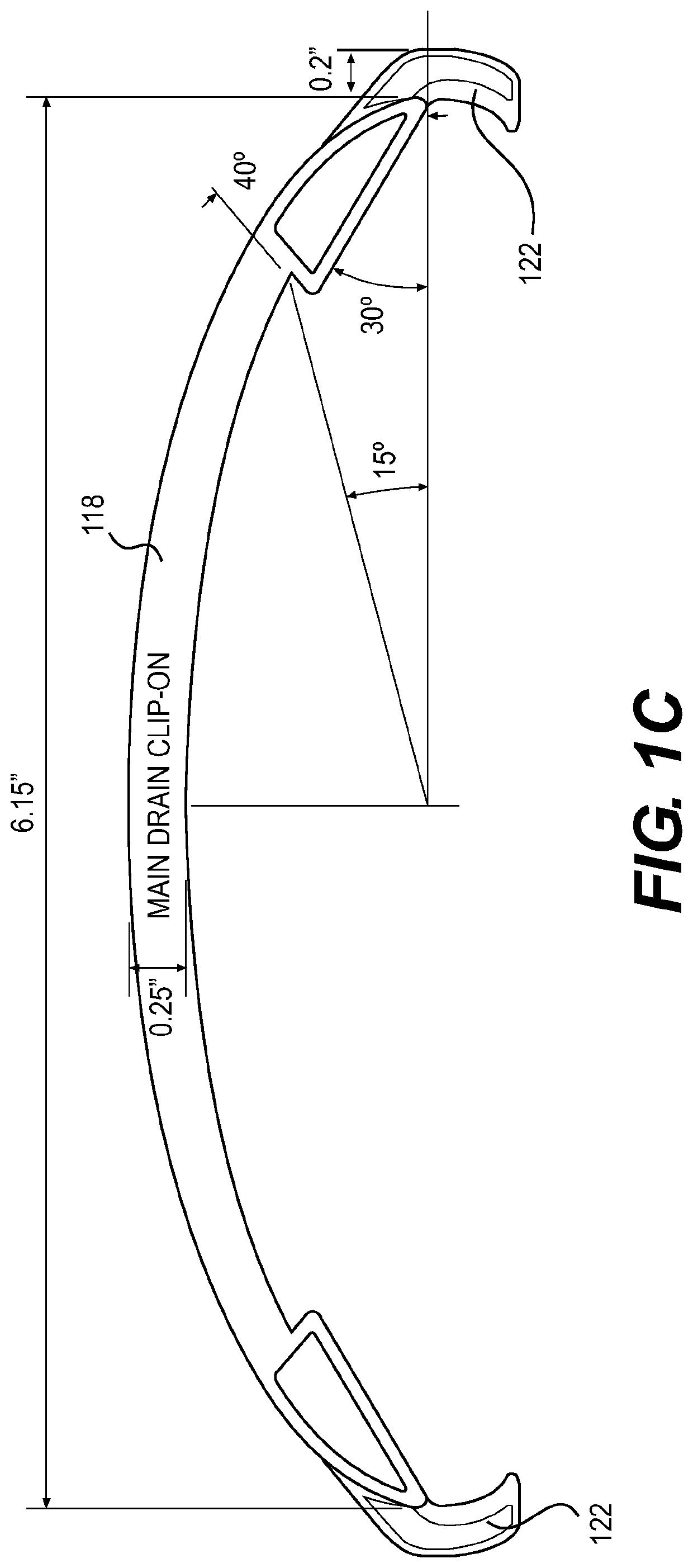

Kit and method for preventing a swimming pool cleaner from becoming caught on a main drain cover

ActiveUS20110225718A1Avoid disadvantagesSimple and inexpensive to manufactureGymnasiumMetal working apparatusSuction forceDraining tube

A kit for preventing a swimming pool cleaner from becoming caught on a main drain cover of a swimming pool including a flexible clip-on protective device with a printed company logo and an installation tool with three cylindrical retainers. The installation tool mounts the clip-on protective device onto the main drain cover to force the swimming pool cleaner to tilt to one side, so that the suction forces of the swimming pool cleaner and the main drain will not interact with each other. The installation tool is made by injection molding with a uniform thickness of 0.165 inch.

Owner:ALBAUGH II HARRY

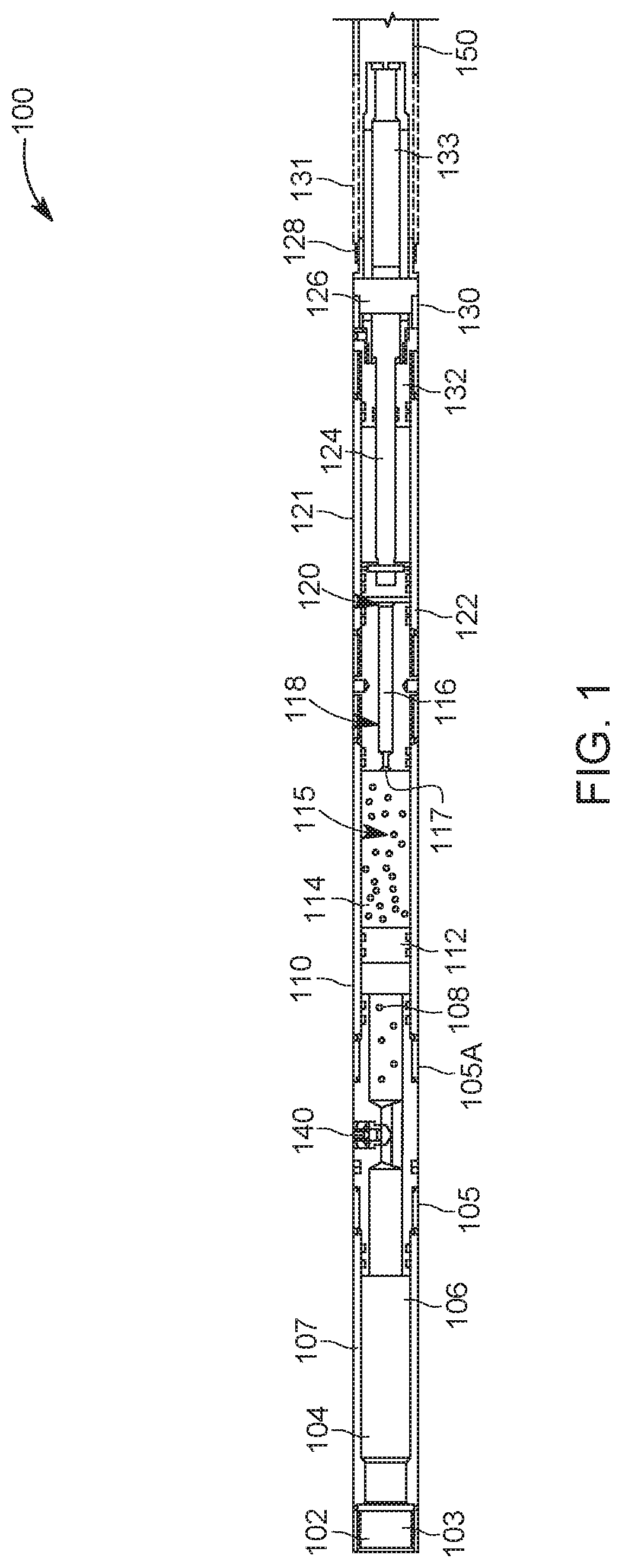

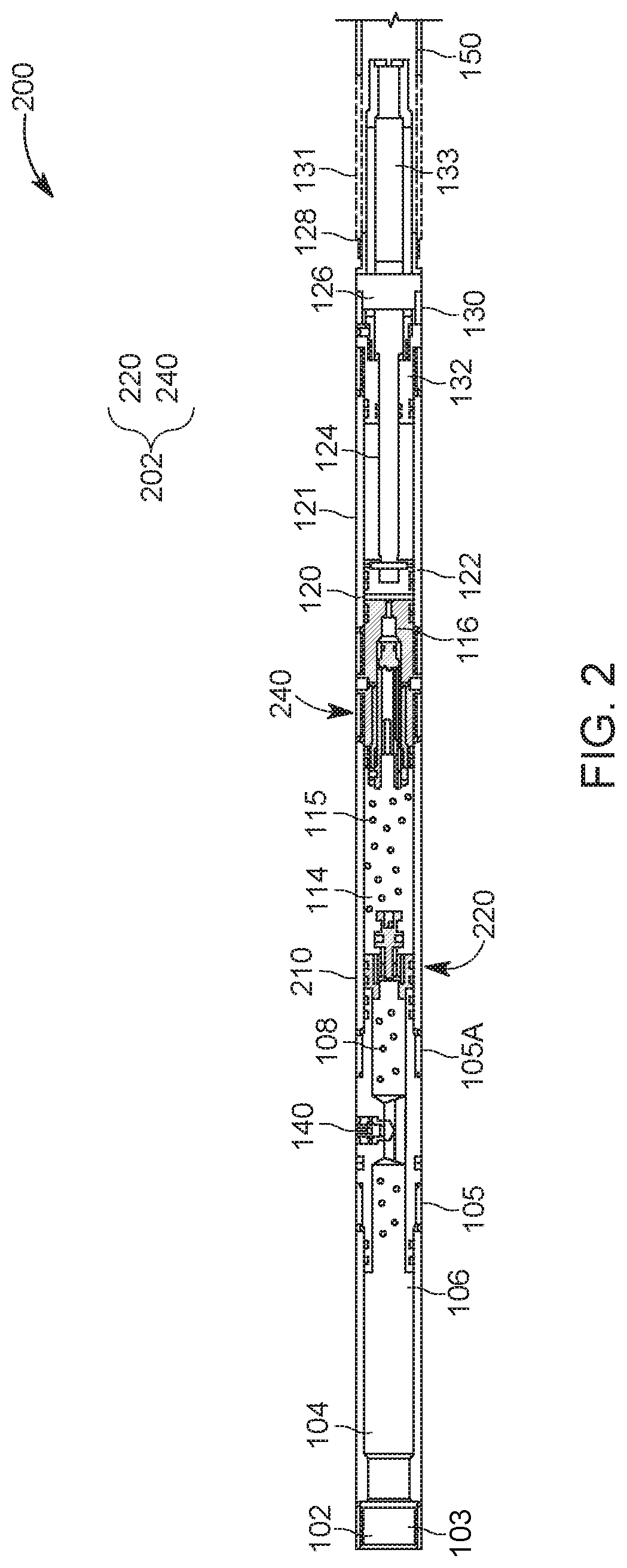

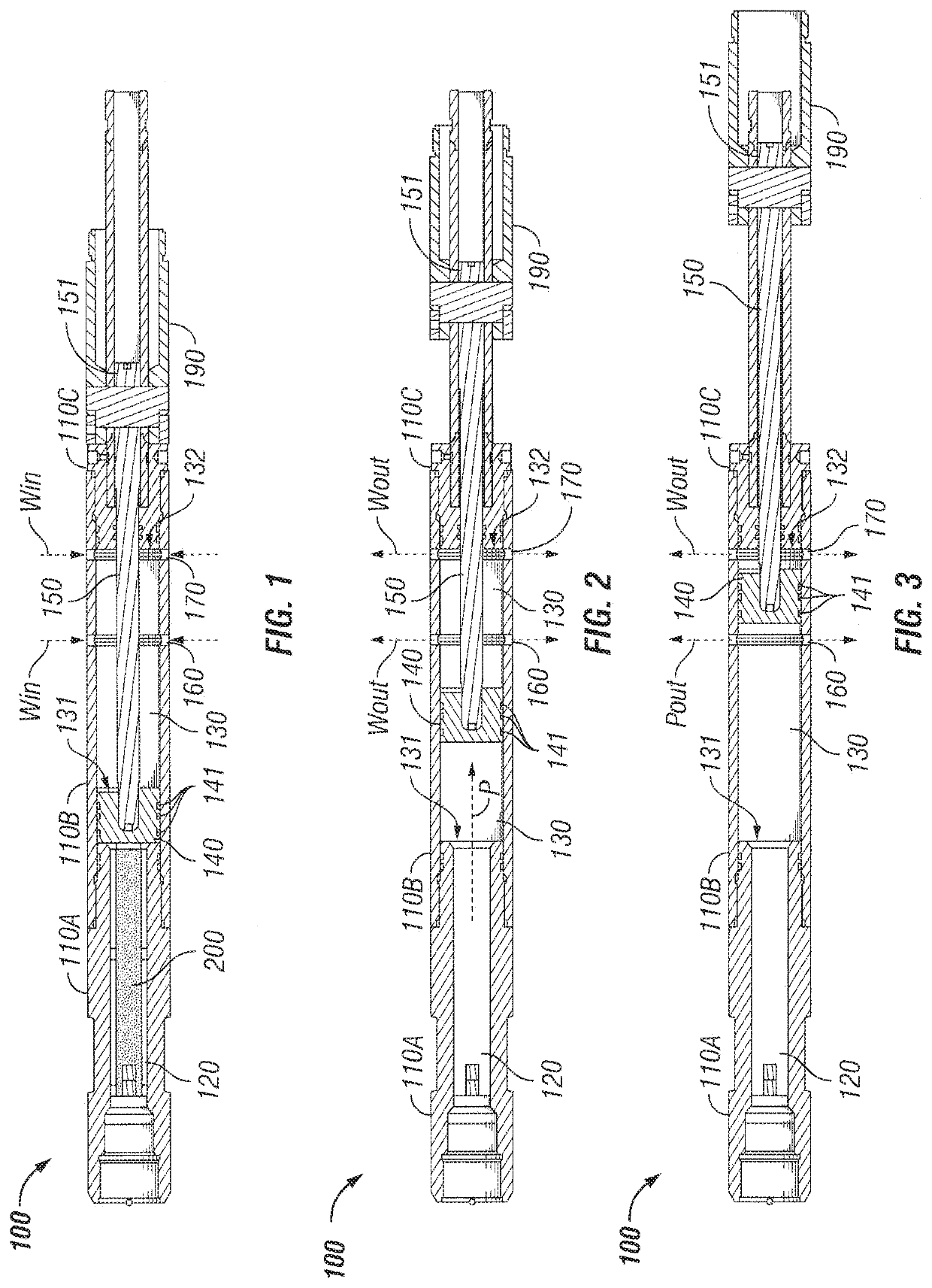

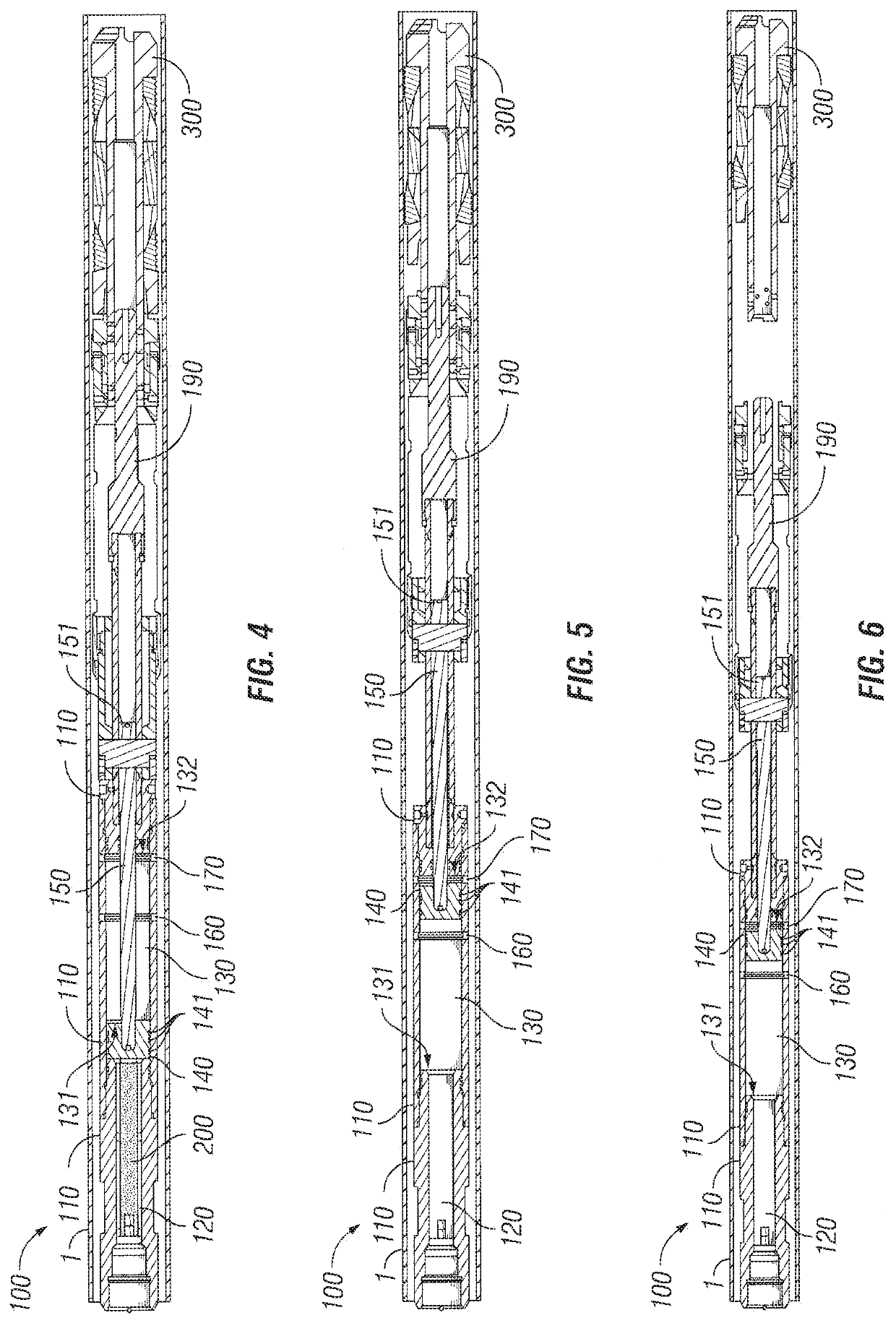

Auto-bleeding setting tool and method

ActiveUS20200256156A1ConstructionsWell/borehole valve arrangementsIsolation valveStructural engineering

A setting tool for setting an auxiliary tool in a well. The setting tool includes a housing holding a floating piston assembly; an isolation valve assembly in fluid contact with an interior of the housing; and a frangible disc located to prevent a high-pressure gas to pass through a bore of the floating piston assembly.

Owner:GEODYNAMICS

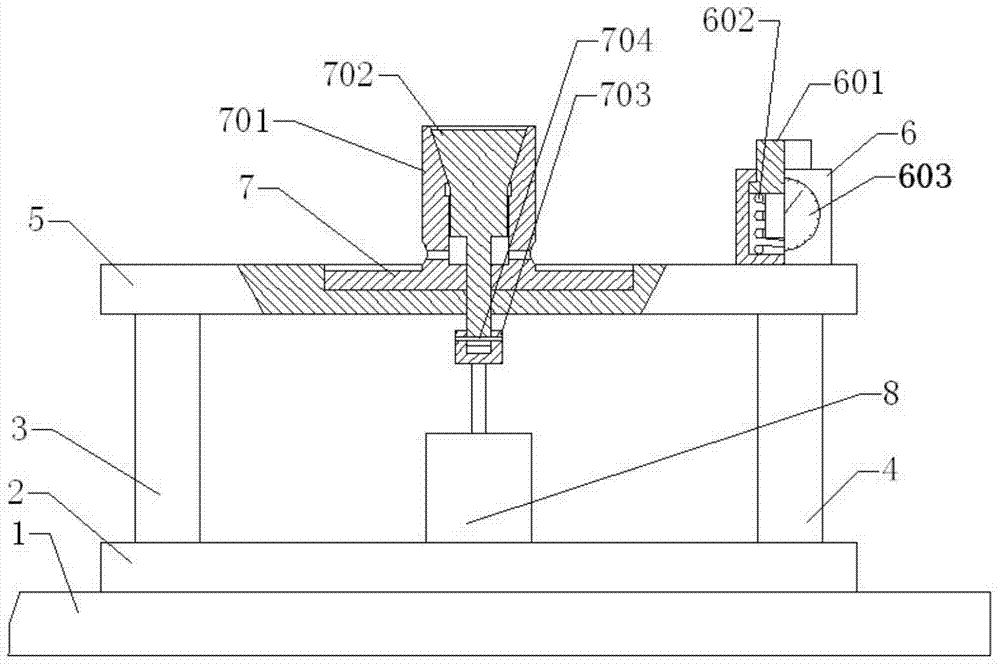

Pneumatic clamping device of machining center zone

InactiveCN104493592AAvoid quality problemsAvoider scrappingAutomatic control devicesWork clamping meansEngineeringPoor quality

The invention discloses a pneumatic clamping device of a machine center zone. The pneumatic clamping device comprises a worktable, and is characterized by comprising a bottom plate, a left vertical plate, a right vertical plate, a top plate, a tool setter, a clamping sleeve and an air cylinder. The bottom plate is arranged at the center of the upper end of the worktable and is in threaded connection with the worktable, the left vertical plate is arranged at the center of the left end of the bottom plate and is connected with the bottom plate in a threaded manner, the right vertical plate is arranged at the center of the right end of the bottom plate and is connected with the bottom plate in a threaded manner, the top plate is arranged at the center of the upper end of the bottom plate and is connected with the left vertical plate and the right vertical plate in a threaded manner, the tool setter is arranged on the right side of the center of the top plate and is connected with the top plate in a threaded manner, the clamping sleeve is arranged at the center of the top plate and is connected with the top plate in a threaded manner, and the air cylinder is arranged at the center of the upper end of the bottom plate and connected with the bottom plate in a threaded manner. Compared with the prior art, the pneumatic clamping device has the advantages that a workpiece to be machined is arranged in the clamping sleeve only, the air cylinder pulls open the clamping sleeve to clamp the workpiece, and tools can be quickly set by the tool setter, so that machining efficiency and accuracy is improved, and poor quality or scrappage of workpieces is avoided.

Owner:池州共康汽车零部件有限公司

Automatic setting device and automatic setting method of tool offset value of machine tool

ActiveCN104423322BEliminate homework burdenProgramme controlComputer controlNumerical controlEngineering

Provided are a method and device for automatically setting a relative position relation between a tool post of a numerical control (NC) machine tool and an edge of a tool mounted on the tool post and fully automating work of setting a tool offset value of a machine tool in which multiple tools are used. Tools mounted on tool posts are measured by cameras or laser length measuring devices. A temporary tool offset value is set using shape data of the tool and data indicating a direction of an edge of the tool designated to a machining program and / or tool data registered with a controller. The edge of the tool is automatically brought into contact with a tool setter using the temporary tool offset value. Thereby, the accurate tool offset value is acquired and set for an NC device. It is possible to simulate a machining operation using the temporary tool offset value or to check interference using the shape data of the tool which is acquired by the camera or the laser length measuring devices.

Owner:NAKAMURATOME SEIMITSU IND

Tool setter of sharpening grinding wheel of semiconductor wafer

InactiveCN101633152AReduce idle travelImprove grinding efficiencySemiconductor/solid-state device manufacturingLapping machinesEngineeringGrinding wheel

The invention relates to a tool setter of a sharpening grinding wheel of a semiconductor wafer. The invention can complete the tool setting of the grinding wheel before the semiconductor wafer is sharpened, shorten the idle stroke of a main shaft of the grinding wheel during sharpening and enhance the sharpening efficiency of the semiconductor wafer. The tool setter of the sharpening grinding wheel of the semiconductor wafer comprises the main shaft of the grinding wheel, a feeding device of the main shaft of the grinding wheel, the grinding wheel and a sucking disk. The tool setter of the sharpening grinding wheel of the semiconductor wafer is characterized in that a microswitch with determined height is arranged in a space on the lower surface of the grinding wheel and the upper surface of the sucking disk, one end of the microswitch is provided with a switch contact, and the microswitch is connected with a driving device by a connecting piece arranged at the side part.

Owner:WUXI MACHINETOOL +1

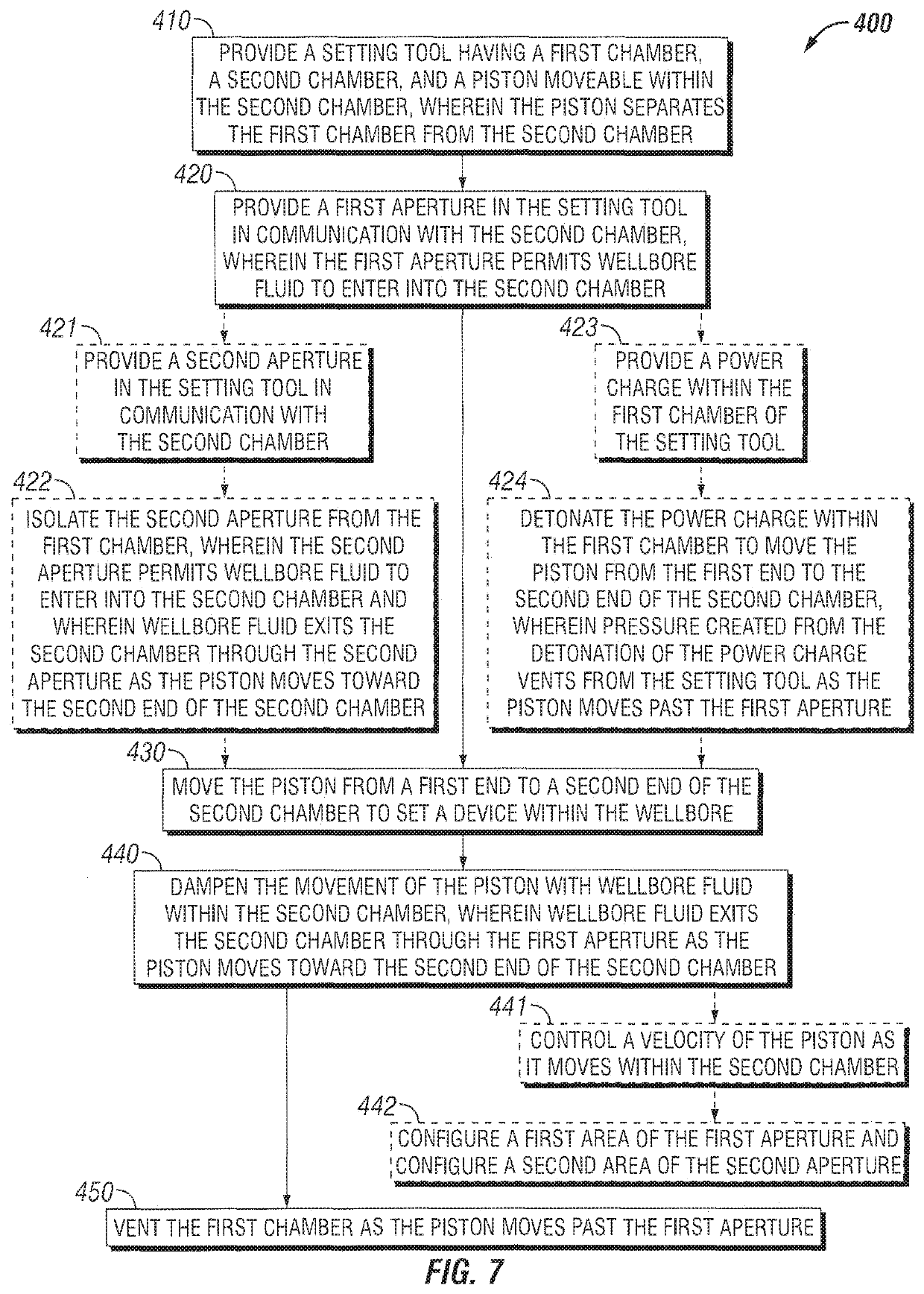

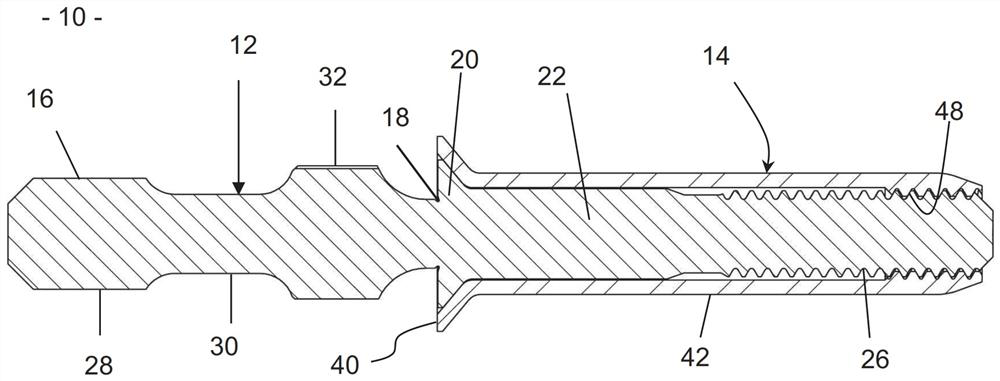

Self Venting Setting Tool That Utilizes Wellbore Fluid to Dampen Setting Motion

A setting tool for setting a device within a wellbore. The setting tool includes first and second chambers within a housing. A piston separates the chambers and is moveable within the second chamber. The piston is initially positioned adjacent a first end of the second chamber. The setting tool includes a first aperture in communication with the second chamber. Wellbore fluid may enter the second chamber through the first aperture. As the piston moves towards the second end of the second chamber, wellbore fluid within the second chamber is forced out of the second chamber through the first aperture. Pressure within the first chamber vents from the first chamber through the first aperture when the piston moves past the first aperture within the second chamber. The housing may include a second aperture adjacent to the second end of the second chamber that permits wellbore fluid to enter and exit.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

Installation tool for blind fasteners and method for installing fasteners

ActiveCN110270957BSimple and mechanically robust constructionContinuous rotary motionSpannersScrewsFlywheelIndustrial engineering

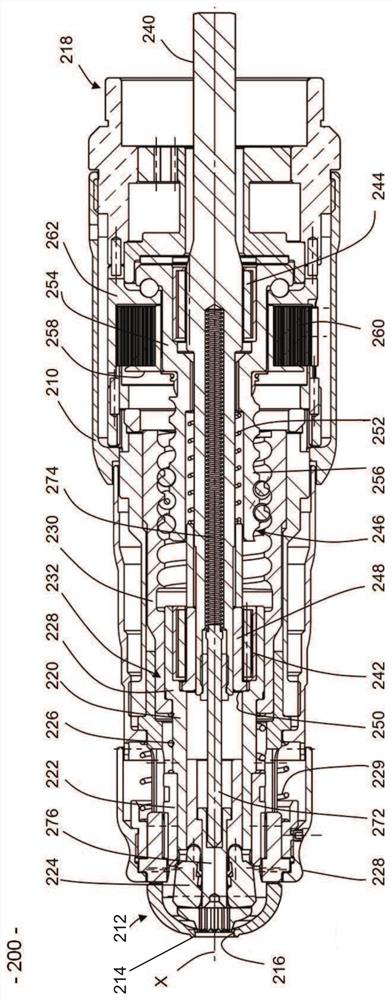

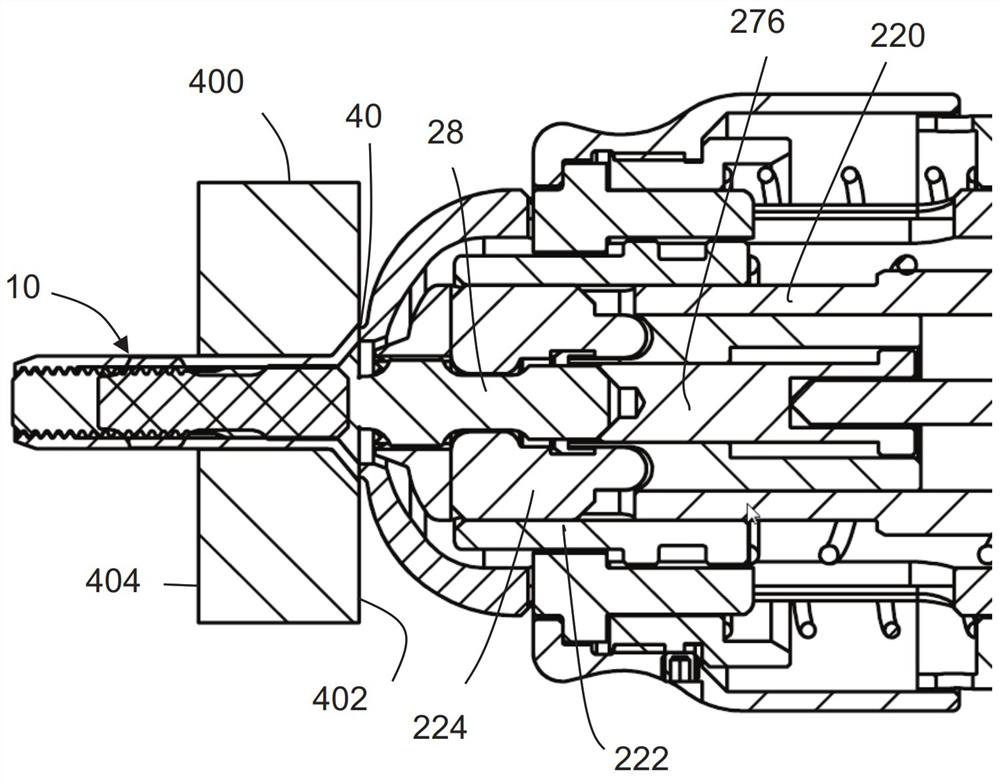

The invention relates to a tool (installation tool) for installing in a structure 400 a fastener 10 of the "pull screw" type comprising a destructible grip. The installation tool includes a main body, a first sleeve shaft 220 that is axially movable and rotatable in the main body and can drive the gripping portion, a second sleeve shaft that is axially movable but not rotatable in the main body, and has a Shaft drive. The shaft includes a first flywheel capable of driving the first sleeve to rotate, a second flywheel, and a drive element coaxially arranged around the second flywheel. The driving element cooperates with the second sleeve shaft through a screw connection. The first flywheel drives the first sleeve shaft to rotate in the first rotational direction of the shaft. The second flywheel rotates the drive element in the second rotational direction of the shaft to move the second sleeve shaft axially. Thus, the installation tool is able to pull the fastener to form a bulb on the blind side of the structure, tighten the screw and break the grip in a single operation.

Owner:LISI AEROSPACE

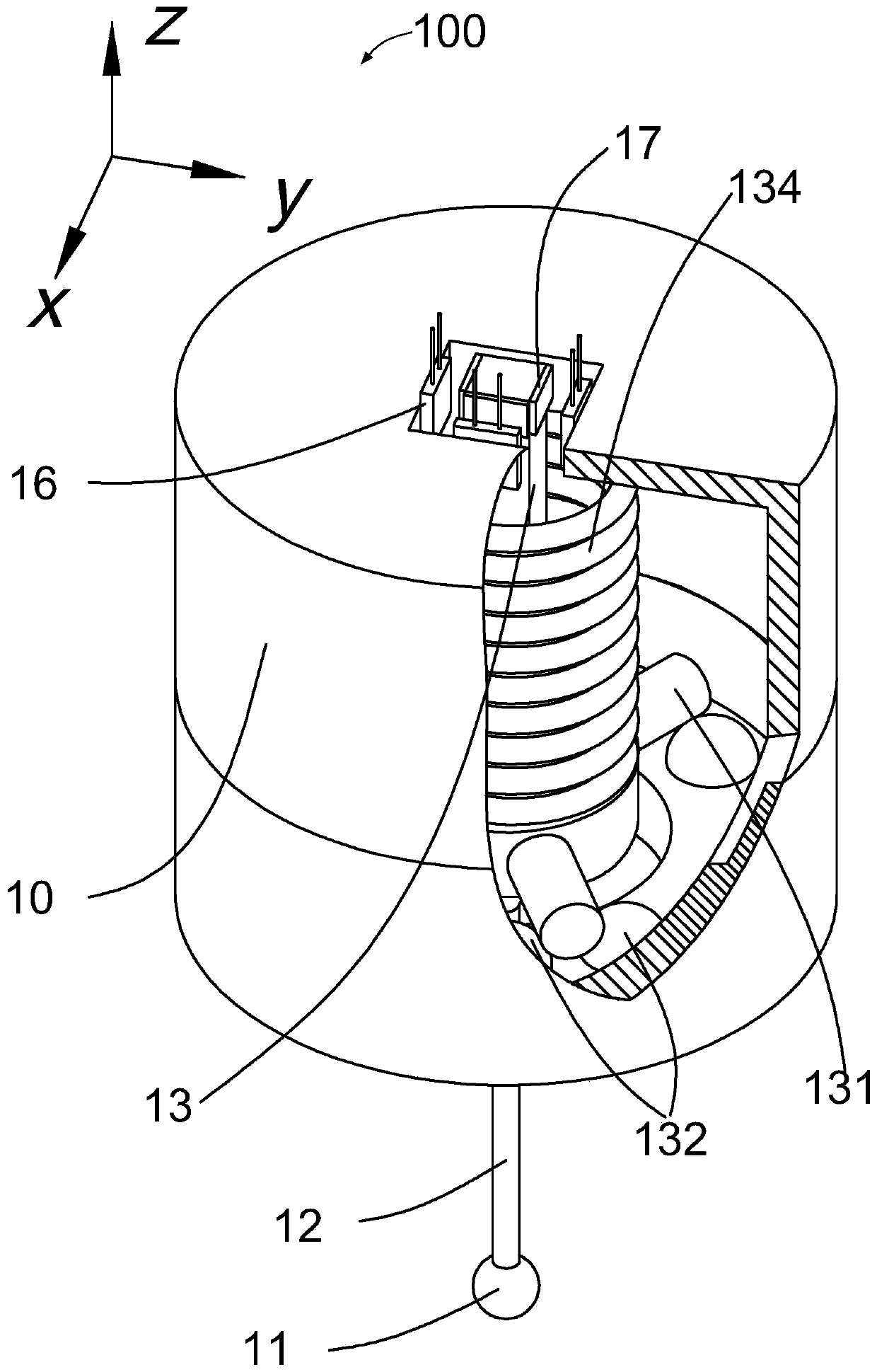

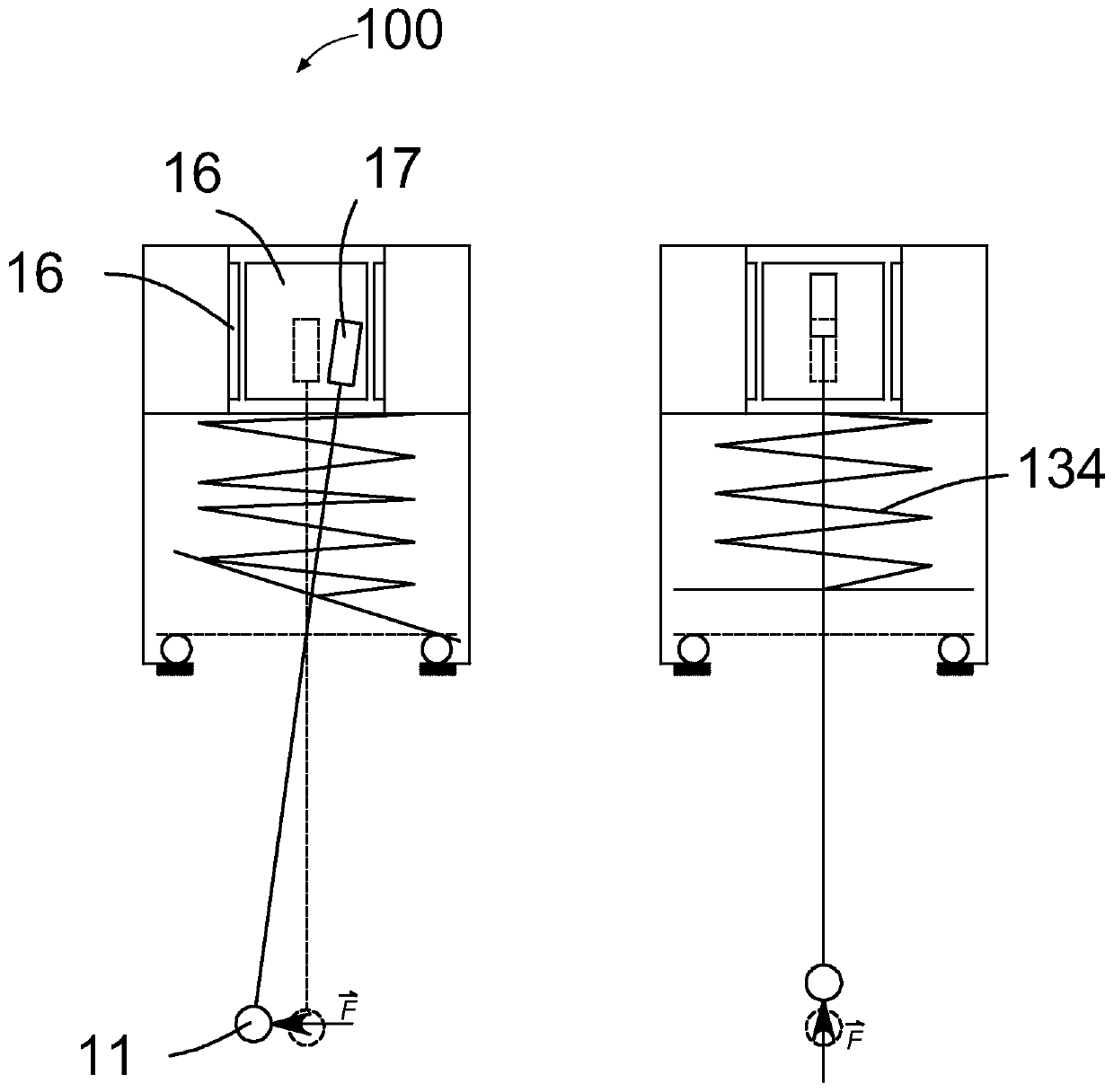

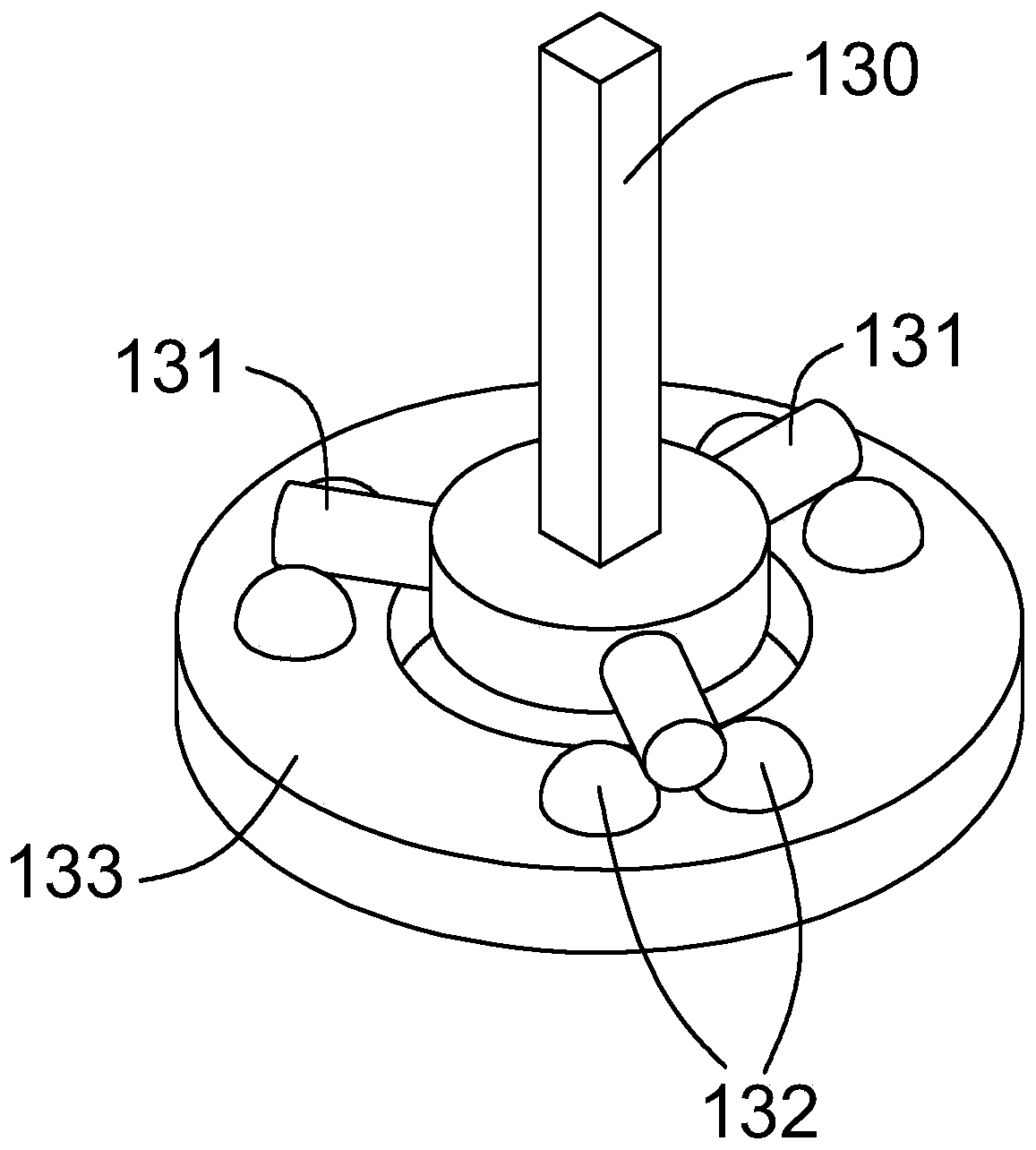

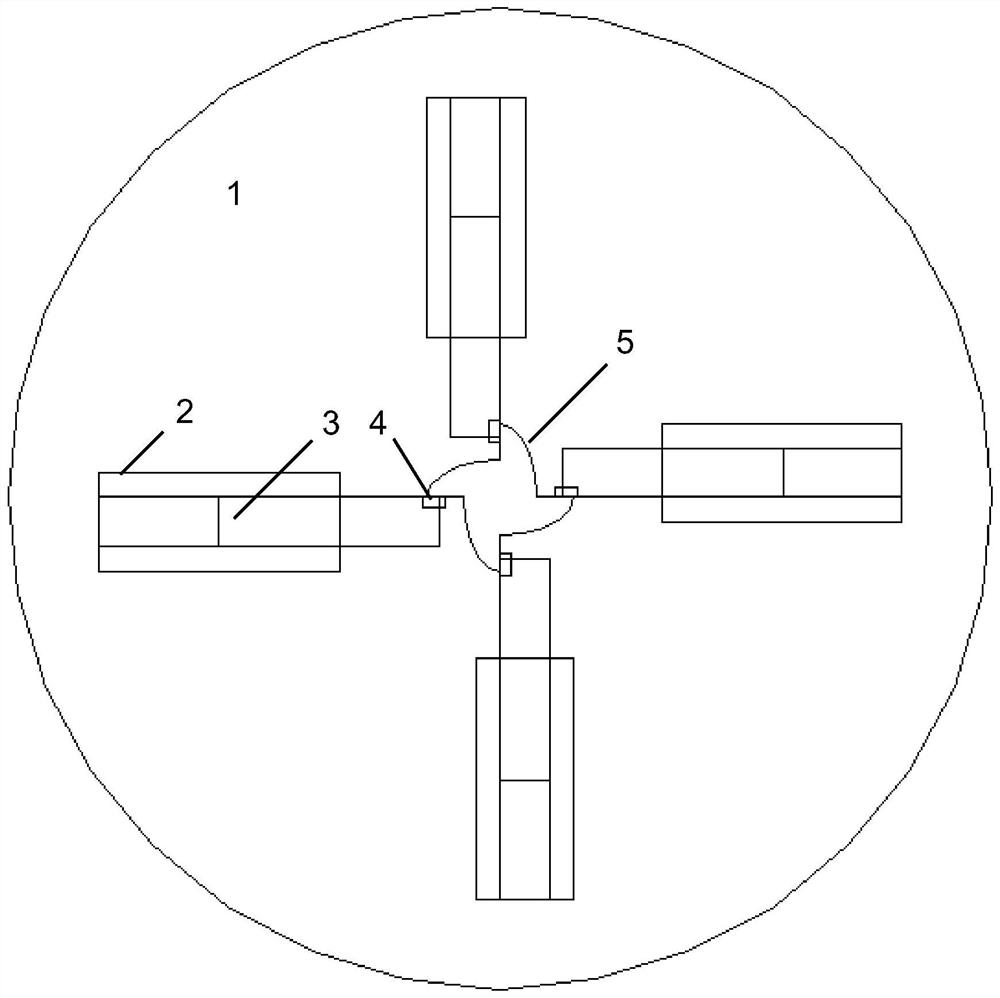

Touch probe, three-coordinate measuring machine and tool setting instrument

ActiveCN108895953BOvercome the defect that the contact direction cannot be obtainedIncreased anisotropyAutomatic control devicesUsing electrical meansGratingMedicine

The invention provides a contact type measuring head which adopts a ball column structure or a spring piece as a supporting reset mode, wherein the grating or the hall device is used as a detection device for displacement information (including the direction and the size of the displacement of the detection end), so that the defect that an existing trigger type measuring head cannot acquire the contact direction is overcome, error compensation can be carried out more accurately, anisotropy of the trigger type measuring head is improved, and the measurement precision is improved. The contact type measuring head is simple in structure, small in quality., small in size, good in dynamic performance, and is suitable for high-precision rapid measurement.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

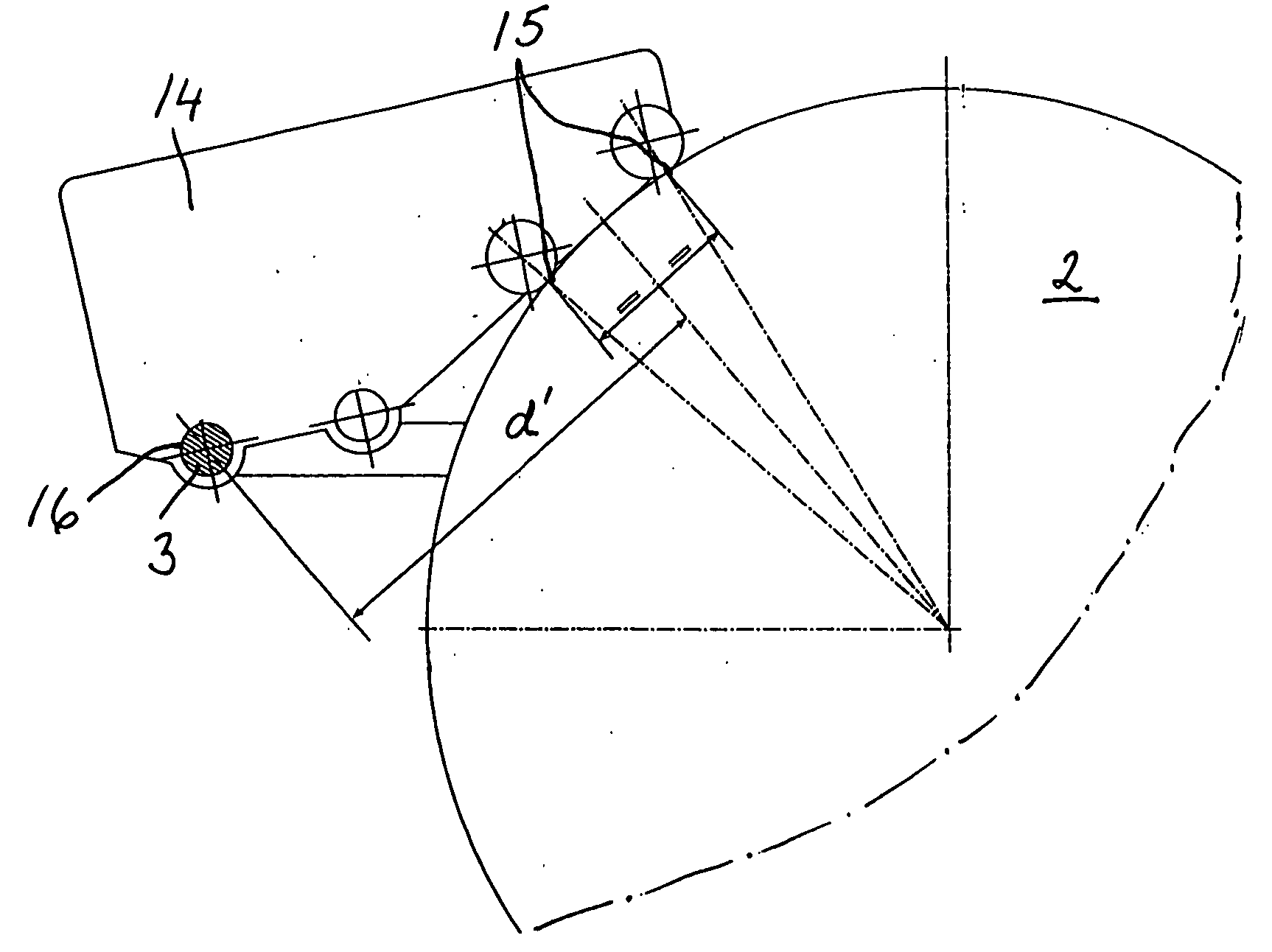

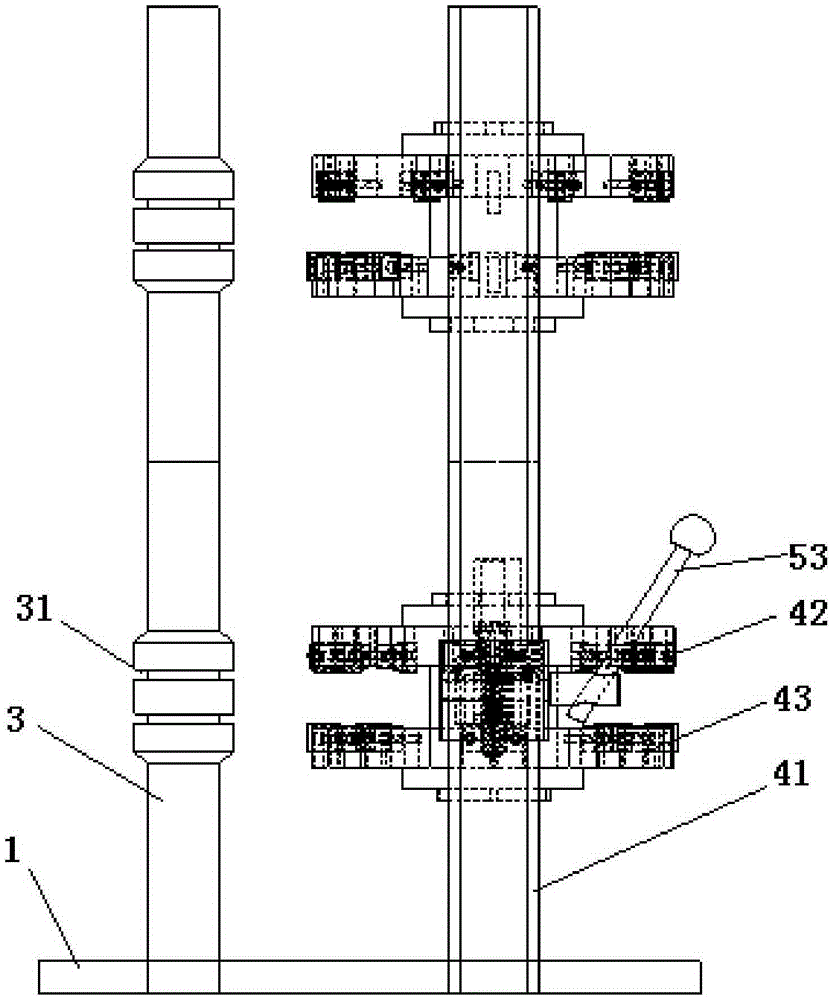

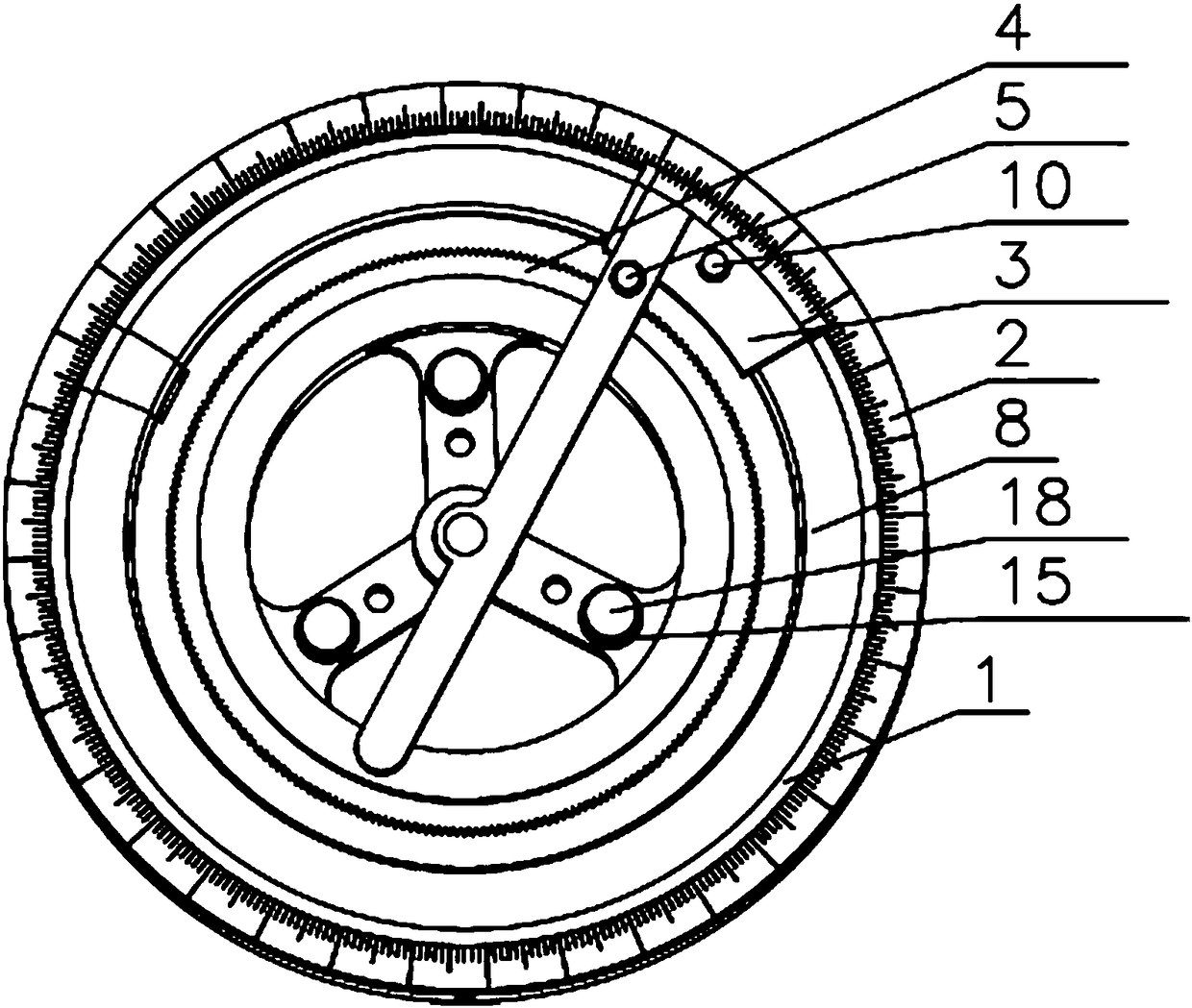

A cutter head suitable for cyclone turning and peeling machine and its roundness detection method

ActiveCN111590392BImprove the finishMeasure Qualitative and QuantitativeMeasurement/indication equipmentsTurning machinesTool bitEngineering

The invention discloses a cutter head suitable for a whirlwind type turning and peeling machine and a method for detecting the same roundness thereof. The cutter heads are all set towards the center point of the cutter head body, and each cutter head is equipped with a blade, and also includes a tool setting instrument set at the same center point as the cutter head body; the tool setting instrument includes several a measuring foot corresponding to the number of said knife rests and in contact with the blade on the corresponding said knife rest, each measuring foot is marked with a scale of the distance of the measuring foot relative to the central point of said cutterhead body, It is used to display the distance between the measuring foot and the center point of the tool setting instrument. The invention can measure the radius parameters of four blades relative to the turning center at the same time, and quickly measure the concentricity parameters of the four blades qualitatively and quantitatively.

Owner:BAOSHAN IRON & STEEL CO LTD

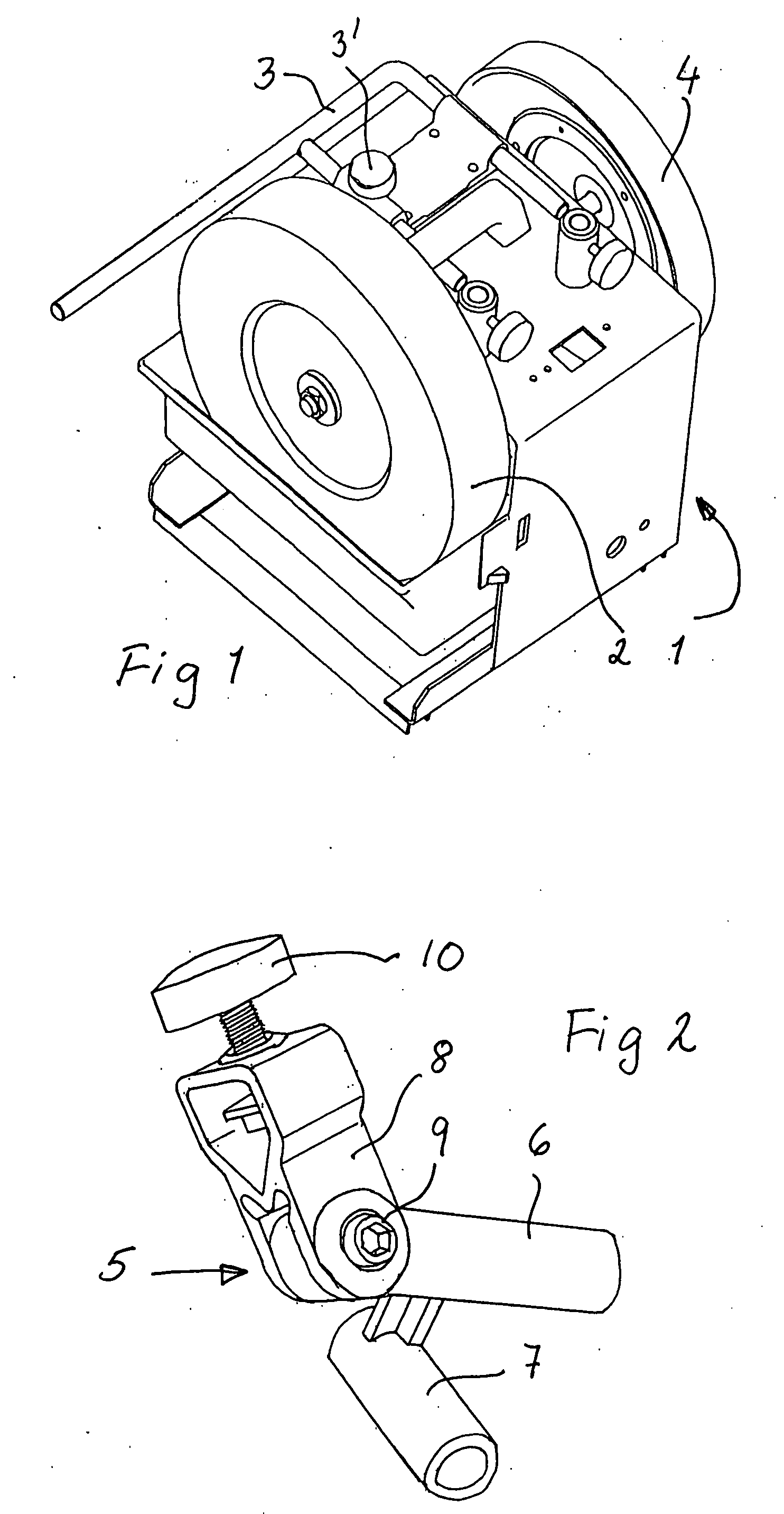

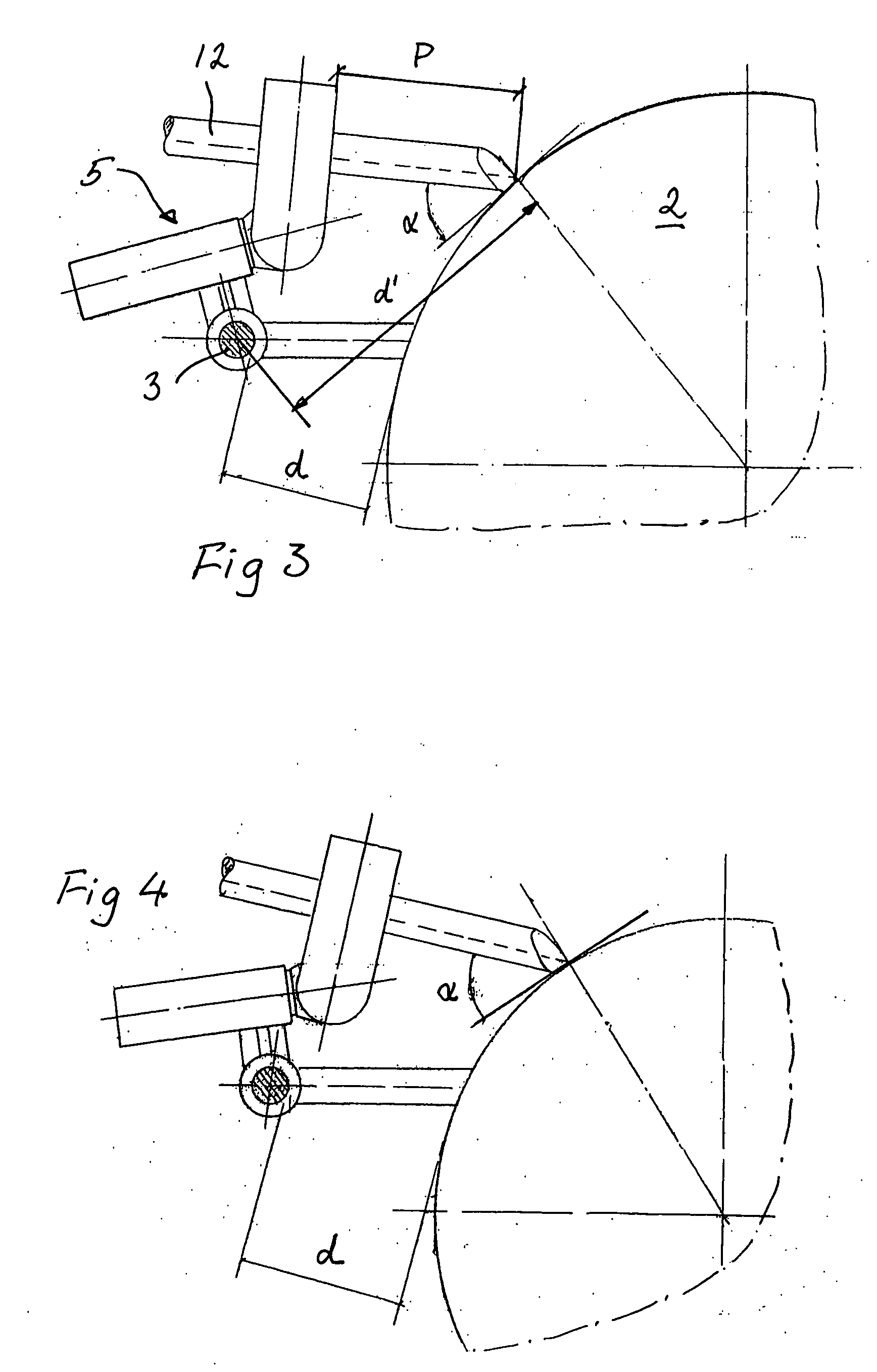

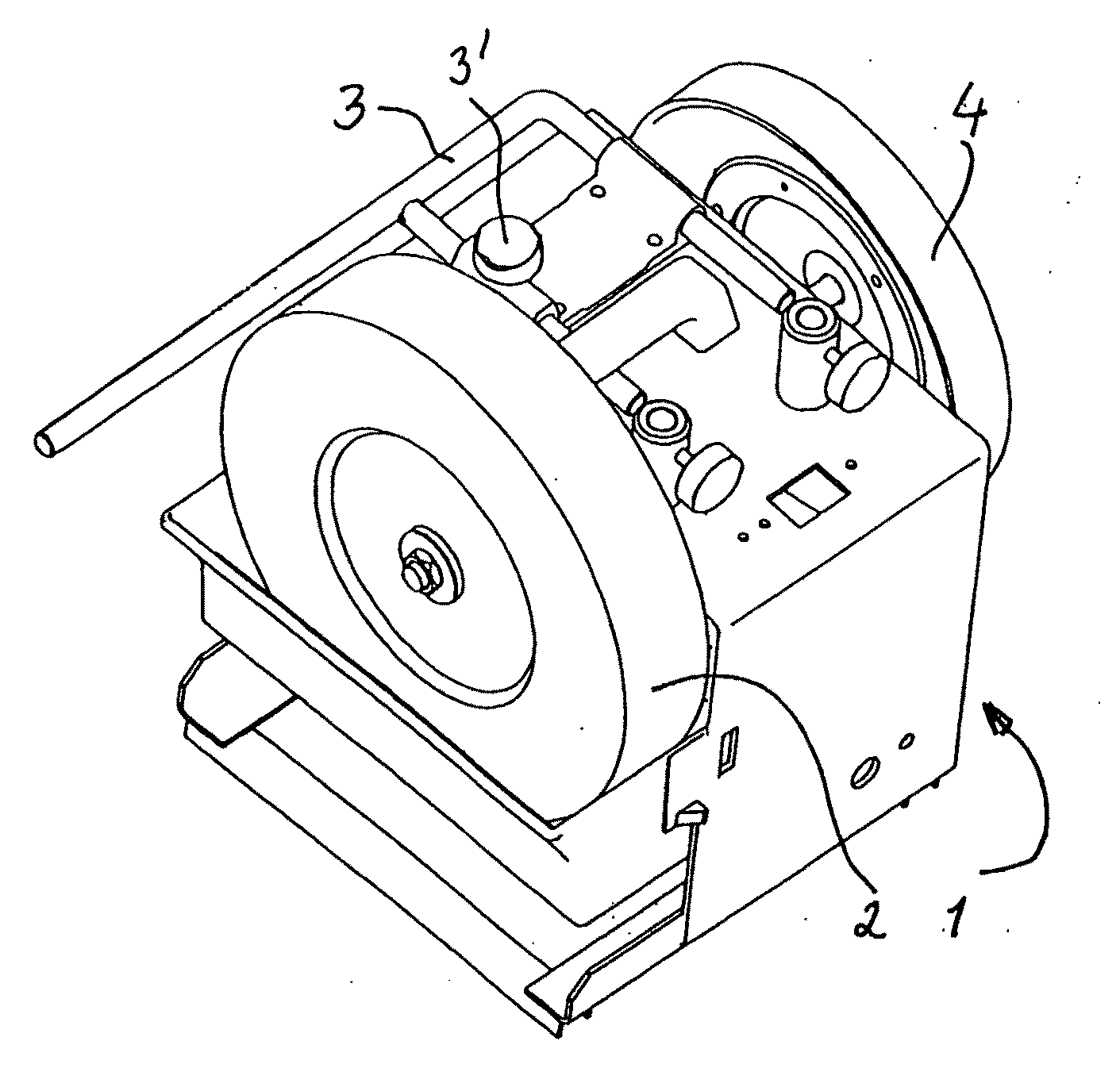

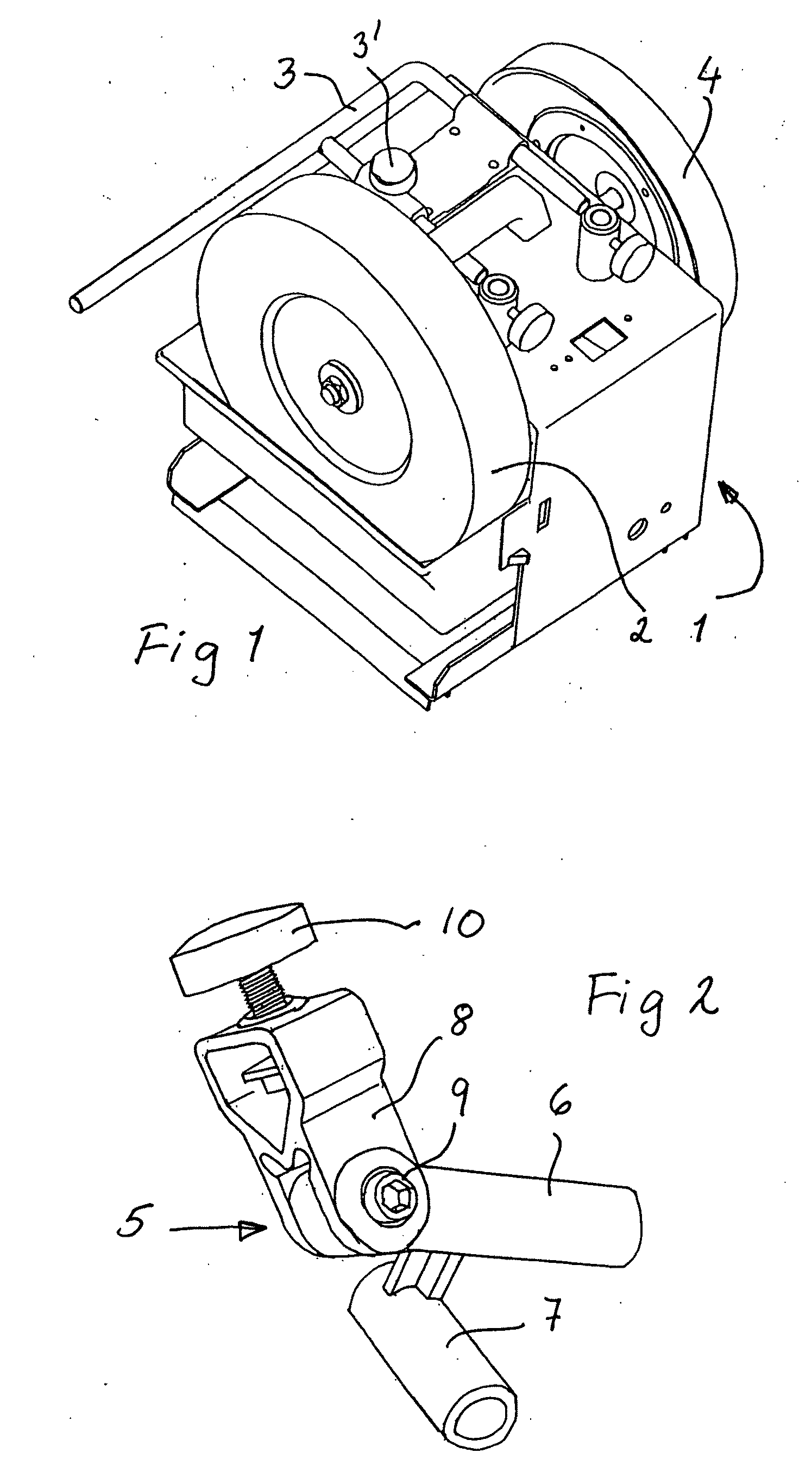

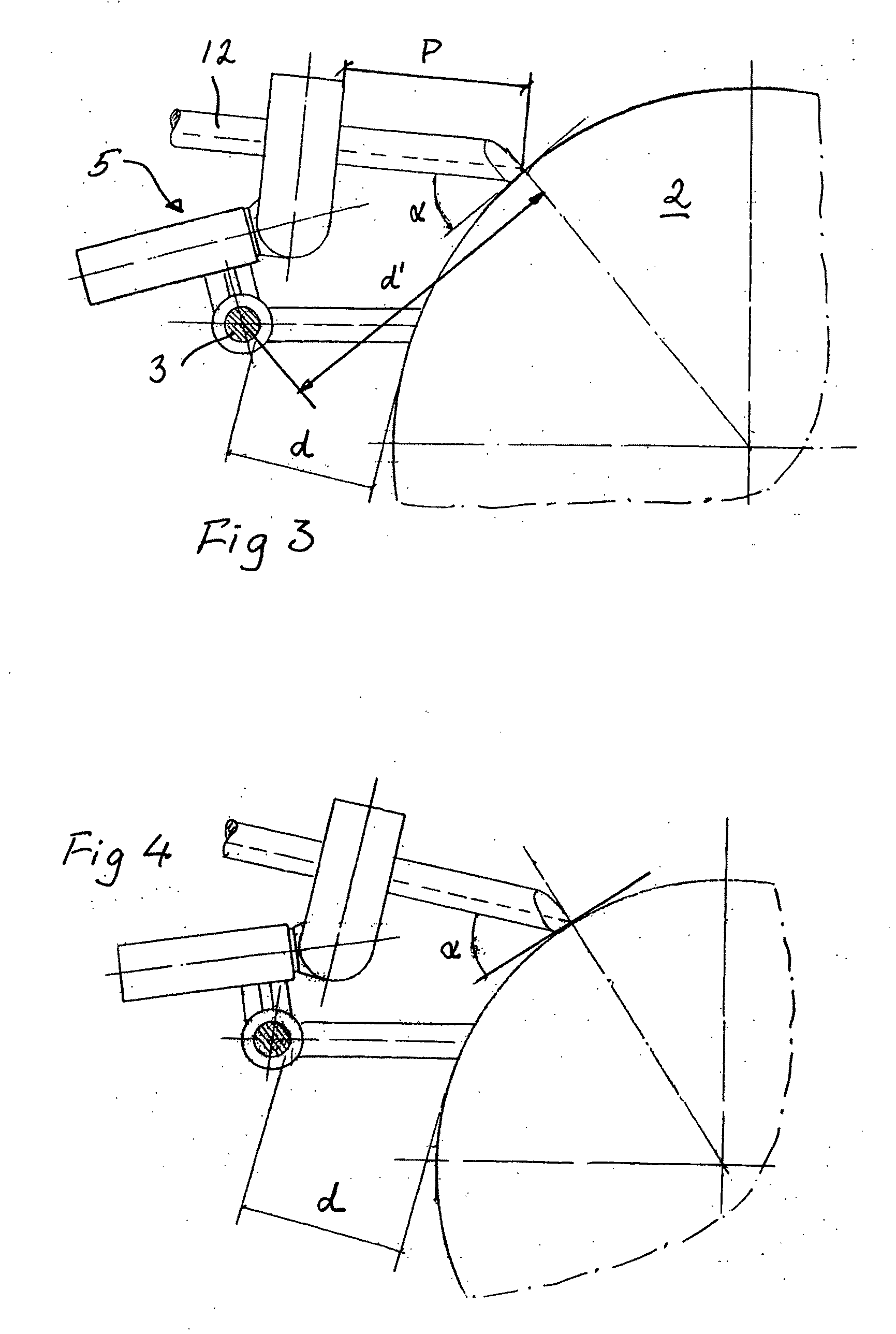

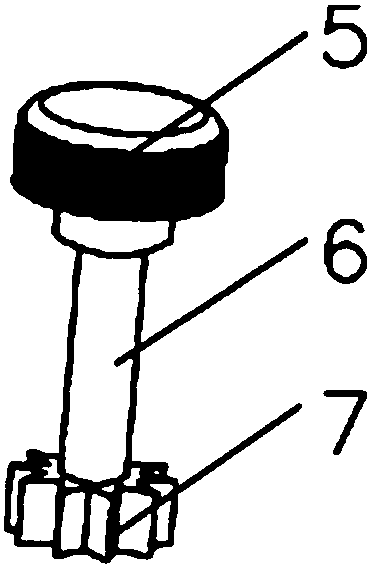

Tool setter for a grinding machine

ActiveUS20070190902A1Improve versatilityMore tool edge shapeGrinding drivesPlaning/slotting toolsEngineeringMechanical engineering

A device or tool setter has the purpose of setting the position of a support bar, adjustably connected to a grinding machine, in relation to a rotatable grindstone of the machine for obtaining a desired edge angle of a tool supported for grinding by the support bar. The device is provided with discs for defining two contact points with the grindstone and a hole for connection to the support bar.

Owner:TORMEK

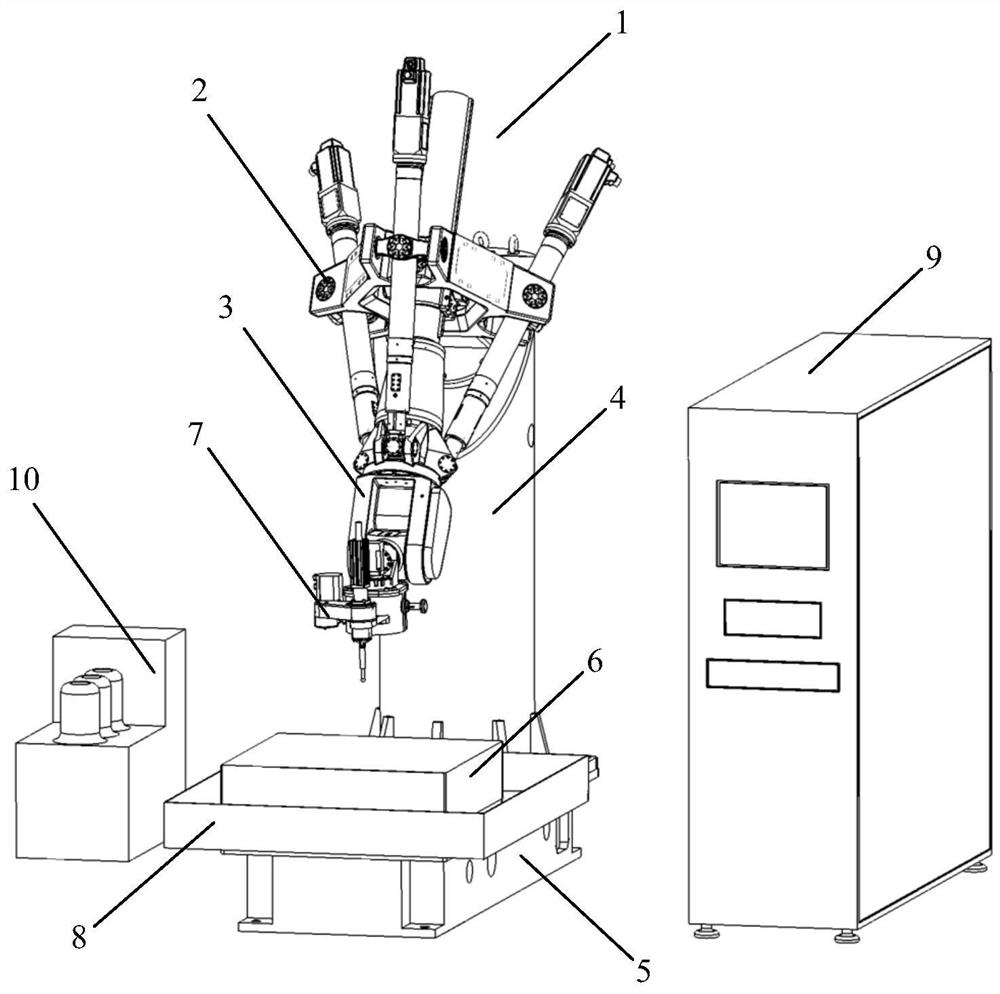

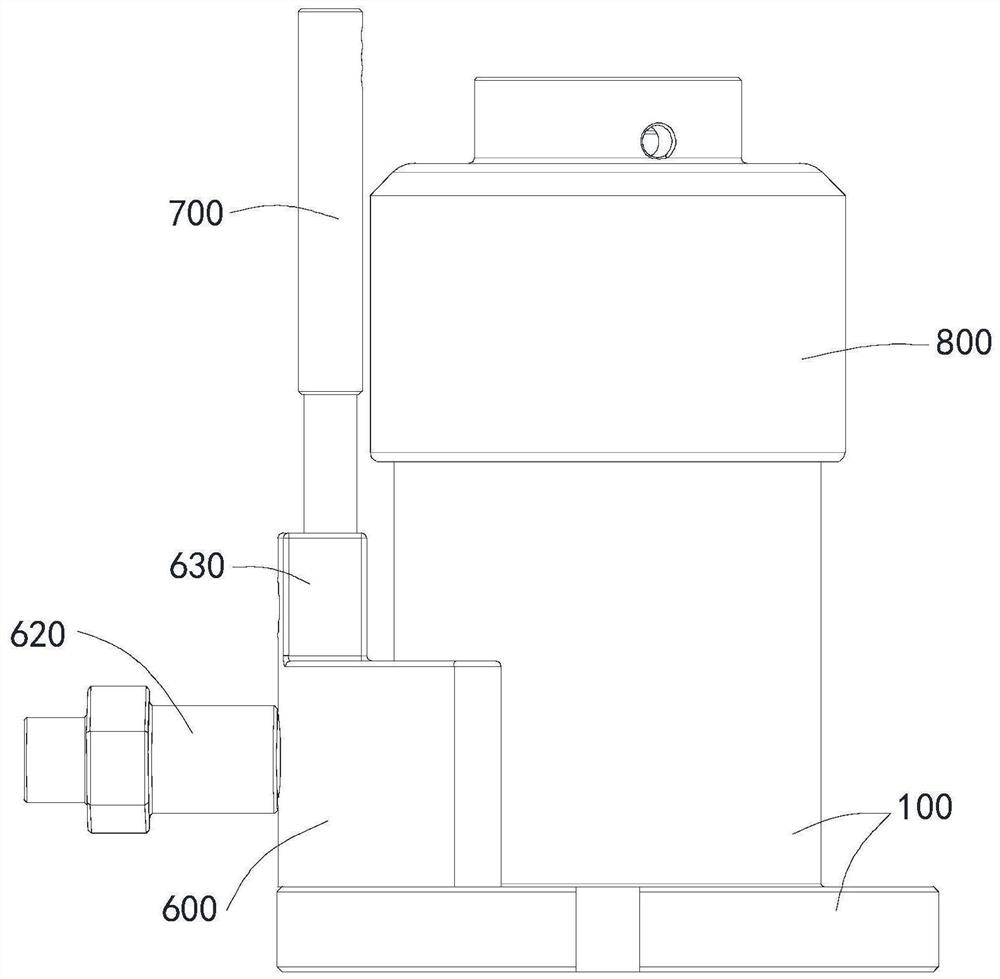

A planter tool magazine for realizing automatic tool change and automatic tool change method

ActiveCN112022386BRealize the need for automatic tool changeMeet processing needsDental implantsCircular discRobotic arm

A planter tool magazine for realizing automatic tool change of the present invention comprises a tool magazine room, the side of the knife magazine room is provided with a knife magazine door which can be opened and closed, and a knife holder base is arranged inside the knife magazine room, and There is a rotating mechanism, on which there is a disc tool holder, on which there are several layers of tool holders uniformly distributed along its circumference, and a tool magazine bracket is provided in the tool magazine room, and a lifting mechanism is provided on the tool magazine bracket And the pressing mechanism, the pressing mechanism is arranged above the disc knife holder, the lifting adjustment of the pressing mechanism is realized through the lifting mechanism, and then the pressing mechanism is used to realize the pressing cooperation with the tool change key on the mechanical arm of the planter, the disc knife holder and the knife magazine door There is a tool setter for aligning the knives on the robot arm of the planter in between. The present invention can cooperate with realizing the requirement of automatic tool change of the mechanical arm of the implanter, greatly improves the degree of automation of the tool magazine system of the implanter, improves the processing efficiency of the implant, and reduces the production cost. The invention also proposes an automatic tool changing method.

Owner:上海微云实业集团有限公司

System and method for automatically recording geometric parameters of numerical-control tools

InactiveCN102662352BLess data entryImprove work efficiencyProgramme controlComputer controlControl engineeringProcess engineering

The invention relates to the technical field of numerical-control machining and discloses a system and a method for automatically recording geometric parameters of numerical-control tools. The method includes that an industrial computer transmits tool geometric parameters acquired by a numerical tool setter to a numerical-control tool management system; the numerical-control tool management system analyzes tool geometric parameters, tool codes and numerical-control machining center codes corresponding to the tools from received data, converts tool geometric parameters and tool codes into a text corresponding to the numerical-control machining center codes and identifiable by the numerical-control system according to the numerical-control machining center codes, and transmit the text to a DNC (direct numerical control) server; a numerical-control machining center downloads the text identifiable by numerical-control system types of the numerical-control machining center from the DNC server, analyzes the text and updates data corresponding to the tools according to acquired data analyzed. During the whole recording process of the tool geometric parameters, the tool codes and the numerical-control machining center codes are recorded only during tool aligning, so that recorded data are few, work efficiency is improved, error is small and safety is high.

Owner:CHONGQING UNIV

Multi-axis linkage mechanical device used for finely repairing micro-defects on surface of optical element

ActiveCN102380913BAccurate observationWorking accessoriesStone-like material working toolsLaser targetEngineering

The invention provides a multi-axis linkage mechanical device used for finely repairing micro-defects on a surface of an optical element and relates to a mechanical device for repairing the optical element. The mechanical device is used for solving the problem of the growth of micro-defects generated during a high-energy beam intense laser targeting process of the optical element. A vertical element is vertically mounted on a plate base; an X-axis linear unit is mounted on the plate base; the X-axis linear unit is connected with a Y-axis linear unit through an XY linear unit connector; the Y-axis linear unit is connected to a C-axis rotating unit through two connectors; an operating platform is mounted on the C-axis rotating unit; a fixture body is mounted on the operating platform; a Z-axis linear unit is mounted on the vertical element; the Z-axis linear unit is connected to a B-axis rotating unit through two connectors; a spindle connector is mounted on the B-axis rotating unit; an electric spindle clamping fixture is mounted between a first spindle clamping element and a second spindle clamping element; and a CCD (Charge Coupled Device) tool setter and a monitoring device are mounted on a main mounting surface of the vertical element. The multi-axis linkage mechanical device is used for repairing the surface of the optical element.

Owner:HARBIN INST OF TECH

Kit and method for preventing a swimming pool cleaner from becoming caught on a main drain cover

ActiveUS10619372B2Avoid disadvantagesSimple and inexpensive to manufactureGymnasiumMetal working apparatusSuction forceEnvironmental engineering

A kit for preventing a swimming pool cleaner from becoming caught on a main drain cover of a swimming pool including a flexible clip-on protective device with a printed company logo and an installation tool with three cylindrical retainers. The installation tool mounts the clip-on protective device onto the main drain cover to force the swimming pool cleaner to tilt to one side, so that the suction forces of the swimming pool cleaner and the main drain will not interact with each other. The installation tool is made by injection molding with a uniform thickness of 0.165 inch.

Owner:ALBAUGH II HARRY

Tool setter of sharpening grinding wheel of semiconductor wafer

InactiveCN101633152BReduce idle travelImprove grinding efficiencySemiconductor/solid-state device manufacturingLapping machinesEngineeringSharpening

The invention relates to a tool setter of a sharpening grinding wheel of a semiconductor wafer. The invention can complete the tool setting of the grinding wheel before the semiconductor wafer is sharpened, shorten the idle stroke of a main shaft of the grinding wheel during sharpening and enhance the sharpening efficiency of the semiconductor wafer. The tool setter of the sharpening grinding wheel of the semiconductor wafer comprises the main shaft of the grinding wheel, a feeding device of the main shaft of the grinding wheel, the grinding wheel and a sucking disk. The tool setter of the sharpening grinding wheel of the semiconductor wafer is characterized in that a microswitch with determined height is arranged in a space on the lower surface of the grinding wheel and the upper surfaceof the sucking disk, one end of the microswitch is provided with a switch contact, and the microswitch is connected with a driving device by a connecting piece arranged at the side part.

Owner:WUXI MACHINETOOL +1

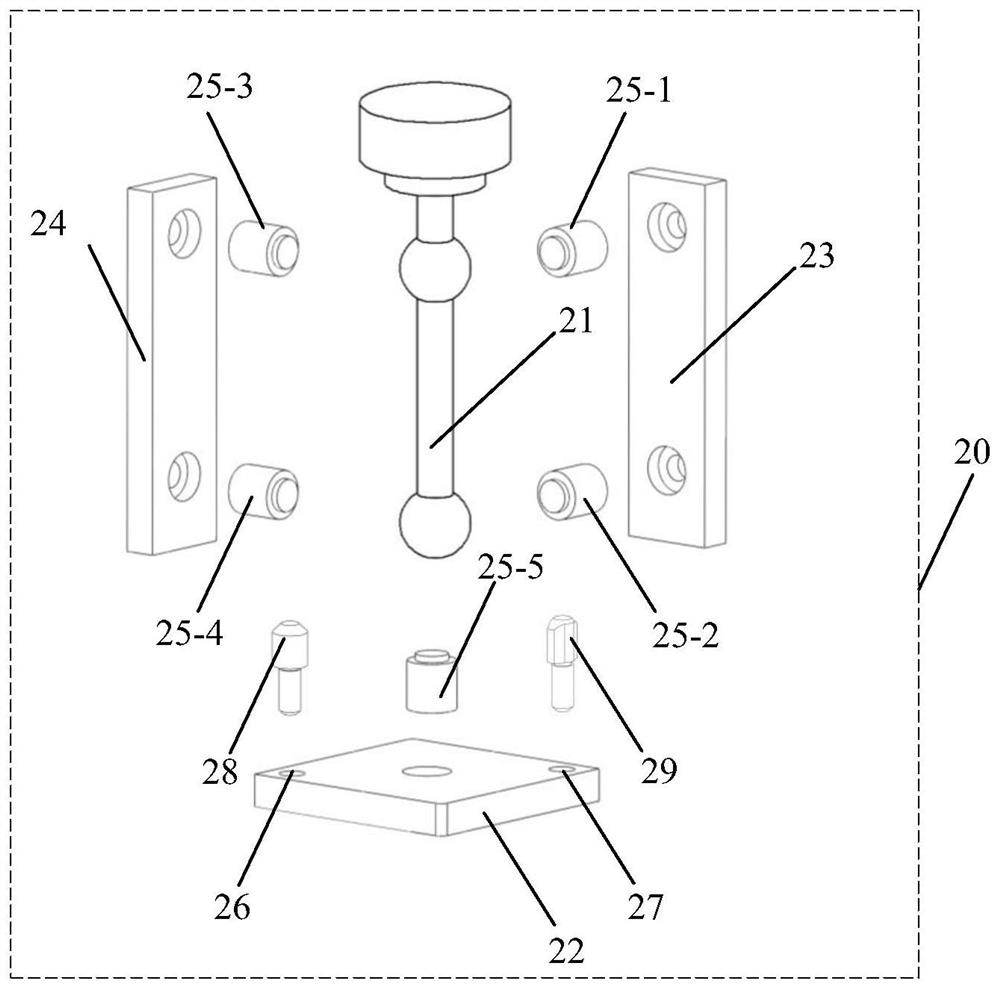

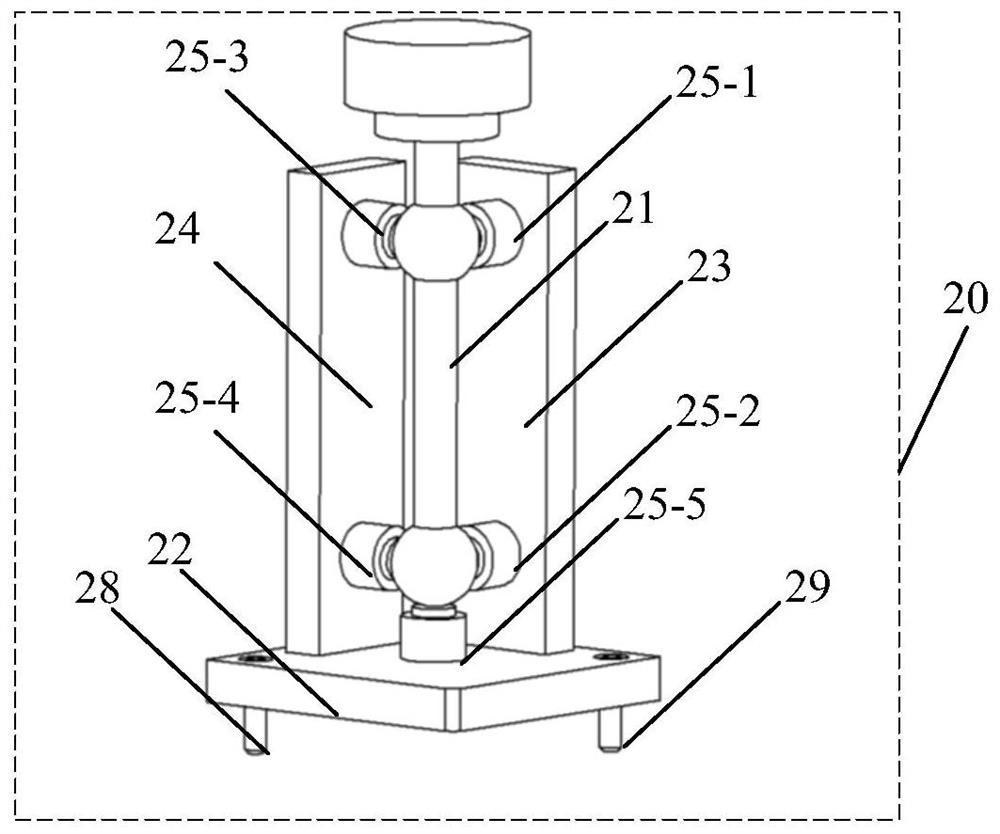

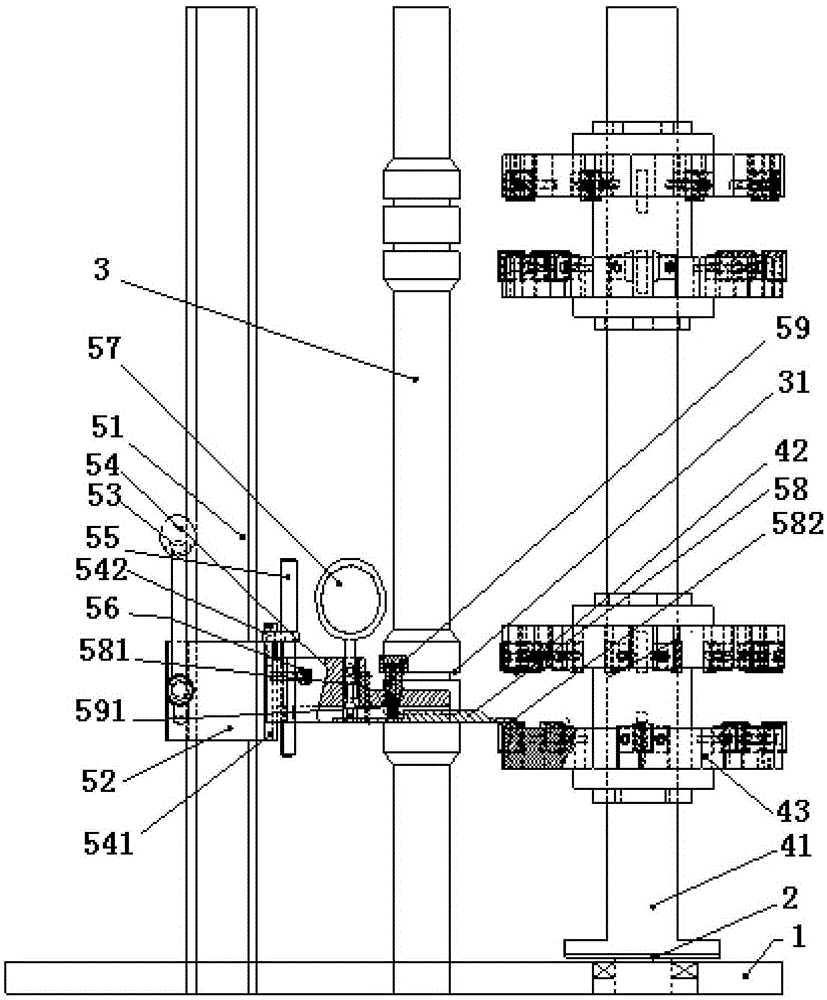

A six-degree-of-freedom hybrid polishing robot pose accuracy calibration device and method

ActiveCN108582047BEasy to measureThe calculation result is accurateProgramme-controlled manipulatorOptical surface grinding machinesSpatial OrientationsControl engineering

The invention discloses a six-degree-of-freedom hybrid polishing robot posture accuracy calibration device and method. The device includes a spherical inspection rod, a bottom plate, a vertical board A, a vertical board B and a workbench, and the spherical inspection rod is fixedly installed on the polishing machine of the polishing robot. At the end of the actuator; the vertical plate A and the vertical plate B are vertically fixed on the bottom plate, and the vertical plate A and the vertical plate B are kept perpendicular to each other; the upper and lower sides of the vertical plate A and the vertical plate B are respectively provided with installation holes, and the installation holes are A tool setting device is installed, and a mounting hole and a tool setting device are also provided at the center of the bottom plate; pin holes are set on the bottom plate and are fixedly connected to the workbench through a pin connection. The pose accuracy calibration method of the present invention only needs to detect the five-dimensional pose error of the end effector, and only needs to keep the spatial orientation of the axis of the spherical test rod unchanged for measurement, so that all controllable degrees of freedom of the robot can be traversed, and zero point errors of all driving joints can be realized. The identification and measurement process are simple, and it is very suitable for robot accuracy calibration under industrial field application conditions.

Owner:TIANJIN UNIV

Shaft cutting tool sharpening machine

InactiveCN103567817BLow costSmall body designGrinding drivesOther manufacturing equipments/toolsDrive shaftGrinding wheel

Owner:JINGJIANG CHANGYUAN HYDRAULIC MACHINERY

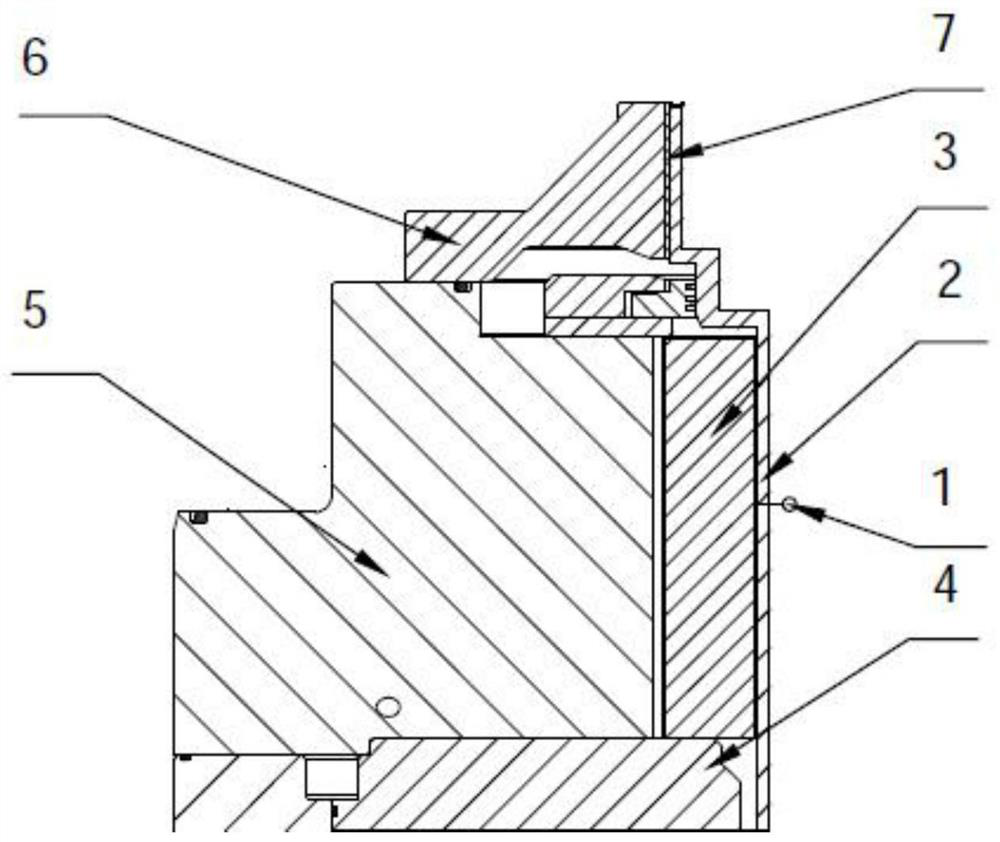

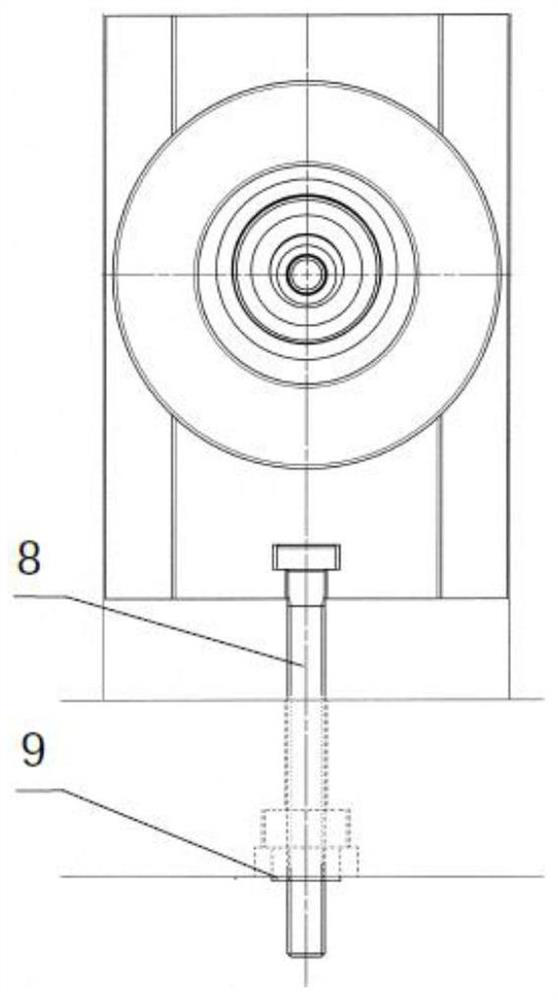

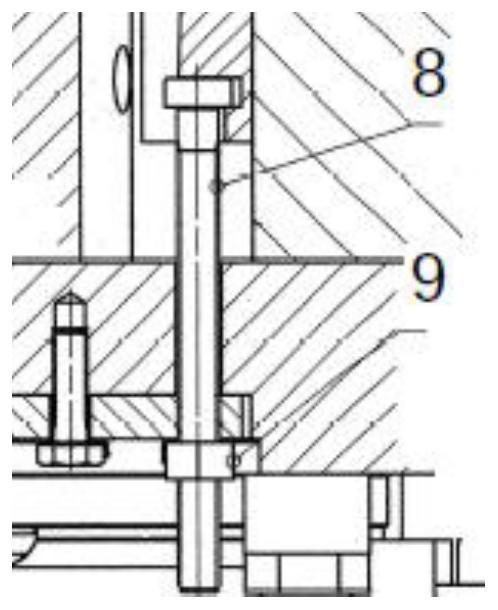

Composite knife adjustment device

ActiveCN103785867BSimple structureFast and efficient elastic functionPrecision positioning equipmentMeasurement/indication equipmentsEngineeringMechanical engineering

The invention discloses a composite tool setting and adjudging device which comprises a tool setter base, a rotary tool apron plate, a cylindrical tool-setting basic shaft and an adjusting and measuring component. The rotary tool apron plate is rotationally arranged on the upper surface of the tool setter base. The tool-setting basic shaft is fixed through the lower end and is vertically arranged on the upper surface of the tool setter base. A plurality of tool-setting reference surfaces are arranged on the peripheral surface of the tool-setting basic shaft. The adjusting and measuring component comprises a rough adjusting component and a fine adjusting component arranged on the rough adjusting component. The rough adjusting component comprises a rough adjusting screw, a ringent nut and a fixing handle. The fine adjusting component comprises a fine adjusting block, a fine adjusting screw, a fastening bolt, a dial indicator, a measuring press rod and a change-over switch. The composite tool setting and adjudging device is simple and reasonable in structure; the contact surface of the measuring press rod is parallel to the processing and rotating surface of a blade, and tool setting reference is provided, so that the device is accurate in tool adjusting, free from inter-component interference, simple and convenient to operate and high in adjusting efficiency.

Owner:GUANGXI YUCHAI MASCH CO LTD

Tool setter for a grinding machine

ActiveUS20100068979A1Improve versatilityMore shapeGrinding drivesPlaning/slotting toolsEngineeringMechanical engineering

A device or tool setter has the purpose of setting the position of a support bar, adjustably connected to a grinding machine, in relation to a rotatable grindstone of the machine for obtaining a desired edge angle of a tool supported for grinding by the support bar. The device is provided with discs for defining two contact points with the grindstone and a hole for connection to the support bar.

Owner:TORMEK

Process for mounting radial bush tool

InactiveCN113524106AGuaranteed service lifeStable and accurate measurementMechanical measuring arrangementsMetal-working hand toolsMechanical engineeringMechanics

The invention relates to a process for mounting a radial bush tool of a shaft seal pump. The process is characterized in that radial bushes generate radial displacement by adjusting the length of bolts, the length change of the bolts is in direct proportion to the radial displacement of the radial bushes, a pointer of a mechanical dial indicator mounted on the tool is changed while the radial bushes generate displacement, and the variation of the radial displacement of the radial bushes is visually reflected by reading measured numerical values. The method comprises the following steps. According to the process, it is guaranteed that each radial bush has the same position pitch circle when matched with a shaft, the dial indicator is placed in an inner cavity of the radial bush tool, the position change of the radial bushes in the center adjusting process is monitored in real time, the reading of the dial indicator gradually returns to zero in the radial bush adjusting process, and the position change of the radial bushes is directly and clearly reflected; and the process method solves the problems that the position of the radial bushes is uncontrollable and the inner diameters of the radial bushes are difficult to measure in the adjustment process of the radial bushes.

Owner:HARBIN ELECTRIC POWER EQUIP

A CNC tool intelligent tool setting monitoring method

ActiveCN112264836BEasy to debugReduce tool setting timeAutomatic control devicesMeasurement/indication equipmentsMachine partsControl engineering

A CNC tool intelligent tool setting monitoring method, including step S1 - type change operation and step S2 - automatic tool setting, wherein step S1 involves installing a fixed tool setting instrument, setting the coordinates of the tool setting instrument, tool setting axis tool setting and program Setting, step S2 includes step S2.1 - replace the tool and install it on the spindle, select the tool setting switch parameter in the macro parameter and change it to 1, step S2.2 - select the tool to be set, and set the corresponding macro parameter Change it to 1 to complete the tool setting operation, step S2.3 - press the cycle start button of the processing program. The system is easy to debug. When changing the model, you only need to find the difference between the workpiece and the tool setting instrument. The macro program is used to judge the mechanical coordinates. For CNC machining parts, automatic tool setting, automatic tool compensation, and tool wear detection can be realized when the tool is changed. , Tool damage and fracture detection, to eliminate the loss of quality cost caused by tool errors, reduce the time for tool setting of parts, and easy to operate.

Owner:内江金鸿曲轴有限公司

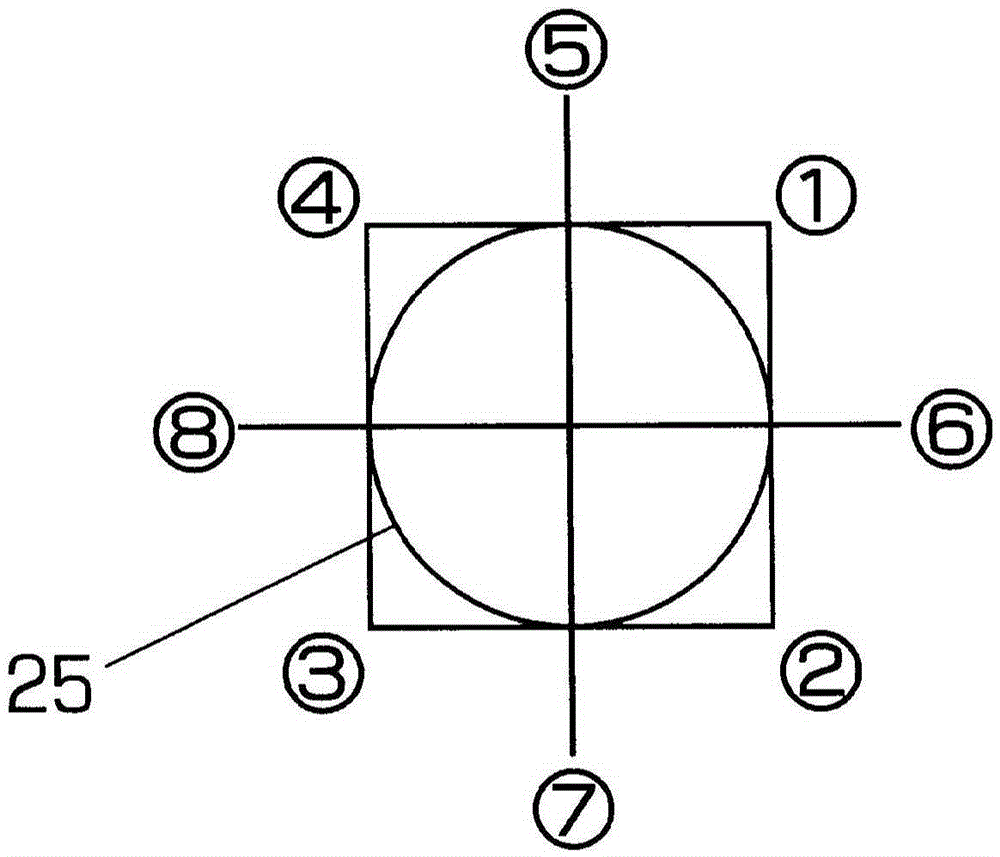

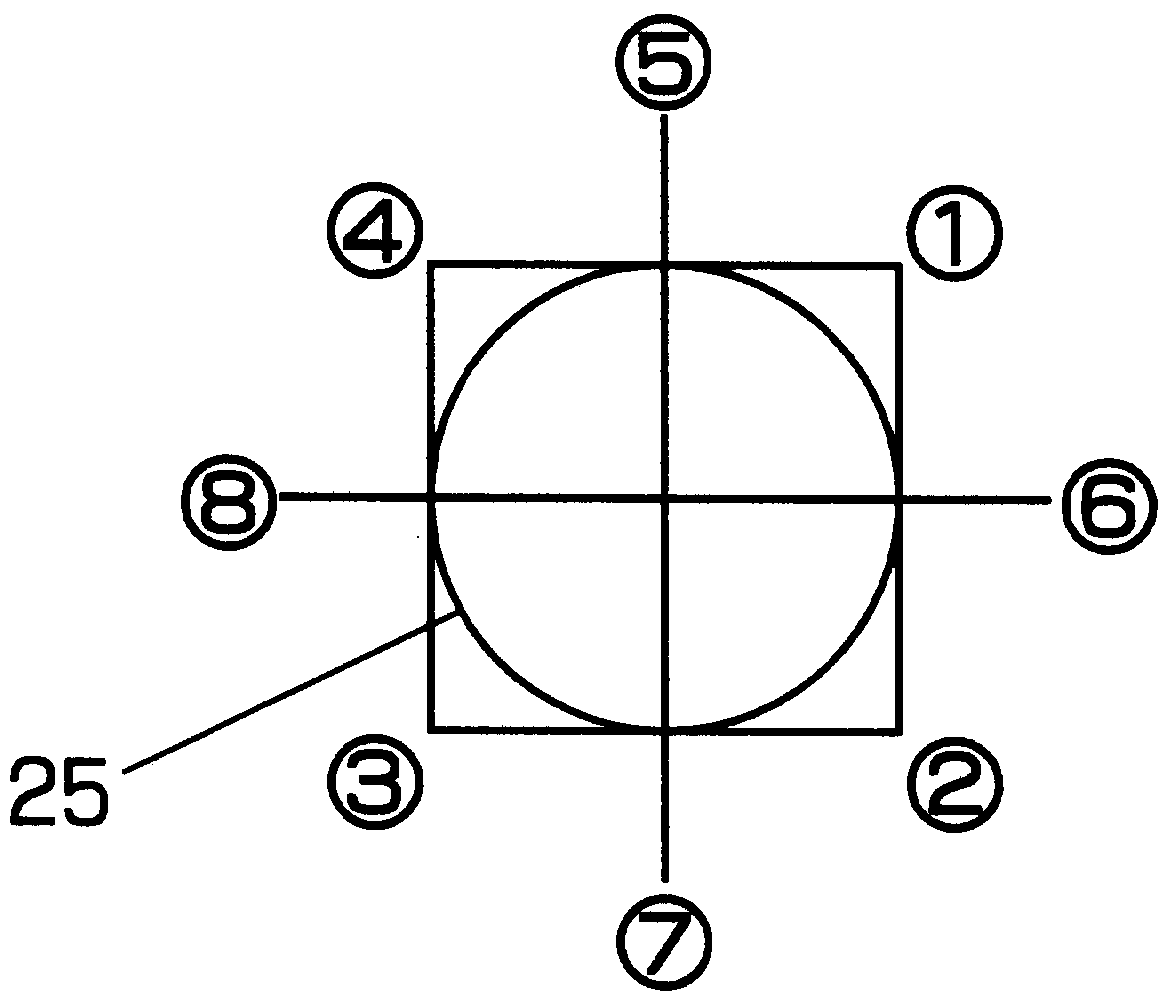

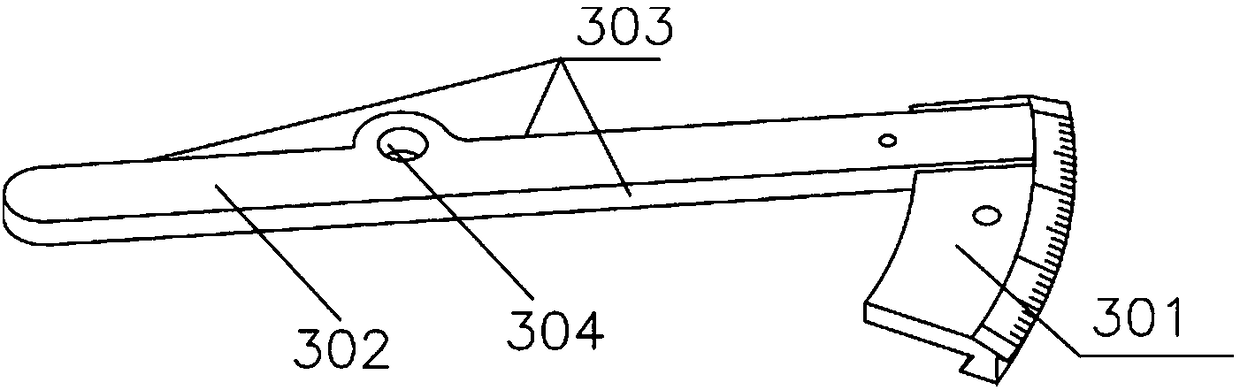

Indexing tool

PendingCN108214098AImprove applicabilityReduce the need for double selectionPrecision positioning equipmentTool bitVernier scale

The invention relates to the field of key groove machining, and provides an indexing tool. The indexing tool comprises a base, and the base is provided with a circular main dial and installing holes;a vernier scale is installed on the base and can slide along the circular main dial, and the circular main dial and the vernier scale are locked through a locking mechanism; and the vernier scale is provided with a machining benchmark. The indexing tool is installed on a to-be-machined workpiece and installed on machining equipment together with the to-be-machined workpiece. The indexing tool is provided with the circular main dial and the vernier scale, and therefore indexing of the to-be-machined workpiece is achieved by adjusting the position of the vernier scale on the circular main dial and always ensuring that the machining benchmark on the vernier scale is located in the movement journey direction of a tool bit of the machining equipment. The indexing tool can be suitable for indexing shaft parts and hole parts simultaneously and can be used on any equipment with an indexing tool installing station, the two-way selection requirements between the equipment and the workpiece are reduced, and the applicability of the equipment and the applicability of the workpiece are enhanced.

Owner:HUNAN ZHONGZHI CHANGTIAN HEAVY IND TECH

Installation tool for clamping rings

ActiveUS11273543B2Sufficient and not excessive forceEliminate manual operationLine/current collector detailsWire toolsGear wheelDisplay device

An installation tool for installing and uninstalling lock rings, bolts, cable lugs, hose clamps is provided. The installation tool comprises a frame assembly and a driving member secured to the frame assembly. The installation tool also comprises a gear assembly operatively coupled to the frame assembly. The gear assembly comprises a plurality of gears which are configured to receive rotational input from the driving member. The installation tool further comprises a jaw assembly operatively coupled to the gear assembly and the frame assembly. The jaw assembly comprises a plurality of jaw members which are configured to receive rotational input from the gear assembly. The installation tool comprises an electronic control unit and an intuitive graphic interface having a touch display. The installation tool ensures precise closing position of the jaw assembly to the tenth of a millimeter.

Owner:SPAZZADESCHI ILARIO GIUSEPPE +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com