Shaft cutting tool sharpening machine

A technology for cutting tools and sharpening machines, which is applied to the parts of grinding machine tools, manufacturing tools, and grinding drives, etc., can solve the problems of tool sharpening, tool scrapping, uneven grinding edges, etc., to improve work efficiency. , The effect of saving tool cost and small body design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

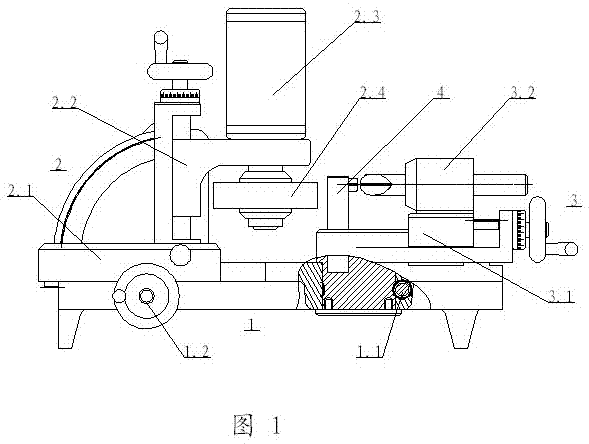

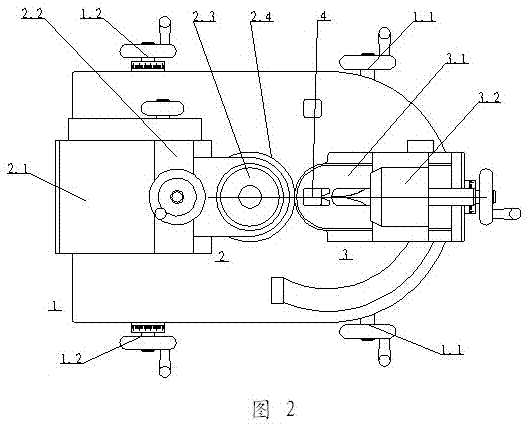

[0013] Embodiments (The following carriages are all composed of seat body and carriage with dovetail groove combined with plug iron sliding fit, including screw nut drive, dial and tightening device, hand wheel, etc., and their structures are well known. technology, not described in detail, or not shown in the accompanying drawings):

[0014] A shaft-type cutting tool sharpening machine, which is connected with the base plate 1 and the base plate 1, consists of a rotating worm 1.1, a feed transmission shaft 1.2, a translation drag table 2.1, a vertical tiltable drag plate 2.2, a motor 2.3, The grinding wheel 2.4, the grinding assembly 2 formed, the tool feeding assembly formed by the journal deflection carriage 3.1, the tool clamping head 3.2, and the tool setting device 4 are formed.

[0015] The middle part of the seat plate 1 is provided with a shaft through hole, and the deep middle part of the through hole traverses the waist of the seat plate to rotate and connect a worm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com