Method and device for automatically setting tool correction value of machine tool

An automatic setting and correction value technology, applied in the direction of automatic control devices, feeding devices, manufacturing tools, etc., can solve problems such as costing a lot of effort and time, changing tool correction values, etc., to reduce the workload, prevent operating errors, prevent The effect of typos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

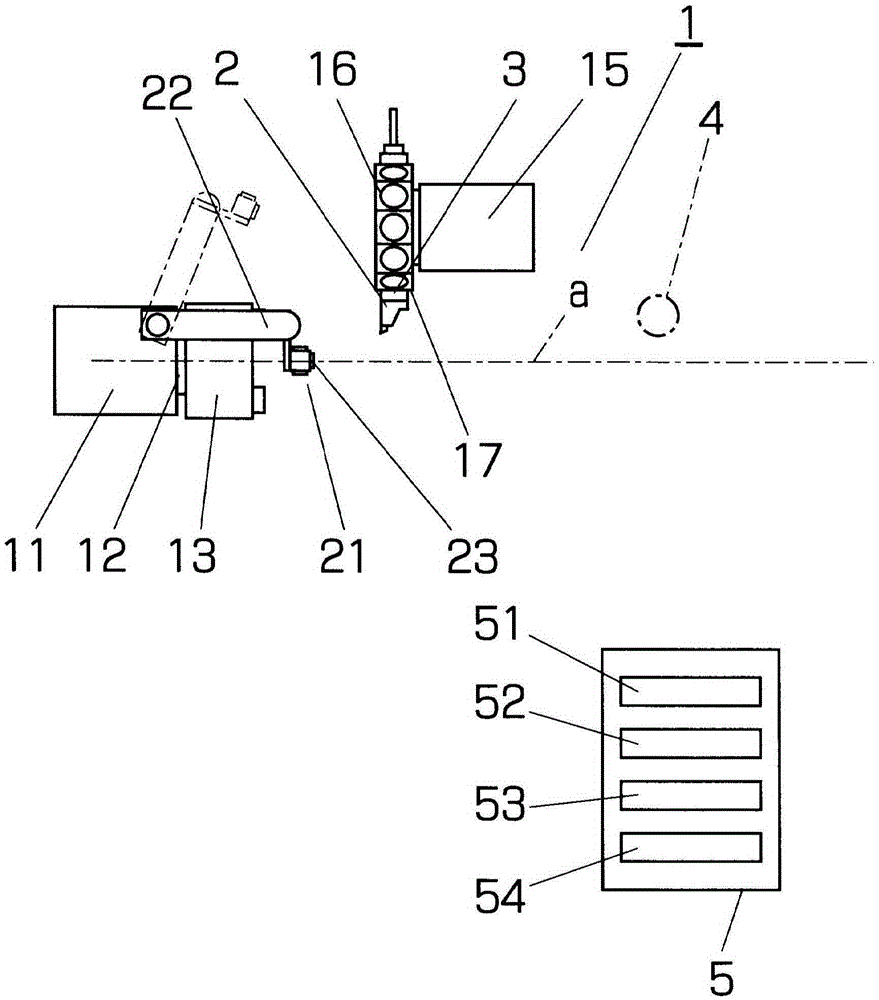

[0036] Hereinafter, embodiments of the present invention will be described by taking an NC turret lathe having a basic structure as an example. The NC turret lathe has a machine body 1 and a controller 5 . The machine main body 1 has a tool post 15 and a spindle 12 supported by a headstock 11 fixed to a bed. A jig 13 for holding a workpiece is attached to the front end of the spindle 12 . The tool holder 15 is a turret tool holder with a turret 16 . A plurality of knives 2 are attached to the turret 16 via holders 3 . The tool post 15 can freely move and locate in the Z-axis direction and the X-axis direction according to the instructions from the controller 5, wherein the Z-axis direction is the direction of the spindle axis a, and the X-axis direction is perpendicular to the Z-axis direction and is parallel to the spindle axis. The direction in which the axis a approaches or departs from.

[0037] A tool setter 21 and its advancing and retreating device 22 are installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com