Process for mounting radial bush tool

An installation process and pad technology, which is applied to manufacturing tools, measuring devices, hand-held tools, etc., can solve the problem of large pitch circle deviation of 5 radial pads, abrasion of motor shaft and radial pads, and burn diameter. To solve problems such as tile and tile surface, it can achieve the effects of high measurement accuracy, guaranteed service life, and intuitive and eye-catching readings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

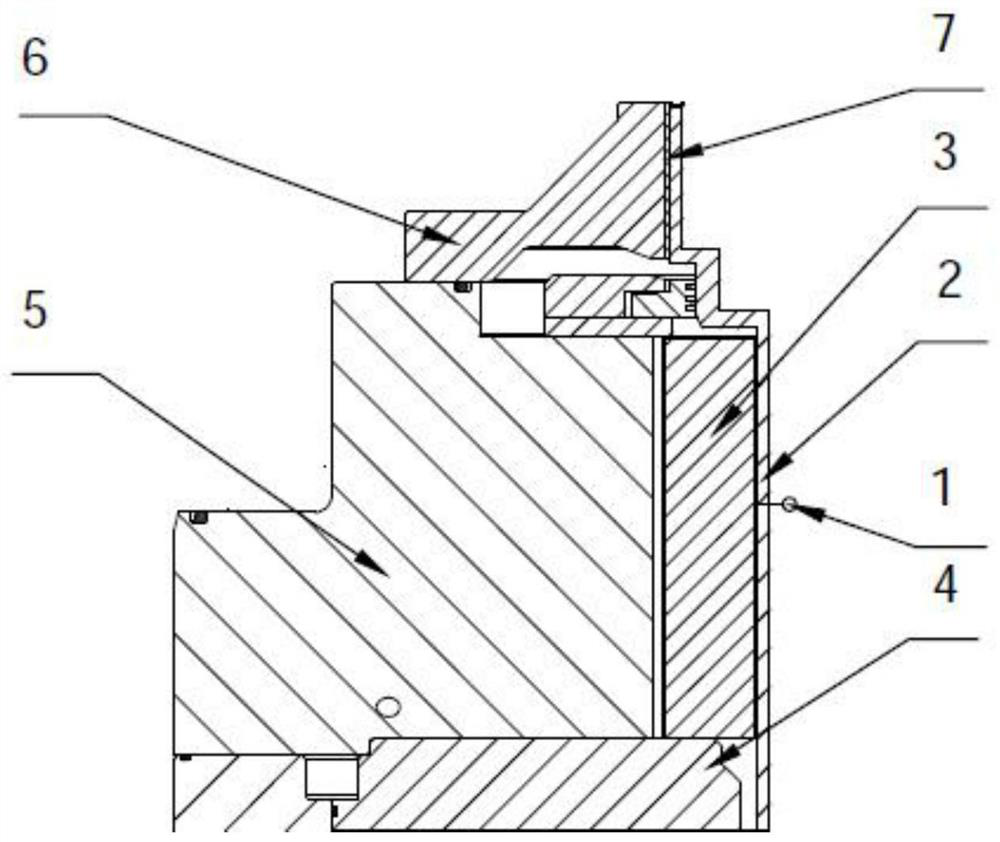

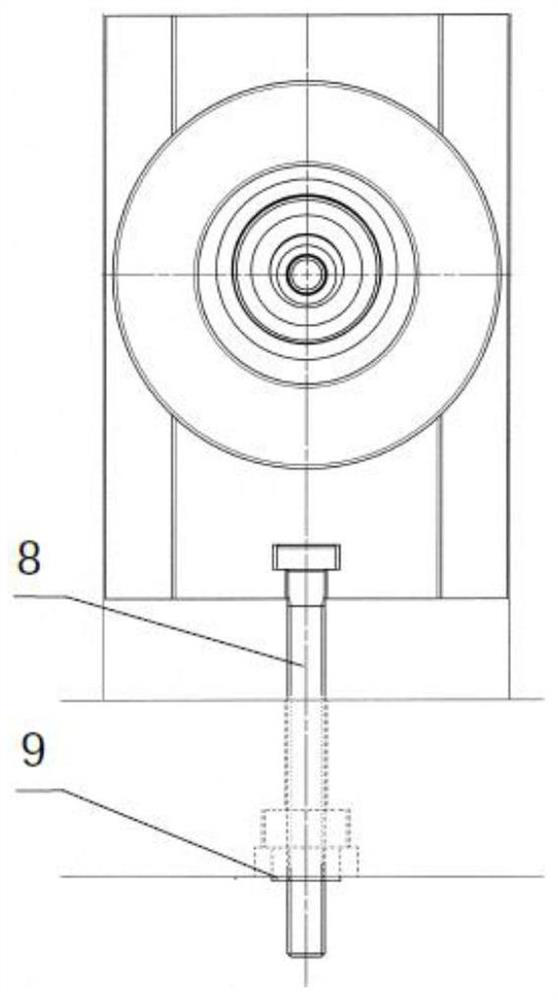

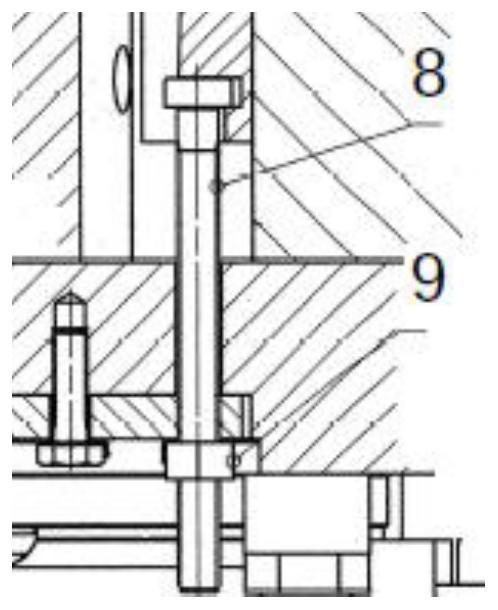

[0023] A radial pad tool installation process, by adjusting the length of the bolt, the radial pad produces a radial displacement, the length change of the bolt is proportional to the radial displacement of the radial pad, and the displacement of the radial pad occurs. At the same time, the pointer of the mechanical dial indicator installed on the tool changes, and by reading the measured value, the change in the radial displacement of the radial pad can be directly reflected. The above method includes the following steps:

[0024] By adjusting the length of the bolt, radial displacement of the radial pad is generated. The change in the length of the bolt is proportional to the radial displacement of the radial pad. When the radial pad is displaced, the mechanical When the pointer of the watch changes, by reading the measured value, the change in the radial displacement of the radial pad can be directly reflected. The above method includes the following steps:

[0025] 1) as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com