Self Venting Setting Tool That Utilizes Wellbore Fluid to Dampen Setting Motion

a setting tool and wellbore technology, which is applied in the direction of earthwork drilling, sealing/packing, and wellbore/well accessories, etc., can solve the problems of venting of the pressure within the setting tool and the undesirable effect of bringing downhole setting tools to the surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

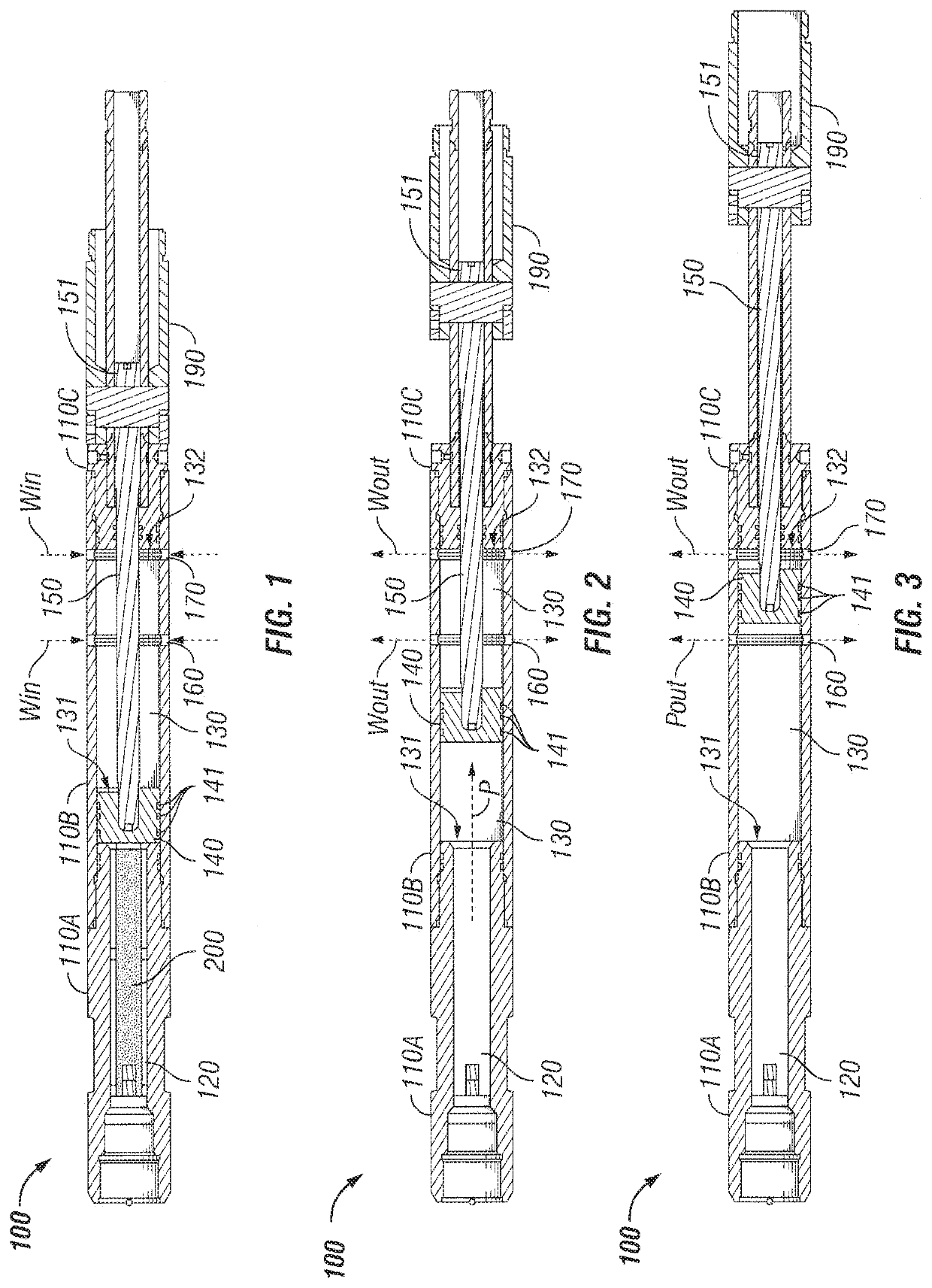

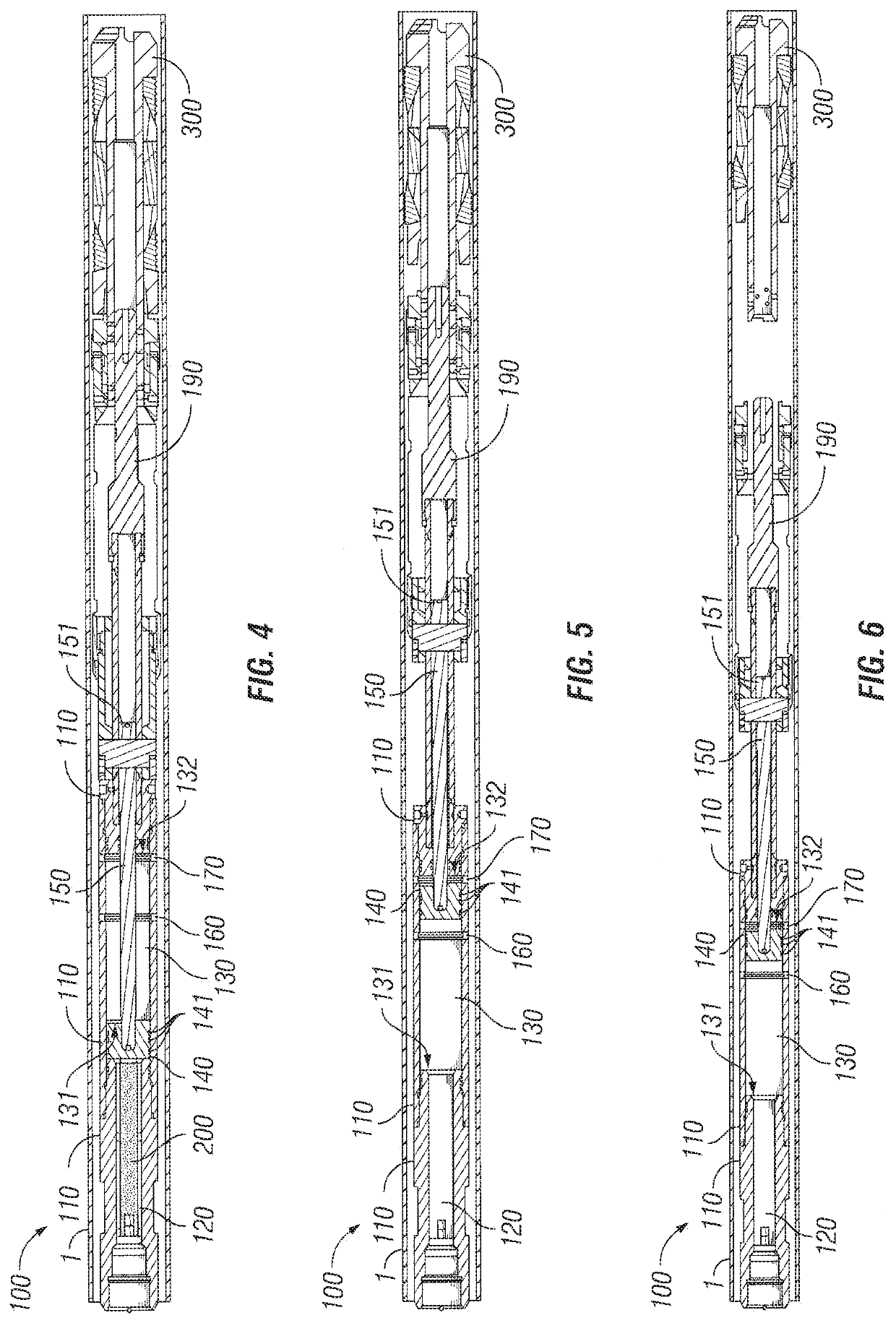

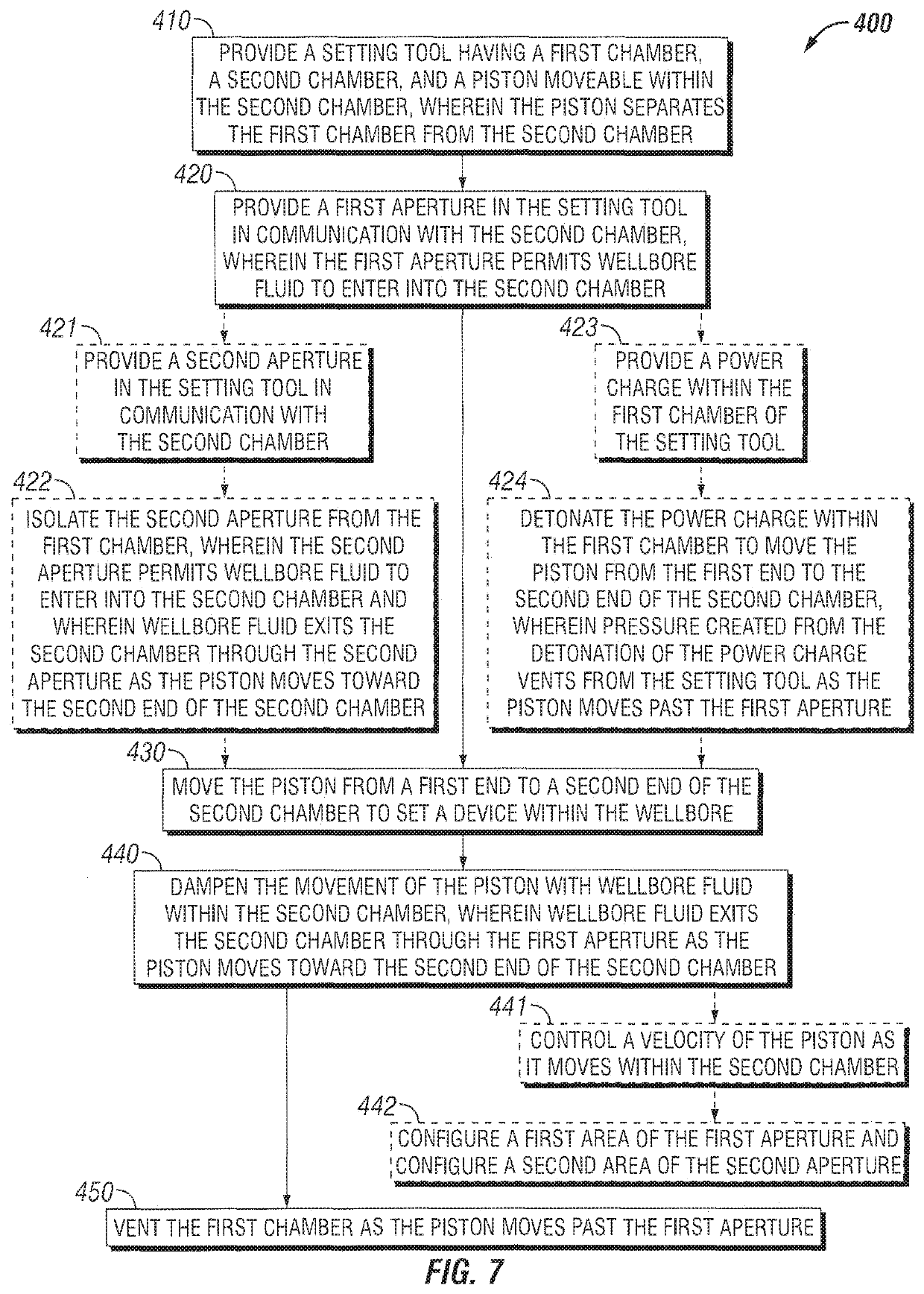

[0019]FIG. 1 shows an embodiment of a setting tool 100. The setting tool includes multiple housing sections 110A, 110B, 110C that collectively form a housing 110 (best shown in FIGS. 4-6). The number of housing sections 110A, 100B, 110C are shown for illustrative purposes only and may be varied as would be appreciated by one of ordinary skill in the art having the benefit of this disclosure. For example, the setting tool 100 may be formed from a single integral housing, but the use of multiple housing sections, such as, but not limited to, 110A, 110B, 110C may aid in the manufacturing of the setting tool 100.

[0020]The setting tool 100 includes a first chamber 120 and a second chamber 130. A piston 140 is positioned within the housing 110 of the setting tool 100. The piston 140 separates the first chamber 120 from the second chamber 130. Seals 141 located on the outside of piston 140 hydraulic isolate the first chamber 120 from the second chamber 130. The piston 140 is moveable withi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com