A six-degree-of-freedom hybrid polishing robot pose accuracy calibration device and method

A technology of calibration device and robot, applied in grinding/polishing equipment, manipulator, optical surface grinder, etc., can solve the problems of high price, small working space, large floor space, etc., to achieve low cost, simple measurement process, measurement and calculation Accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

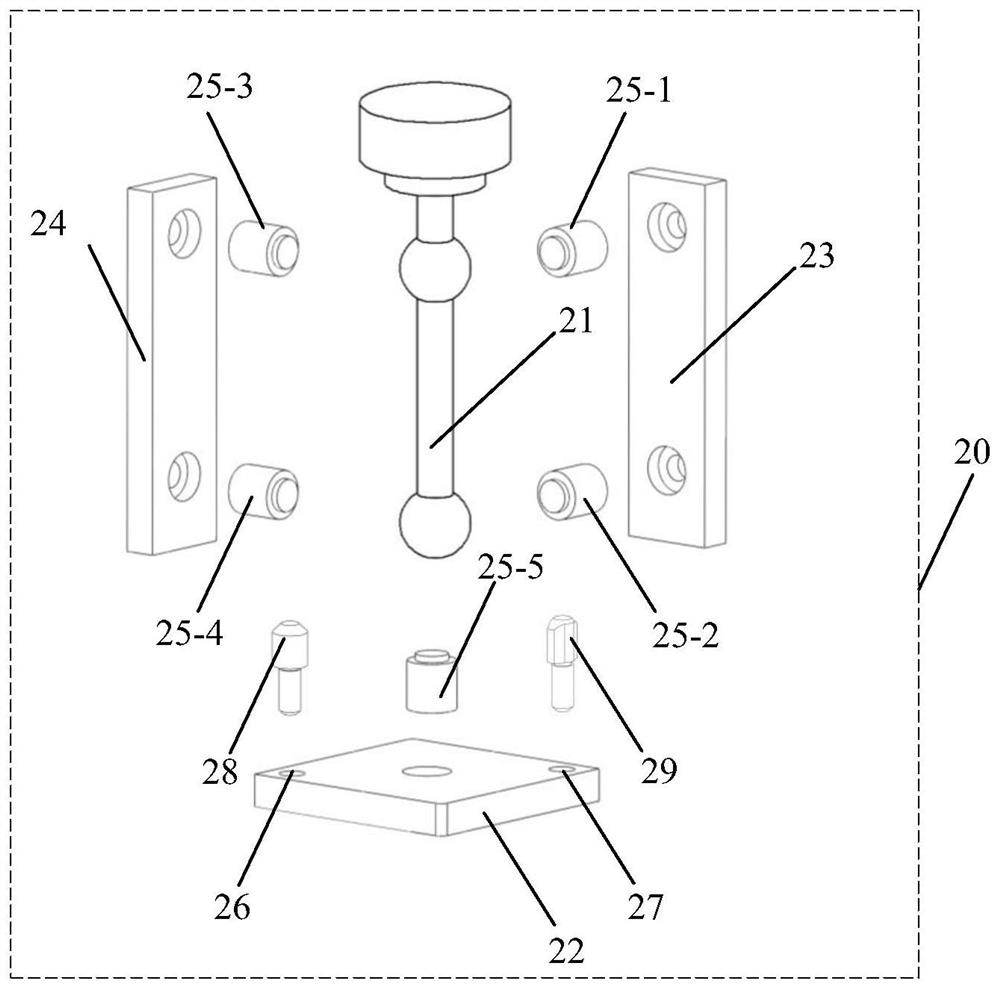

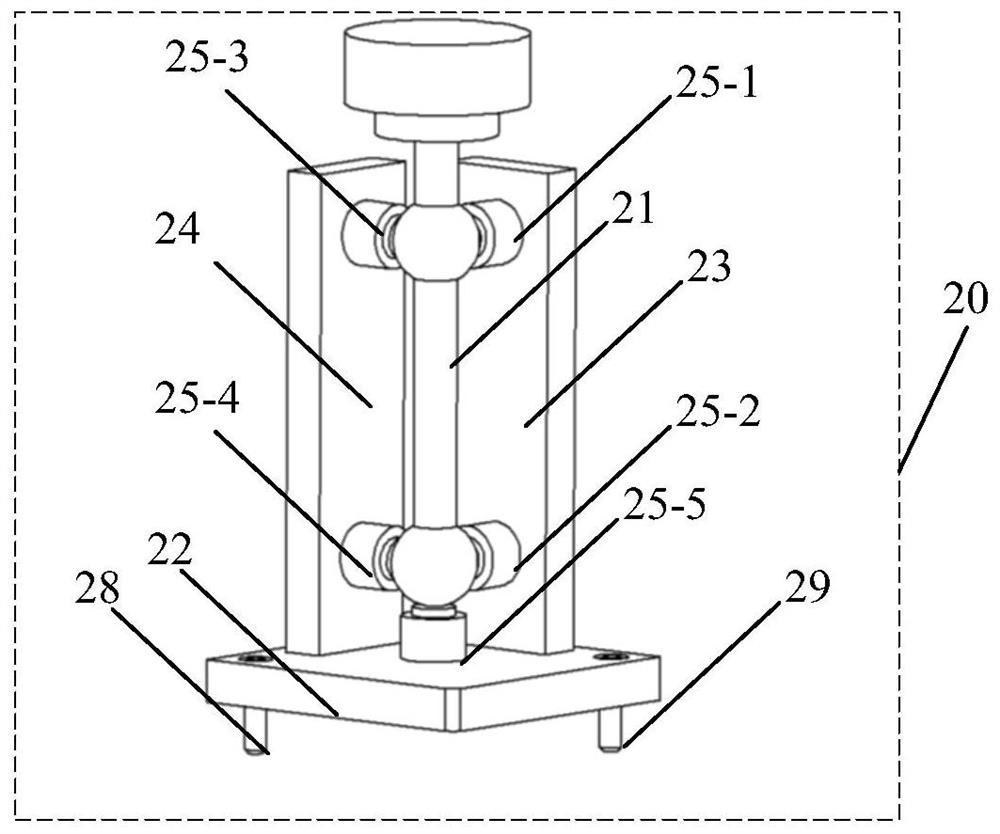

[0052] The present invention will be further described below in conjunction with the accompanying drawings.

[0053] This embodiment is a proposal for an over-constrained high-rigidity robot with trisymmetric kinematics disclosed in Chinese patent application No. 201510506108.2 and a compact planetary polishing device disclosed in Chinese patent No. 201710591618.3. A six-degree-of-freedom hybrid polishing robot polishing actuator pose accuracy calibration device and method.

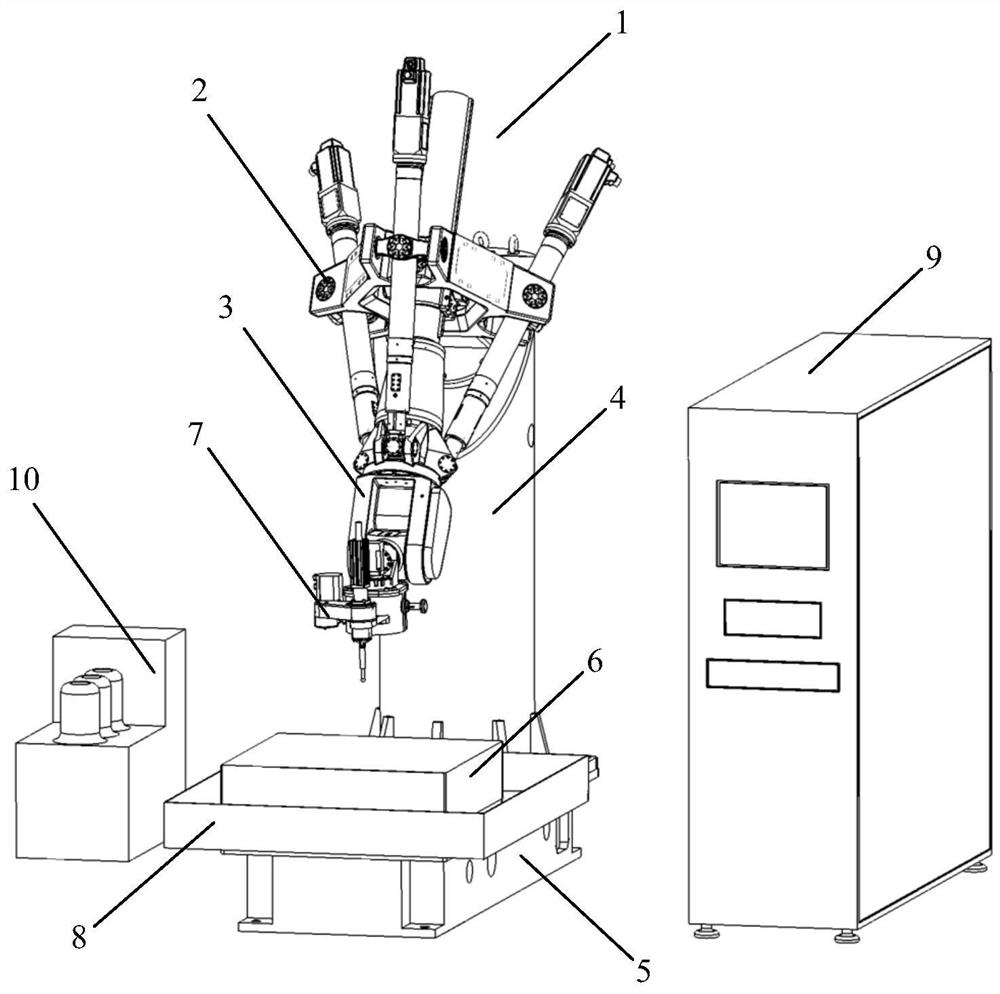

[0054] 1. The six-degree-of-freedom hybrid polishing robot 1 involved in this embodiment includes two parts: a three-degree-of-freedom parallel module 2 and a three-degree-of-freedom serial rotor 3, a six-degree-of-freedom hybrid polishing robot 1, a column 4, and a base 5 The workbench 6 is fixedly connected in sequence to form a "C"-shaped structure, and the polishing actuator 7 is fixedly connected to the end of the three-degree-of-freedom series rotor 3 . fixed connection to form a "C"-shaped structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com