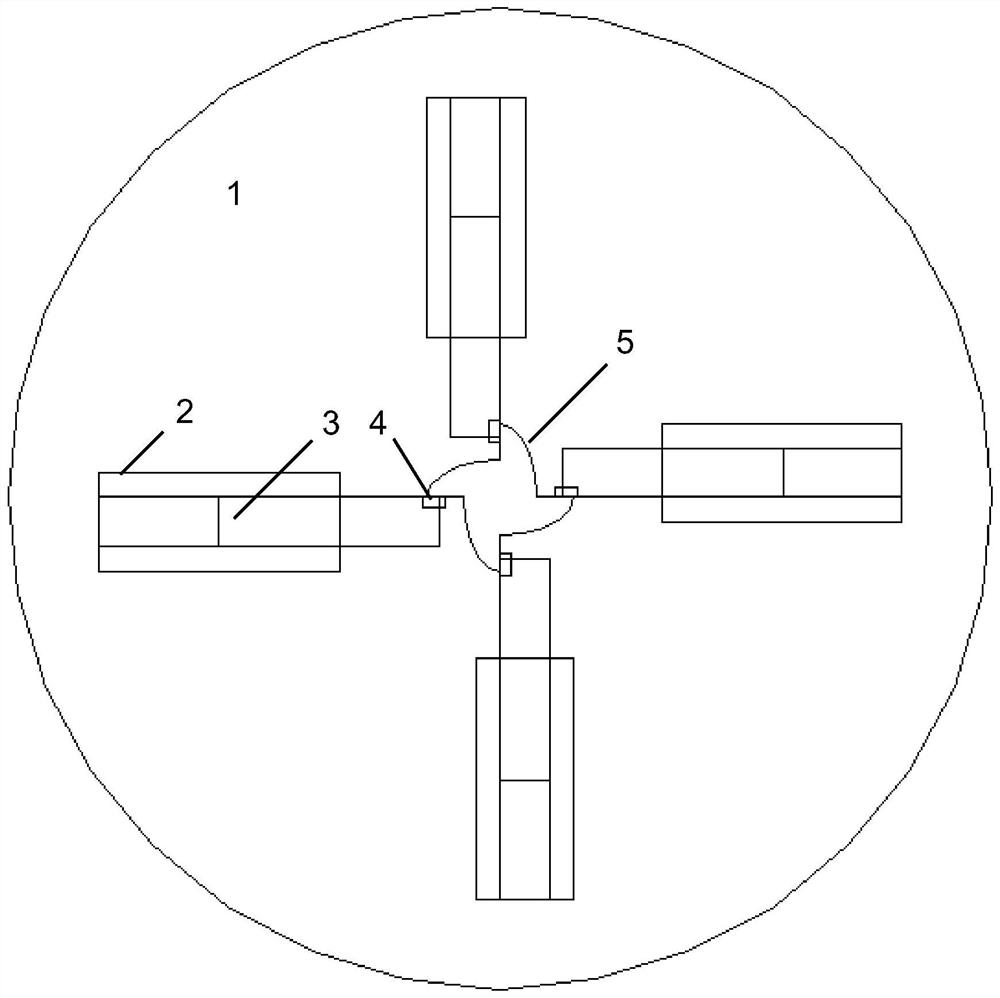

A cutter head suitable for cyclone turning and peeling machine and its roundness detection method

A detection method and technology of peeling machine, which are applied in turning equipment, turning equipment, measuring/indicating equipment, etc., can solve the problems of cumbersome detection process, low detection efficiency, poor measurement effect, etc., and achieve the effect of broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

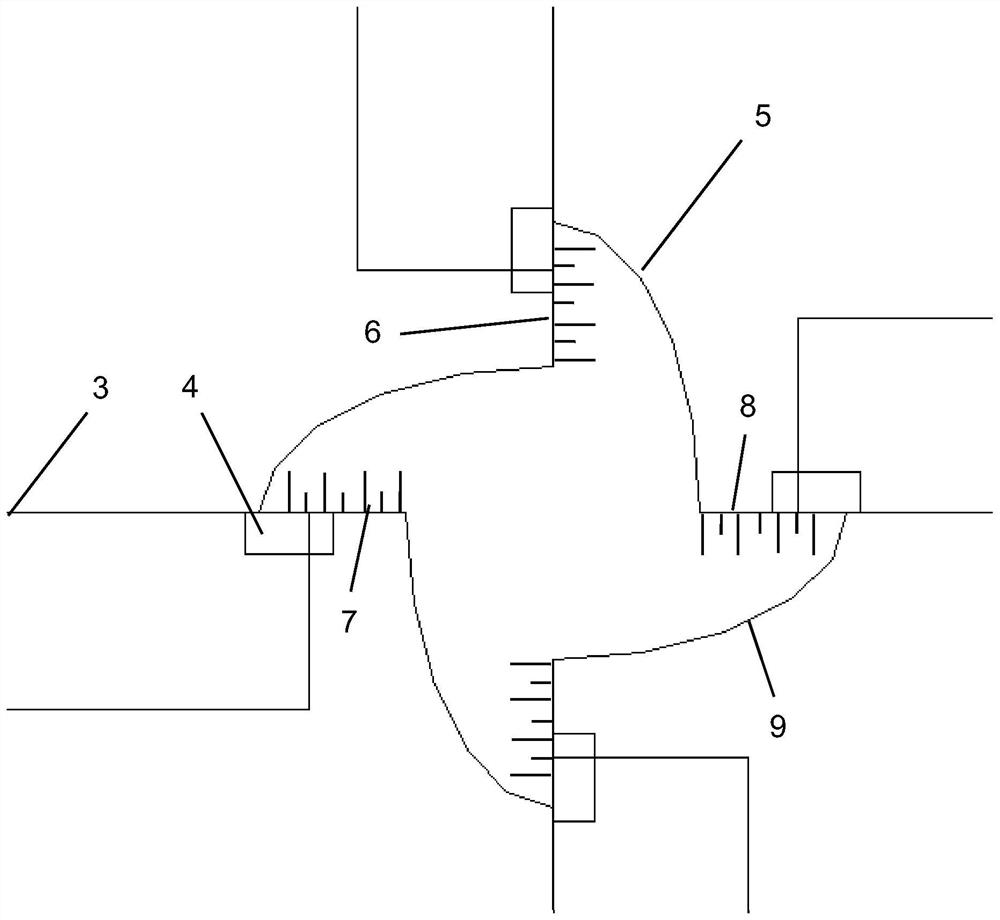

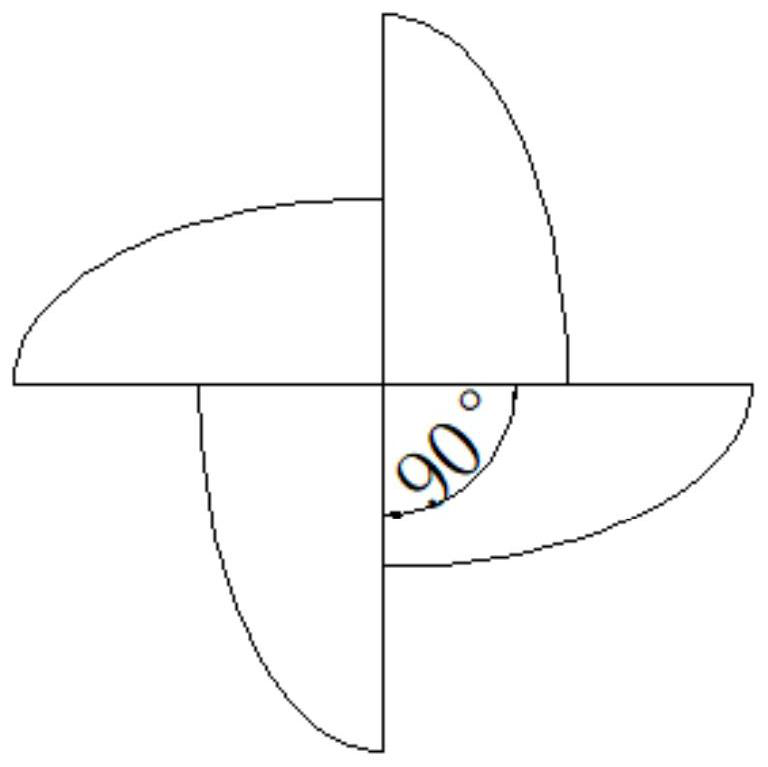

Method used

Image

Examples

Embodiment 1

[0060] When turning 113 circles, the center distances of the four blades measured according to the above steps are 56mm, 56.5mm, 56.5mm, 56mm, and the difference in roundness is 0.5mm, which meets the specifications. The position of the cutter head does not need to be adjusted. After turning, the surface quality is normal. The roundness difference detection time is 3 minutes.

Embodiment 2

[0062] When turning 178 circles, it was found that the turning groove marks were obvious. Therefore, the distances between the centers of the four blades were measured according to the above steps. They were 88.5mm, 87mm, 88.5mm, and 88.5mm. The position of the cutter head is adjusted, and the radial position of the cutter head is increased by 1.5 mm. After the adjustment, the quality of the turned surface is normal, and the detection time for the difference in roundness of the blade is 4 minutes.

Embodiment 3

[0064] When turning 195 circles, the center distances of the four blades measured according to the above steps are 97mm, 97.5mm, 96mm, and 97mm respectively, and the difference in roundness is 1.5mm, which does not meet the specifications. Therefore, adjust the position of the third cutter head and place the cutter The radial position of the head is increased by 1 mm, the turning surface quality is normal after adjustment, and the detection time of the same roundness difference of the blade is 4 minutes.

[0065] In summary, the present invention can quickly measure the distance between the blade of the whirlwind turning and peeling machine and the turning center, only needs one person to operate, the detection time is less than 5 minutes, and the work intensity is small. At the same time, the measurement accuracy can fully meet the roundness requirements of the whirlwind turning and peeling machine for the blade. After adjusting the position of the cutter head according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com