Device and method for automatically setting tool offset value of machine tool

A technology of automatic setting and offset value, applied in the field of CNC lathes, which can solve problems such as the inability to use the interference check program, the difficulty of automating the detection of the tool tip, and the increased workload of the operator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

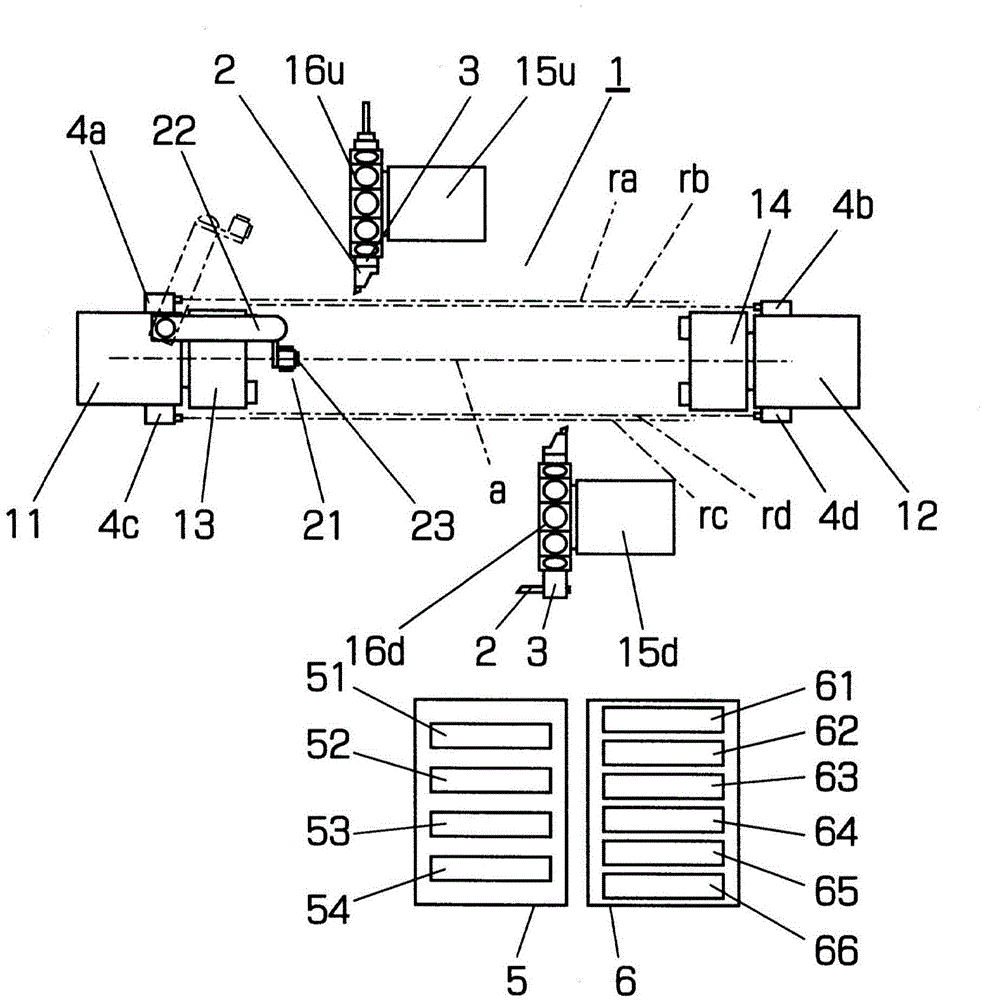

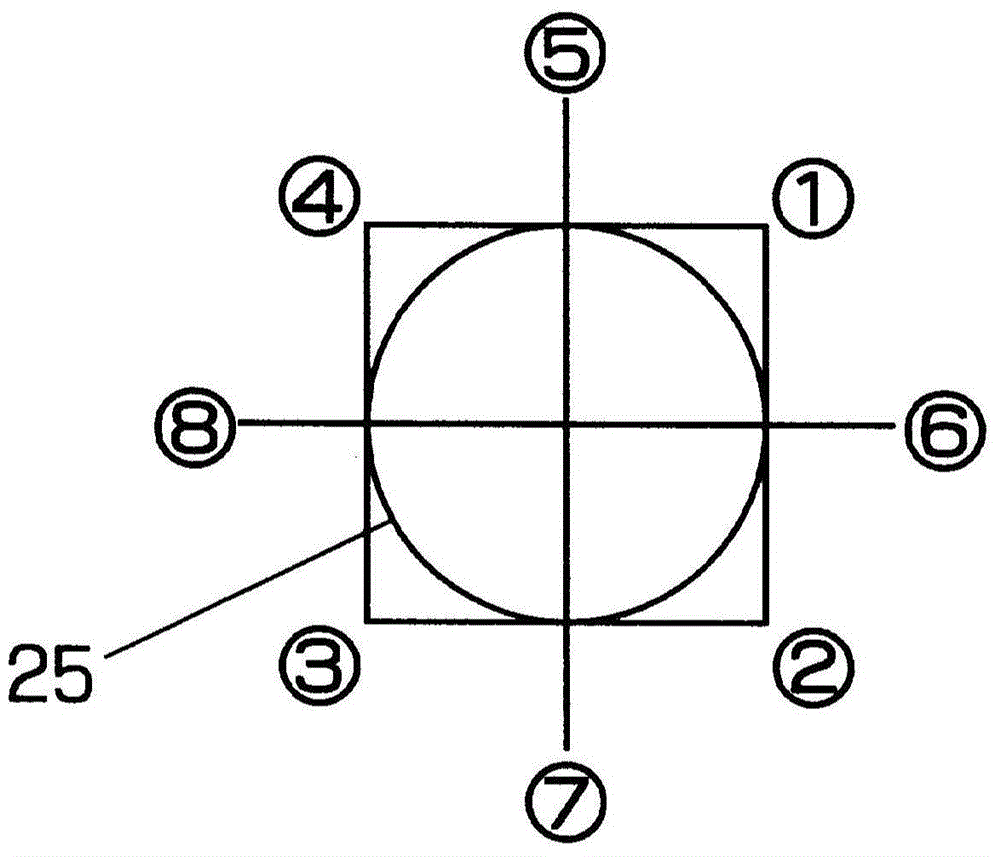

[0046]Hereinafter, an embodiment of the present invention will be described by taking, as an example, a dual-spindle opposed CNC lathe provided with two turret tool holders. A numerically controlled lathe includes an equipment main body 1 , a numerically controlled device 5 and a PC (computer) 6 . The main body 1 of the equipment includes a left spindle and a right spindle facing each other on the same spindle axis a. The left spindle is pivotally supported by a left headstock 11 fixed on the bed, and a left chuck 13 is attached to the right end thereof. The right main shaft is pivotally supported by a right main headstock 12 which is movable and positionable in a direction parallel to the main shaft axis a (Z-axis direction), and a right chuck 14 is mounted on the left end thereof.

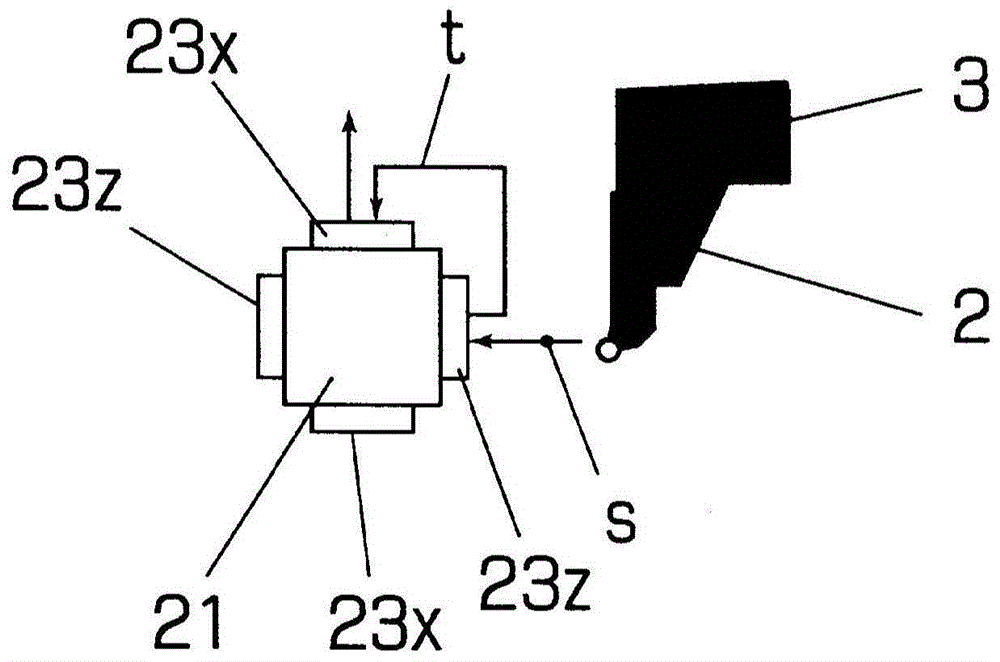

[0047] When viewed from the operator's direction, the upper tool rest 15u and the lower tool rest 15d are disposed above the rear side and below the near side with the spindle axis a interposed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com