A planter tool magazine for realizing automatic tool change and automatic tool change method

An automatic tool change and implant machine technology, applied in dental implants, medical science, dental prosthetics, etc., can solve the problem that the tool cannot be disengaged independently, and achieve the effect of reducing production costs, increasing the capacity of the tool magazine, and improving the degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

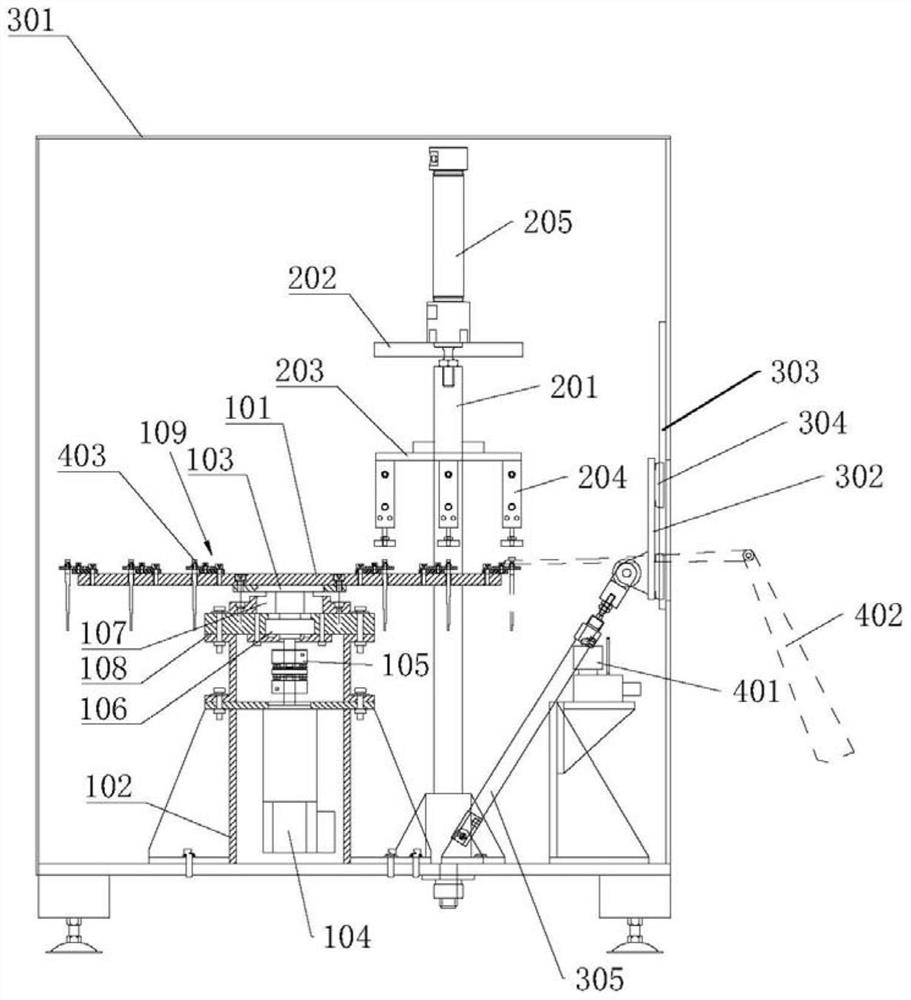

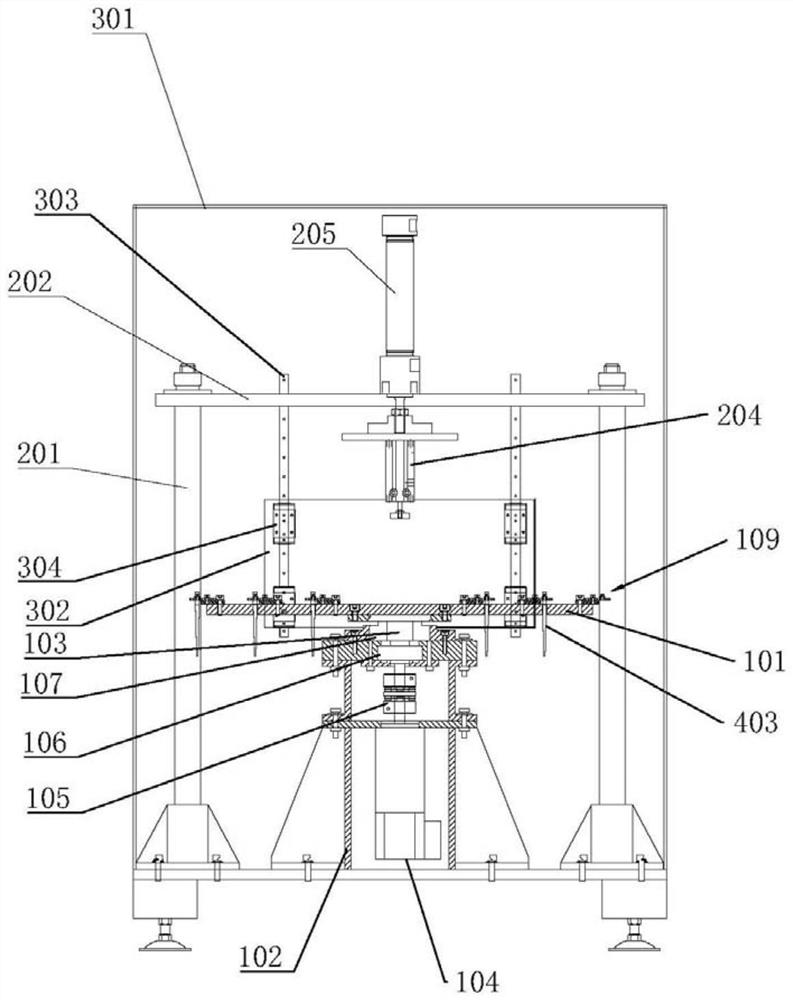

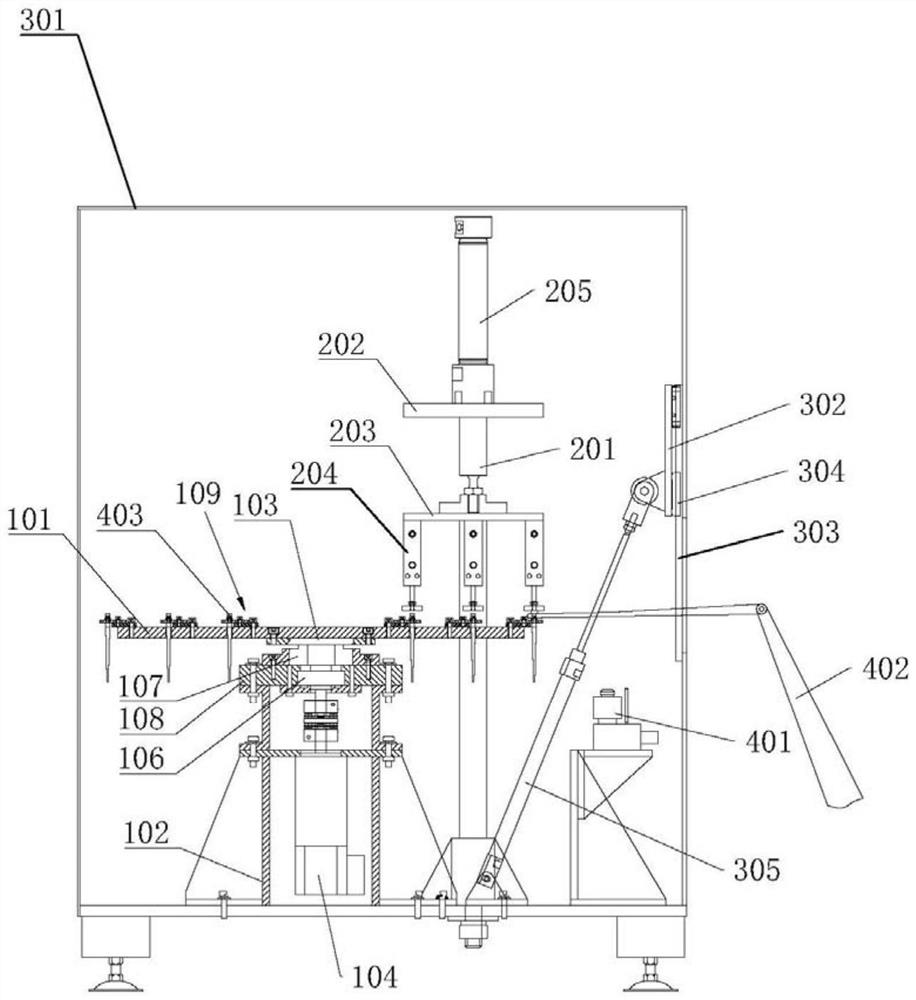

[0029] Embodiment 1: as figure 1 with figure 2 As shown, a planter tool magazine for realizing automatic tool change according to the preferred embodiment of the present invention includes a tool magazine room 301, the side of the tool magazine room 301 is provided with a knife magazine door 302 that can be opened and closed, and the knife magazine door 302 is vertically Slide blocks are respectively provided on the two sides of the tool magazine chamber, and slide rails 303 cooperating with the slide blocks on both sides are provided on the inner wall of the tool magazine chamber 301 . A stretching mechanism 305 is provided in the tool magazine chamber 301, and the stretching mechanism 305 can adopt a motor, an air cylinder or a hydraulic cylinder, and a hydraulic cylinder is used in this embodiment. Both ends of the stretching mechanism 305 are respectively hinged on the inner side of the tool magazine door 302 and the bottom of the tool magazine chamber 301 , and the open...

Embodiment 2

[0034] Embodiment 2: A planter tool magazine for automatic tool change. The difference from Embodiment 1 is that the number of spring cylinders is one, the bottom of the connecting plate 203 is provided with a linear guide rail, and the end of the spring cylinder body is provided with The slider and the spring cylinder are connected on the linear guide rail through sliding of the slider, and the connecting plate 203 is provided with a servo motor for driving the slider to slide. The sliding control of the slider on the linear guide rail is realized by the servo motor, so as to realize the switch between the three tool changing positions of the spring cylinder.

[0035] The present invention also proposes an automatic tool changing method, comprising the following steps:

[0036] S1: The tool magazine door is opened, and the disc tool holder 101 rotates under the drive of the rotary mechanism, so that the corresponding tool seat 109 moves to the bottom of the single-acting cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com