Rotary clamping type planter tool magazine and automatic tool changing method

A planter and clamping technology, which is applied in implantology, medical science, dentistry, etc., can solve the problem that the mechanical arm of the planter cannot complete the tool change process quickly and accurately, the tool clamping is unstable, and the tool cannot be disengaged independently. problems, to achieve the effect of improving the degree of automation, convenient operation and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

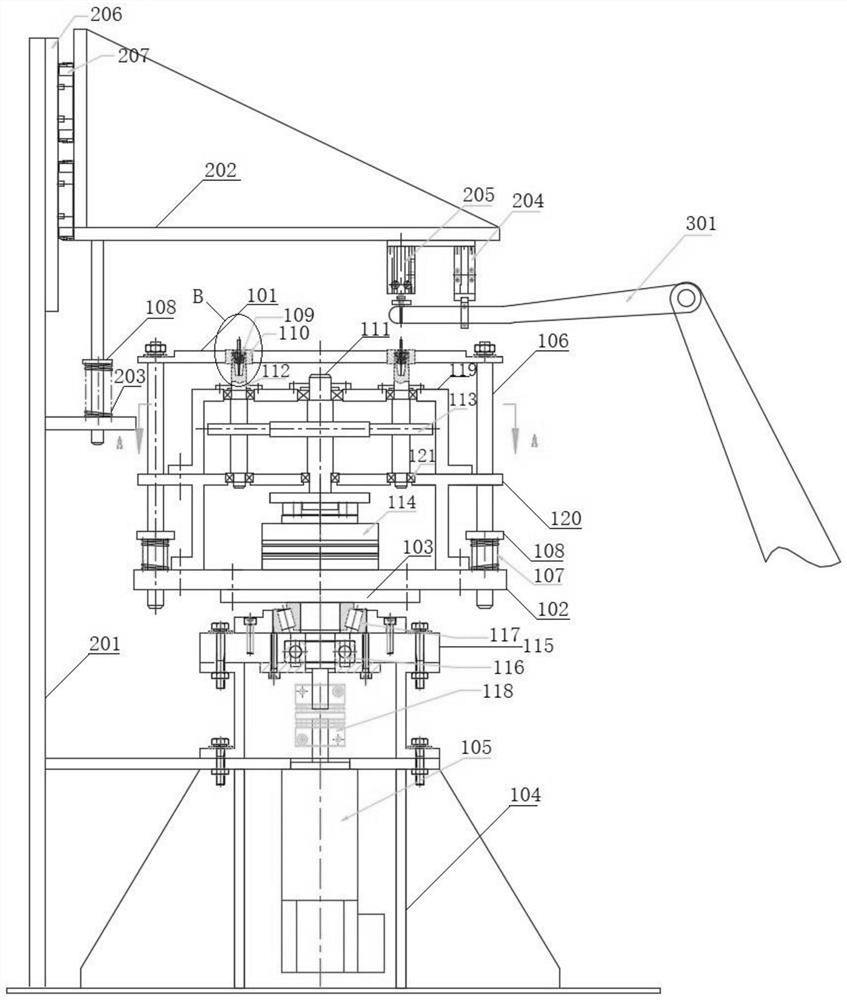

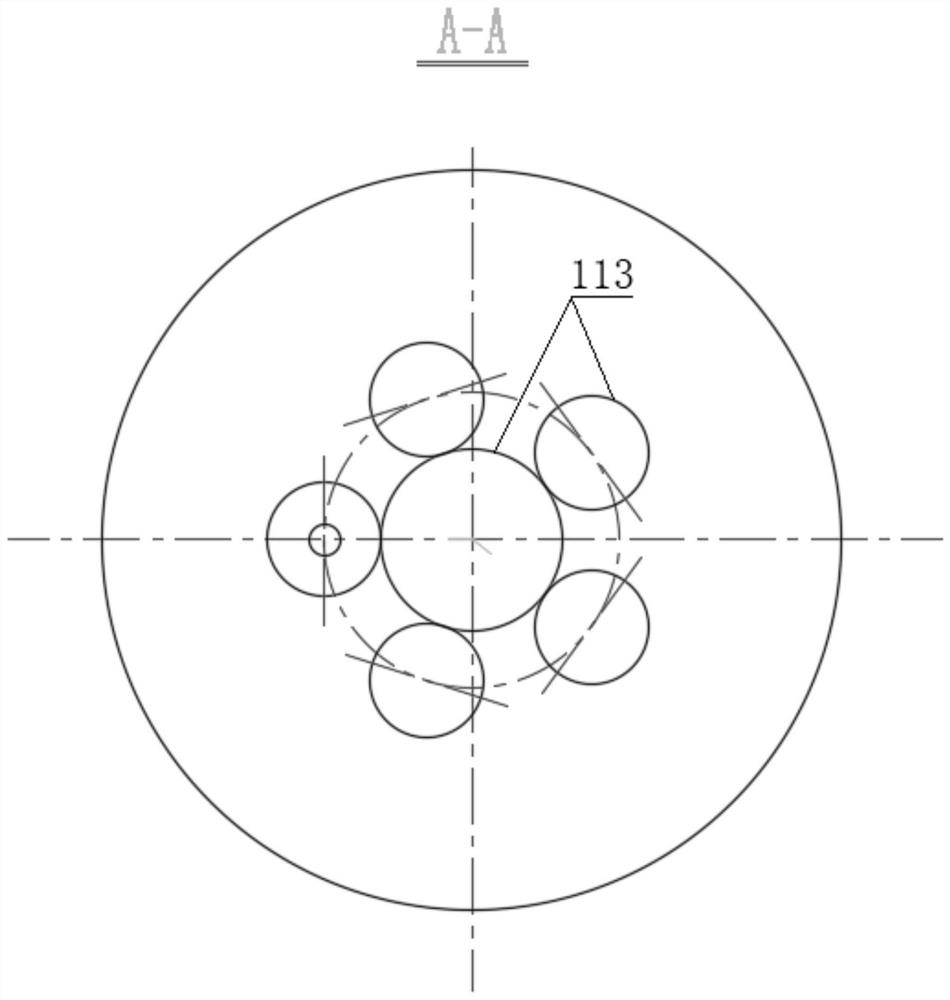

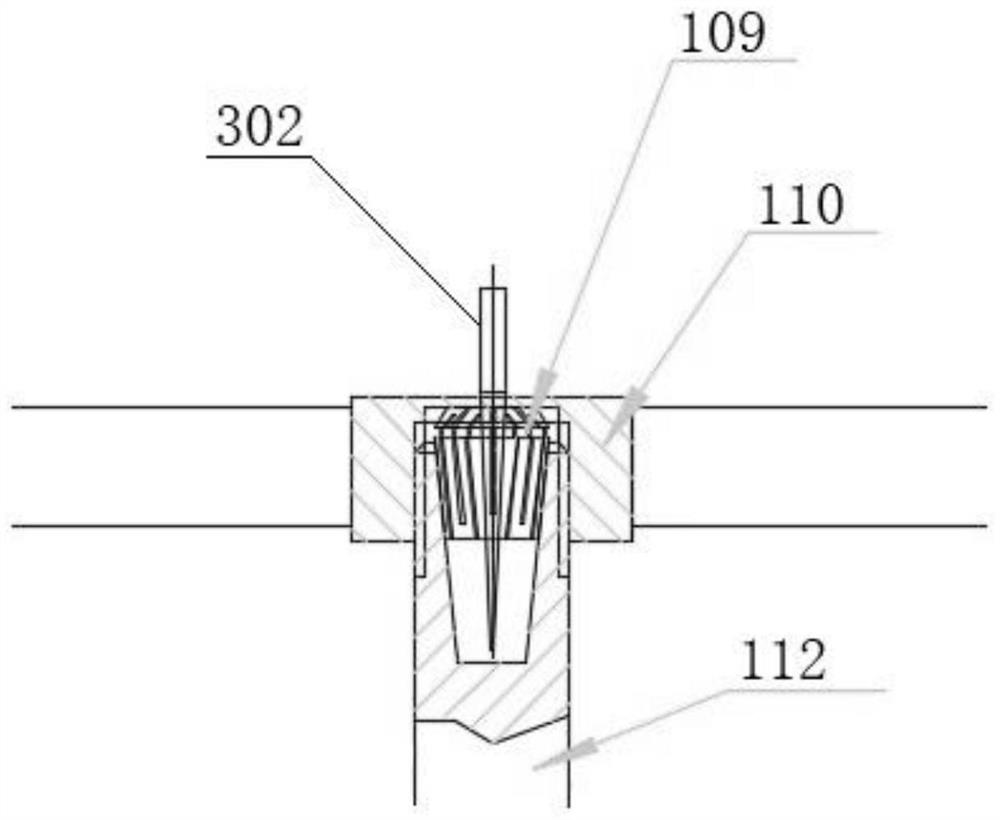

[0027] Embodiment 1: as figure 1 As shown, a rotary clamping type planter tool magazine according to the preferred embodiment of the present invention includes a tool holder base 104, a first rotating mechanism 105 is provided on the tool holder base 104, and a tool holder base is provided on the first rotating mechanism 105. One side of the base 102 and the knife holder base 104 is provided with a knife setting instrument (not shown in the figure) for aligning the knife 302 on the mechanical arm 301 of the planter. The first rotating mechanism 105 may adopt a rotating motor, a rotating cylinder or a rotating hydraulic cylinder, and a rotating motor is used in this embodiment. The top of the tool rest base 104 is provided with a mounting seat 115, and the center of the mounting seat 115 is provided with a ball bearing 116 and a tapered roller bearing 117. The bottom of the tool rest base 102 is provided with a tool post main shaft 103, and the tool post main shaft 103 extends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com