Automatic implanter tool magazine and tool changing method

A technology for planting machines and knife magazines, applied in the dental field, can solve problems such as the inability of the knives to be disengaged independently, and achieve the effects of reducing production costs, increasing the capacity of the knife magazine, and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

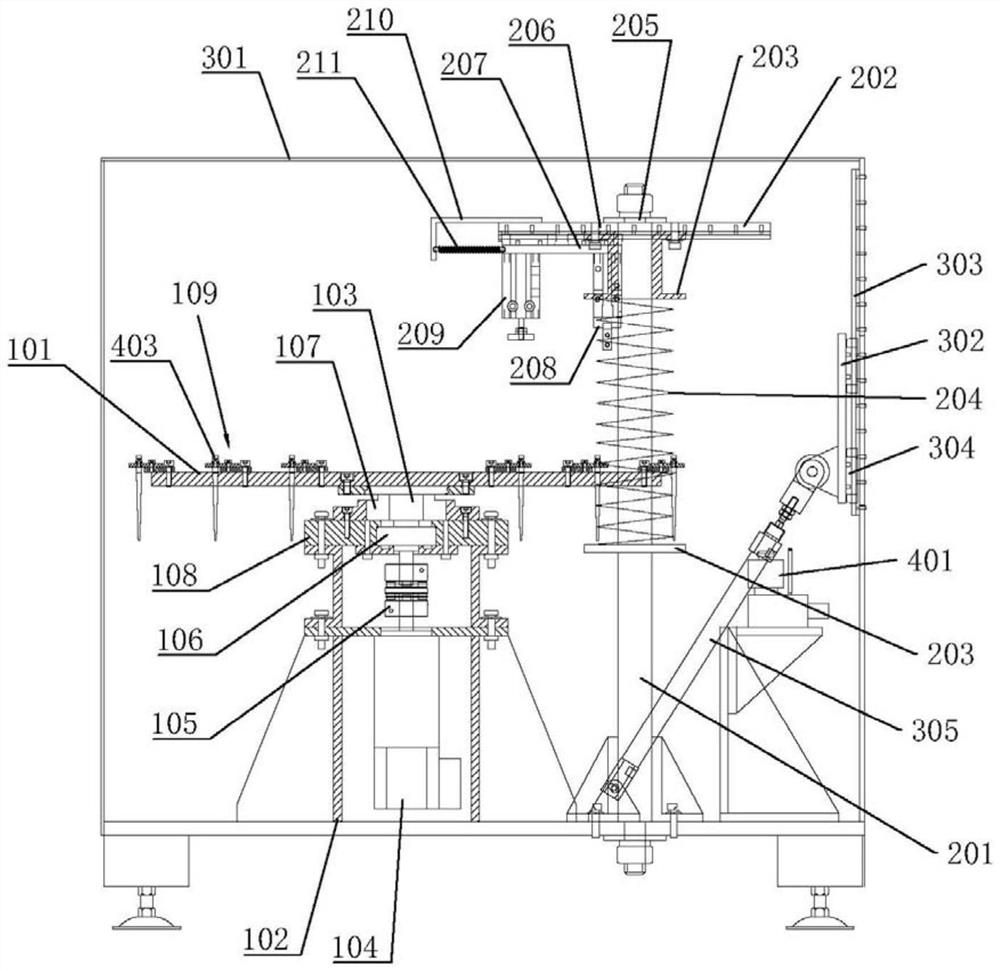

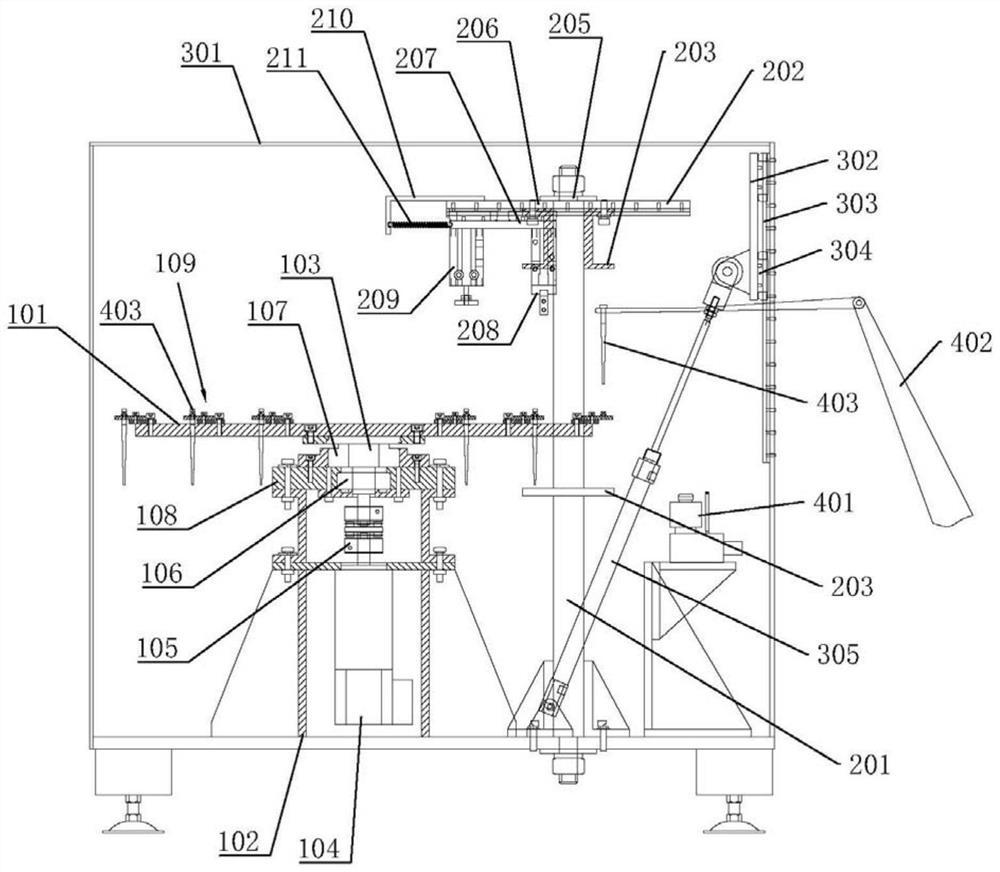

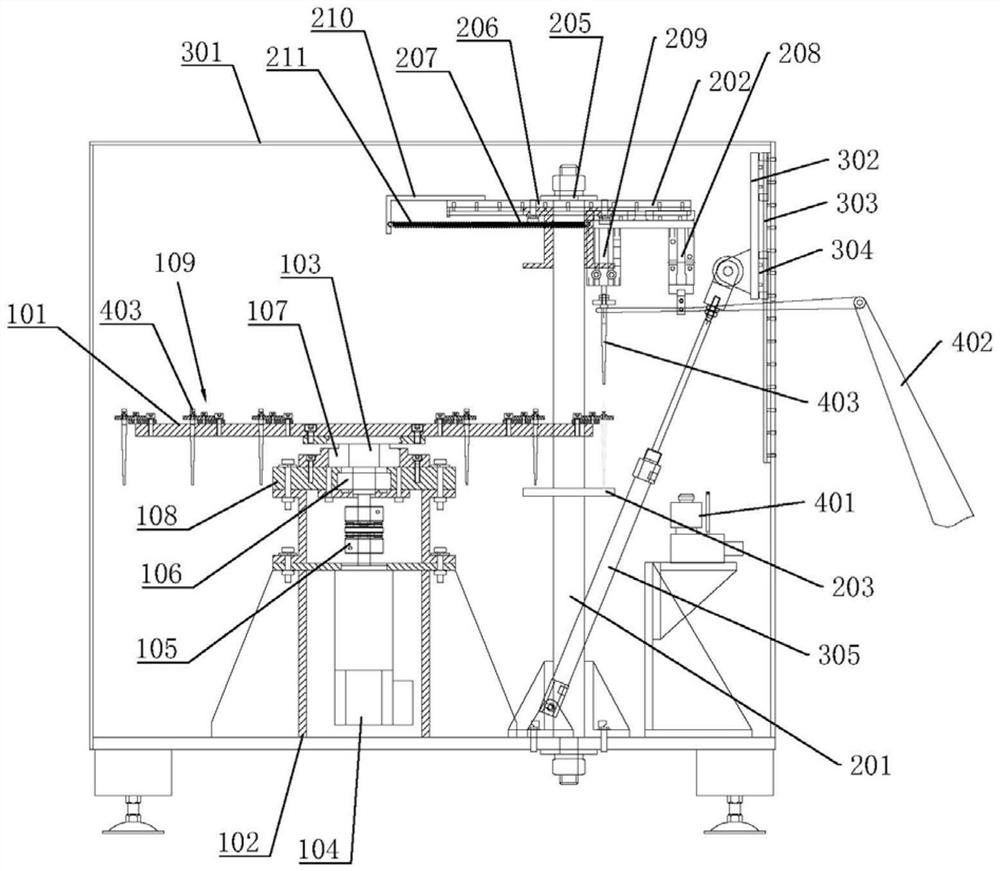

[0030] Embodiment 1: as figure 1 As shown, a kind of automatic planter tool magazine according to the preferred embodiment of the present invention includes a knife magazine room 301, the side of the knife magazine room 301 is provided with a knife magazine door 302 which can be opened and closed, and the two sides of the knife magazine door 302 in the vertical direction Slide blocks are respectively arranged on the top, and slide rails 303 that cooperate with the slide blocks on both sides are provided on the inner wall of the tool magazine chamber 301 . A stretching mechanism 305 is provided in the tool magazine chamber 301, and the stretching mechanism 305 can adopt a motor, an air cylinder or a hydraulic cylinder, and a hydraulic cylinder is used in this embodiment. Both ends of the stretching mechanism 305 are respectively hinged on the inner side of the tool magazine door 302 and the bottom of the tool magazine chamber 301 , and the opening and closing control of the too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com