Vertical pulling silicon single crystal growing furnace with water-cooling jacket

A water-cooled jacket and growth furnace technology, which is applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of crystal defects, unsatisfactory cooling effect of single crystal rods, and the lifting speed of single crystal rods should not be too fast. , to achieve the effect of reducing micro-defects, good cooling effect and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

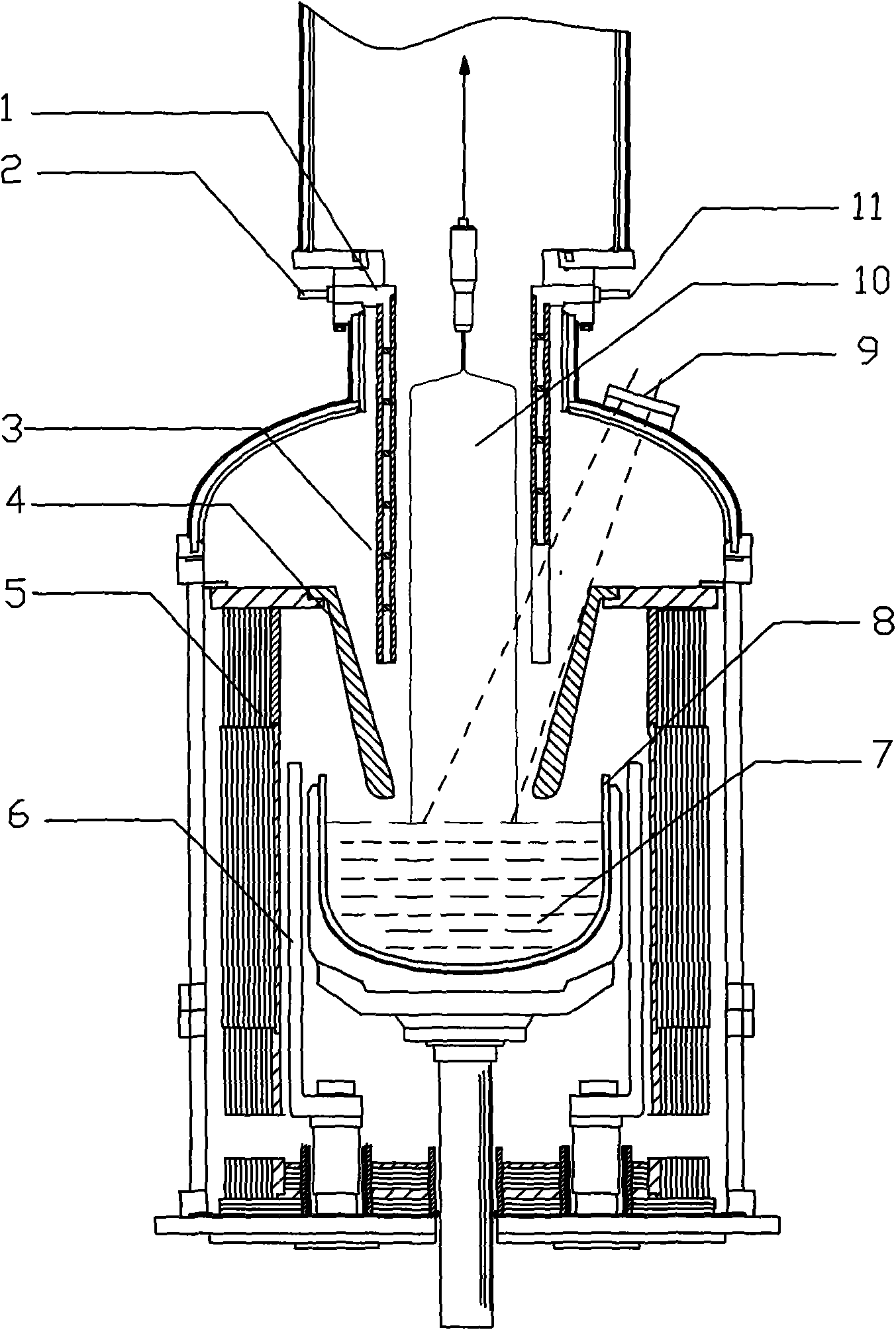

[0034] In conjunction with the accompanying drawings, the present invention will be described in detail below.

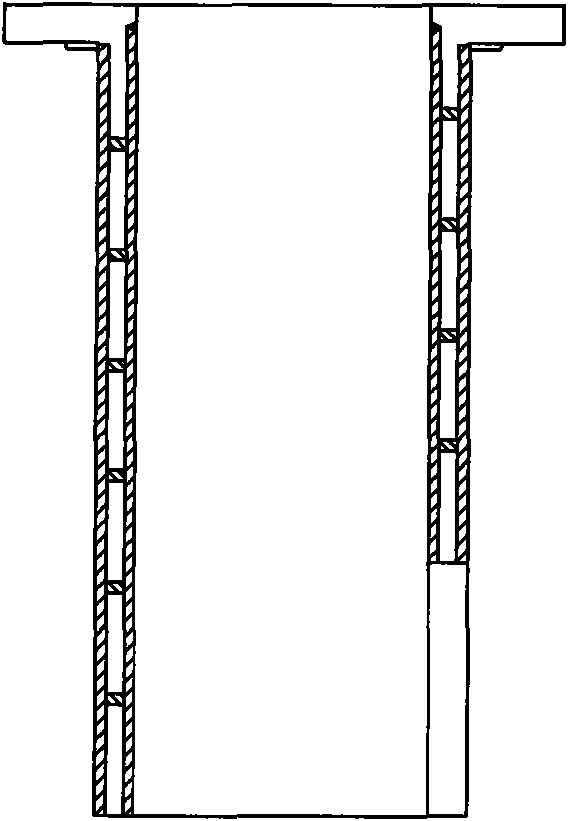

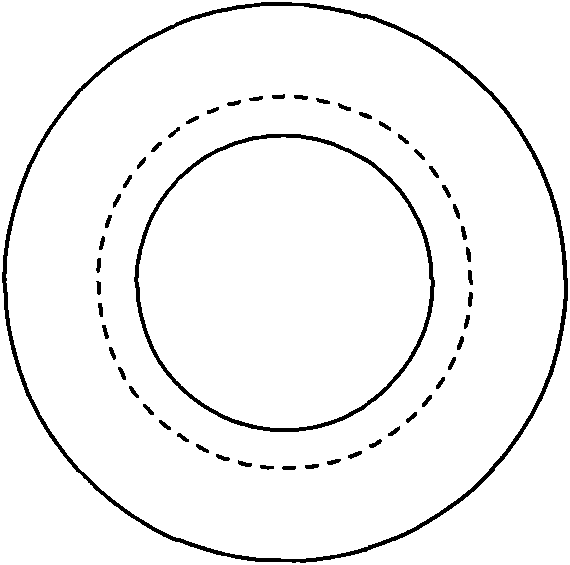

[0035] In the present invention, the Czochralski silicon single crystal growth furnace with a water-cooled jacket includes a heater 6, a quartz crucible 8 and a heat preservation device 5, and the quartz crucible 8 is provided with a heat shield device 4 surrounding the lifting area of the single crystal rod; A cylindrical water-cooling jacket 3 is set between the heat shield device 4 and the lifting area of the single crystal rod 10; the water-cooling jacket 3 is a hollow jacket device, and the inside of the water-cooling jacket 3 is a channel for cooling water to flow, and a water inlet pipe is provided 2 and outlet pipe 11.

[0036] The water-cooling jacket is made of stainless steel, and its upper part is provided with a flange 1 matching the furnace mouth of the growth furnace, which can be fixed on the flange of the furnace cover by bolts and sealed with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com