Dispenser with optical keying system

a technology of optical keying and dispenser, which is applied in the direction of liquid transfer devices, volume meters, instruments, etc., can solve the problems of presenting contamination and health concerns, and incorrect materials may be devastating to the health of users, and the service is messy and difficul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

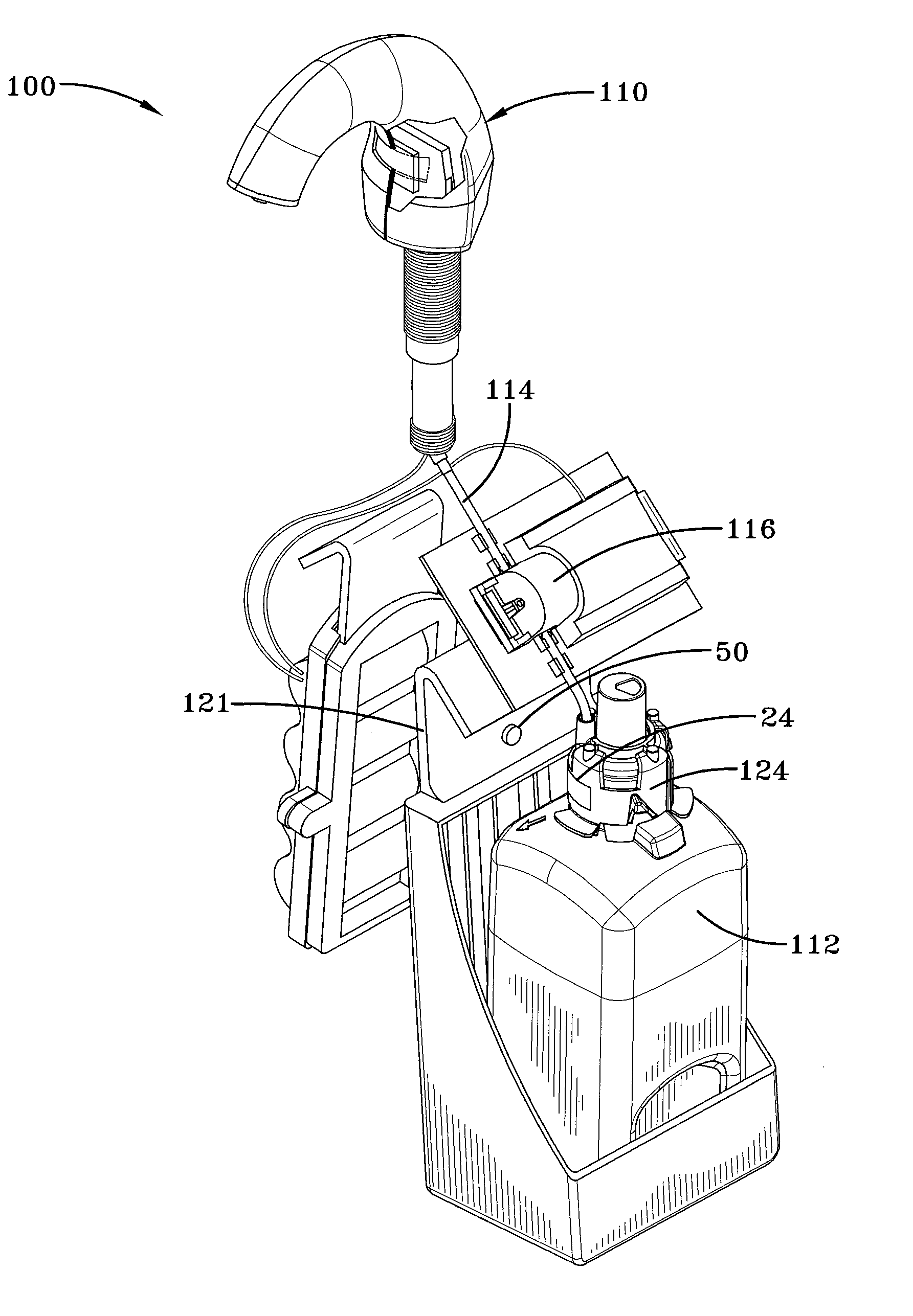

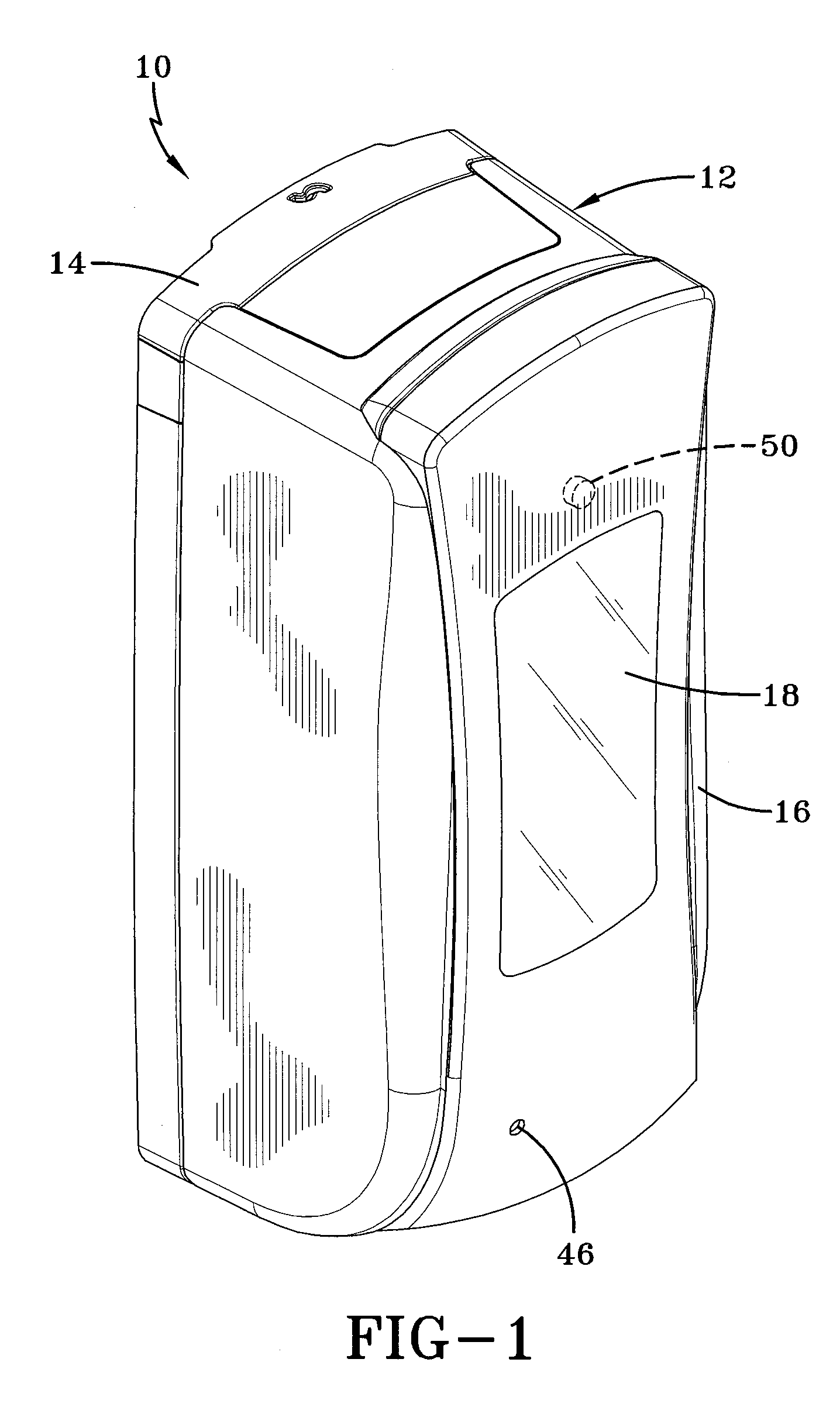

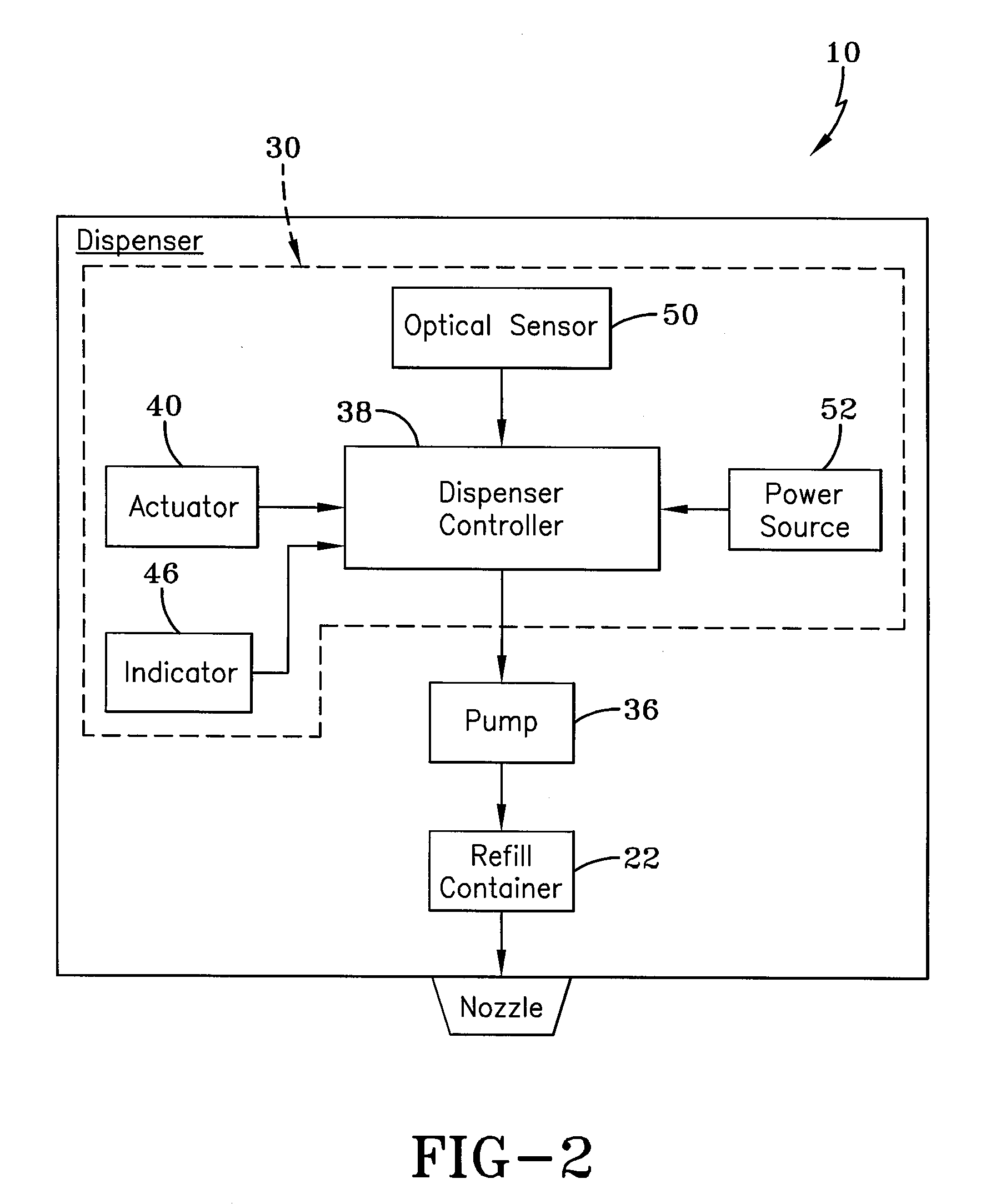

[0028]A dispenser having an optical keying system is generally referred to by the numeral 10, as shown in FIGS. 1-5 of the drawings. The dispenser 10 includes a housing 12, which includes a back plate 14 adapted to be secured to a vertical surface, and a cover 16 that is pivotable relative to the back plate 14. The cover 16 permits access to the internal components of the dispenser 10 and may include a window 18 so that the interior of the dispenser 10 can be viewed. As such, the cover 16 may be removed to install or remove a refill container 22 that contains a label 24 having indicia 26 disposed thereon, which defines various predetermined reference codes used in part to determine if the refill container 22 is authorized for use with the dispenser 10. It should be appreciated that the term “indicia” as used herein is defined as any microscopic mark, indentation, or the like, such as one or more microscopic printed dots, that cannot be viewed by the human eye, but is capable of bein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com