Automatic coarse cereal food flour mill with automatic weighing function

An automatic weighing technology for whole grains, which is applied in the direction of grain processing, etc., can solve the problems of poor taste of grains and grains powder, affect the health of operators, and has no screening function, so as to facilitate quantitative sales and use, and facilitate promotion The effect of using and saving weighing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

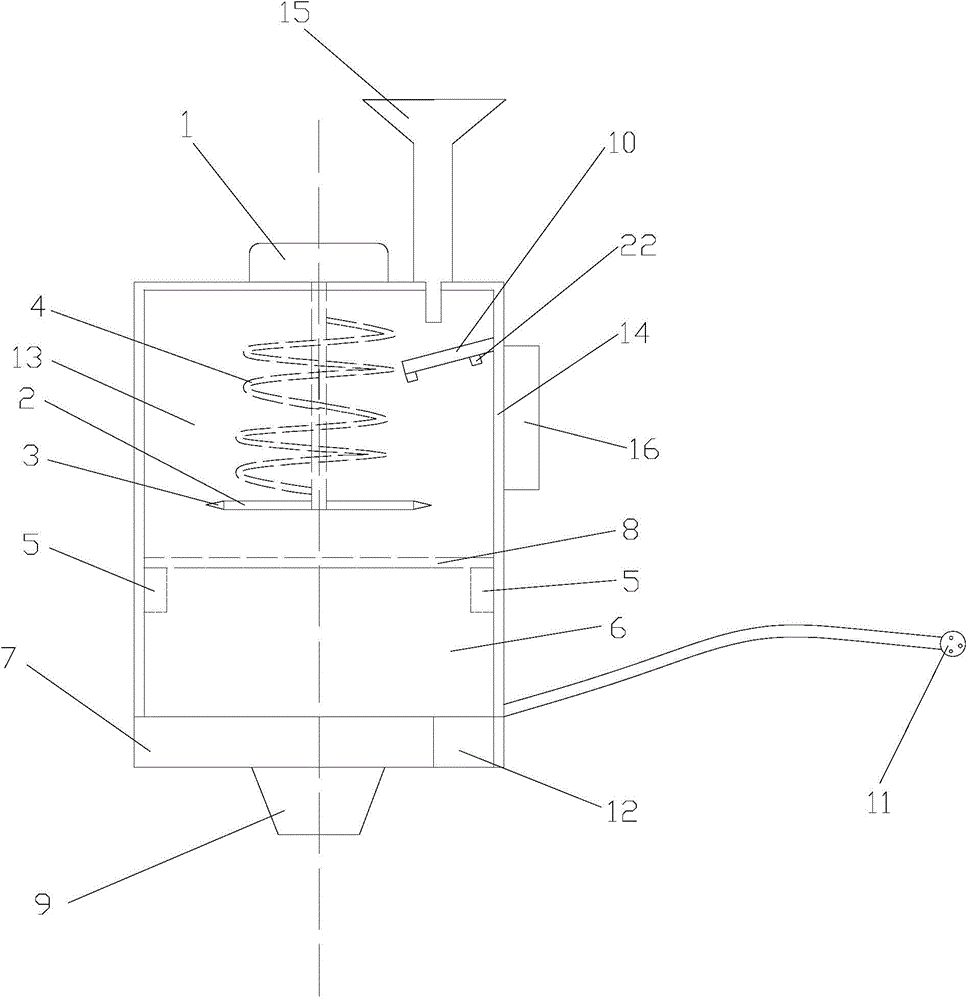

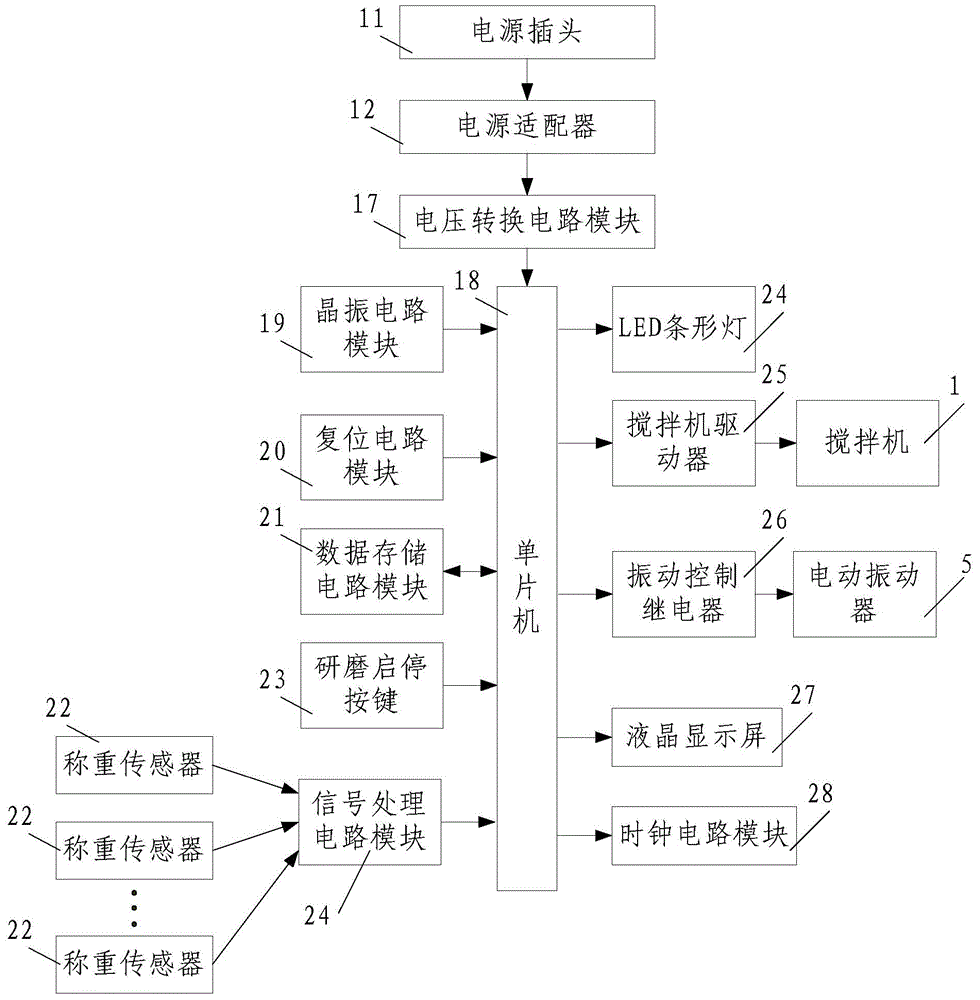

[0032] Such as figure 1 and figure 2 As shown, the present invention includes a whole grains food mill body and a whole grains food mill controller 16, and the whole grains food mill body includes a machine base 7, a casing 14 and a card that are arranged on the top of the machine base 7 A feed funnel 15 connected to the top of the casing 14, the top of the casing 14 is fixedly connected with a mixer 1 with a stirring rod extending into the inside of the casing 14, and the stirring rod of the mixer 1 is fixedly connected with a spiral stirring blade 4. The bottom of the stirring rod of the mixer 1 is fixedly connected with a stirring and crushing knife 2, and the end of the stirring and crushing knife 2 is fixedly connected with a cutter head 3, and the upper part of the casing 14 is located at the front of the feeding funnel 15. Below is provided with weighing plate 10, and the bottom of described weighing plate 10 is fixedly connected with a plurality of weighing sensors 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com