Patents

Literature

32results about How to "Easy to operate and controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

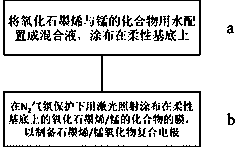

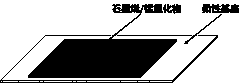

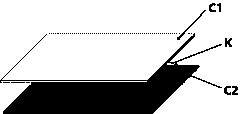

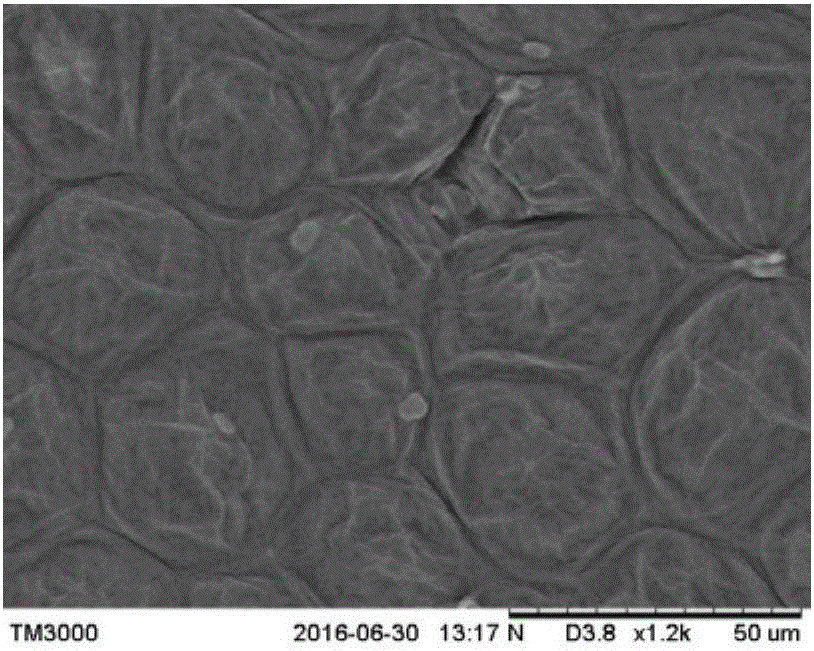

Preparation of graphene/manganese oxide flexible electrode for super capacitor by employing laser one-step method

InactiveCN106098410ASimple processLow costHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceFully developed

The invention belongs to the field of electrochemical materials, and discloses a method for preparing graphene / manganese oxide flexible electrodes by using laser one-step in-situ reduction of graphene oxide and decomposing manganese compounds, which is applied to supercapacitors. Wherein the preparation method of the graphene / manganese oxide flexible electrode comprises the following steps: uniformly mixing the aqueous solution of graphene oxide and the compound of manganese, coating on the flexible substrate; under the protection of an inert atmosphere, utilizing laser to irradiate the graphene oxide prepared by the above steps / Manganese compound film: while graphene oxide is reduced to graphene by laser, manganese compound is thermally decomposed to obtain manganese oxide. Pure graphene supercapacitors have low specific capacitance; manganese oxide supercapacitors have poor cycle stability. Combining these two materials can maximize their strengths and avoid weaknesses, give full play to the advantages of both, and obtain supercapacitors with good cycle stability and high specific capacity. The advantages of the present invention are: one-step laser reduction of graphene oxide and decomposition of manganese compounds to obtain reduced graphene and manganese oxide flexible composite electrodes, and assemble them into flexible supercapacitors. The preparation process is simple, the efficiency is high, and the preparation process is green and environmentally friendly. It can be produced industrially.

Owner:于有海

Method for preparing super hydrophobic magnetic wood surface and wood

InactiveCN106553249AHigh value-added utilizationIncrease useWood treatment detailsWood impregnation detailsWeather resistanceSilanes

The invention relates to a method for preparing a super hydrophobic magnetic wood surface. The method includes the following steps: mixing polydimethylsiloxane with a curing agent to form a first mixture; mixing polydimethylsiloxane with magnetic nanoparticles to form a second mixture; coating the first mixture on a super hydrophobic surface for primary curing, and then soaking the super hydrophobic surface with fluoroalkyl silane to obtain a first mixture layer; coating the second mixture on a wood surface, and covering the front surface of the first mixture layer with the wood surface coated with the second mixture for secondary curing; stripping and removing other substances from the wood surface to obtain the super hydrophobic magnetic wood surface. According to the method for preparing the super hydrophobic magnetic wood surface and the wood, a wood resource is allowed to exert the super hydrophobic property, the hydrophily of the wood surface is changed, therefore, not only deterioration of the weather resistance of the wood can be effectively prevented, but also the method is of important significance for the high value-added utilization and functional development of the wood.

Owner:ZHEJIANG FORESTRY UNIVERSITY

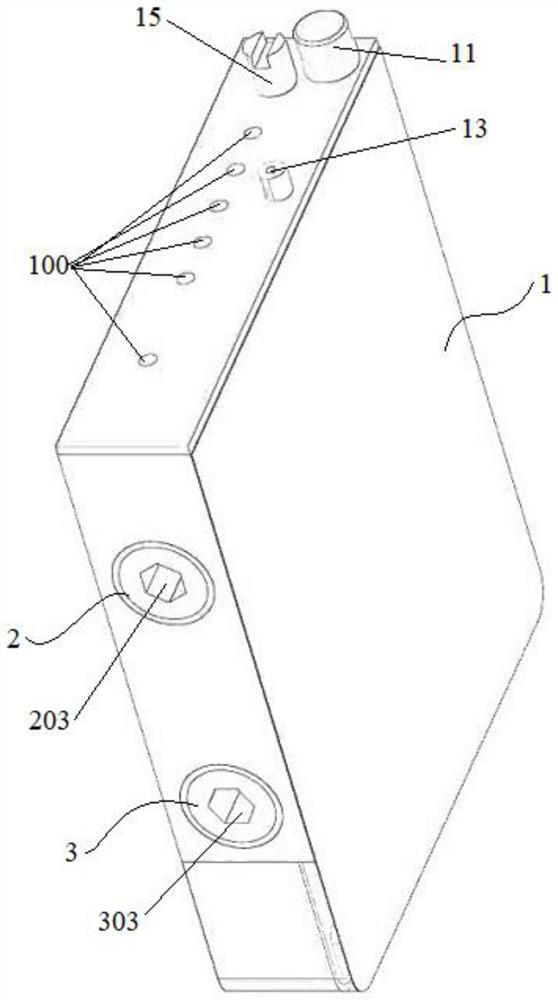

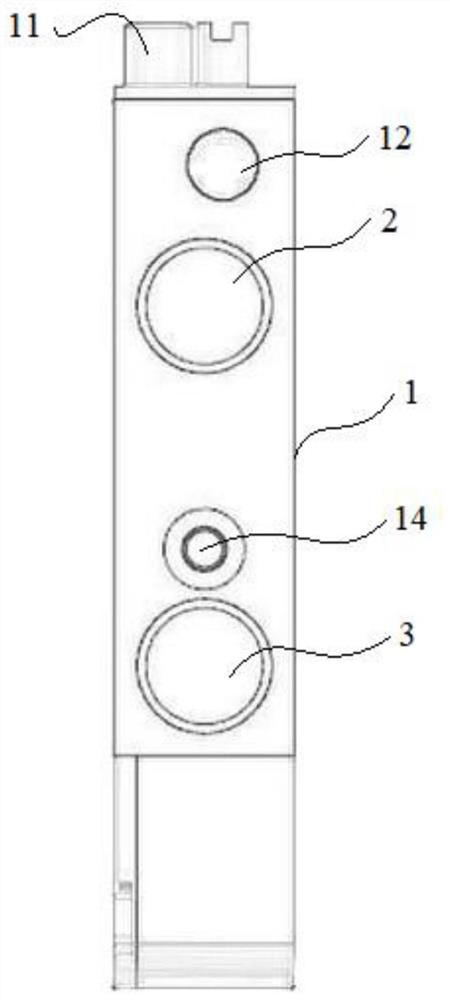

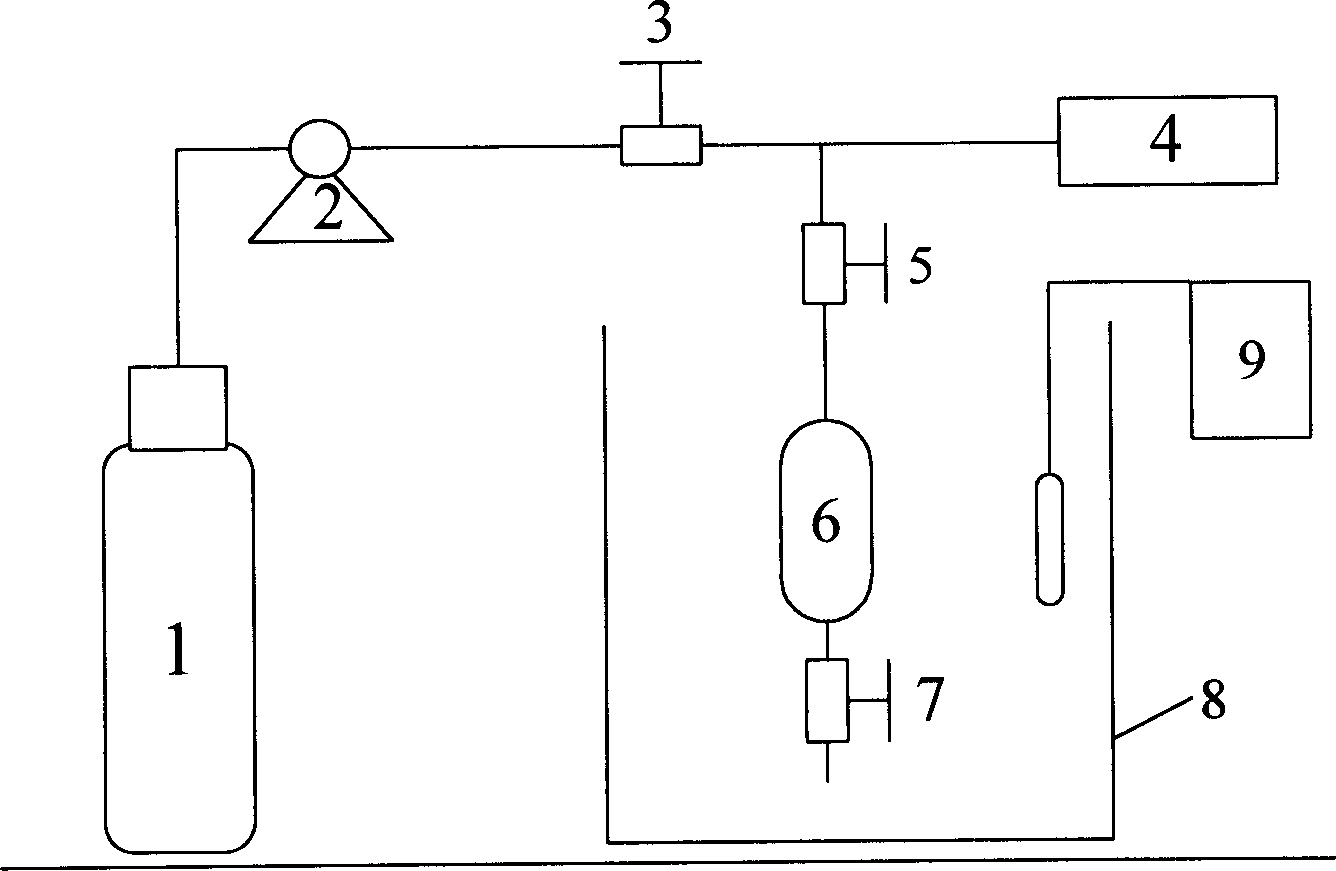

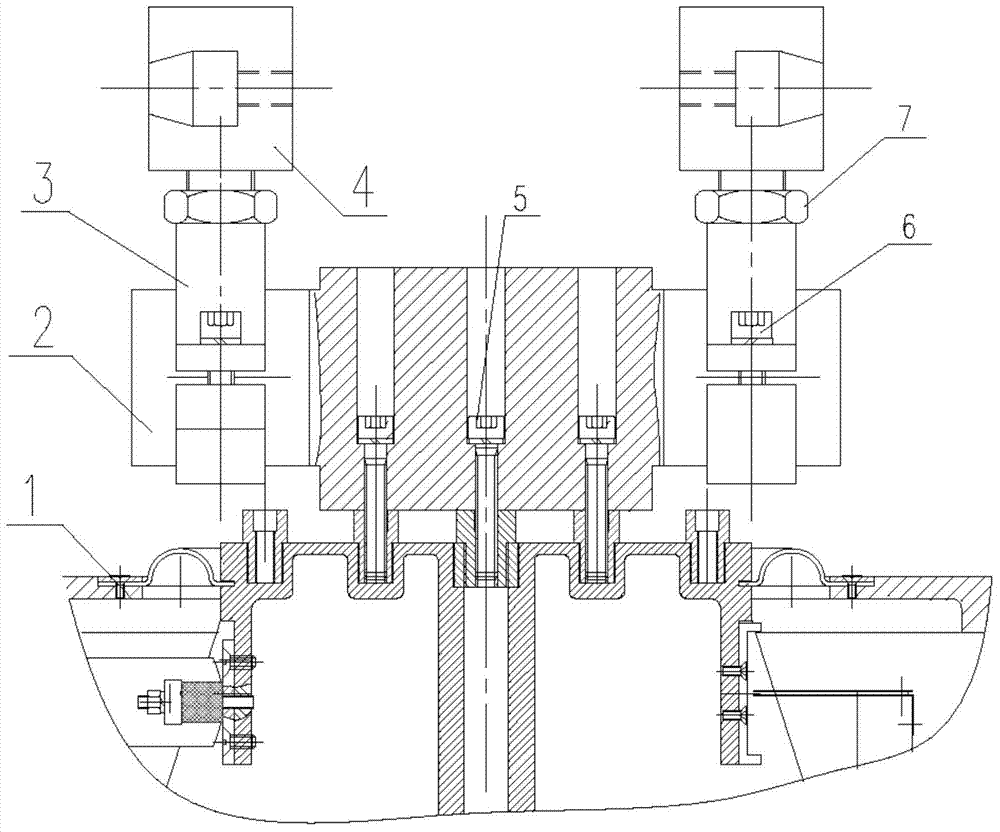

Vertical micro-fluidic chip and method for nucleic acid extraction and amplification

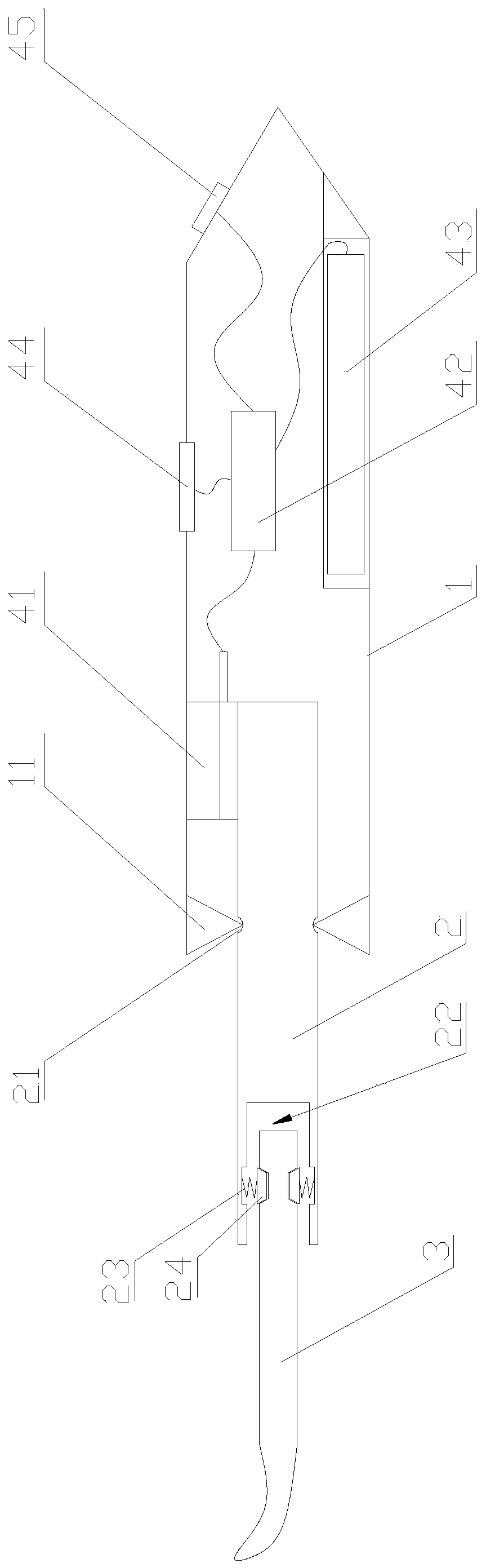

PendingCN112844505APrecise feedingNo pollution in the processBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringAnalytical chemistry

The invention discloses a vertical micro-fluidic chip and a method for nucleic acid extraction and amplification. The vertical micro-fluidic chip comprises a body provided with cavities, wherein the body is also provided with a sample cavity, a reagent cavity, a second amplification cavity and liquid flow channels respectively communicated with the cavities; and vertical micro-fluidic chip further comprises: a first rotary piston which is rotatably arranged in the body, wherein the sample cavity and the reagent cavity are located above the first rotary piston, the first amplification cavity is located below the first rotary piston, a reagent communicating groove capable of communicating a liquid flow channel of the sample cavity with a liquid flow channel of the reagent cavity is formed in the first rotary piston, the first rotary piston is also provided with a nucleic acid transfer groove capable of communicating the liquid flow channel of the sample cavity with the first liquid inlet channel; and a second rotary piston which is rotatably arranged in the body, and an amplification communicating groove capable of communicating the first liquid outlet channel with the liquid flow channel of the second amplification cavity is formed in the second rotary piston. The nucleic acid extraction and amplification device can perform nucleic acid extraction and amplification and is simple in structure and accurate in reagent quantification.

Owner:HEMOSMART MEDICAL TECH LTD

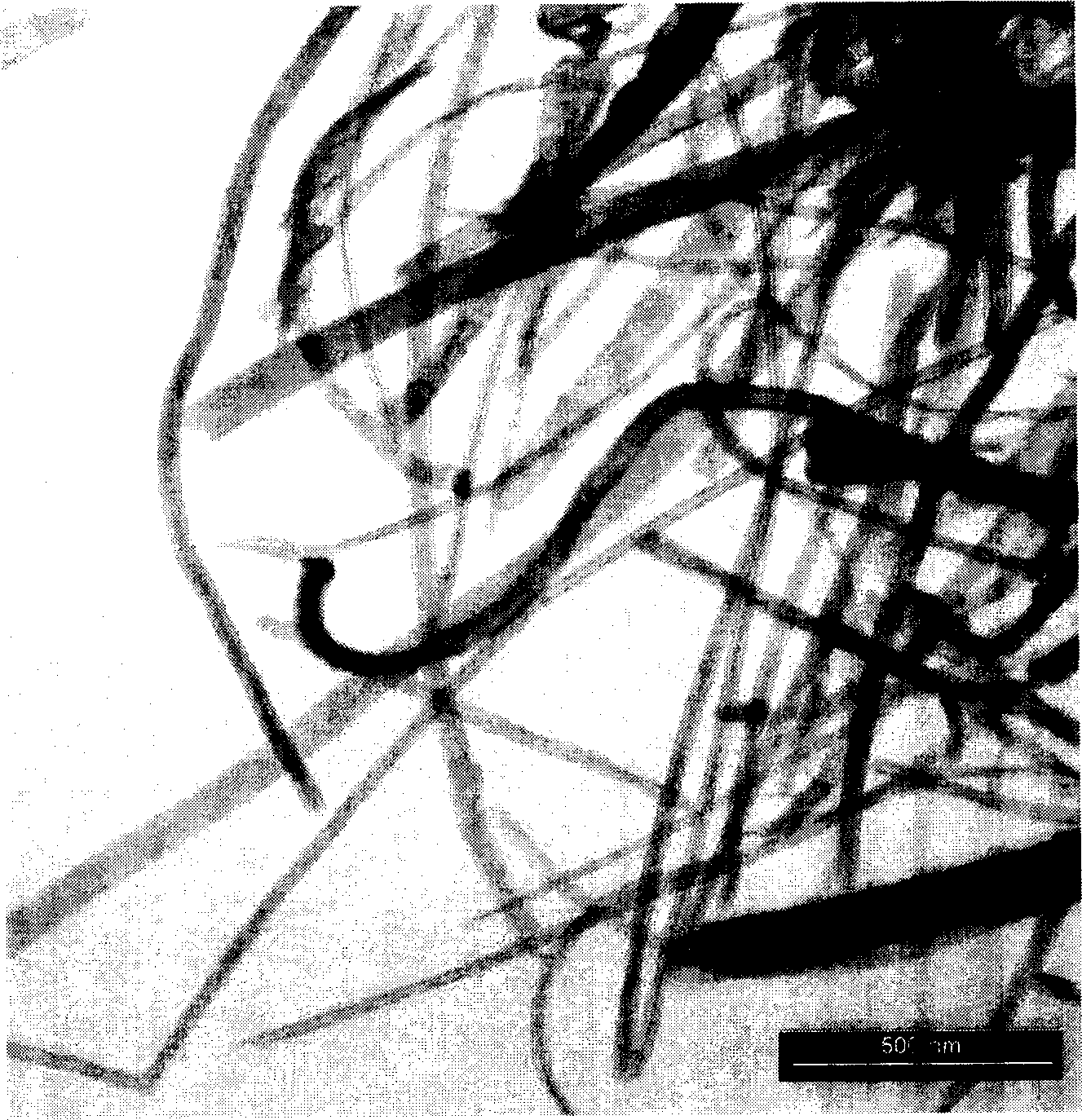

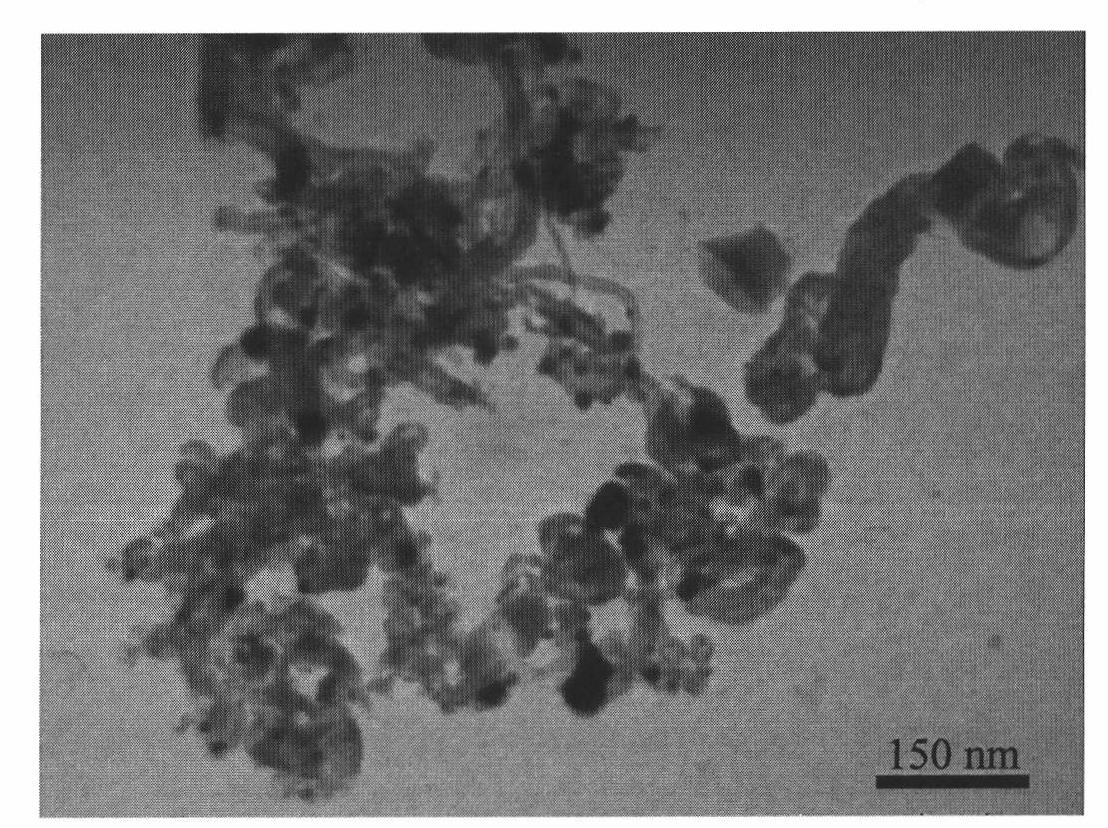

Preparation method of carbon nano pipe filled with organic solvent

InactiveCN1442359AImprove filling efficiencyEasy to operate and controllableBulk chemical productionPentaneCarbon nanotube

A process for preparing the carbon nanotubes filled by organic solvent (benzene, toluene, pentane, methanol, etc) features use of supercritical fluid technique. Said carbon nanotubes have 1-200 nm ofdiameter and 0.01-50 microns of length. Its advantages are high fill efficiency and controllable operation.

Owner:INST OF CHEM CHINESE ACAD OF SCI

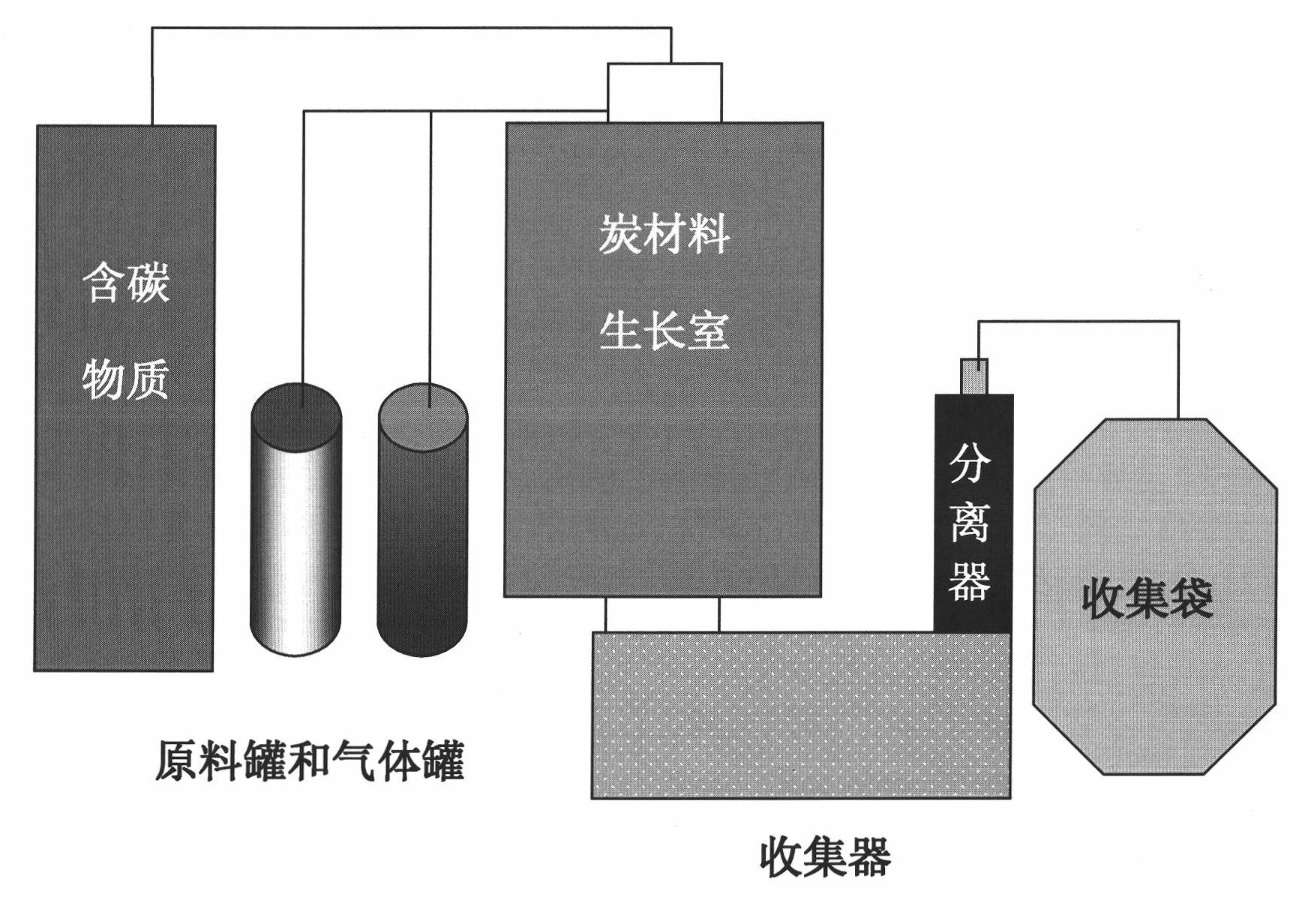

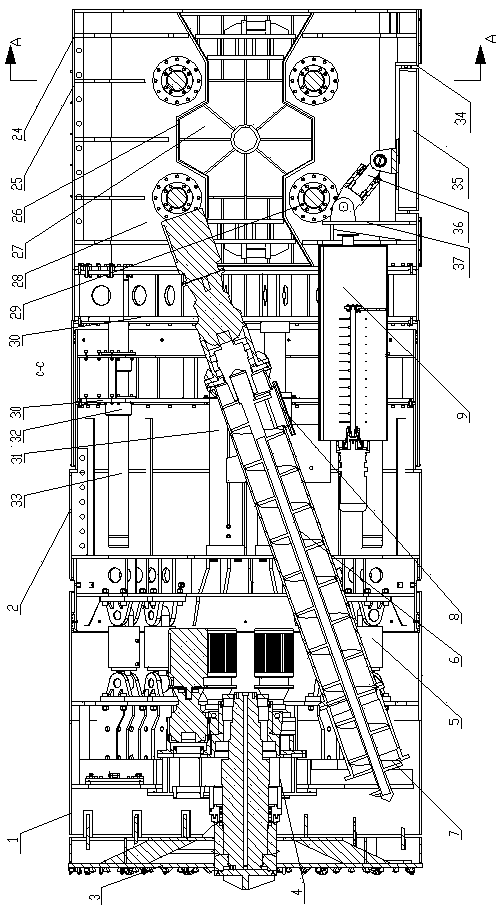

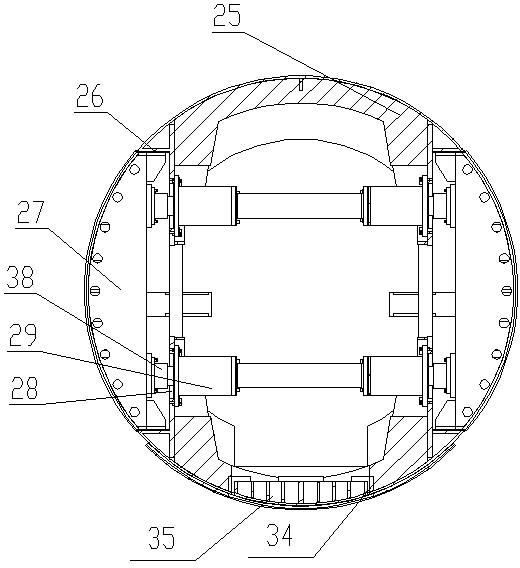

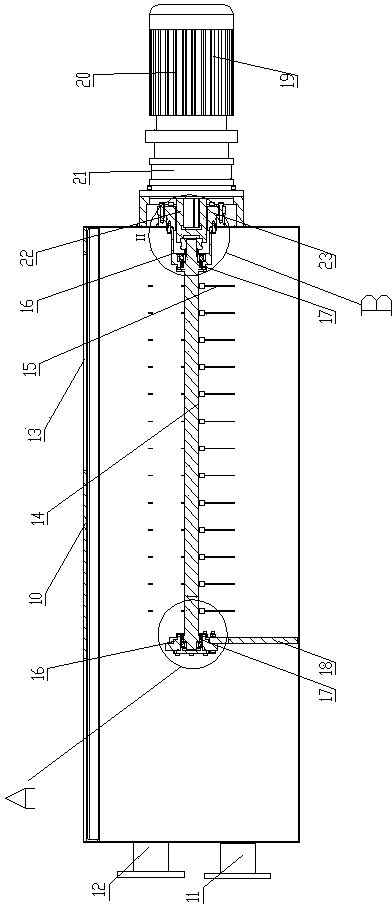

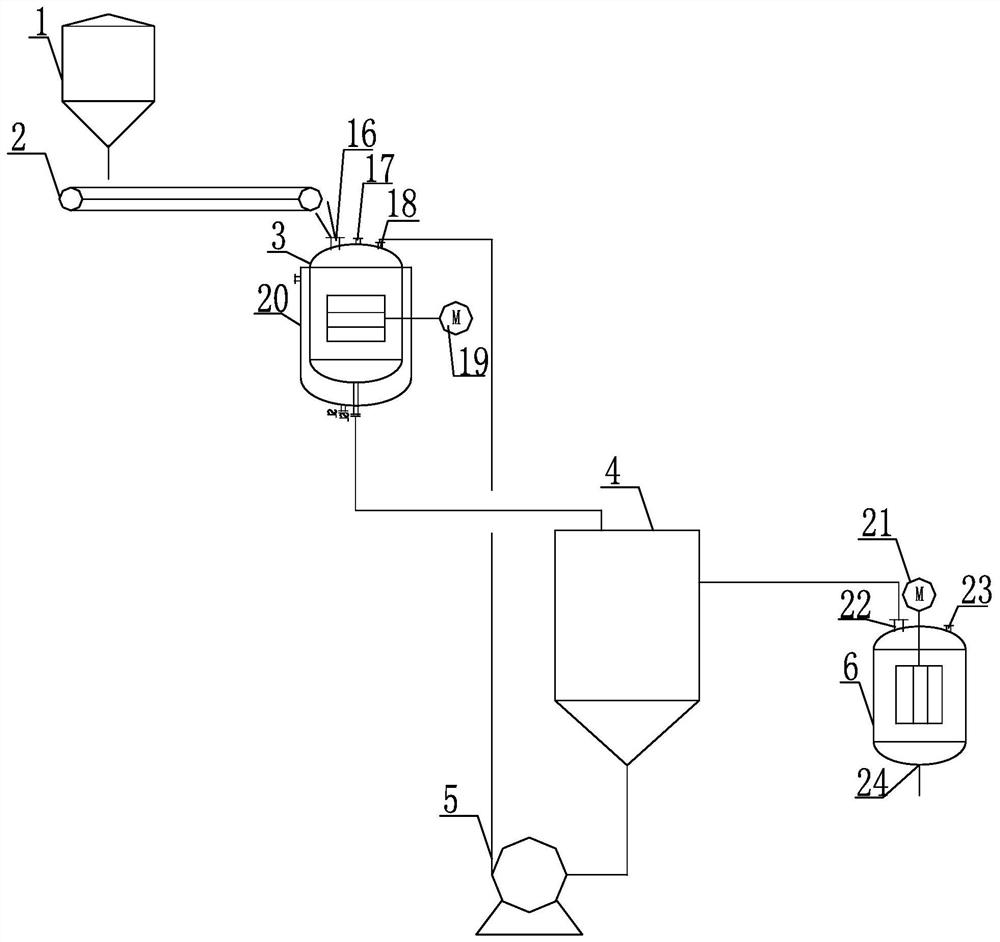

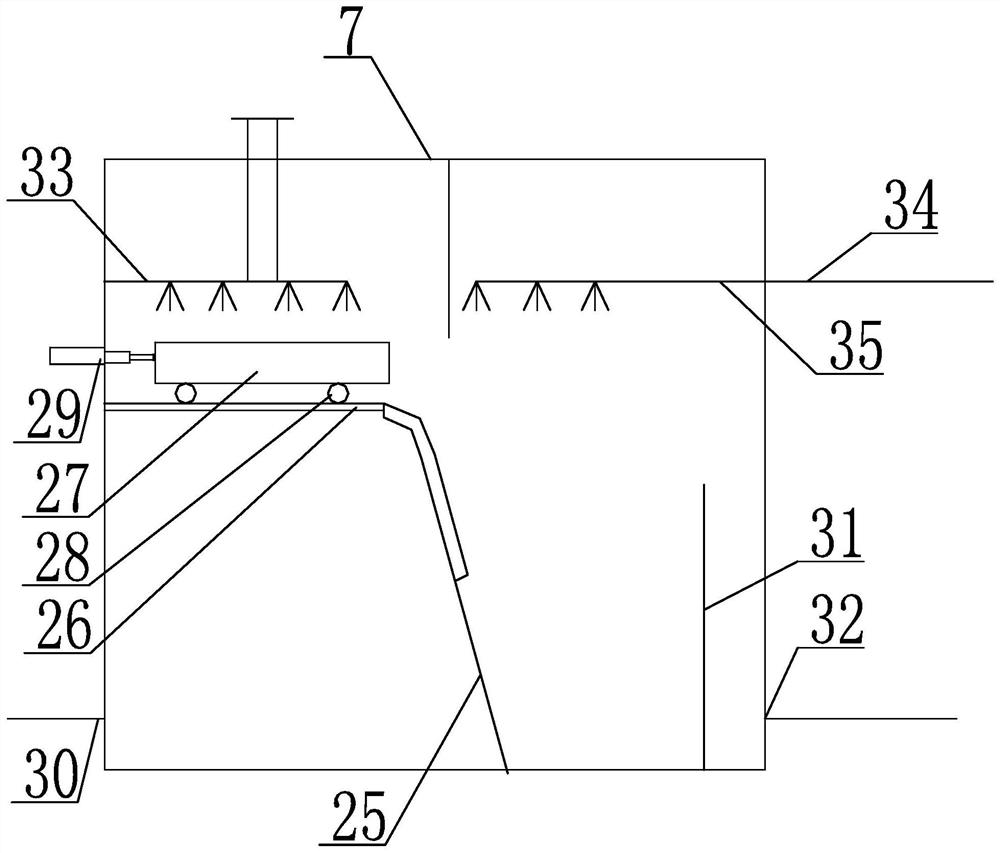

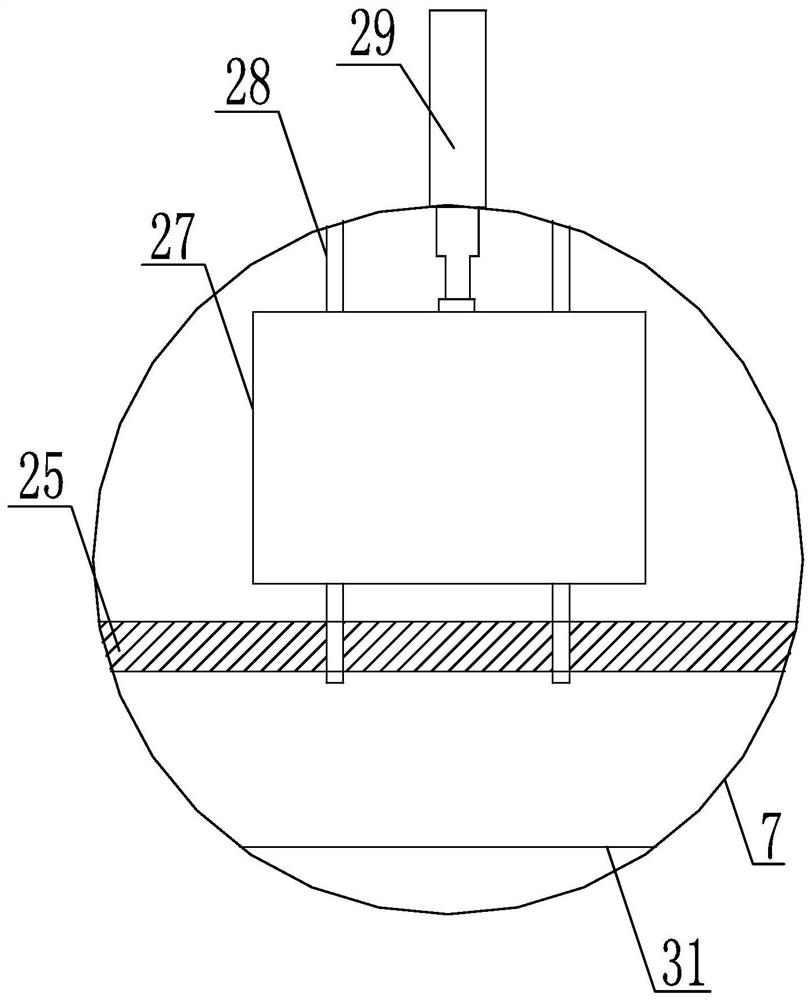

Process and device for industrial production of carbon nanofiber

The invention relates to a process and equipment for preparing carbon nanofiber. A liquid-state or gas-state hydrocarbon is taken as a carbon source, and the carbon source is one or the mixture of aromatic heavy oil, residual oil, coal tar, mixed benzene, coal pitch, coke oven gas, anthracene oil, naphthalene oil, carbolic oil, CH4, C2H2 or toluene. The process comprises the following steps of: uniformly mixing the carbon source and a catalyst in a static mixer according to a certain proportion; spraying under a high pressure by using a honeycomb duct and introducing into a cracking reaction furnace; performing a cracking reaction at the material flow speed of between 1,000 <3>h<-1> and 3,000 m<3>h<-1> at the temperature of between 1,000 DEG C and 1,400 DEG C under the pressure of between 0.5 MPa and 3.0 MPa so as to obtain carbon nanofiber; separating gas from solid by using a cyclone separator; and recycling hot air stream for preheating raw materials so as to save energy. The diameter of the prepared carbon nanofiber can be between 20 nanometers and 100 nanometers, the length is between 300 nanometers and 5 microns, and the content of fiber in a product is up to 90 percent. In a method, gas-state and liquid-state carbon-containing hydrocarbons are taken as the carbon source, so that carbon source is very rich, and price is low. The invention has the characteristics that: the method is safe and easy and is easy to realize industrial production, price is low, carbon source transformation rate is high, and the like.

Owner:BEIJING UNIV OF CHEM TECH +1

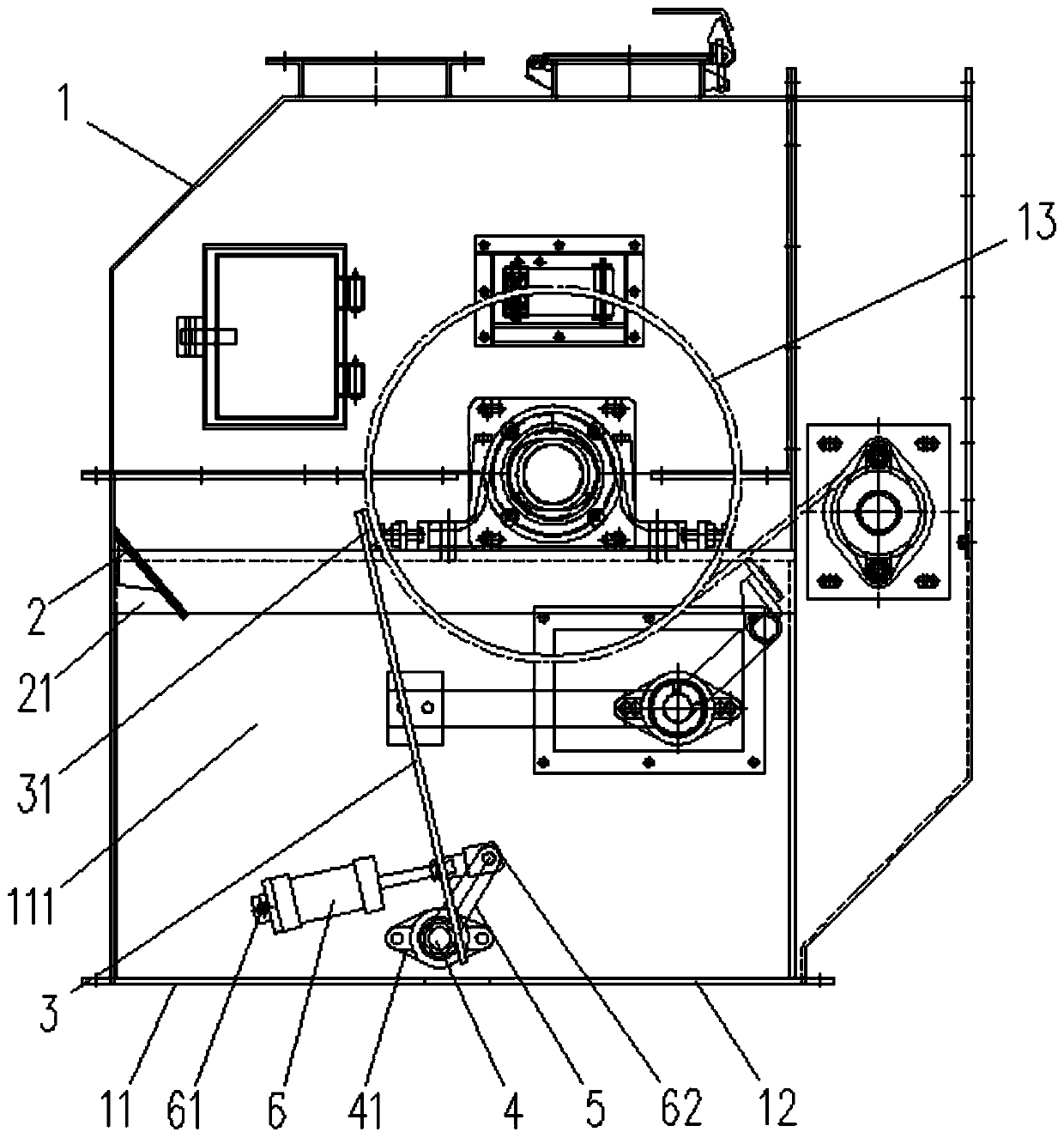

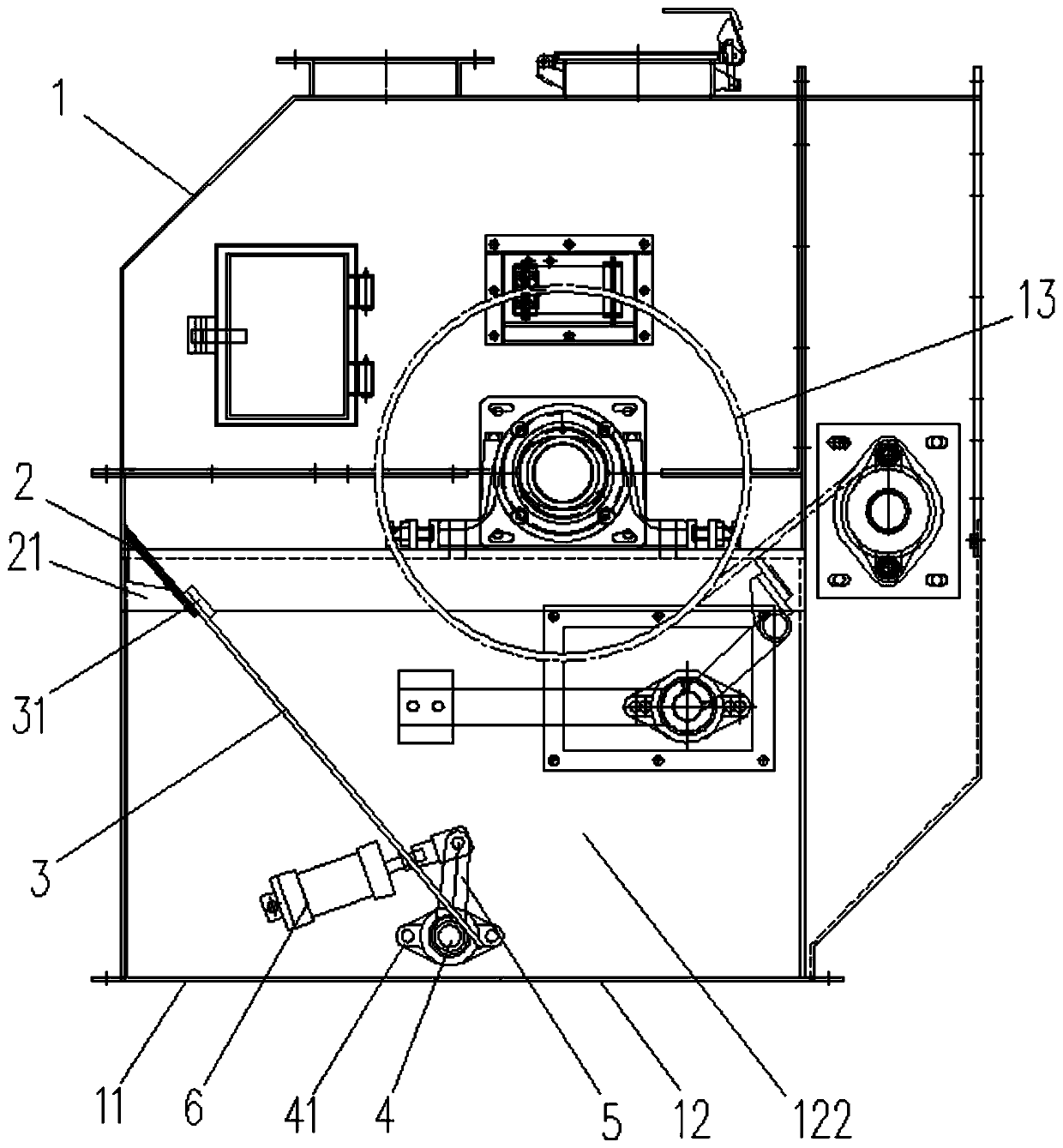

Self-propelling earth pressure balance pipe-jacking heading machine

InactiveCN104131819AReduce engineering costsEasy to operate and controllableTunnelsX-machineEarth pressure balance

The invention provides a self-propelling earth pressure balance pipe-jacking heading machine and relates to a heading machine. The self-propelling earth pressure balance pipe-jacking heading machine comprises a front shell and a rear shell, wherein the front shell and the rear shell are connected, a cutterhead is installed on the head of the front shell, a power mechanism which drives the cutterhead to rotate is installed in the front shell, a deviation correction oil cylinder is connected to the rear portion of the cutterhead, spiral augers are installed in the front shell and the rear shell, a muddy water stirring device is arranged below the spiral auger in the rear shell, and a self-propelling mechanism is connected to the rear portion of the rear shell. According to the self-propelling earth pressure balance pipe-jacking heading machine, a traditional jacking way is changed, the self-propelling mechanism is installed in a body of the pipe-jacking heading machine, and the jacking way is completely different from the traditional jacking way; the rear portion of the pipe-jacking heading machine is prevented from bearing pushing force of the oil cylinder, bearing of a large jacking load does not need to be considered when the wall thickness and the bearing capacity of a delivery pipeline are designed, designing and manufacturing can be conducted completely according to conventional parameters, and project cost is greatly reduced.

Owner:扬州斯普森机械制造有限公司

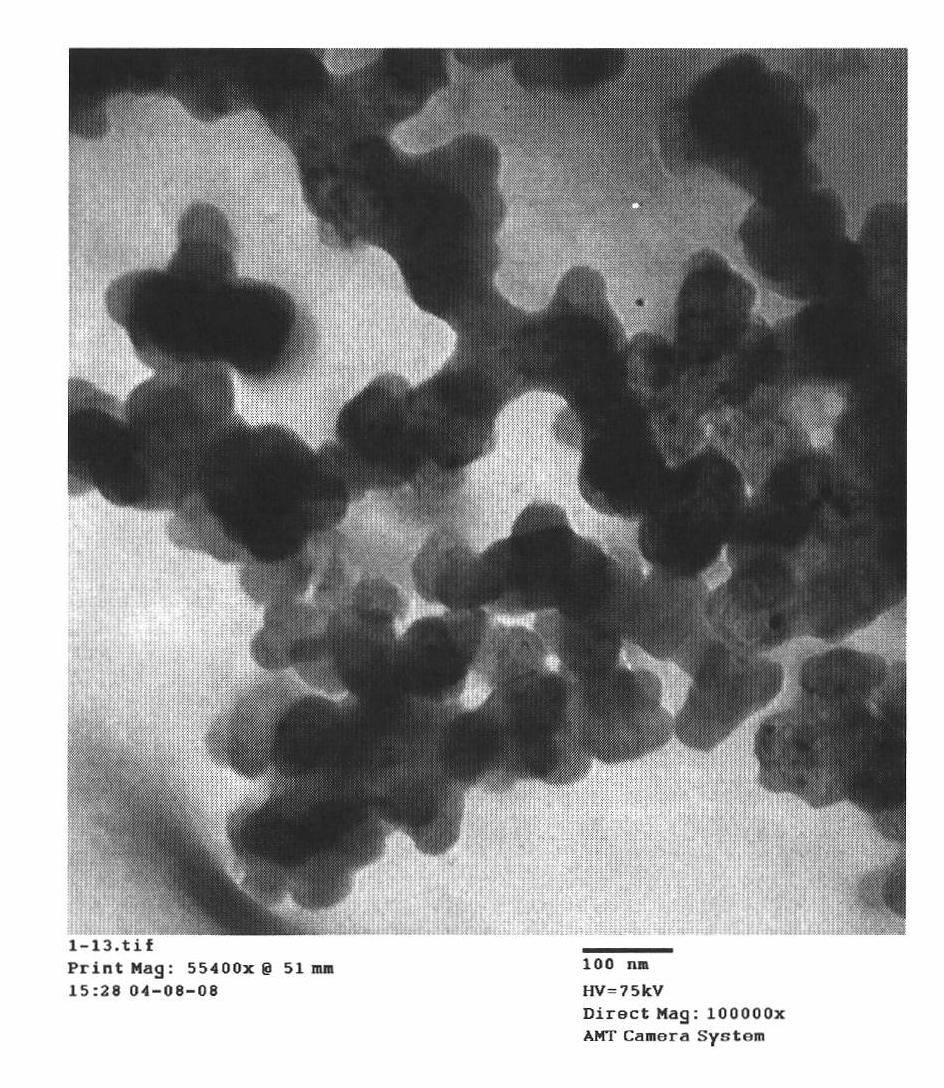

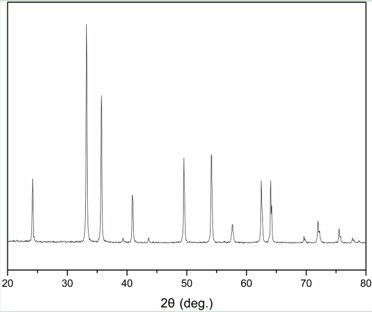

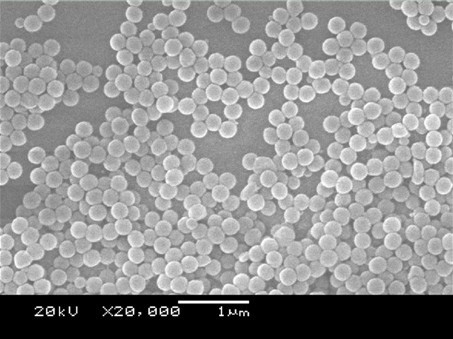

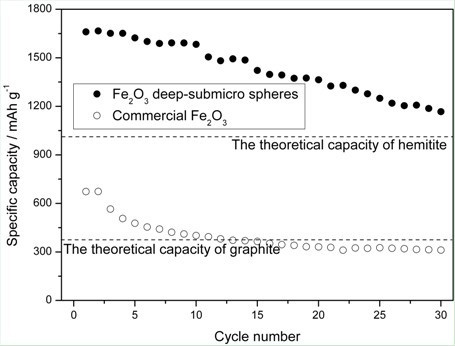

Cathode material, alpha-Fe2O3, of high-capacity lithium ion battery and preparation method for material

InactiveCN102583574ANo pollutionLow costCell electrodesFerric oxidesThermal insulationPhysical chemistry

The invention relates to a cathode material, alpha-Fe2O3, of a high-capacity lithium ion battery and a preparation method for the cathode material. According to the preparation method, soluble trivalent molysite and an alkali metal hydroxide easy to dissolve are adopted as raw materials, and the hematite alpha-Fe2O3 is prepared by a hydrothermal method. The preparation method comprises the following specific steps that: 1) aqueous solution of the trivalent molysite with molarity being 0.5mol / L-2mol / L and aqueous solution of the alkali metal hydroxide easy to dissolve with molarity being 2mol / L-6mol / L are prepared; 2) the aqueous solution of the trivalent molysite and the aqueous solution of the alkali metal hydroxide obtained in the step 1) are mixed to generate suspension, the suspension is stirred for certain time, and then ammonia water drops into the suspension, so that the pH value of the suspension is adjusted to be 9-13; and 3) the suspension obtained in the step 2) is poured into a hydrothermal reaction kettle which can be airtight, the hydrothermal reaction kettle is put into an oven to be heated at a temperature of 160 DEG C-200 DEG C and then is subjected to thermal insulation for 3 hours to 20 hours, and after the reaction is finished, a product is subjected to solid-liquid separation, washing and drying so as to obtain the alpha-Fe2O3. When serving as the cathode material of the lithium ion battery, the alpha-Fe2O3 prepared by the method has higher specific capacity and better cycling stability. According to the method, the operation is simple, the cost is low, additives are not required, and the product quality is stable.

Owner:SICHUAN UNIV

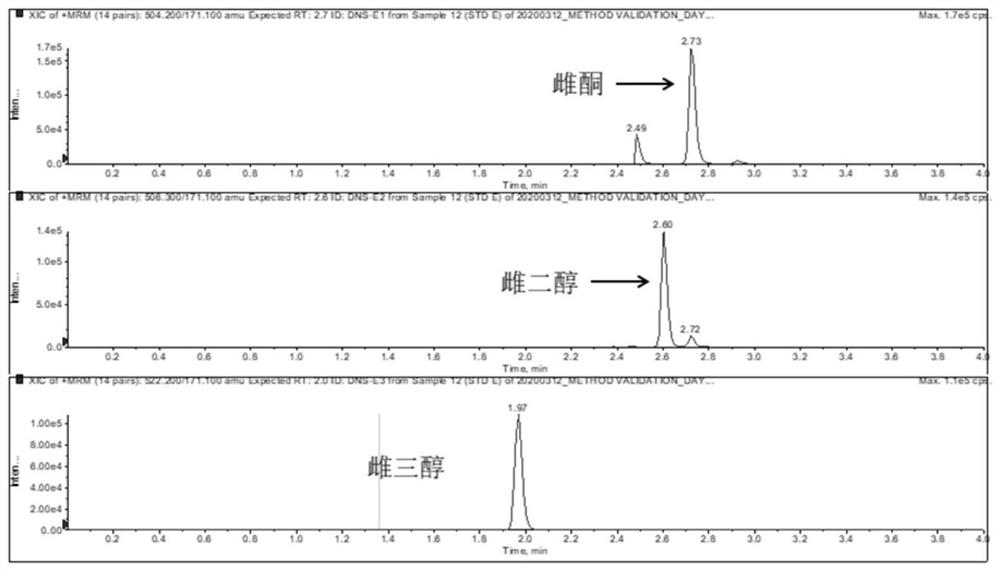

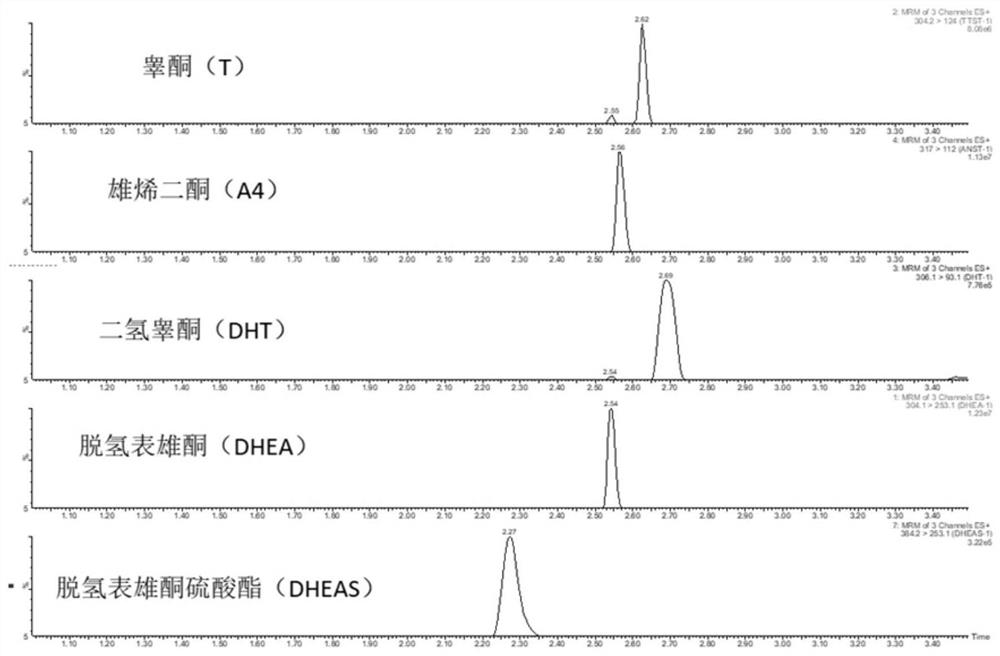

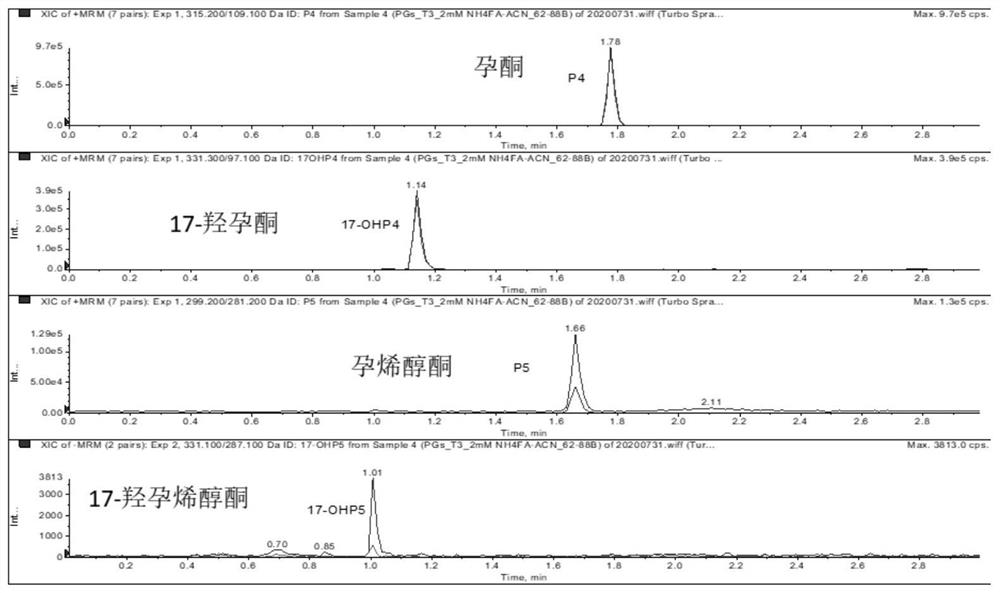

Method for purifying, enriching and detecting steroid hormones in blood

ActiveCN112611828ANovel structureAchieve toleranceComponent separationFluid phaseMass Spectrometry-Mass Spectrometry

The invention relates to a method for purifying, enriching and detecting steroid hormones in blood, and belongs to the technical field of medical examination and analysis. A sample containing steroid hormones is prepared from a low-density three-point bonded C18 filler taking silica gel as a matrix, and purification and enrichment of steroid hormones in the sample are realized by optimizing parameters such as solvent dosage and leacheate proportion in the preparation process. The prepared steroid hormone sample is analyzed through liquid chromatography-tandem mass spectrometry under certain conditions, and multiple steroid hormones can be detected at the same time at a time. The method has the characteristics of good stability, high sensitivity, high recovery rate, simplicity, convenience and controllability in operation, capability of realizing automatic operation and the like.

Owner:大连博源医学检验实验室有限公司

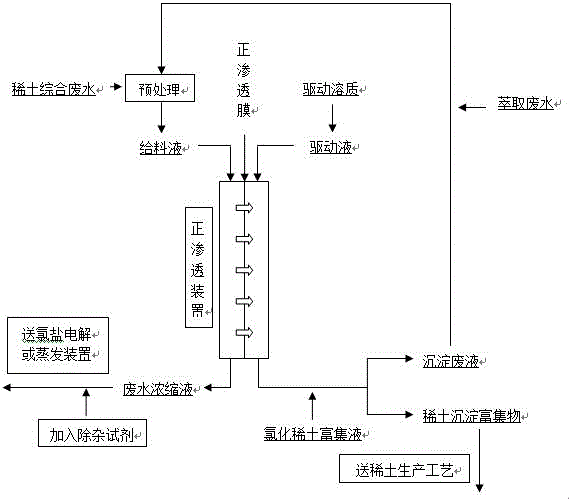

Method for treating rare-earth comprehensive wastewater by forward osmosis membrane separation

InactiveCN104355433AAchieving zero emissionsReduce processing energy consumptionFatty/oily/floating substances removal devicesWaste water treatment from metallurgical processHigh concentrationLiquid waste

The invention discloses a method for treating rare-earth comprehensive wastewater by forward osmosis membrane separation, and belongs to the technical field of environmental engineering wastewater treatment. The method comprises the following steps: by taking pretreated rare-earth comprehensive wastewater as feed liquid and taking a sodium carbonate solution as a driving fluid, concentrating the rare-earth comprehensive wastewater by using a forward osmosis membrane separation method, so that the driving fluid is diluted; mixing the diluted driving fluid with chlorinated rare-earth enrichment liquid enriched by using a rare-earth production process, so that a rare-earth carbonate precipitate and precipitate waste liquid are generated; feeding a rare-earth precipitate enriched substance into a subsequent rare-earth production process; and preparing sodium chloride crystals by taking a concentrated solution of the rare-earth comprehensive wastewater on the feed liquid side, after being subjected to impurity removal, as a chlorine salt electrolysis raw material, or through carrying out evaporation and concentration. According to the method, a forward osmosis membrane separation process and a rare-earth double salt precipitation process are combined together, and sodium chloride-containing waste liquid is applied to a rare-earth production process, so that the zero release of medium / high-concentration sodium chloride-containing rare-earth waste liquid can be realized, therefore, the method has the characteristics of good treatment effect and environmental friendliness.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

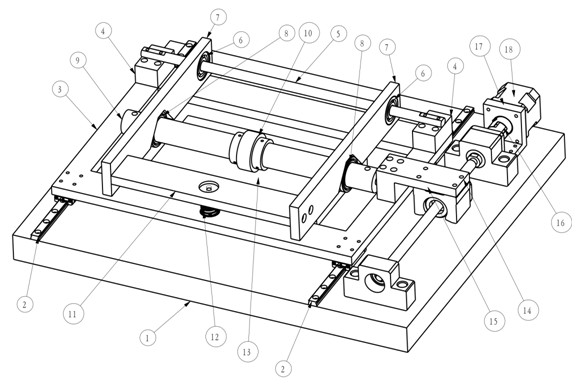

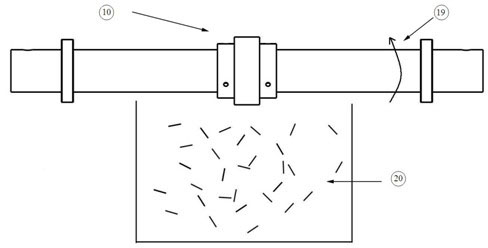

Method for large area arrangement of nanowires

InactiveCN102328898AConvenient ArrangementSimple design and manufactureDecorative surface effectsChemical vapor deposition coatingSpinningOrganic solvent

The invention discloses a method for arranging a one-dimensional nanowire array in a large area from a solvent, which is a method with simplicity and easiness in operation. The method comprises the following steps of: firstly taking oriented spinning nano fiber on a roller as a template, immersing the roller with the oriented fiber into a nanowire suspension, rotating the roller in the nanowire suspension at a certain speed, causing the nanowires in the solution to be adsorbed into the roller with the oriented fiber, finally putting the roller with oriented-adsorbed nanowires on a designed device, adding a little water or organic solvent lubricant on a substrate, and driving the roller with the oriented spinning fiber to roll forward by a transmission device to realize a successful transfer of the nanowires adsorbed on the fiber to the substrate. The method disclosed by the invention not only has convenience for operation, and the needed equipment is easy to design and manufacture; the method is applicable to various types of substrates, easy to realize large-area parallel arrangement of nanowires, and available for preparation of micron / nanometer electronic detecting members and the like.

Owner:SOUTHEAST UNIV

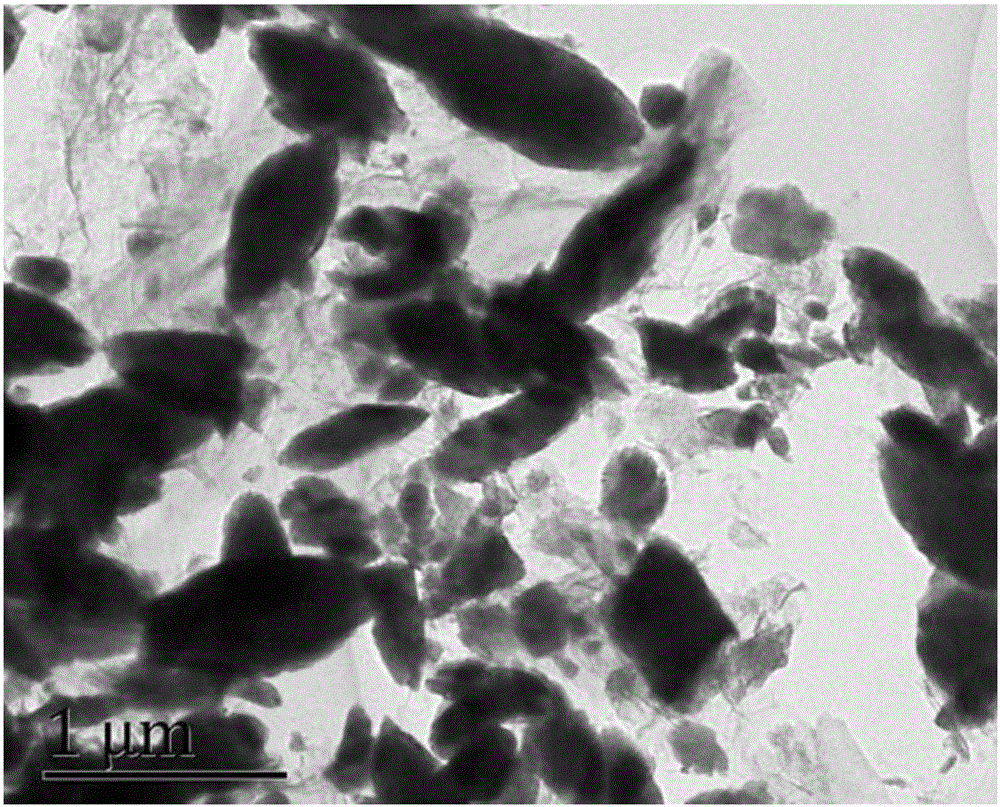

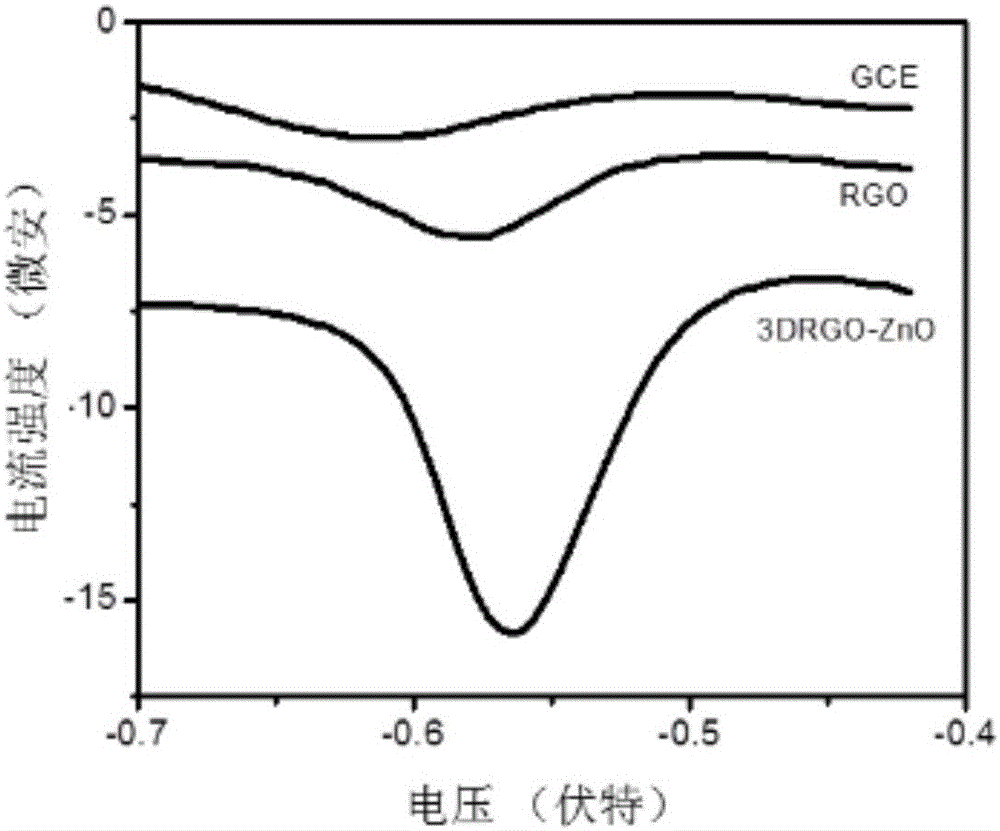

Graphene-wrapping zinc oxide three-dimensional composite material catalyst and preparation method and application thereof

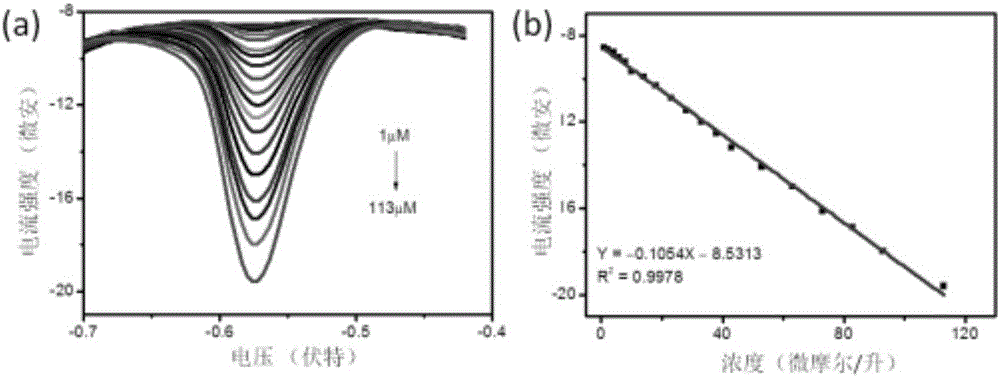

ActiveCN106000381AShort preparation timeImprove efficiencyMaterial analysis by electric/magnetic meansMetal/metal-oxides/metal-hydroxide catalystsLower limitElectrochemical biosensor

The invention relates to a graphene-wrapping zinc oxide three-dimensional composite material catalyst and a preparation method and application thereof. The mass percent of zinc oxide in the three-dimensional composite material catalyst is 66-70%. The graphene-wrapping zinc oxide in the composite material catalyst is in a three-dimensional shuttle shape. The preparation method comprises the steps that zinc foil is immersed into a graphene oxide water solution, a hydrothermal reaction is carried out at the temperature of 80-100 DEG C for 0.5-1 hour, ultrasonic concussion, washing and drying are carried out, and the graphene-wrapping zinc oxide three-dimensional composite material catalyst is obtained. The surface of a glassy carbon electrode is decorated with the composite material so that an electrochemical transducer can be formed, the composite material is directly applied to sensitivity detection of chloramphenicol, and the lower limit of detection can reach 0.5 micrometer. According to the grephene-wrapping zinc oxide three-dimensional composite material catalyst and the preparation method and application thereof, operation is easy and quick, and the prepared three-dimensional composite material can be applied to electrochemical sensing of chloramphenicol, has the advantages of being high in sensitivity, good in stability and capable of being repeatedly used and has potential application prospects in an electrochemical biosensor.

Owner:DONGHUA UNIV

Electronic weighing medicine spoon device

InactiveCN110918151AEasy, quick and efficient operationEasy to operate and controllableSpatulasSpecial purpose weighing apparatusElectrical connectionStress sensors

The invention relates to an electronic weighing medicine spoon device. A first assembly is of a shell-shaped structure with an opening in one end, and supporting parts are arranged at the opening of the first assembly in longitudinal symmetry. One end of a second assembly is arranged in the first assembly in a penetrating mode, the second assembly is in multi-point contact or linear contact with the supporting parts of the first assembly, and a medicine spoon fixing part is arranged at the other end of the second assembly and used for fixing a medicine spoon. A pressure sensor, an integrated circuit board and a power source are arranged in the first assembly, and a display screen and a switch are arranged on the shell of the first assembly. The pressure sensor is fixed in the first assembly and arranged above the end, located in the first assembly, of the second assembly. The integrated circuit board is in power supply connection with the power source. and the integrated circuit boardis electrically connected with the pressure sensor, the display screen and the switch. The device is convenient, quick and efficient to operate, and is simpler, more convenient and controllable in operation than decrement weighing when being used for weighing a reagent which is easy to deteriorate in air, so that the weighing time is shortened, and the weighing error is reduced.

Owner:FUJIAN NORMAL UNIV

Preparation method and application of water-soluble natural pigment microcapsule

The invention discloses a preparation method of a water-soluble natural pigment microcapsule. The preparation method comprises the following steps: with methyl methacrylate and acrylic acid or acrylamide as a wall material and a water-soluble natural pigment as a core material, adding an emulsifying agent and an initiator, mixing at a certain condition to prepare an emulsion, and carrying out polymerization, so as to obtain the microcapsule. The preparation method has the beneficial effects that the preparation process is environment-friendly, the operation is simple and convenient, and the prepared microcapsule is excellent in stability, acid-base resistance and light resistance and can be used as color paste to be applied to the field of textile.

Owner:ZHONGYUAN ENGINEERING COLLEGE +1

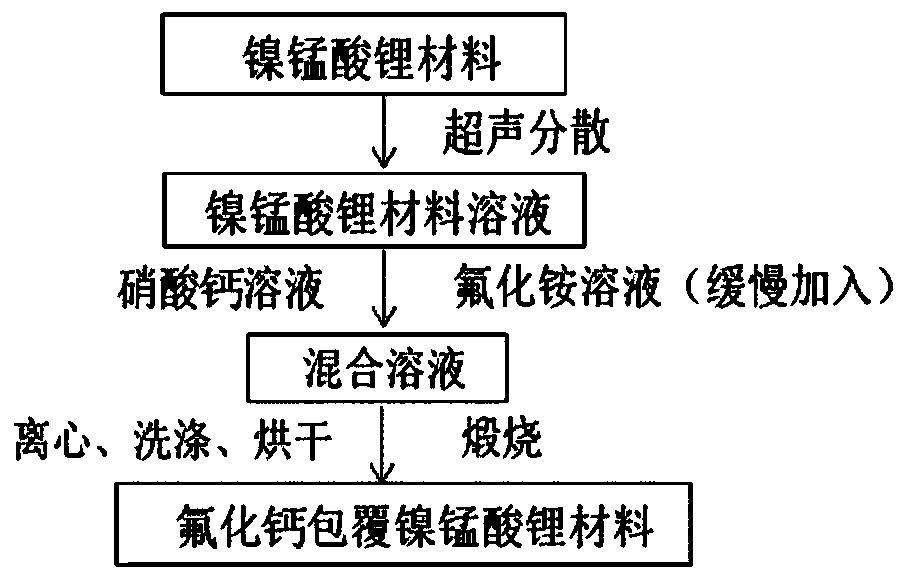

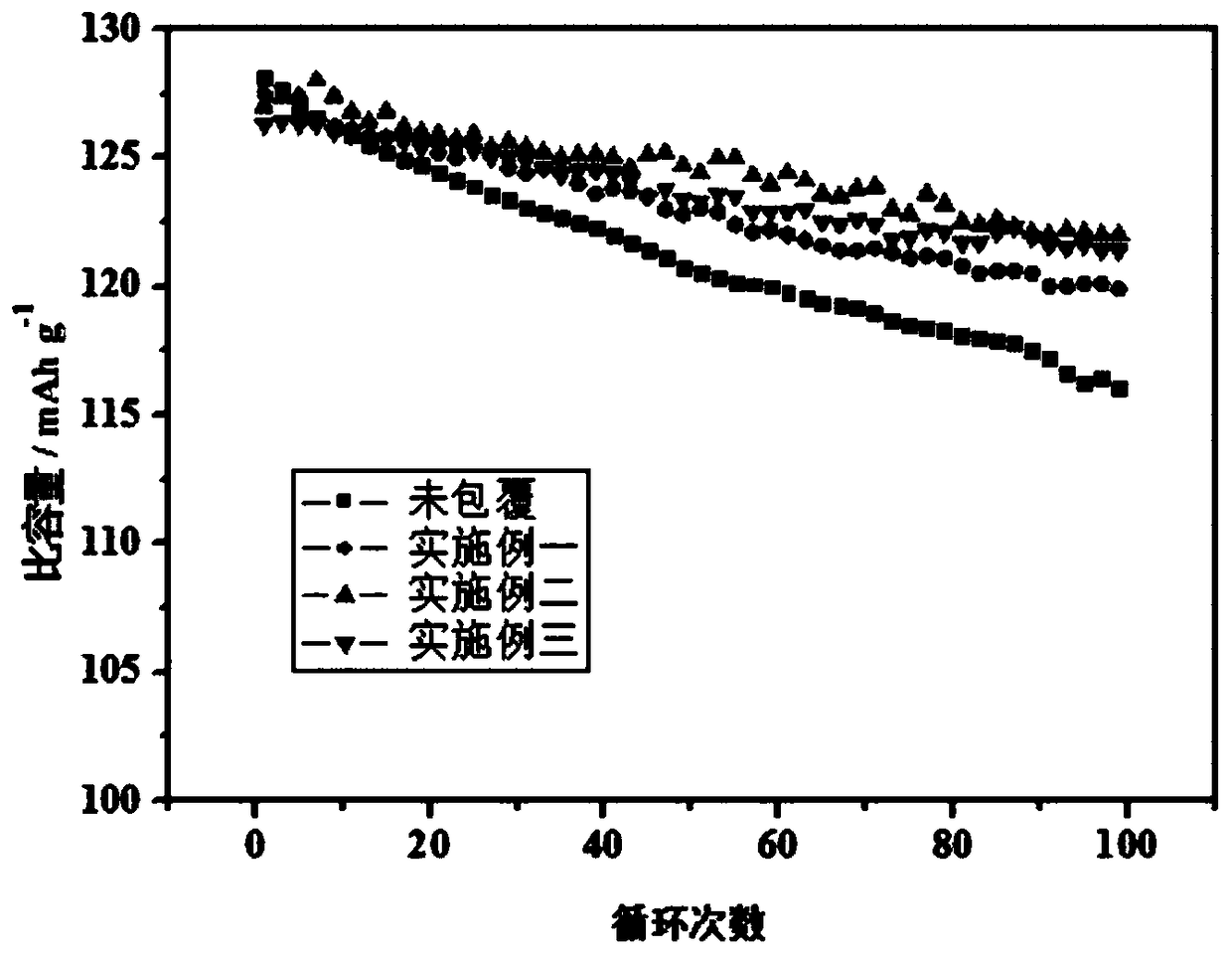

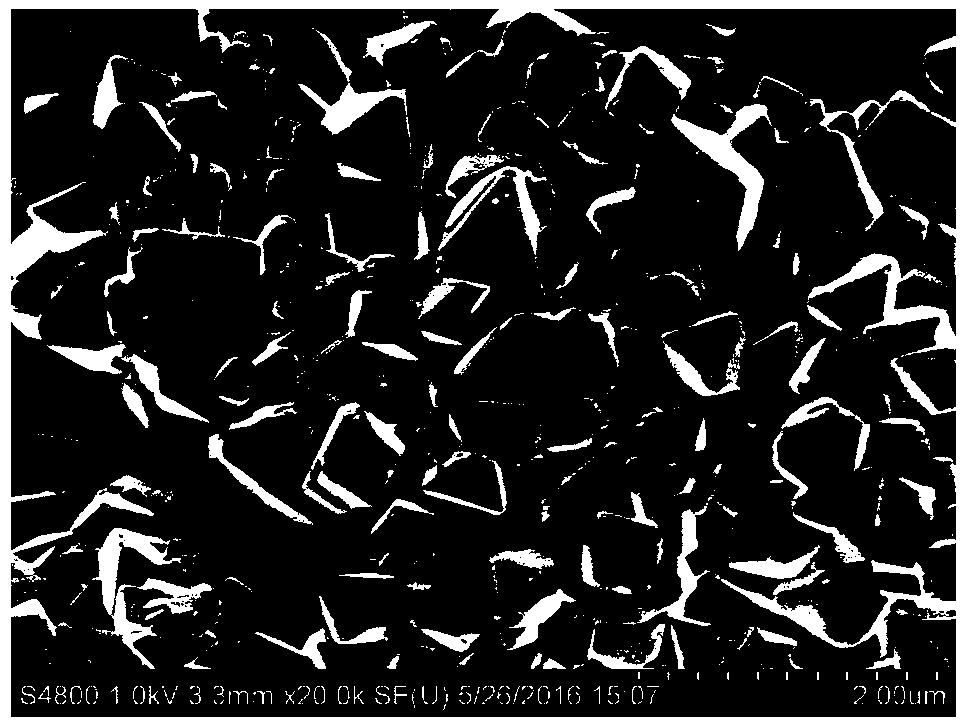

Calcium fluoride coated lithium nickel manganate and preparation method thereof

InactiveCN109065868AImprove high temperature electrochemical cycle performanceReduce solubilityCell electrodesSecondary cellsWater bathsLithium

The invention discloses a calcium fluoride coated lithium nickel manganate and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing the ammonium fluoride solution with a mixed solution of lithium nickel manganate and calcium nitrate; performing Water bath reaction at 60 to 90 degree centigrade for 5 to 10 hours, centrifuging, wahsing, drying, and calcining to obtain calcium fluoride coated lithium nickel manganate; The calcination temperature is 200 to 500 degree centigrade for 2 to 6 hours; In the calcium fluoride coated lithium nickel manganate, the mass ratio of calcium fluoride to lithium nickel manganate is 0.5% to 8%. The calcium fluoride coated lithium nickel manganate prepared by the method has uniform distribution and can remarkablyimprove the high-temperature cycling performance of the lithium nickel manganate material.

Owner:SHANGHAI ELECTRICGROUP CORP

Nutrient health-care food as well as preparation method and application thereof

InactiveCN107594315AEasy to eatGreat tasteDough treatmentModified nutritive productsSide effectSemen

The invention relates to the field of foods, and particularly provides a nutrient health-care food as well as a preparation method and application thereof. The nutrient health-care food mainly comprises the following raw materials of ginseng, lotus seeds, coix seeds, fructus momordicae, thallus laminariae, black wood ears, carrots, dendrobium nobile, Chinese wolfberry fruits, Chinese yams, poria cocos, lily bulbs, black beans, green tea, oat, purslane herbs, rice beans, phaseolus coccineus and semen sterculiae lychnophorae. According to the nutrient health-care food, through a reasonable compounding ratio, various nutrient substances desired by human bodies are provided, so that after people insist on eating the nutrient health-care food, the improvement effect on symptoms of eccyclomastopathy and dysmenorrhea of women is obvious, and the immunity of human bodies is also enhanced to a certain extent. The preparation method of the nutrient health-care food is simple, and convenient andcontrollable in making technology, and the nutrient health-care food is convenient to eat and free from side effects.

Owner:李秀飞

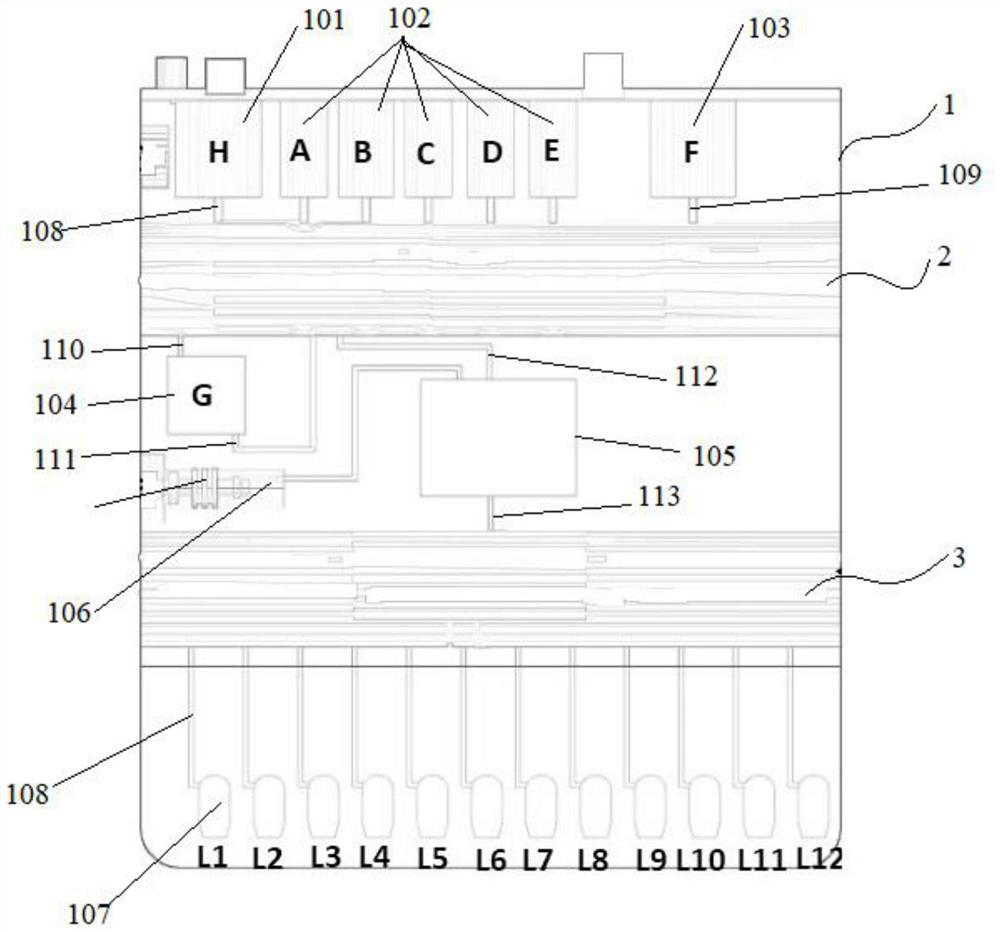

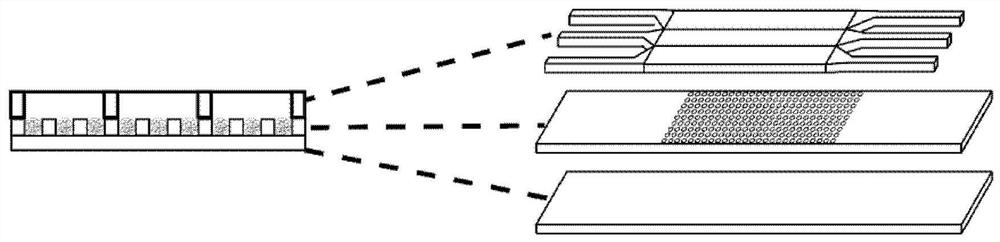

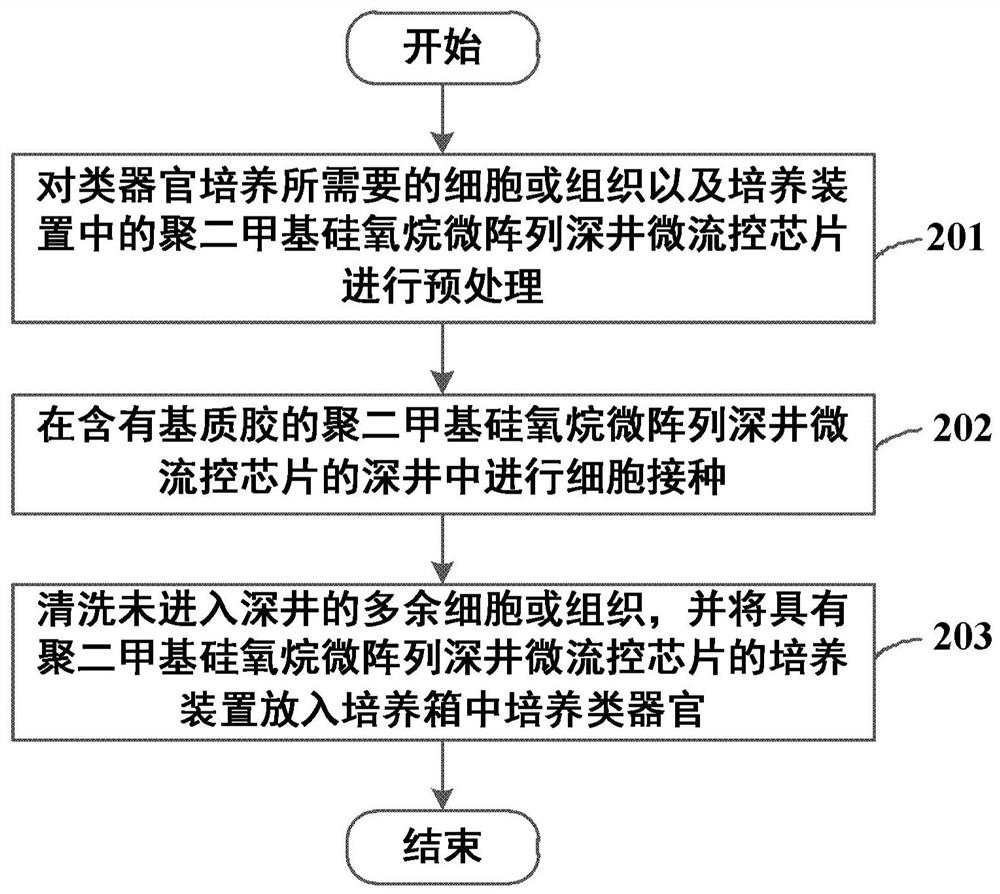

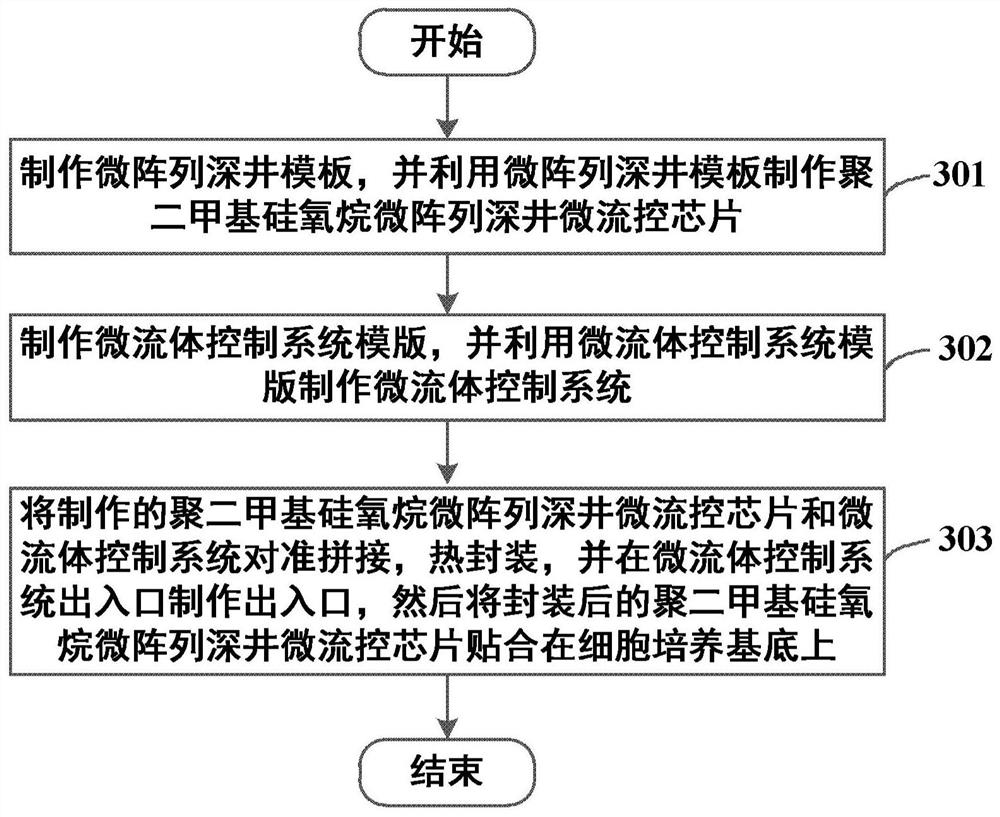

Device and method for culturing high-throughput organoids by using micro-array deep well

ActiveCN112226363ASimple structureEasy to operate and controllableBioreactor/fermenter combinationsCompound screeningMicro fluidicMicrofluidic chip

The invention relates to a device and method for culturing high-throughput organoids by using a micro-array deep well. The device comprises a cell culture substrate, a polydimethylsiloxane micro-arraydeep well micro-fluidic chip and a micro-fluidic control system, wherein the cell culture substrate is bonded under the polydimethylsiloxane micro-array deep well micro-fluidic chip; the polydimethylsiloxane micro-array deep well micro-fluidic chip is bonded under the micro-fluidic control system, and meanwhile is bonded over the cell culture substrate; and the micro-fluid control system is bonded over the polydimethylsiloxane micro-array deep well micro-fluidic chip. According to the device and the method for culturing the high-throughput organoids by using the micro-array deep well, the device comprising the cell culture substrate, the polydimethylsiloxane micro-array deep well micro-fluidic chip and the micro-fluidic control system is employed, has a simple structure, convenient and controllable to operate, and overcomes the defect that sizes of the high-throughput organoids are very hard to be uniform due to uncontrollability of the operation process.

Owner:PEKING UNIV

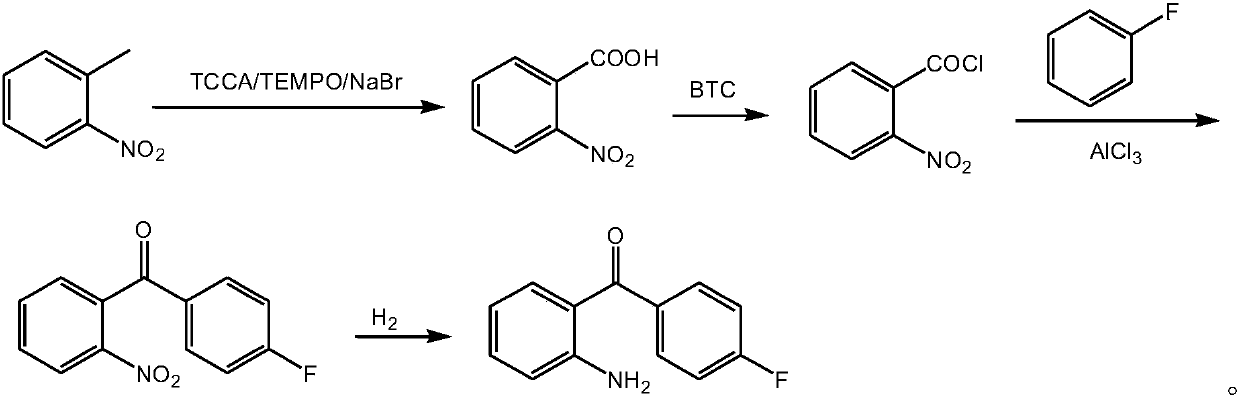

Method for preparing 2-amino-4'-fluorobenzophenone

ActiveCN107652192AEasy to operate and controllableLow costOrganic chemistryOrganic compound preparationAluminum trichlorideNitrobenzoic acid

The invention discloses a method for preparing 2-amino-4'-fluorobenzophenone. The method comprises the following steps: o-nitrotoluene, trichloroisocyanuric acid, tetramethylpiperidine nitrogen oxideand sodium bromide undergo an oxidation reaction to obtain o-nitrobenzoic acid; the o-nitrobenzoic acid and trichloromethyl carbonate undergo an acylating chlorination to obtain o-nitrobenzoyl chloride; the o-nitrobenzoyl chloride, fluorobenzene and aluminum trichloride undergo a Friedel-Crafts reaction to obtain 2-nitro-4'-fluorobenzophenone; and the 2-nitro-4'-fluorobenzophenone is reduced by hydrogen to the 2-amino-4'-fluorobenzophenone. The method has the advantages of green and environmentally-friendly synthesis route, cheap and easily available initial raw materials, low cost, convenience in operation, suitableness for industrial production, and high yield, and the prepared 2-amino-4'-fluorobenzophenone has a good purity.

Owner:ANHUI QINGYUN PHARMA & CHEM

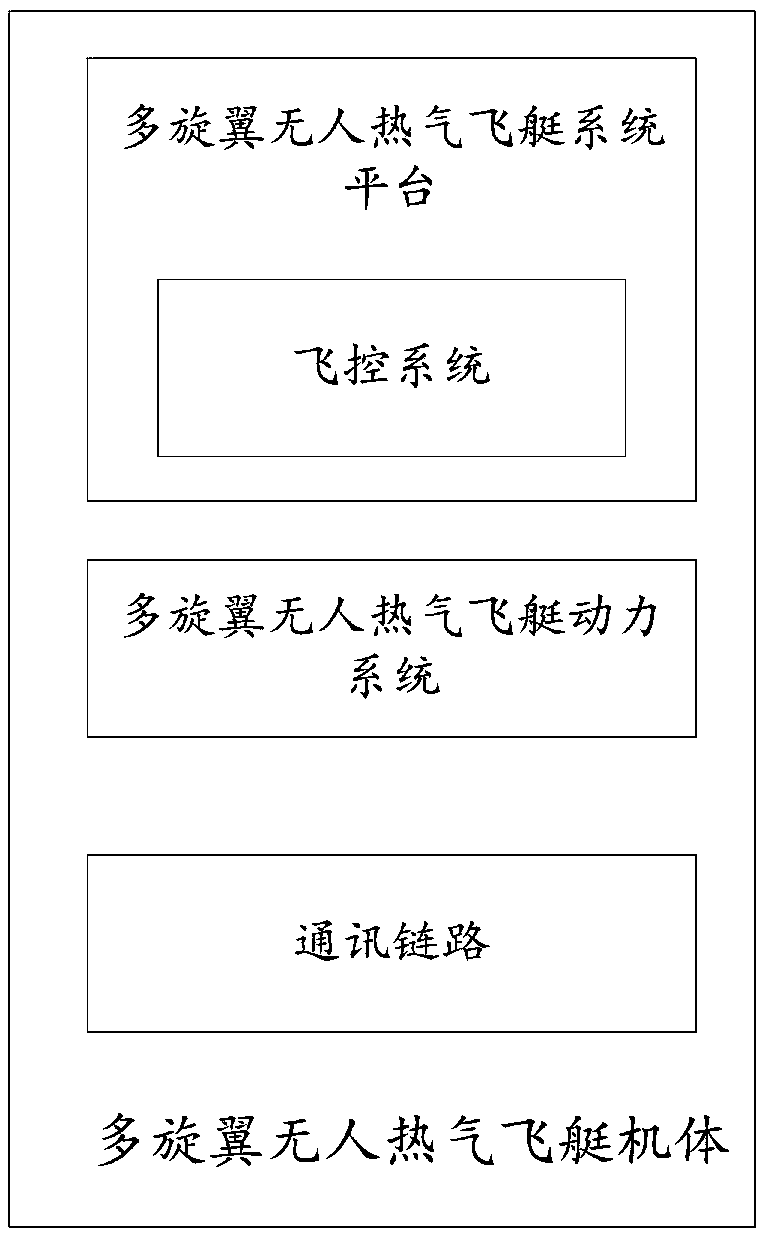

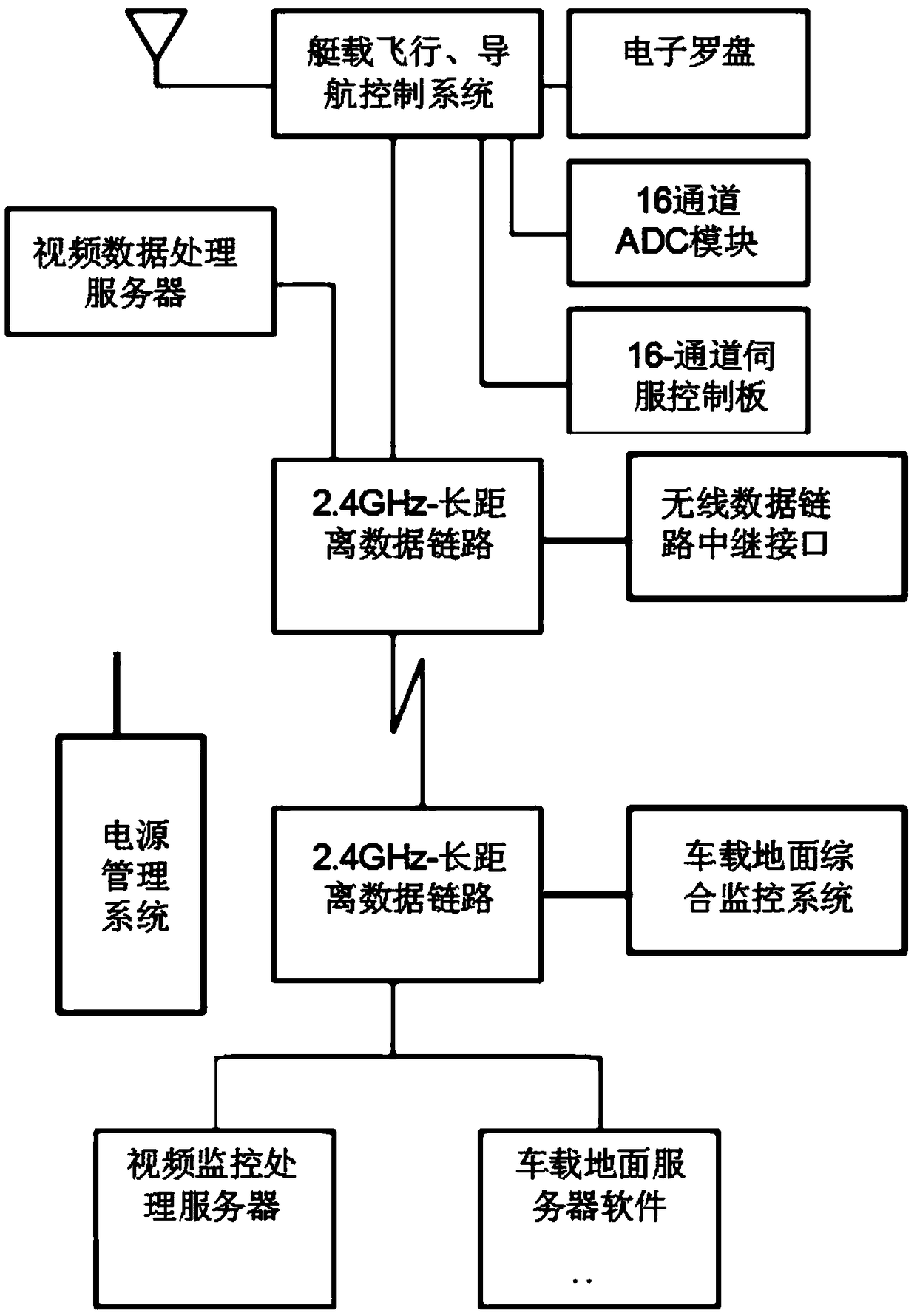

Multi-rotor unmanned hot air airship system

ActiveCN108974316AImprove data exchange capabilitiesImprove statusLighter-than-air aircraftNacelleOn board

The invention discloses a multi-rotor unmanned hot-air airship system, which comprises a multi-rotor unmanned hot-air airship body, a multi-rotor unmanned hot-air airship system platform and a multi-rotor unmanned hot-air airship power system. The multi-rotor unmanned hot-air airship body adopts a spliced and assembled floater shell, a double-layer airbag, a nacelle and a multi-rotor unmanned hot-air airship power system. The platform of multi-rotor unmanned hot-air airship system is equipped with flight control system and navigation system, on-board measurement and control system, on-board electrical system, on-board ground measurement and control system, and on-board ground integrated monitoring and processing system. Multi-rotor unmanned hot-air airship power system adopts rotor assembly, rotor assembly includes: adjustable inclination rotor motor, blade, tilt angle control, tilt lock protection and vector power control; The multi-rotor unmanned hot-air airship system and the groundintegrated command vehicle realize the regional mobile data link networking, automatic roaming, interconnection and intercommunication, hierarchical management and unified command of the whole network.

Owner:CHONGQING VOCATIONAL COLLEGE OF TRANSPORTATION

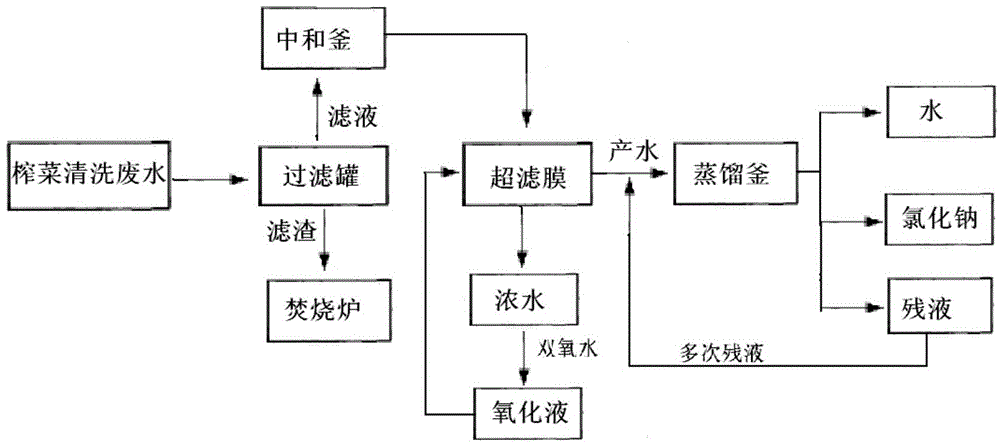

Wastewater comprehensive treatment and utilization process

InactiveCN104445708AReduce investmentEasy to operate and controllableTreatment involving filtrationMultistage water/sewage treatmentUltrafiltrationControllability

The invention discloses a wastewater comprehensive treatment and utilization process for treating preserved szechuan pickle cleaning wastewater. The technical scheme is as follows: the wastewater comprehensive treatment and utilization process comprises the following steps of: a, introducing the preserved szechuan pickle cleaning wastewater into a filtering tank by using a pressure pump, filtering preserved szechuan pickle leaves and various large-granular impurities, and carrying out incineration treatment in an incinerator; b, transferring filter liquor obtained from the step a into a neutralization kettle with stirring, and dropping a sodium hydroxide solution to regulate the pH value to be 5-7; c, introducing a solution obtained from the step b into an ultrafiltration membrane device for ultrafiltration to obtain concentrated water and produced water; d, adding the concentrated water obtained from the step c to hydrogen peroxide for oxidation reaction, and returning the obtained reaction liquid into the step c for the ultrafiltration; e, introducing the produced water obtained from the step c into a concentration kettle for concentration, recovering water and salt, recycling a generated mother solution into the produced water obtained from the step c, and operating for multiple times. The wastewater comprehensive treatment and utilization process disclosed by the invention has the advantages of easiness, convenience and controllability for operation, environmental friendliness, high waste liquid treatment capacity, high recovery rate and zero discharge of polluting wastes.

Owner:NANJING BEST ENVIRONMENTAL PROTECTION EQUIP CO LTD

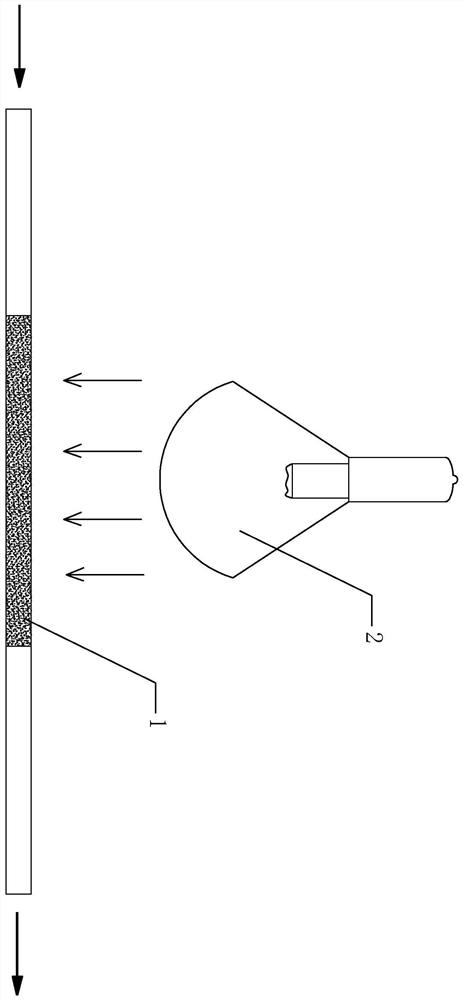

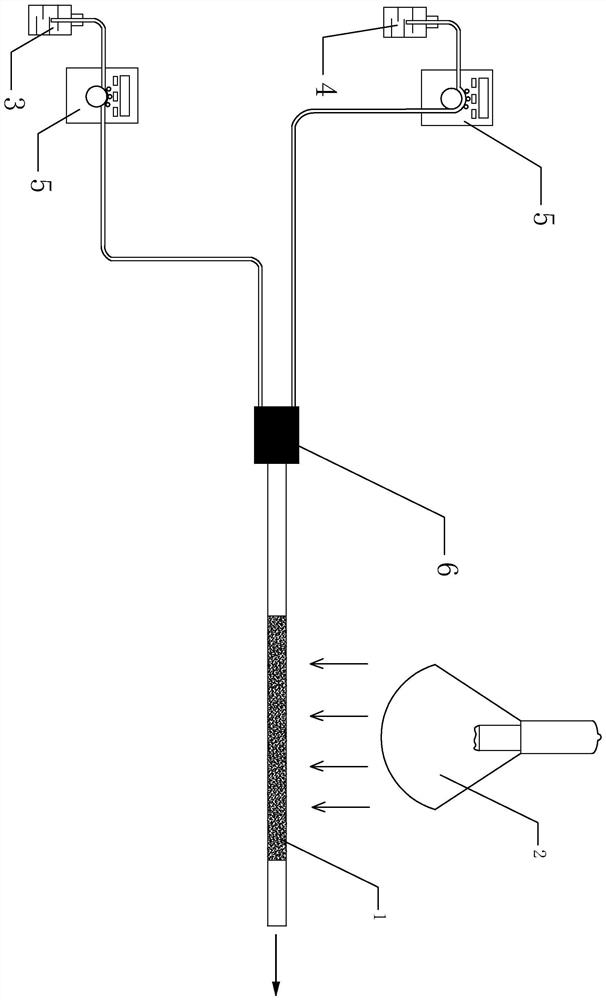

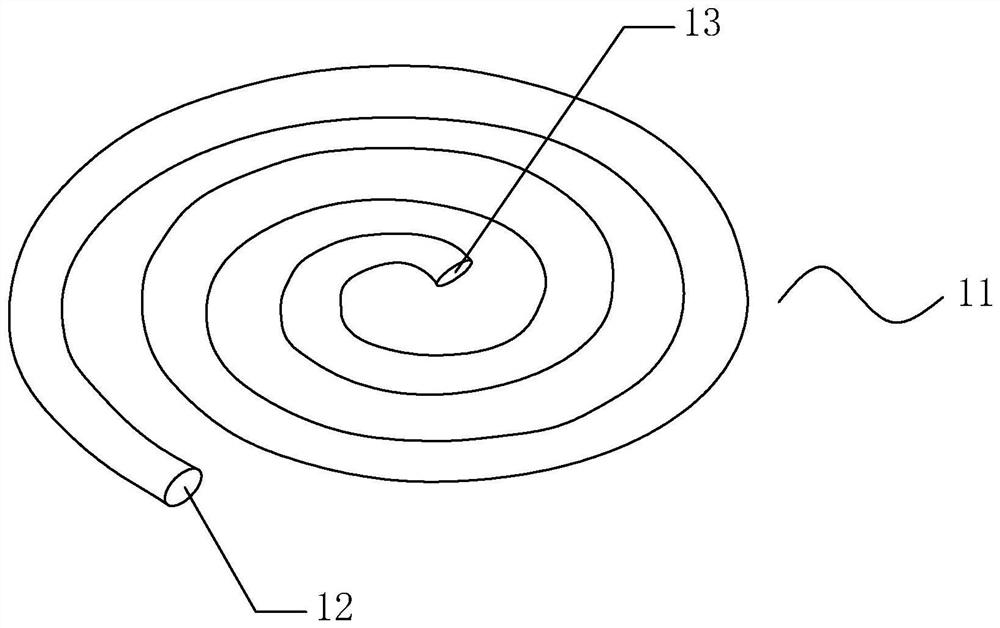

Planar tubular continuous flow-photocatalytic oxidation degradation water treatment device, system and method

PendingCN114516673ACompact structureMaterials are readily availableWater/sewage treatment by irradiationWater treatment compoundsPhysical chemistryEnergy supply

The invention relates to a planar tubular continuous flow-photocatalytic oxidation degradation water treatment device and system and a use method, the planar tubular continuous flow-photocatalytic oxidation degradation water treatment device comprises a planar tubular reactor, the planar tubular reactor is provided with a multi-bending channel part, the multi-bending channel part is located on the same plane, the multi-bending channel part is provided with a medium inlet and a medium outlet, and the medium inlet is communicated with the medium outlet. A medium flows in from the inlet and flows out from the outlet and is in a continuous flowing state; the medium contains a photocatalyst and an oxidizing agent; a light source is arranged at the upper part of the planar tubular reactor, the light source vertically irradiates the planar tubular reactor, and the irradiation range of the light source is not smaller than the area of the planar tubular reactor; compared with a traditional static sequencing batch water treatment method, the technical scheme is flexible and efficient, light is used as an energy supply and activation mode, online simultaneous photocatalytic degradation and chemical advanced oxidative degradation are cooperatively achieved, and the photocatalytic oxidative degradation water treatment capacity and range are improved.

Owner:ZHEJIANG WANLI UNIV

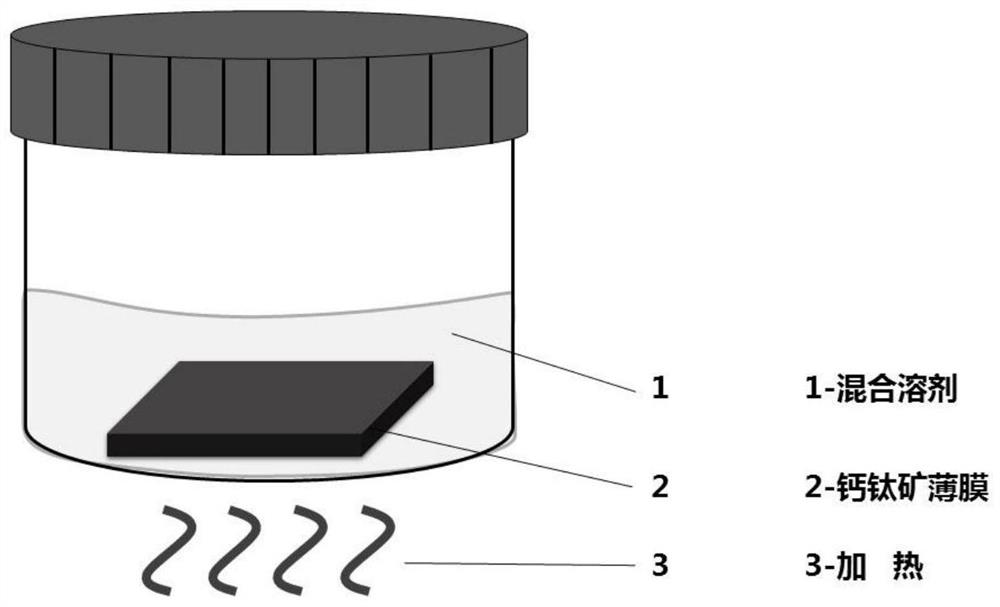

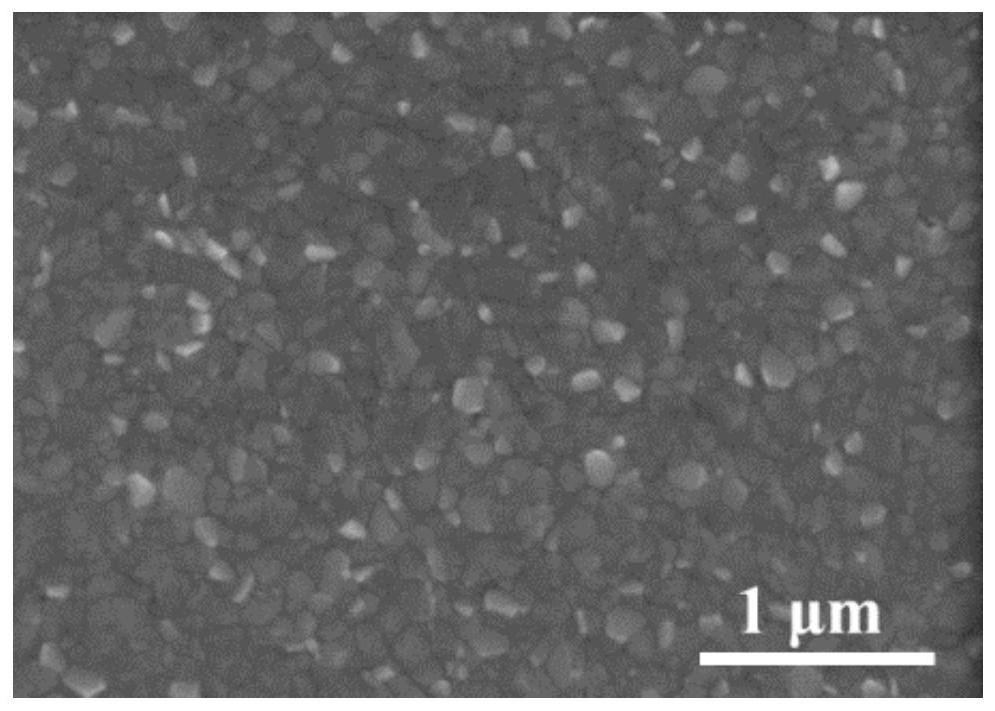

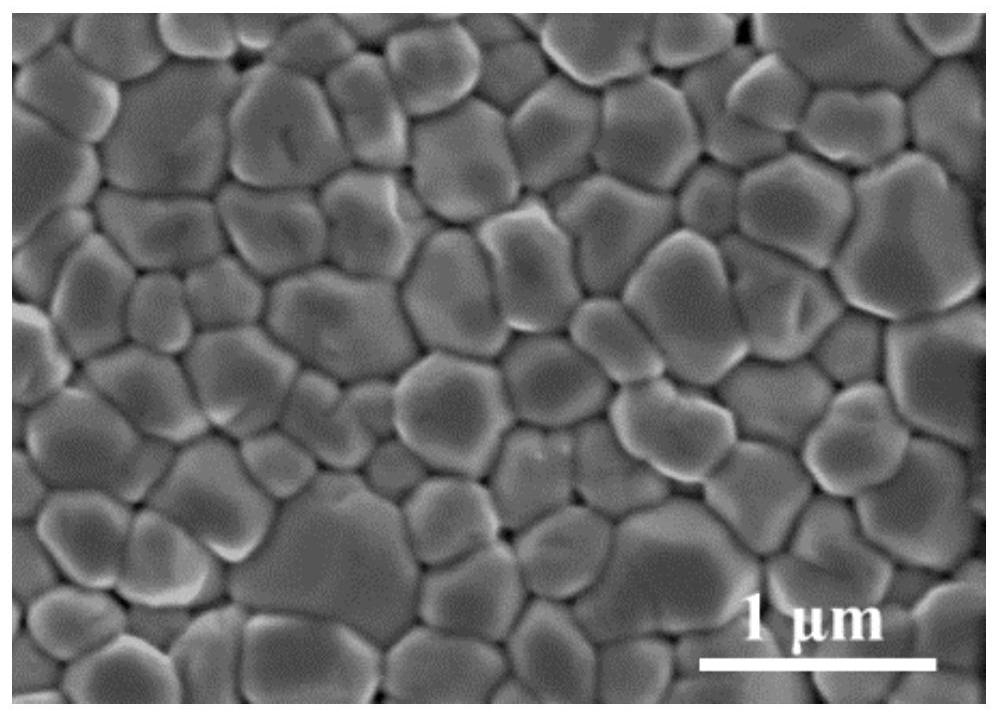

Method for improving quality of perovskite thin film through solvent bath assisted heat treatment

InactiveCN111628091ARefine the grain sizeImprove performanceFinal product manufactureSolid-state devicesSingle crystalSolvent

The invention discloses a method for improving the quality of a perovskite thin film through solvent bath assisted heat treatment, and belongs to the technical field of new materials. The method comprises the following steps: firstly, preparing a perovskite thin film by adopting a spin-coating method; then, immersing the perovskite thin film in a mixed solvent of a polar solvent and a non-polar solvent, wherein the volume ratio of the polar solvent is 0.1%-10%; and finally, heating the mixed solvent in which the perovskite thin film is placed to 80-200 DEG C, keeping the temperature for 10-120minutes, taking out the perovskite thin film from the mixed solvent after the perovskite thin film is naturally cooled after heat preservation, cleaning the perovskite thin film with a non-polar solvent, blow-drying the perovskite thin film with inert gas, and placing the perovskite thin film on a heating table to heat and dry the perovskite thin film, thereby finally obtaining the improved perovskite thin film. The method can also be used for improving the surface characteristics of perovskite single crystals or microcrystals, reducing surface defects and component segregation and obtaininghigh-quality perovskite crystal surfaces.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

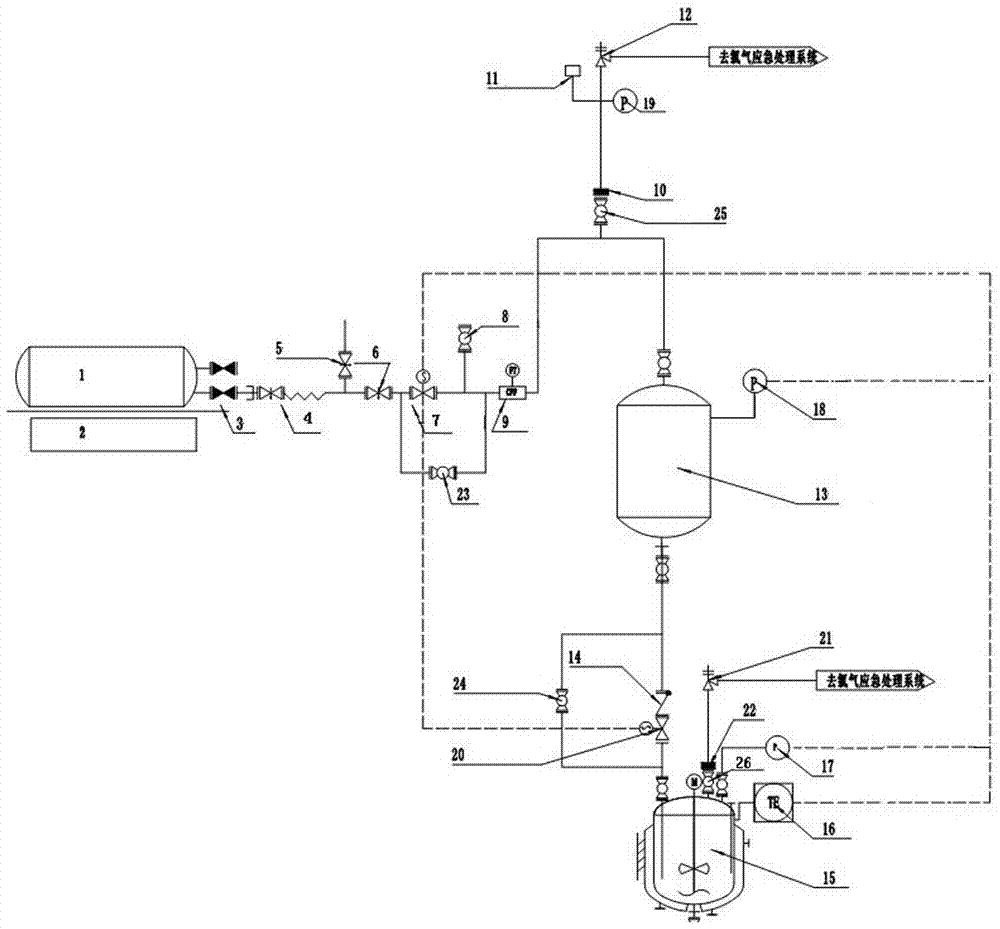

Device for chlorination reaction directly adopting industrial liquid chlorine

InactiveCN106989269AEasy to operateLow running costVessel mounting detailsContainer filling methodsProcess engineeringPneumatic valve

The invention discloses a device for chlorination reaction directly adopting industrial liquid chlorine. The device is characterized in that the discharge opening of a liquid chlorine steel cylinder (1) is connected with a buffer tank (13) and a reaction kettle (15) in sequence through a main delivery pipe; valves A (3) are arranged at the discharge opening; a liquid chlorine weighing scale (2) is arranged below the liquid chlorine steel cylinder (1); a needle valve (4), a pneumatic valve (7) and a flowmeter (9) are arranged on the main delivery pipe at the front end of the buffer tank (13) in sequence; a pressure gauge A (18) is arranged on the buffer tank (13); a one-way valve (14), a pneumatic valve (20) and a by-pass valve B (24) are arranged between the buffer tank (13) and the reaction kettle (15); a pressure gauge B (17) and a temperature gauge (16) are arranged on the reaction kettle (15). The device for chlorination reaction directly adopting industrial liquid chlorine provided by the invention is convenient to operate, stable, safe, reliable and low in operating cost; besides, the using safety and reliability of liquid chlorine are improved, and meanwhile the operation is more convenient and controllable.

Owner:DALIAN BIO CHEM

Regeneration device and regeneration process of furfuryl alcohol waste catalyst

PendingCN111957325AAchieve regenerationReduce manufacturing costCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystProcess engineering

The invention belongs to a regeneration device and a regeneration process of a furfuryl alcohol waste catalyst. The device comprises at least one furfuryl alcohol waste catalyst bin; at least one furfuryl alcohol waste catalyst dissolving and regenerating unit used for ensuring the solubility of a copper sulfate solution and realizing regeneration of a copper sulfate solution; at least one cleaning unit used for cleaning a solid-liquid mixture produced by the regenerating unit; and at least one crushing unit used for drying and crushing the catalyst, wherein the furfuryl alcohol waste catalystbin is connected with a screening machine through the furfuryl alcohol waste catalyst dissolving and regenerating unit, the cleaning unit and the crushing unit, an undersize product channel of the screening machine is communicated with the packaging machine, and an oversize product channel of the screening machine is communicated with the crushing unit; the device has the advantages of being simple in structure, reasonable in process design, simple, convenient and controllable to operate, capable of achieving regeneration of the furfuryl alcohol waste catalyst and reducing the furfuryl alcohol production cost and being environmentally friendly.

Owner:HENAN XINLIANXIN FERTILIZER

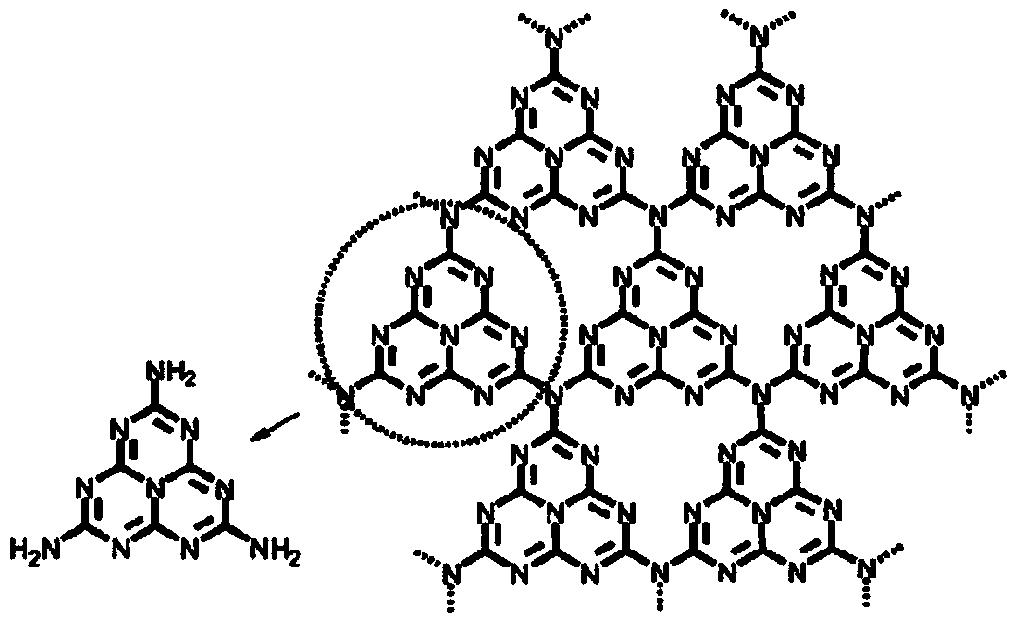

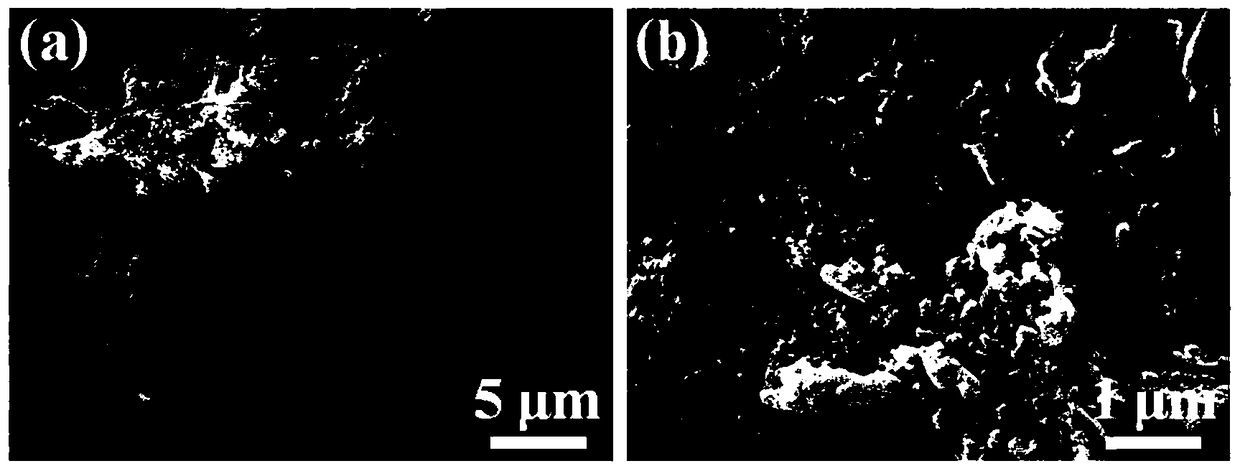

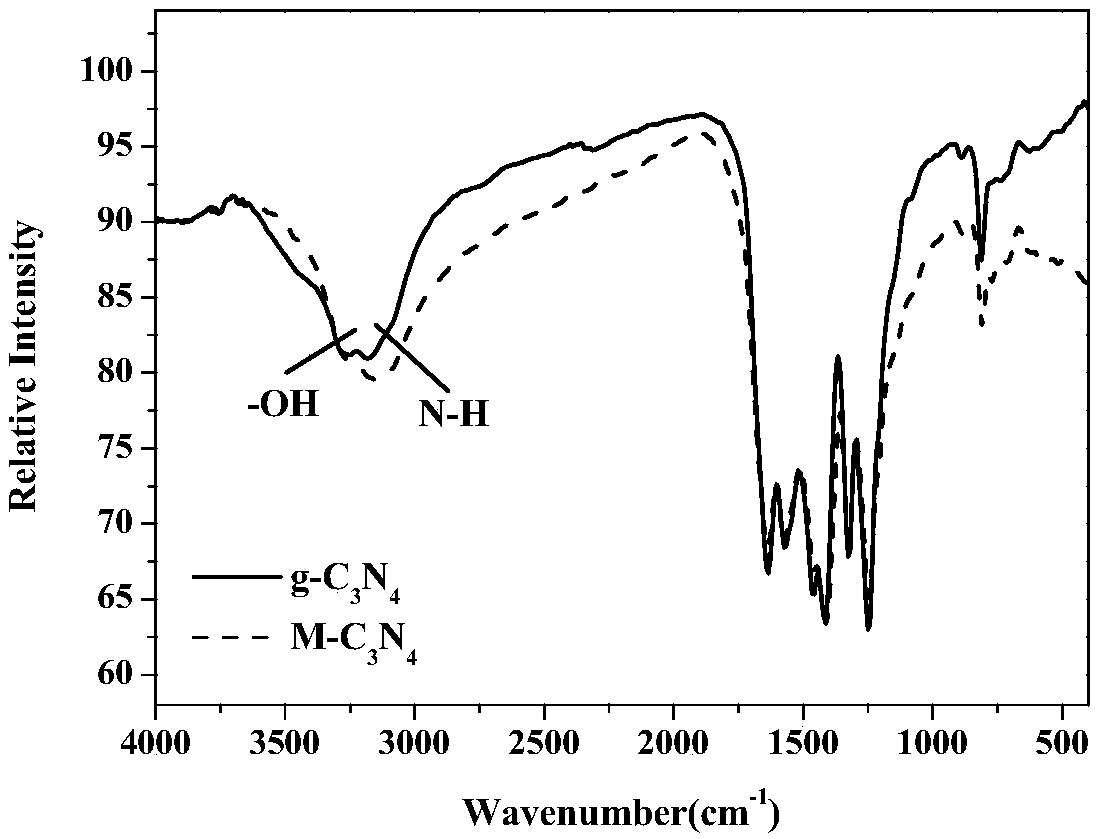

Facultative carbon nitride hydrophilic enrichment material as well as preparation method and application thereof

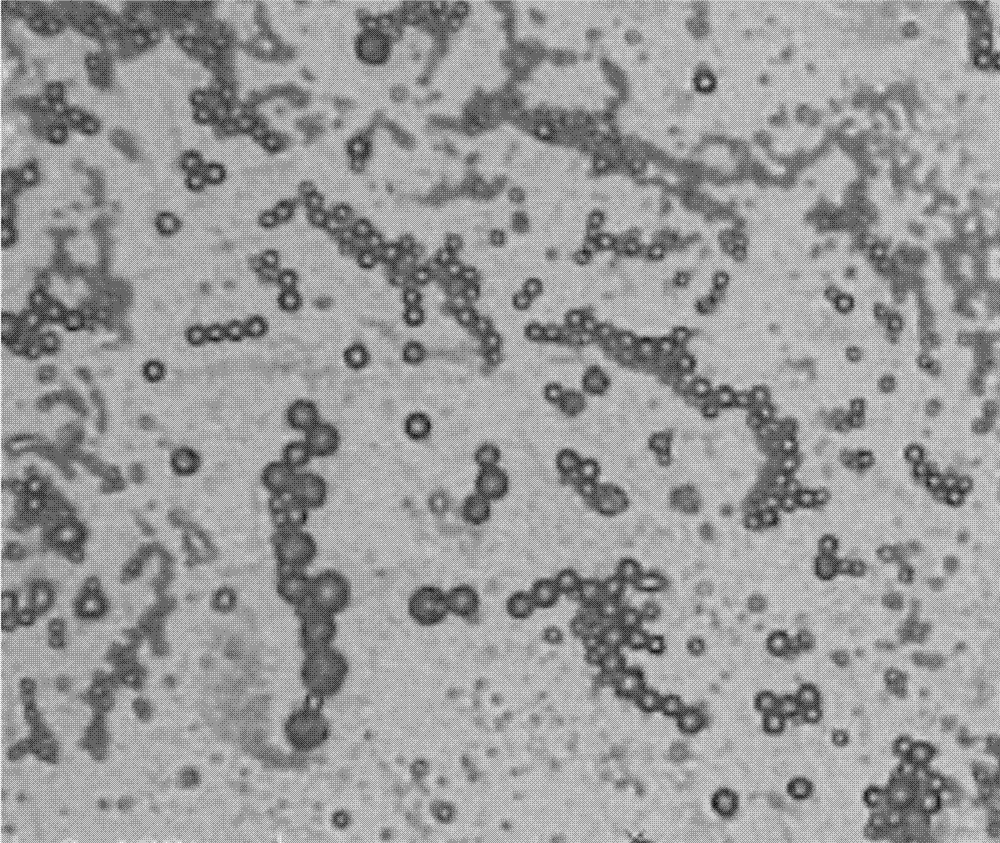

InactiveCN108854971AUniform sizeGood dispersionOther chemical processesPeptide preparation methodsThin layerCarbon nitride

The invention relates to a facultative carbon nitride hydrophilic enrichment material (L-Cys-Au@M-C3N4) as well as a preparation method and application thereof. The facultative carbon nitride hydrophilic enrichment material is L-Cys-Au@M-C3N4, wherein L-Cys-Au represents L-cysteine bonded to gold, and M-C3N4 represents thin layer graphite phase carbon nitride. The preparation method provided by the invention is simple and rapid, and low in cost. The material obtained by optimizing the synthesis conditions has a larger specific surface area, and the surface of the material is rich in amino groups and carboxyl hydrophilic functional groups, so that the material shows remarkable hydrophilicity. By optimizing the enrichment conditions, the material can be applied to glycopeptide in high-selectivity enrichment biological samples.

Owner:ACADEMY OF MILITARY MEDICAL SCI

Method and device for generating high accelerated speed

ActiveCN103528785AAcceleration value increaseHigh acceleration valueVibration testingResonanceEngineering

The invention discloses a method and device for generating high accelerated speed. The method comprises the following steps: fixedly connecting a clamp bearing body to a motion part of vibration test equipment, symmetrically arranging at least two shaft bodies on the clamp bearing body, enabling a shaft line of any shaft body to be vertical to a vibration direction of the vibration test equipment, arranging at least a sliding sleeve on any shaft body, enabling any sliding sleeve to move along the corresponding shaft body, and locking the selected position of any sliding sleeve on the corresponding shaft body according to the vibration test need, wherein a test piece is fixedly connected to any sliding sleeve through a clamp. According to the method, a test piece clamp structure is improved, so that the acceleration value of the test piece can be increased by 10-30 times by resonance of the clamp and a moving coil, wherein the resonant frequency can be changed by adjusting the vibration position of the clamp only. The device is simple in structure, superior in performance, easy, convenient and controllable to operate and low in cost, and has a wide application prospect in the technical field of vibration tests.

Owner:SUZHOU DONGLING VIBRATION TEST INSTR

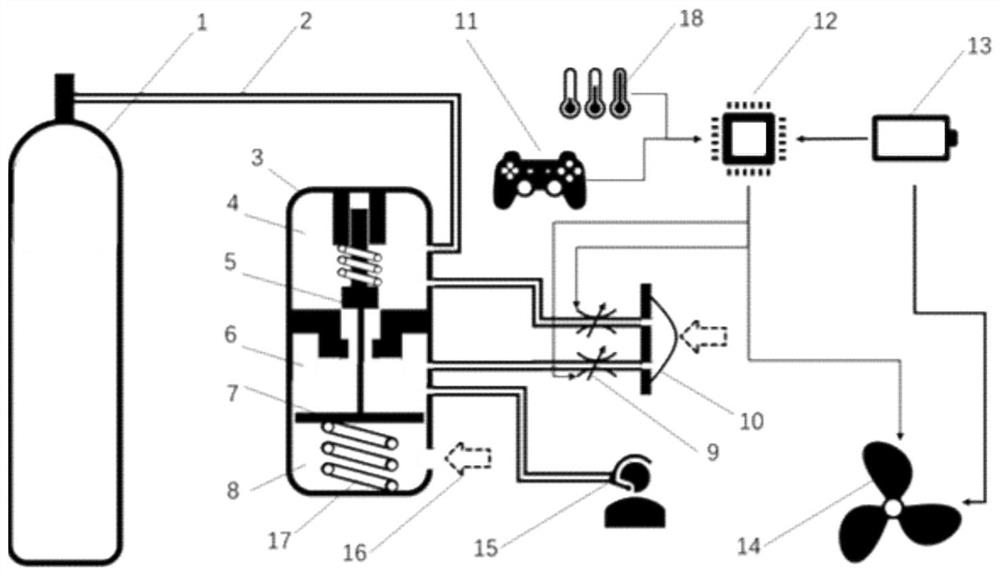

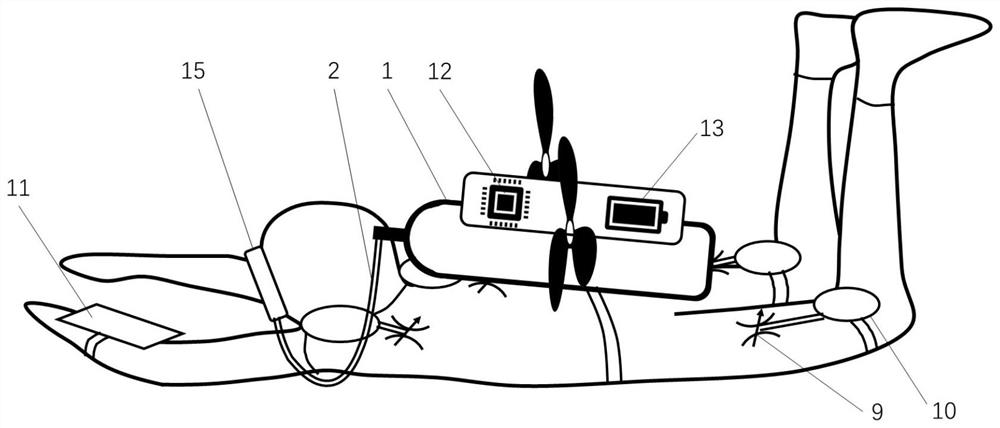

Underwater wearable auxiliary robot

PendingCN114715361AExpand the scope of workSave energyUnderwater equipmentBuoyancy regulationGas cylinder

The invention provides an underwater wearable auxiliary robot which comprises an air supply system, a buoyancy adjusting system and a controller, the buoyancy adjusting system is provided with a breathing adjuster, two sets of throttling valves and a buoyancy air bag, and the buoyancy air bag has a buoyancy state and an air leakage state; the breathing regulator can maintain the air pressure difference between the high-pressure chamber and the medium-pressure chamber, the buoyancy air bag can adjust the volume through inflation and deflation so as to adjust the buoyancy, and inflation and deflation are controlled by an air inlet throttling valve and an air outlet throttling valve respectively. Forward thrust is jointly provided by the propeller and the flipper pedaled by the diver, on one hand, the underwater moving speed is increased, the working range of underwater operation is expanded, on the other hand, the physical strength of the diver is saved, then the breathing gas consumption is saved, and the time of diving operation under the same gas cylinder capacity is prolonged.

Owner:UNIV OF SCI & TECH OF CHINA

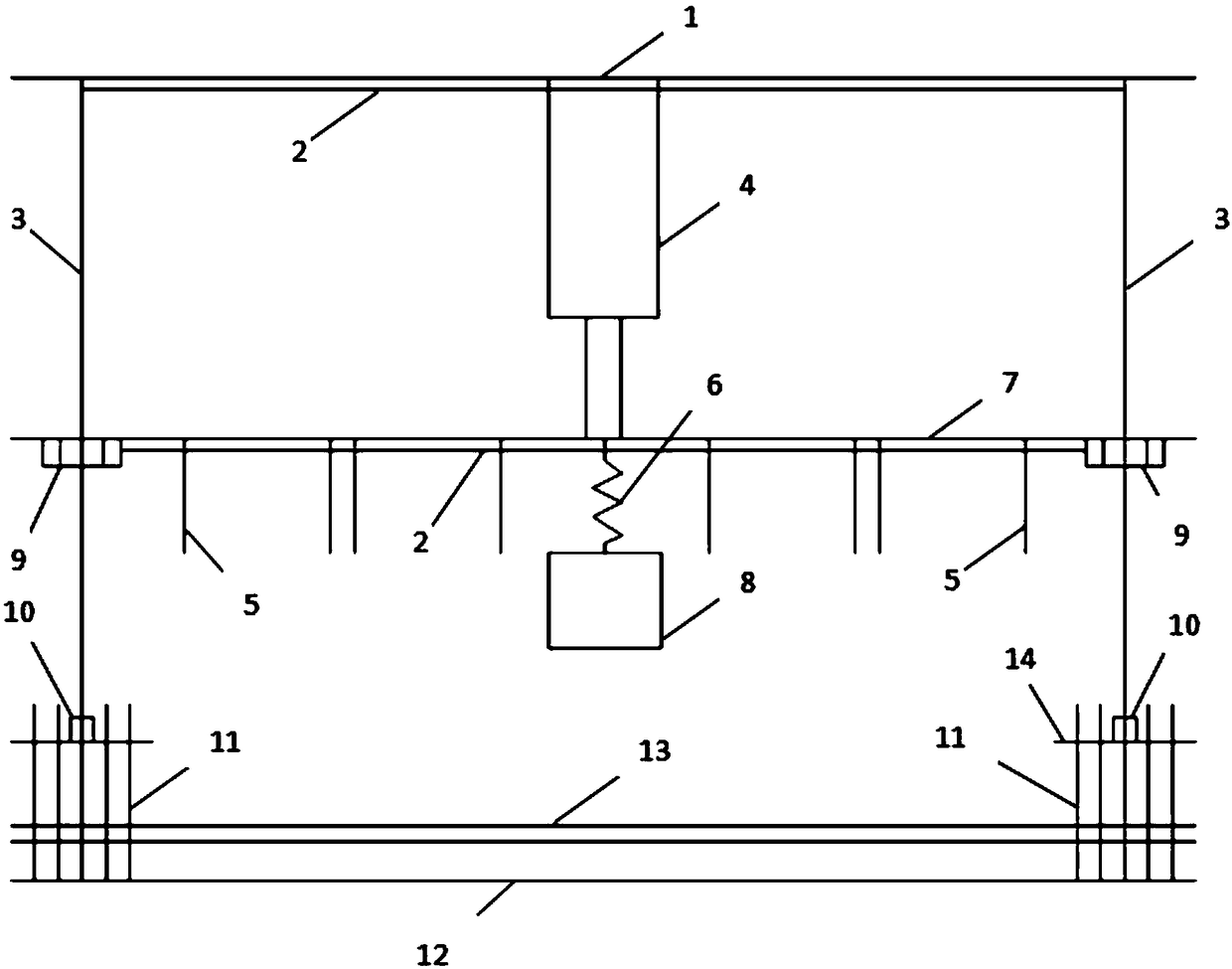

Multipurpose testing filer paper cutting device and method

ActiveCN108312191ANovel structureLower control costsMetal working apparatusPulp and paper industryFilter paper

The invention discloses a multipurpose testing filter paper cutting device and method. The device comprises a circular top plate, a horizontal plate, a circular bottom plate and two vertical rods. Thecircular top plate, the horizontal plate and the circular bottom plate are sequentially arranged in parallel from top to bottom. The two vertical rods are connected to the left side and the right side between the circular top plate and the circular bottom plate, the bottom of the circular top plate is provided with a jack, the jack is located between the circular top plate and the horizontal plate, the portion, facing the horizontal plate, of the jack is provided with a telescopic rod, the end of the telescopic rod of the jack is fixedly connected with the top of the horizontal plate, the bottom of the horizontal plate is connected with a cylindrical iron block through a spring, the bottom of the horizontal plate is provided with a plurality of annular blades, and filter paper pressing nuts are in threaded connection with the lower portions of the vertical rods. The cutting device has the advantages of being simple and novel in structure, stable in cutting quality, easy and convenientto operate in a cutting mode, and the like, and the scientific research level of geotechnical tests is improved; and the cutting method is easy and convenient to operate and controllable, the cut filter paper finished product is quite high in quality, and filter paper raw materials are saved.

Owner:SHANXI PROVINCIAL RES INST OF COMM

Method for testing degradation time of paper in soil

PendingCN114441256AEasy to operate and controllableTargetedPreparing sample for investigationPaper testingPaper sheetSoil science

The invention relates to a method for testing the degradation time of paper in soil, which divides the degradation time into preliminary degradation time and deep degradation time, and clarifies the test requirements, the test method and steps by adopting the method provided by the invention have the advantages of simplicity, intuition, easiness in operation, controllability and strong pertinence. The measured index can objectively reflect the degradation speed of the agricultural mulching film paper in the soil and has actual reference value and guiding significance, and the paper produced from the plant fiber raw material generally has the initial degradation time of 30-180 days and the deep degradation time of 100-400 days in the soil.

Owner:ZHEJIANG JINCHANG SPECIALTY PAPER CO LTD

Belt conveyor head guide device

The invention discloses a belt conveyor head guide device applied to the material conveying field. The belt conveyor head guide device structurally comprises a driving air cylinder, a connecting shaftand a discharging baffle. The driving air cylinder achieves rotary driving of the shaft through a connecting plate, one end of the discharging baffle is fixedly connected to the connecting shaft, theother end of the discharging baffle is a moving end capable of being connected to a conveying belt or belt conveyor shell, when the moving end is connected with the conveying belt, a first discharging channel communicating with a first discharging opening is defined by the discharging baffle and the belt conveyor shell, and when the moving end is connected with the belt conveyor shell, a second discharging channel communicating with a second discharging opening is formed between the discharging baffle and the conveying belt. The guide device and the head of a belt conveyor are fused into a whole, the guide device does not need to be additionally customized, cost is reduced, the structure is integrated, the need of the device for the application space is reduced, due to the simple structure, achieving of the subsequent maintaining operating can be obtained, meanwhile, operation is convenient and controllable, the application effect is improved, and practicability of the device is ensured.

Owner:JIANGSU JIANGDA MACHINERY

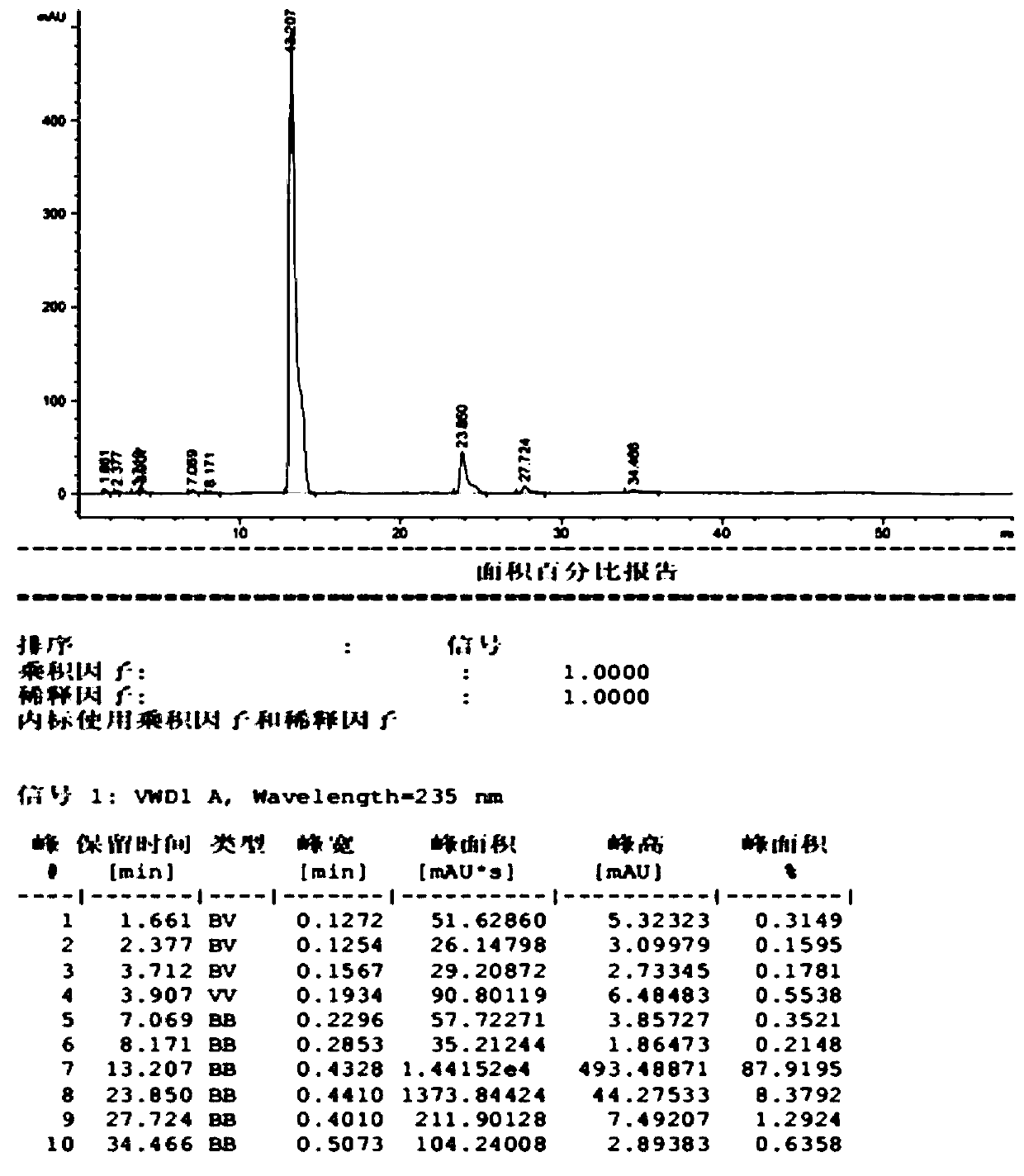

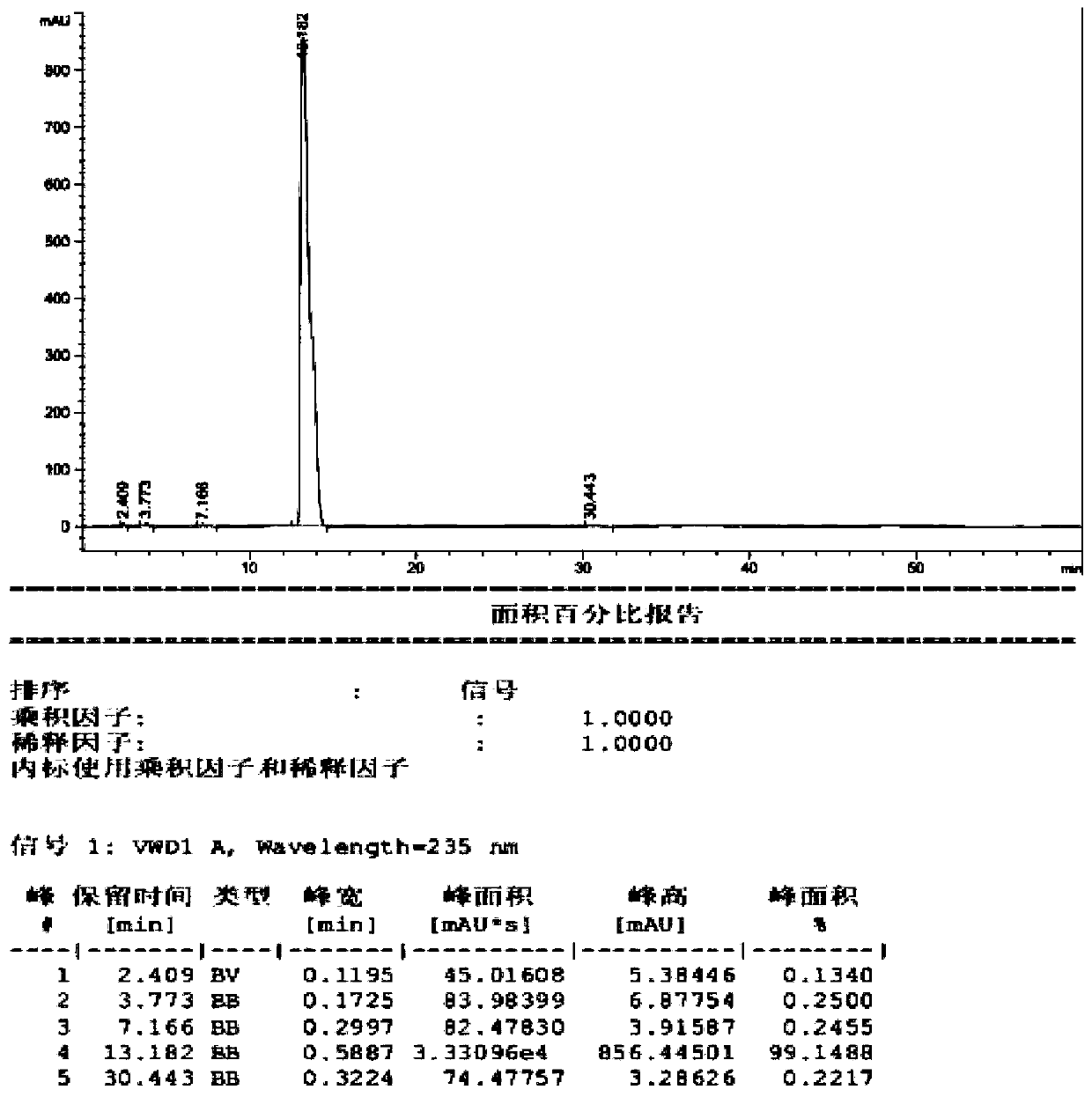

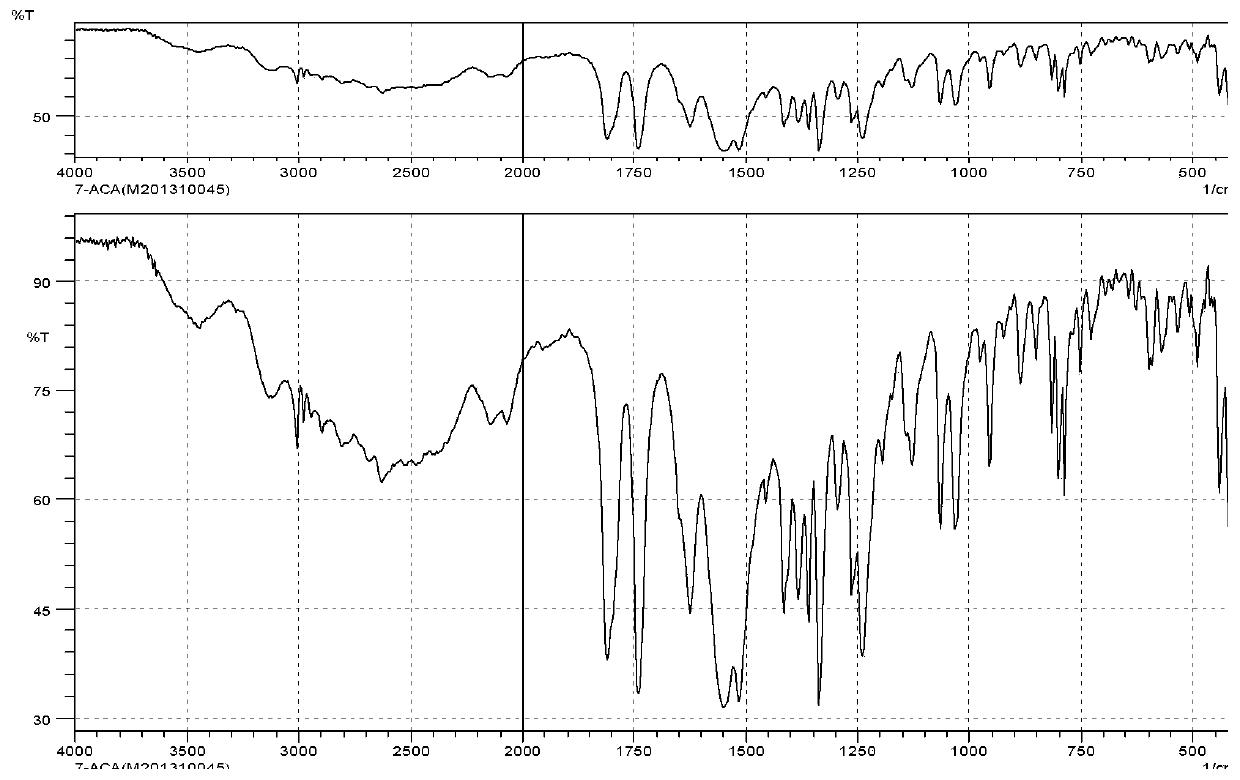

Crystallization method for reducing alpha-aminoadipic acid

The invention relates to a crystallization method of 3-acetyloxymethyl-5-thio-7-amino-8-oxo-1-azabicyclooctyl-2-ene-2-carboxylic acid, and in particular relates to a crystallization method for removing alpha-aminoadipic acid in the 3-acetyloxymethyl-5-thio-7-amino-8-oxo-1-azabicyclooctyl-2-ene-2-carboxylic acid. The method comprises the following steps: adding carboxylic acid ultrafiltrate into areactor, adding an appropriate amount of assisted solvents, regulating the pH value to a certain range value with an acid of a proper concentration, crystallizing, growing the grain and filtering, washing with acid water, filtering and drying, thereby obtaining the product. According to the preparation method disclosed by the invention, the residue of the alpha-aminoadipic acid in a target compound is effectively reduced, so that a characteristic peak of the alpha-aminoadipic acid disappears when the content of impurities is reduced to be detected by IR.

Owner:GUANGZHOU HC PHARM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com