Preparation method of carbon nano pipe filled with organic solvent

A carbon nanotube and organic solvent technology, which is applied in the field of carbon nanotube preparation to achieve the effects of improving filling efficiency, less solvent consumption, and easy separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

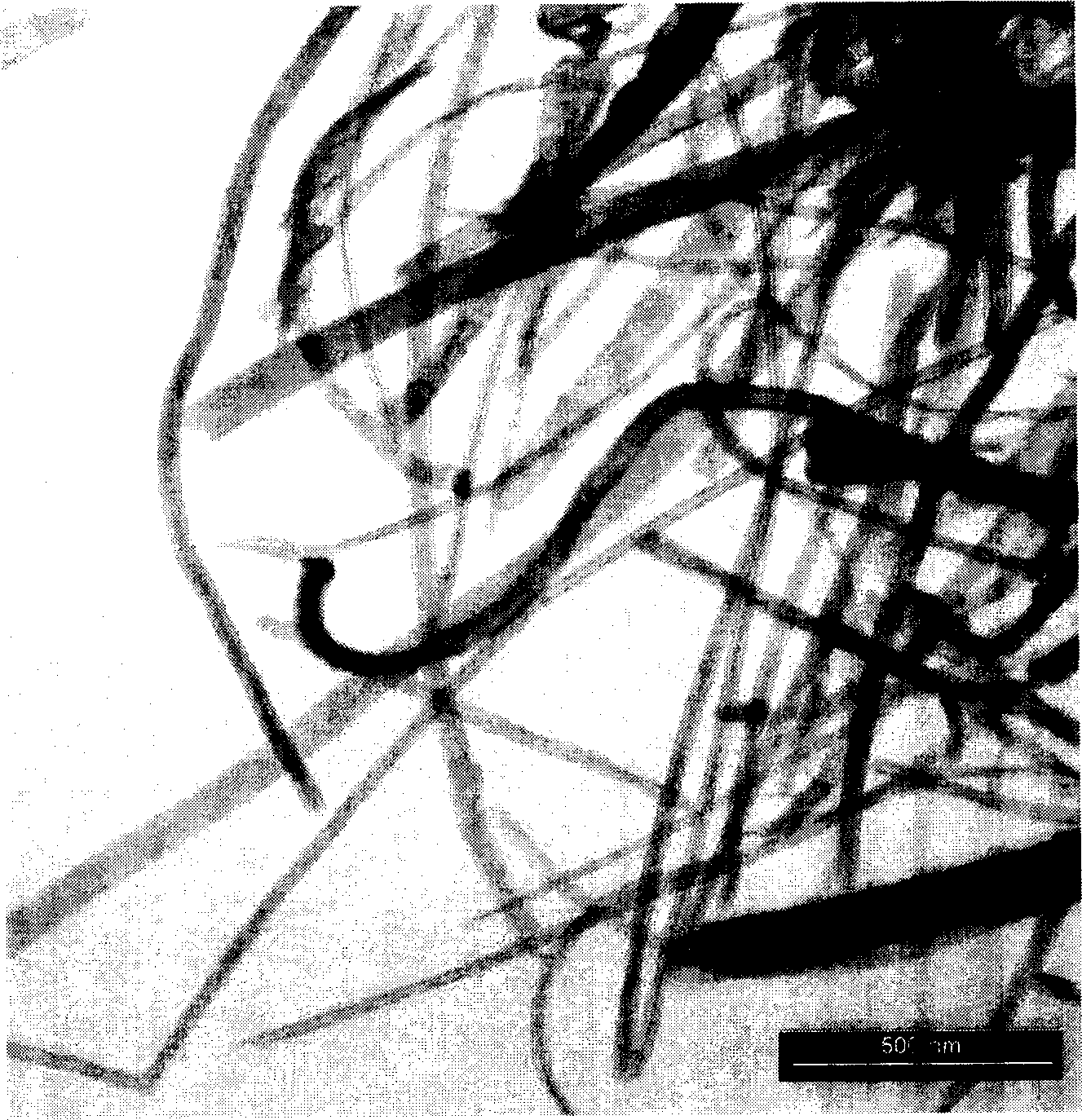

[0019] Example 1 100 mg of multi-walled carbon nanotubes were added to 20 ml of mixed acid of sulfuric acid and nitric acid (volume ratio of 3), ultrasonicated for 2 hours, diluted with 100 ml of water and filtered, then washed with distilled water until medium properties and vacuum drying to obtain purified chopped carbon nanotubes with a diameter of 50-80 nanometers and a length of 0.5-5 micrometers.

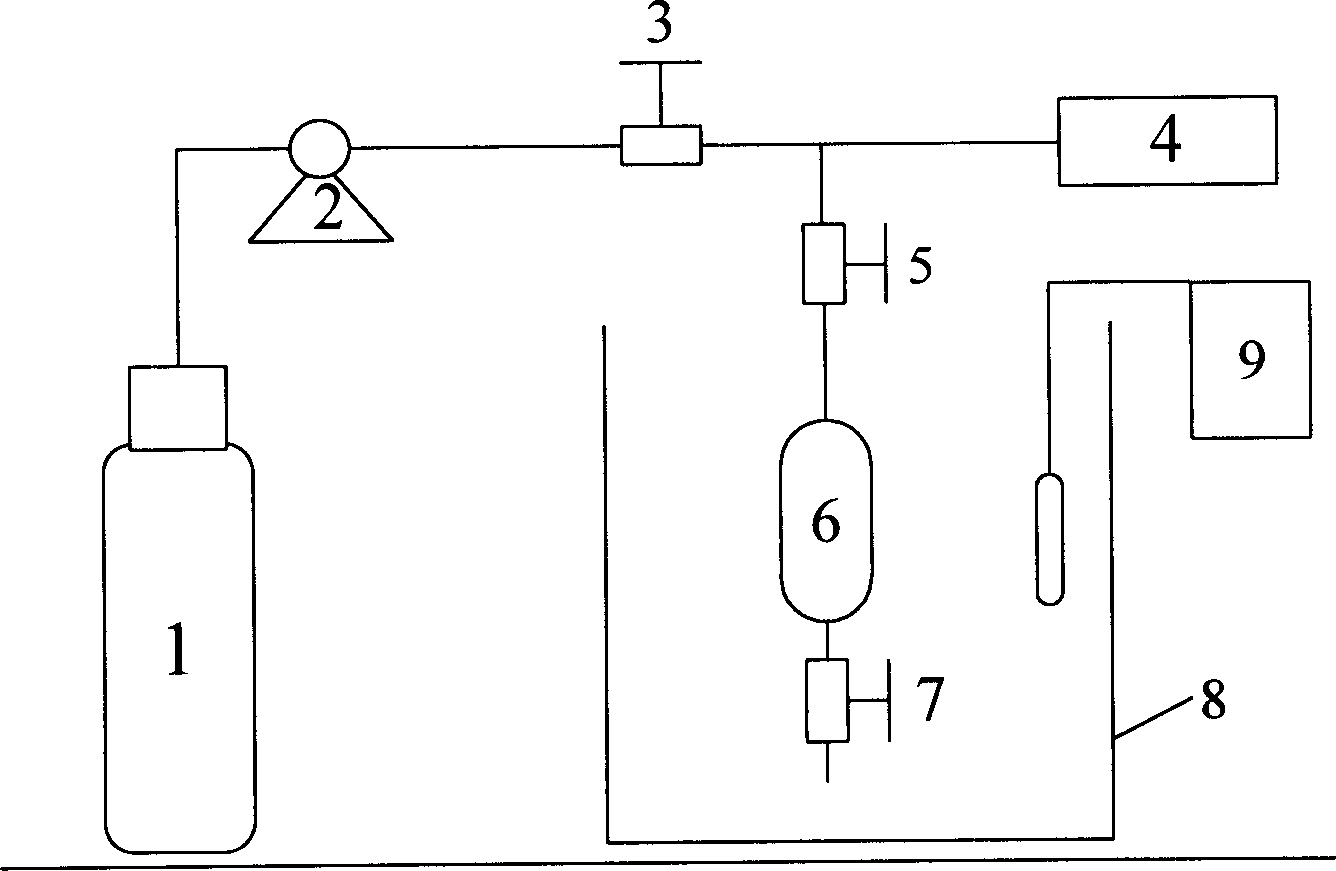

[0020] Such as figure 1 As shown, after adding 20 mg of purified carbon nanotubes and 1.5 ml of toluene into the stainless steel high-pressure vessel 6, put it into the constant temperature water tank 8, adjust the temperature controller 9 to keep the temperature constant at 40 ° C, open the valve 3 and 5. Inject carbon dioxide through the syringe pump 2, when the pressure of the barometer 4 reaches 1.1×10 6 After Pascal, close the valve 3, keep the pressure and temperature for 15 hours, then lower the temperature to room temperature, open the valve 7 to decompress and vent t...

Embodiment 2

[0021] Example 2 According to the preparation method of Example 1, except that toluene is replaced by benzene, the filling rate of the obtained carbon nanotubes is also as high as 90%.

Embodiment 3

[0022] Example 3 According to the preparation method of Example 1, except that toluene is replaced by pentane, the filling rate of the obtained carbon nanotubes is as high as 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com