Belt conveyor head guide device

A technology of material guide device and belt conveyor, which is applied in the direction of cleaning device, transportation and packaging, conveyor objects, etc., which can solve the problems of increasing the space configuration requirements of the device, which is not conducive to the wide application of the device, and reducing the practicability of the device, so as to increase the Structural support effect, improve connection diversion effect, ensure practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

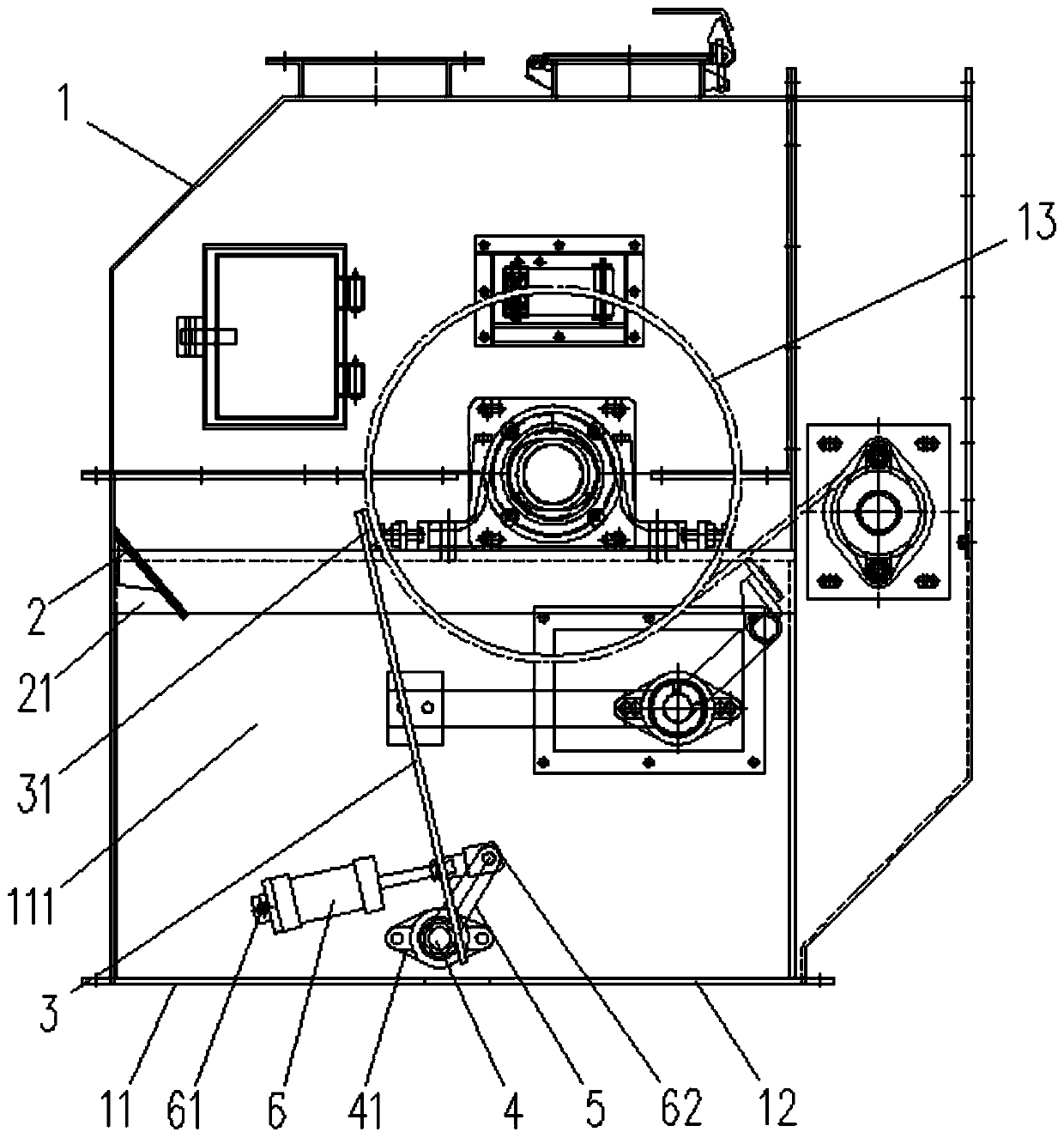

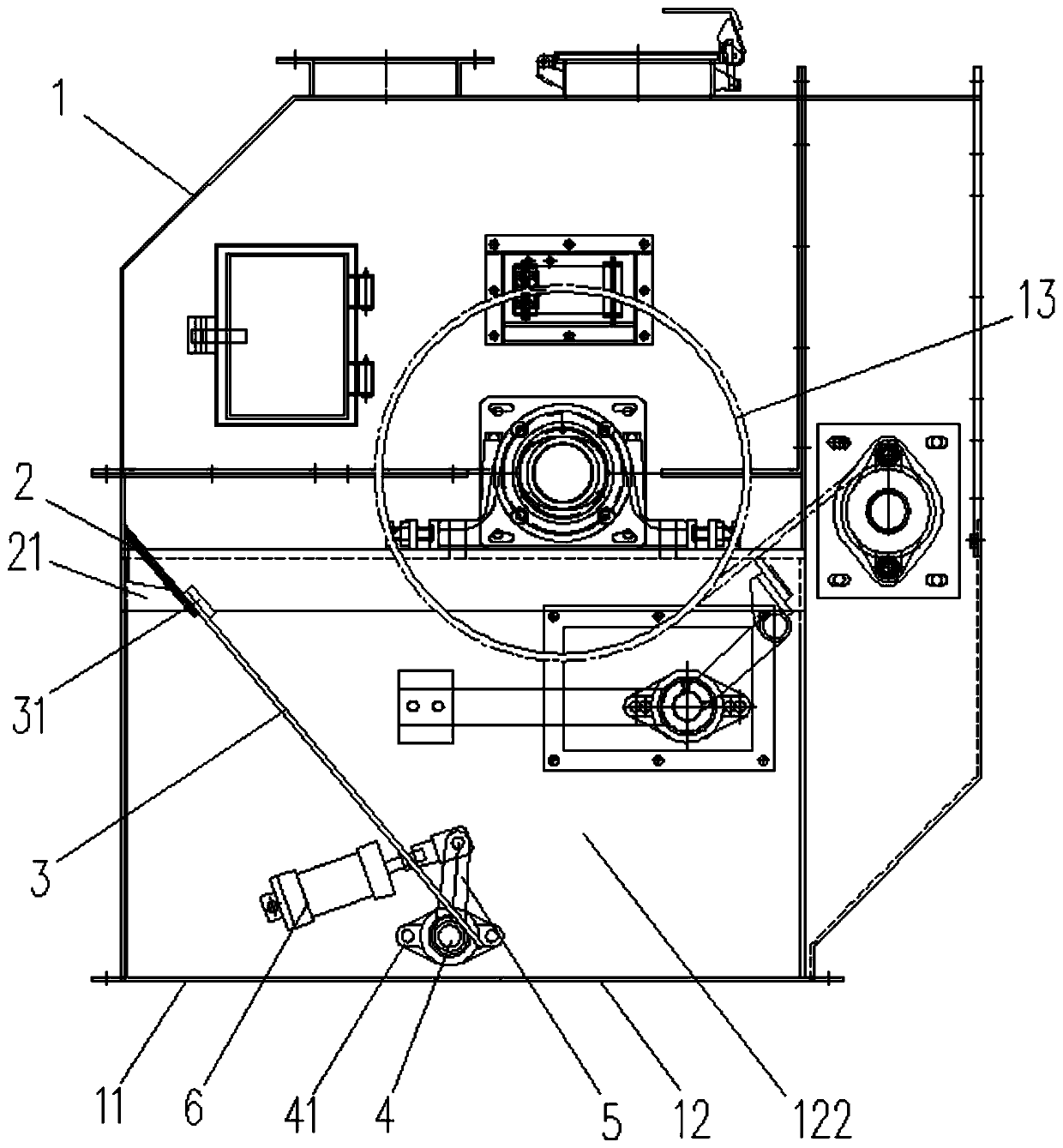

[0020] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0021] The structure of the material guide device at the head of the belt conveyor is as follows: figure 1 and figure 2 Shown includes the drive cylinder 6, the connecting shaft 4 and the discharge baffle 3. The connecting shaft 4 is arranged between the first discharge port 11 and the second discharge port 12 of the belt conveyor head along the direction parallel to the drive shaft of the conveying belt motor. The second outlet 12 of the head of the belt conveyor is arranged on the side close to the conveying belt 13 , and the first outlet 11 is arranged at the end of the belt conveyor casing 1 opposite to the conveying belt 13 . The two ends thereof are respectively positioned through the bearing seat 41 fixed on the casing 1 of the belt conveyor, and can realize relative rotation. In the figure, the fixed single of the driving cylinder 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com