Method for treating rare-earth comprehensive wastewater by forward osmosis membrane separation

A technology of integrated wastewater and forward osmosis membrane, applied in multi-stage water treatment, water/sewage treatment, metallurgical wastewater treatment, etc., can solve undiscovered problems, achieve good stability, low energy consumption for treatment, and easy recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

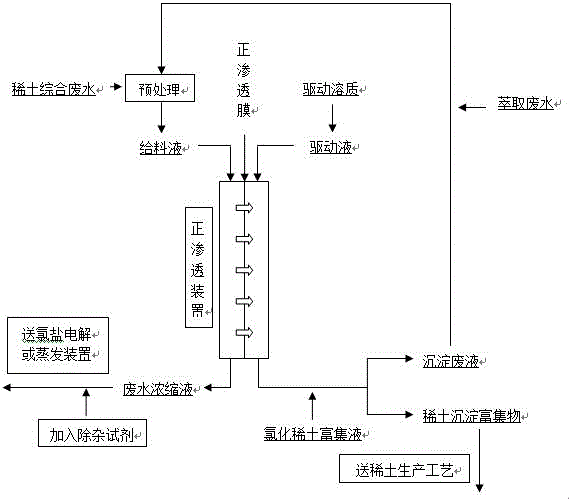

Image

Examples

Embodiment 1

[0052] Rare earth comprehensive wastewater sample 1, in which the concentration of sodium chloride is 42.80g / L, the concentration of calcium ion is 0.63g / L, the concentration of magnesium ion is 14.8mg / L, the concentration of ammonia nitrogen is 22.6mg / L, and the concentration of fluoride ion is 2.0mg / L L, COD concentration 5.0mg / L, sample pH value 4.2.

[0053] A method for separating and treating rare earth comprehensive wastewater by forward osmosis membrane, the method is carried out according to the following steps:

[0054] (1) Pretreatment: pretreatment of rare earth comprehensive wastewater, oil-water separation treatment of rare earth comprehensive wastewater, and removal of residual extractant in wastewater. Add sodium carbonate to the wastewater to adjust the pH of the wastewater to 7.0, and at the same time remove the precipitates produced by the reaction of carbonate and calcium and magnesium ions in the wastewater, so that the concentration of calcium and magnesi...

Embodiment 2

[0061] Rare earth comprehensive wastewater sample 1, in which the concentration of sodium chloride is 42.80g / L, the concentration of calcium ion is 0.63g / L, the concentration of magnesium ion is 14.8mg / L, the concentration of ammonia nitrogen is 22.6mg / L, and the concentration of fluoride ion is 2.0mg / L L, COD concentration 5.0mg / L, sample pH value 4.2.

[0062] A method for separating and treating rare earth comprehensive wastewater by forward osmosis membrane, the method is carried out according to the following steps:

[0063] (1) Pretreatment: pretreatment of rare earth comprehensive wastewater, oil-water separation treatment of rare earth comprehensive wastewater, and removal of residual extractant in wastewater. Add sodium carbonate to the wastewater, adjust the pH of the wastewater to 7.5, and remove the precipitates produced by the reaction of carbonate and calcium and magnesium ions in the wastewater, so that the concentrations of calcium and magnesium ions in the was...

Embodiment 3

[0070] Rare earth comprehensive wastewater sample 1, in which the concentration of sodium chloride is 42.80g / L, the concentration of calcium ion is 0.63g / L, the concentration of magnesium ion is 14.8mg / L, the concentration of ammonia nitrogen is 22.6mg / L, and the concentration of fluoride ion is 2.0mg / L L, COD concentration 5.0mg / L, sample pH value 4.2.

[0071] A method for separating and treating rare earth comprehensive wastewater by forward osmosis membrane, the method is carried out according to the following steps:

[0072] (1) Pretreatment: pretreatment of rare earth comprehensive wastewater, oil-water separation treatment of rare earth comprehensive wastewater, and removal of residual extractant in wastewater. Add sodium carbonate to the wastewater, adjust the pH of the wastewater to 6.3, and remove the precipitates produced by the reaction of carbonate and calcium and magnesium ions in the wastewater, so that the concentration of calcium and magnesium ions in the wastew...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com