Self-propelling earth pressure balance pipe-jacking heading machine

A pipe jacking machine and self-propelled technology, which is applied in earthwork drilling, mining equipment, tunnels, etc., can solve the problems of broken pipes and damage, increase of backrest oil cylinders, etc., and achieve the effect of reducing engineering costs and convenient and controllable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

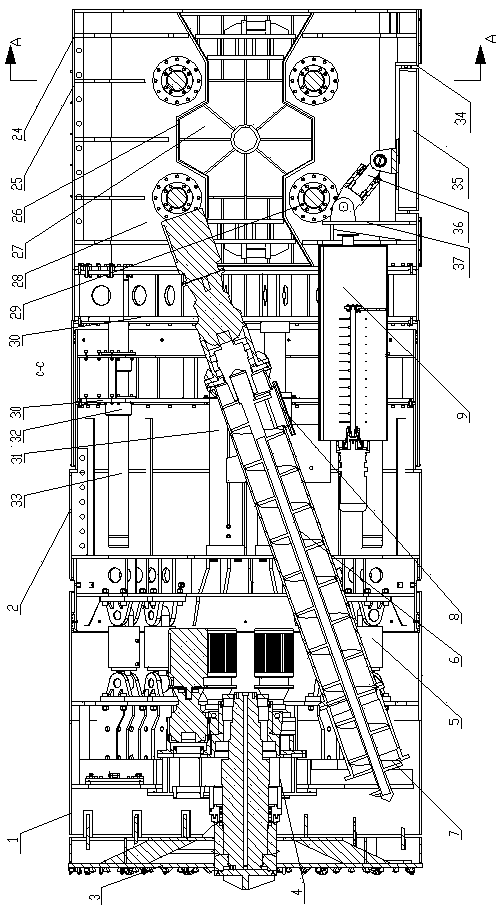

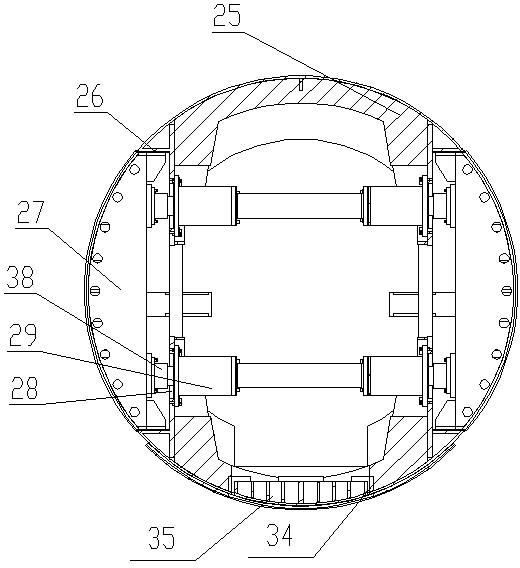

[0015] Such as figure 1 - As shown in -5, the present invention comprises a front casing 1 and a rear casing 2 connected together, the head of the front casing 1 is equipped with a cutterhead 3, and a power mechanism for driving the cutterhead 3 to rotate is installed in the front casing 1 4. A deviation correction oil cylinder 5 is connected to the rear of the cutterhead 3, and an auger 6 is installed in the front housing 1 and the rear housing 2, and the auger 6 includes a feed port 7 arranged in the front housing 1, And the discharge port 8 arranged in the rear housing 2 .

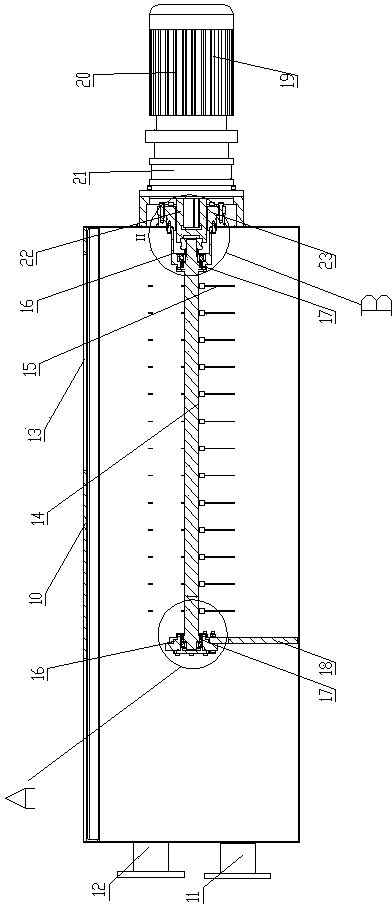

[0016] Below the auger 6 in the rear housing 2, a muddy water stirring device 9 is arranged, and the muddy water stirring device 9 includes a housing 10, the housing 10 is provided with a discharge port 11 and a water inlet 12, and the upper end of the housing 10 is arranged The feed port 13, the feed port 13 of the housing 10 corresponds to the discharge port 8 of the auger 6 located above, the housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com