Planar tubular continuous flow-photocatalytic oxidation degradation water treatment device, system and method

A technology of photocatalytic oxidation and water treatment device, which is applied in the direction of oxidized water/sewage treatment, special compound water treatment, light water/sewage treatment, etc. Low energy utilization rate and other issues, to achieve the effect of improving light energy utilization efficiency, reducing device operation difficulty, and high light energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

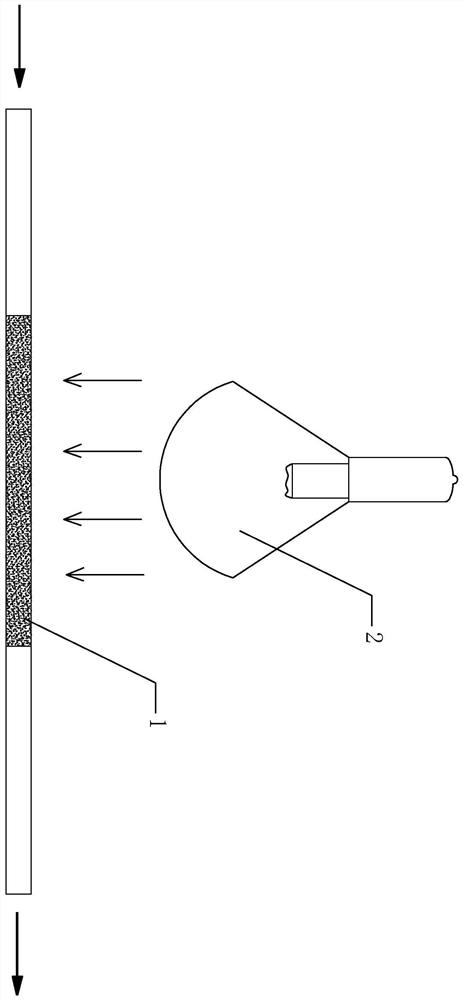

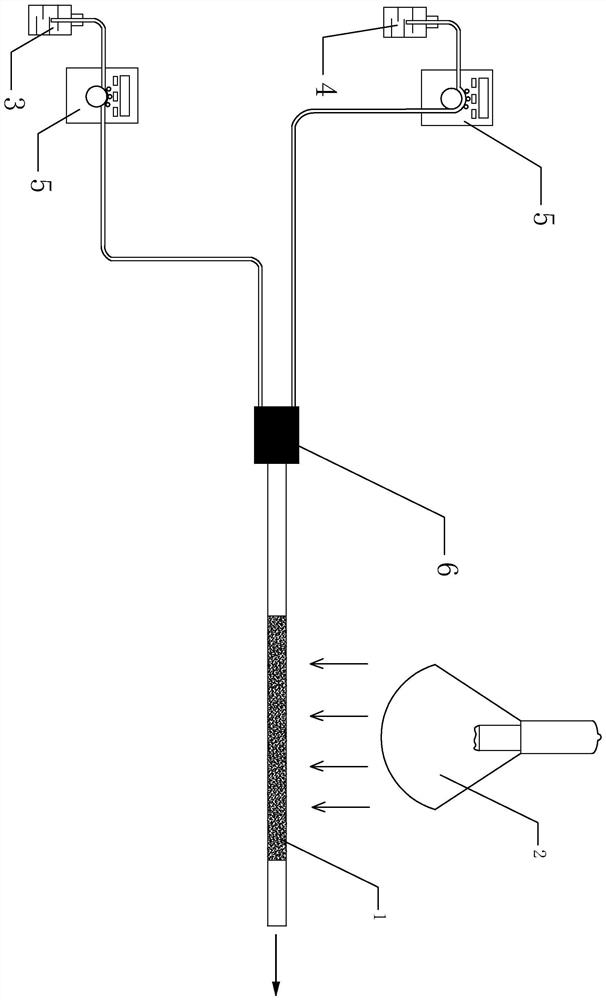

[0051] This embodiment adopts serpentine planar tubular reactor (with attached Figure 4 As shown), the material is high light-transmitting quartz glass, the inner diameter is 5mm, the wall thickness is 1mm, the length of a single plane tube is 10cm, the distance between tubes is 2mm, the total length is 100cm, the ambient temperature is 30°C, the external light source is 300W analog fluorescent lamp, and the distance from the plane tube 20cm, 10μmol / L Rhodamine B solution is simulated waste liquid, Ce-doped ZnO nanoparticles are photocatalysts (for commercially available or photocatalysts obtained by conventional doping process, the following examples are also the same), and the dosage is 1.0g / 1000mL, the hydrogen peroxide concentration is 5mmol / L, the flow rate is 10.0mL / min, and the degradation rate is 97.5%;

[0052] Change the concentration of hydrogen peroxide to 0mmol / L and the other conditions remain unchanged. The degradation rate is 38.2%. Turn off the simulated flu...

Embodiment 2

[0060] This embodiment adopts back-shaped planar tubular reactor (with attached Figure 5 As shown, in order to facilitate the connection of the medium inlet and outlet, the pipes located at the inlet and outlet positions can also be set perpendicular to the overall planar tubular reactor), the material is high light-transmitting quartz glass, the inner diameter is 5mm, and the wall thickness is 1mm. The tube spacing is 2mm, the total length is 100cm, the ambient temperature is 30°C, the external light source is a 300W simulated fluorescent lamp, and the distance from the flat tube is 20cm, the 10μmol / L rhodamine B solution is the simulated waste solution, Ce doped with TiO 2 Nanoparticles are photocatalysts, the dosage is 1.0g / 1000mL, the concentration of potassium persulfate is 10mmol / L, and the flow rate is 20.0mL / min. The degradation rate is 99.4%. Change the concentration of potassium persulfate to 0mmol / L and the other conditions remain unchanged. The degradation rate wa...

Embodiment 3

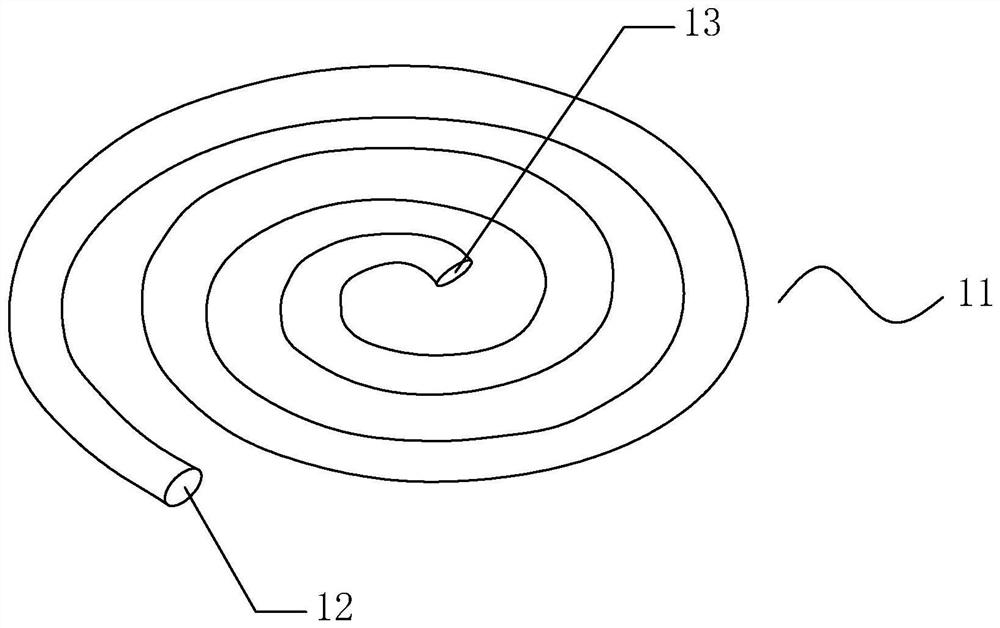

[0062] The present embodiment adopts the helical planar tubular reactor (as attached image 3 As shown, in order to facilitate the connection of the medium inlet and outlet, the pipes located at the inlet and outlet positions can also be set perpendicular to the overall planar tubular reactor), the material is high light-transmitting quartz glass, the inner diameter is 5mm, and the wall thickness is 1mm. The tube spacing is 2mm, the total length is 100cm, the ambient temperature is 30°C, the external light source is a 300W simulated fluorescent lamp, the distance from the flat tube is 20cm, the 10μmol / L rhodamine B solution is the simulated waste solution, Fe 3 o 4 Magnetic core-shell nanoparticles doped with Ce as the core and ZnO as the shell are used as photocatalysts. The dosage is 2.0g / 1000mL, the hydrogen peroxide concentration is 10mmol / L, and the flow rate is 10.0mL / min. The hydrogen concentration is 0mmol / L and the degradation rate is 31.7%, and the degradation rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com