Regeneration device and regeneration process of furfuryl alcohol waste catalyst

A waste catalyst and regeneration device technology, applied in the direction of catalyst regeneration/reactivation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. Small quantity and other problems, to achieve the effect of reducing production costs, simple and controllable operation, and reasonable process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

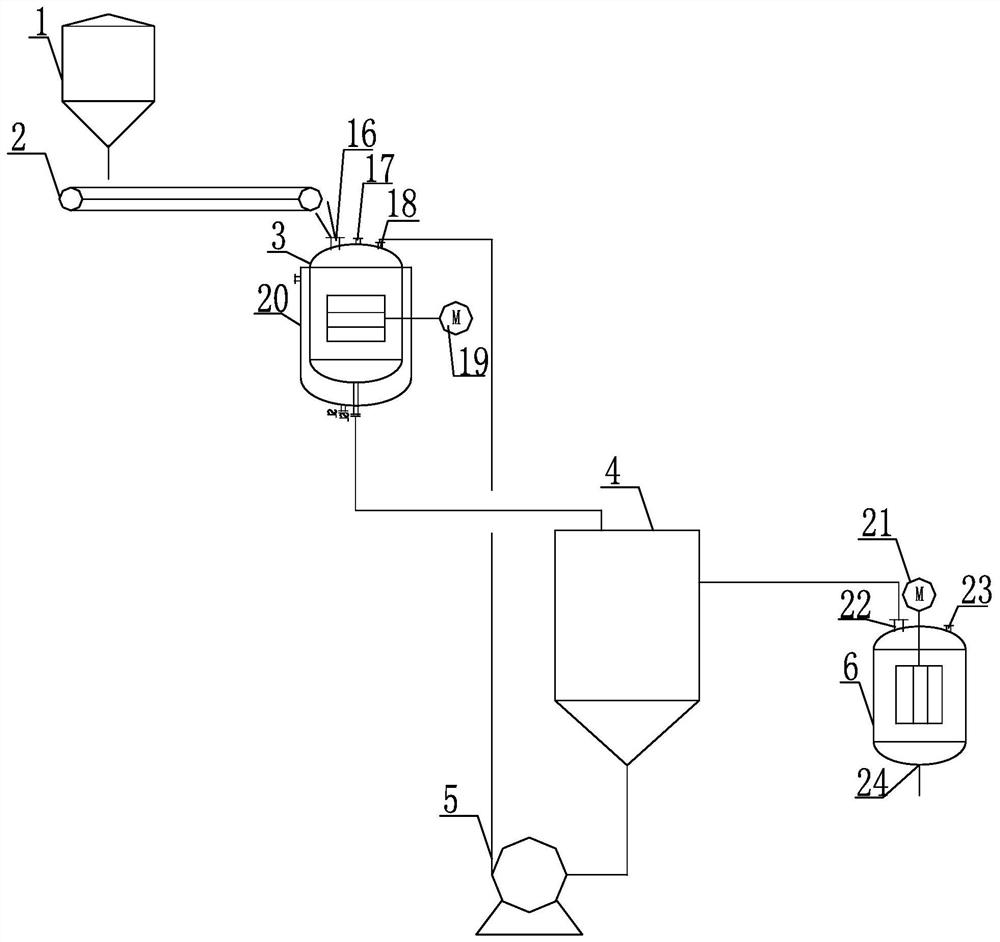

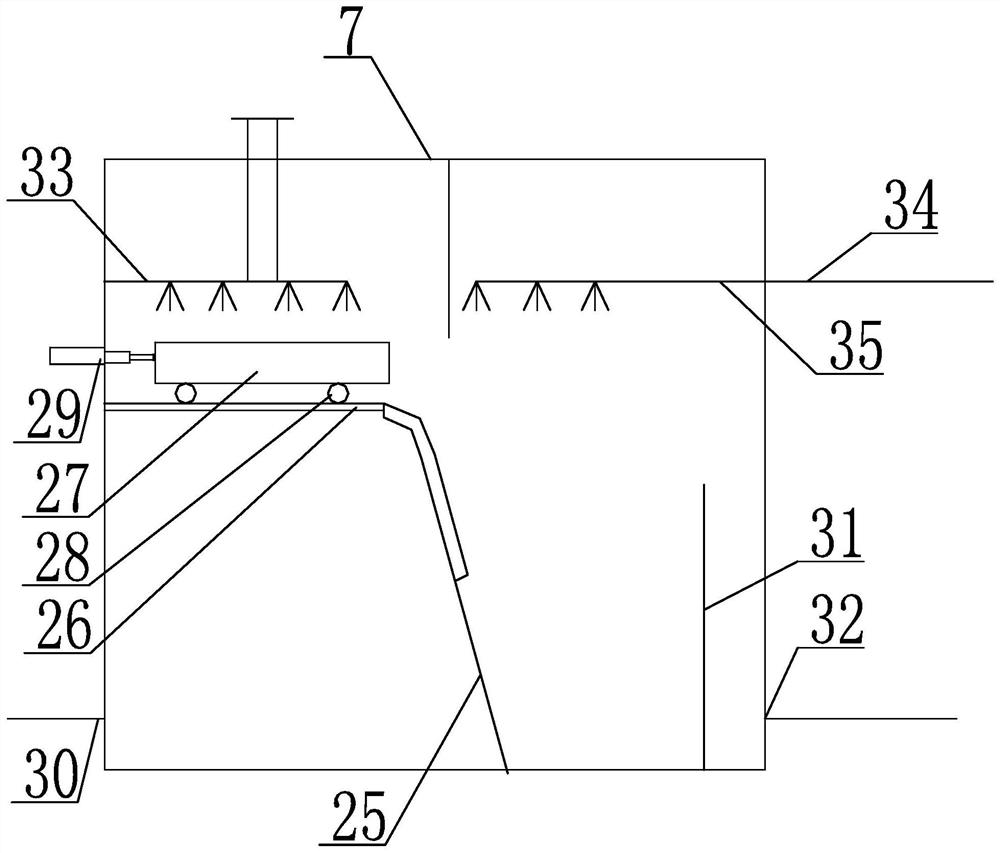

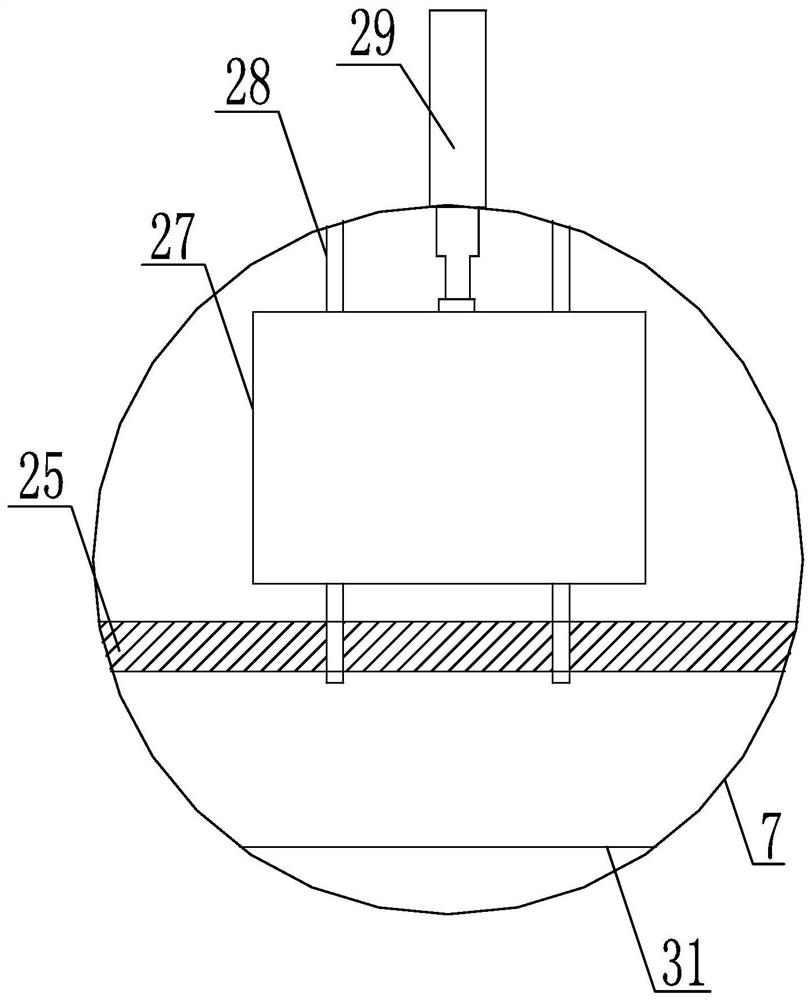

[0056] A regeneration device for furfuryl alcohol waste catalyst, the device includes: at least one furfuryl alcohol waste catalyst silo 1; at least one furfuryl alcohol waste catalyst dissolution and regeneration unit for ensuring the solubility of copper sulfate solution and realizing the regeneration of copper sulfate solution; at least one A cleaning unit for cleaning the regeneration unit to produce a solid-liquid mixture; at least one crushing unit for drying and crushing the catalyst; the spent furfuryl alcohol catalyst silo 1 is dissolved and regenerated by the spent furfuryl alcohol catalyst, a cleaning unit and a crushing unit It is connected with the screening machine 14, the undersize passage of the screening machine 14 is connected with the packaging machine 38, and the oversize passage of the screening machine 14 is connected with the crushing unit. The spent furfuryl alcohol catalyst dissolution and regeneration unit includes a metering belt 2 connected to the di...

Embodiment 2

[0071]A regeneration device for furfuryl alcohol waste catalyst, the device includes: at least one furfuryl alcohol waste catalyst silo 1; at least one furfuryl alcohol waste catalyst dissolution and regeneration unit for ensuring the solubility of copper sulfate solution and realizing the regeneration of copper sulfate solution; at least one A cleaning unit for cleaning the regeneration unit to produce a solid-liquid mixture; at least one crushing unit for drying and crushing the catalyst; the spent furfuryl alcohol catalyst silo 1 is dissolved and regenerated by the spent furfuryl alcohol catalyst, a cleaning unit and a crushing unit It is connected with the screening machine 14, the undersize passage of the screening machine 14 is connected with the packaging machine 38, and the oversize passage of the screening machine 14 is connected with the crushing unit. The spent furfuryl alcohol catalyst dissolution and regeneration unit includes a metering belt 2 connected to the dis...

Embodiment 3

[0086] A regeneration device for furfuryl alcohol waste catalyst, the device includes: at least one furfuryl alcohol waste catalyst silo 1; at least one furfuryl alcohol waste catalyst dissolution and regeneration unit for ensuring the solubility of copper sulfate solution and realizing the regeneration of copper sulfate solution; at least one A cleaning unit for cleaning the regeneration unit to produce a solid-liquid mixture; at least one crushing unit for drying and crushing the catalyst; the spent furfuryl alcohol catalyst silo 1 is dissolved and regenerated by the spent furfuryl alcohol catalyst, a cleaning unit and a crushing unit It is connected with the screening machine 14, the undersize passage of the screening machine 14 is connected with the packaging machine 38, and the oversize passage of the screening machine 14 is connected with the crushing unit. The spent furfuryl alcohol catalyst dissolution and regeneration unit includes a metering belt 2 connected to the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com